ECTFE melt-blown film and preparation method thereof

A melt-blown and melt-based technology, which is applied in the field of membrane materials, can solve the problems of unsatisfactory filtration accuracy, unresolved technical problems, large pore size of melt-blown membranes, etc., and achieve high elongation at break and uniform pore size distribution , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

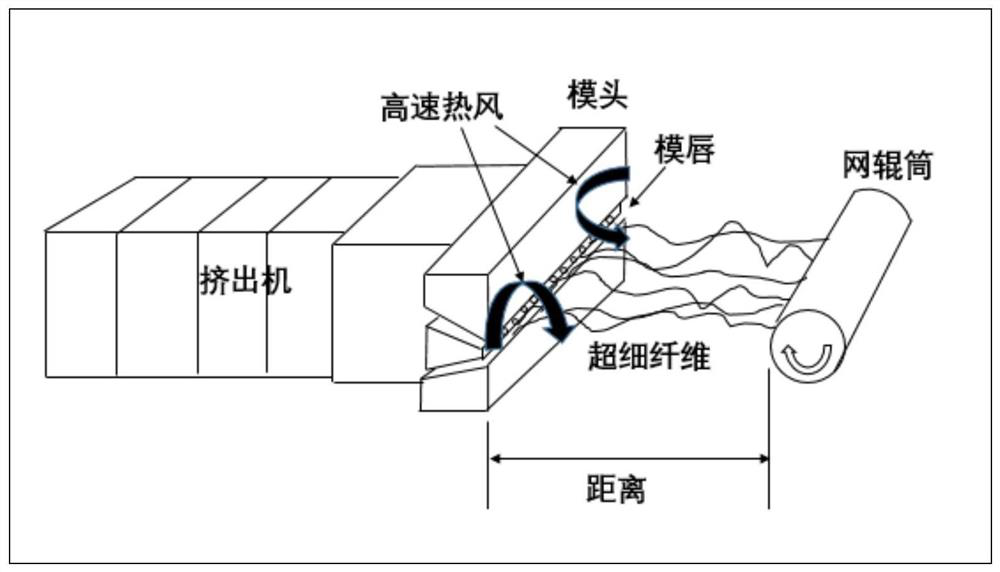

Method used

Image

Examples

Embodiment 1

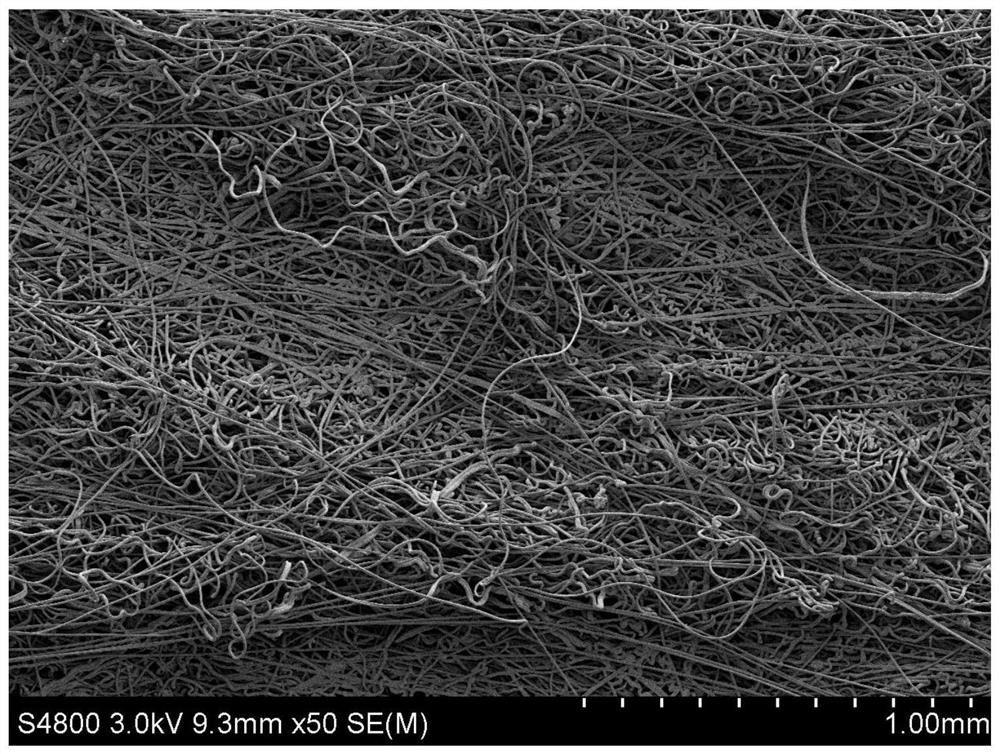

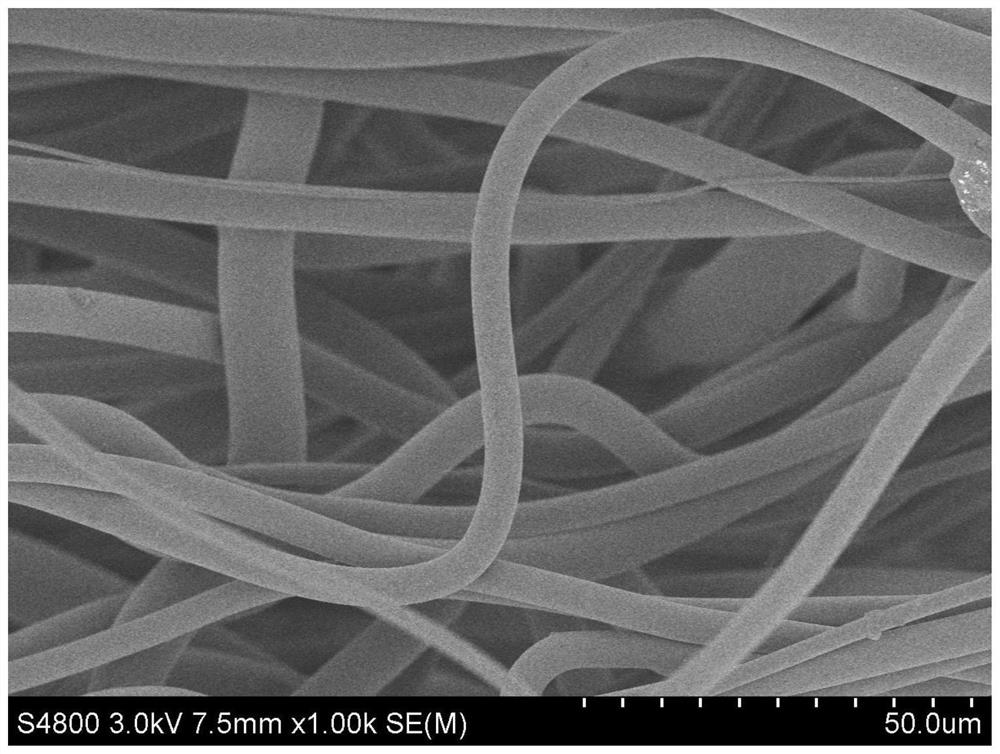

[0034] ECTFE resin (melt index: 600g / 10min, 2.16kg, 275°C) with a melting temperature of 195°C was melt-processed in a twin-screw extruder, and the melt-processing temperature was 200°C. The hot air temperature of the high-speed high-temperature airflow is 230°C, the hot air pressure is 0.1MPa, the temperature of the mesh roller is 30°C, the distance between the die lip and the mesh roller is 2cm, and the diameter of the obtained ECTFE ultrafine fiber is 1.0μm.

[0035] During hot-pressing, the hot-pressing temperature is 100°C, the hot-pressing pressure is 0.05MPa, and the hot-pressing time is 10s.

[0036] In the prepared melt-blown film, at least 75% of the melt-blown film has a pore size between 0.3 μm and 0.7 μm, and less than 10% of the melt-blown film has a pore size between 0.1 μm and 0.3 μm, and less than 10% The pore diameter of the melt blown film is between 0.7 μm and 1.0 μm, and the pore diameter of less than 5% of the melt blown film exceeds 0.1 μm to 1.0 μm.

...

Embodiment 2

[0039] The operation of this embodiment is the same as that of Example 1, except that the temperature of the mesh roller is 40° C., the distance between the die lip and the mesh roller is 1 cm, and the obtained ECTFE superfine fibers have a diameter of 0.5 μm.

[0040] During hot-pressing, the hot-pressing temperature is 100°C, the hot-pressing pressure is 0.05MPa, and the hot-pressing time is 10s. The pore diameter of at least 80% of the melt blown film is between 0.3 μm and 0.7 μm, the pore diameter of 10% of the melt blown film is between 0.1 μm and 0.3 μm, and the pore diameter of 5% of the melt blown film is between Between 0.7 μm and 1.0 μm, 5% of the melt-blown membranes have a pore diameter exceeding 0.1 μm to 1.0 μm. The longitudinal tensile strength of the prepared melt-blown film was 2.08 MPa, and the longitudinal elongation at break was 50%; the transverse tensile strength of the melt-blown film was 1.50 MPa, and the transverse elongation at break was 108%.

Embodiment 3

[0042] The operation of this embodiment is the same as that of Example 1, and the difference is that: the ECTFE resin (melt index is 600g / 10min, 2.16kg, 275°C) with a melting temperature of 180°C is melt-processed in a twin-screw extruder, and the melt-processing temperature is 185°C. The obtained ECTFE ultrafine fiber has a diameter of 0.4 μm.

[0043]The pore diameter of 85% of the prepared melt-blown film is between 0.3 μm and 0.7 μm, the pore diameter of less than 5% of the melt-blown film is between 0.1 μm and 0.3 μm, and less than 5% of the melt-blown film The pore diameter of the membrane is between 0.7 μm and 1.0 μm, and the pore diameter of less than 5% of the melt blown membrane exceeds 0.1 μm to 1.0 μm.

[0044] The longitudinal tensile strength of the prepared melt-blown film was 2.13 MPa, and the longitudinal elongation at break was 53%; the transverse tensile strength of the melt-blown film was 1.53 MPa, and the transverse elongation at break was 110%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com