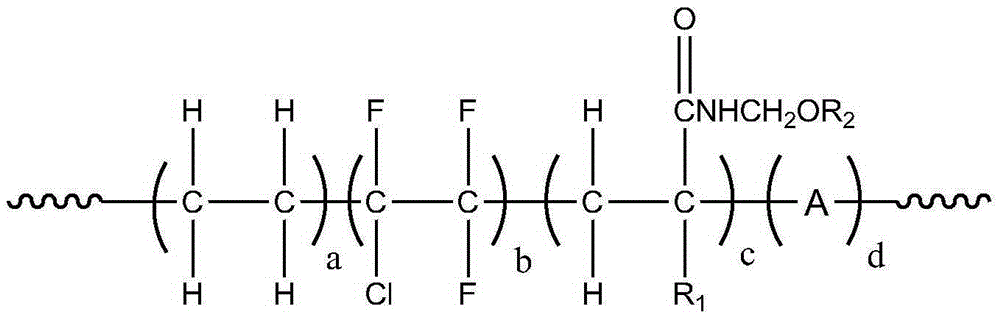

ECTFE (ethylene-chlorotrifluoroethylene copolymer) fluororesin with self-crosslinking structure, and preparation method thereof

A self-crosslinking and resin technology, applied in the field of fluororesin, can solve the problems of polymer decomposition, affecting polymer performance, increasing process steps, etc., and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 55L of high-purity deionized water, 60g of PFOA and 100g of sodium bicarbonate were added to a 100L stainless steel high-pressure reactor, and the reactor was evacuated and replaced with nitrogen three times. After the replacement is qualified, add 10KG chlorotrifluoroethylene and 880g N-methylolacrylamide into the reactor, stir and raise the temperature to 80°C. After the temperature of the system is constant, add ethylene into the reactor with a compressor until the pressure is 1.5MPa , use a metering pump to add an aqueous initiator solution containing 20g of ammonium persulfate to the reactor to initiate polymerization, continue to feed ethylene, maintain the polymerization pressure at 1.5MPa, stop adding ethylene gas after 1.5 hours of reaction, cool down, and recover unreacted ethylene, Chlorotrifluoroethylene, put the material into the coagulation bucket through the discharge valve of the reactor, coagulate and dehydrate. The material was washed several times wit...

Embodiment 2

[0051] Add 60L of high-purity deionized water, 30g of PFOA, 80g of disodium hydrogen phosphate and 10g of diethyl malonate into a 100L stainless steel autoclave, and the reactor is evacuated and replaced with nitrogen three times. After the replacement is qualified, add 20KG chlorotrifluoroethylene and 240g N-methoxymethacrylamide into the reactor, stir and raise the temperature to 65°C. After the temperature of the system is constant, add ethylene into the reactor with a compressor until the pressure is 3.5 MPa, use a metering pump to add an aqueous initiator solution containing 15g potassium persulfate to the reactor to initiate polymerization, continue to feed ethylene, maintain the polymerization pressure at 3.5MPa, stop adding ethylene gas after 6 hours of reaction, cool down, and recover unreacted ethylene , Chlorotrifluoroethylene, put the material into the coagulation bucket through the discharge valve of the reactor, coagulate and dehydrate. The material was washed se...

Embodiment 3

[0054] Add 60L of high-purity deionized water, 240g of PFOA, and 100g of sodium bicarbonate into a 100L stainless steel autoclave, and the reactor is evacuated and replaced with nitrogen three times. After the replacement is qualified, add 10KG of chlorotrifluoroethylene and 770g of N-methoxymethacrylamide into the reactor, stir and raise the temperature to 70°C. After the temperature of the system is constant, add ethylene into the reactor with a compressor until the pressure is 3.5 MPa, use a metering pump to add an aqueous initiator solution containing 35g potassium persulfate to the reactor to initiate polymerization, continue to feed ethylene, maintain the polymerization pressure at 3.5MPa, and add 120g methylcyclopentadiene to the system through a metering pump after 1 hour of polymerization After 4 hours of reaction, the addition of ethylene gas is stopped, the temperature is lowered, unreacted ethylene and chlorotrifluoroethylene are recovered, and the materials are put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com