Ethylene-chlorotrifluor ethylene copolymer microporous separation membrane, preparation method and application thereof

A technology of chlorotrifluoroethylene and copolymer, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the serious pollution of waste liquid, the mechanical strength of the membrane cannot meet the needs of actual production, and the cost of waste liquid treatment Higher problems, achieve the effect of low porosity, excellent resistance to strong alkali and strong acid, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

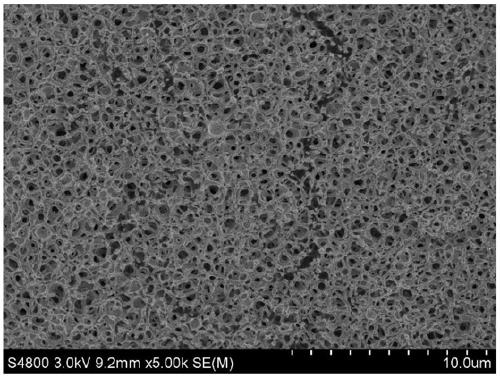

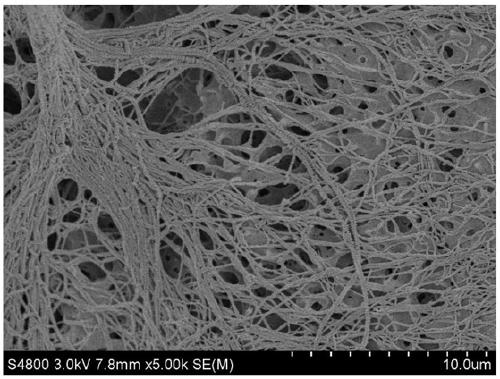

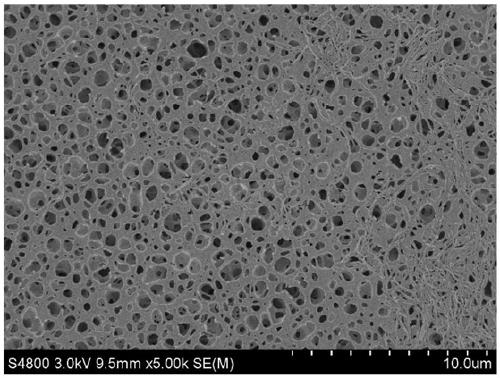

[0036] Weigh ethylene-trifluorochloroethylene copolymer 620g, tris(2,4-di-tert-butylphenyl) phosphite 10g, first diluent diphenyl carbonate 670g and second diluent diethyl phthalate Ester 700g. First, use a ball mill to grind diphenyl carbonate, and then use a kneader to mix ethylene-chlorotrifluoroethylene, ground diphenyl carbonate and tris(2,4-di-tert-butylphenyl)phosphite evenly to obtain Solid mixed material, then solid material is added in the extruder by artificial feeding mode, and feed rate is 18g / min, and diethyl phthalate is joined in the extruder, and feed rate is 9.7g / min, finally The extruder screw is completely melted and extruded at 210°C, the die temperature is set at 197°C, and the core liquid is a mixed solution of 80°C mass fraction of 90% ethylene glycol and mass fraction of 10% glycerol, and then The extruded membrane filaments were cooled in a water bath at 55°C to form a film, wound and wound, and finally immersed in water-washed ethanol for extraction...

Embodiment 2

[0046] Weigh ethylene-trifluorochloroethylene copolymer 620g, tris(2,4-di-tert-butylphenyl) phosphite 10g, first diluent diphenyl carbonate 670g and second diluent diethyl phthalate Ester 700g. First, use a ball mill to grind diphenyl carbonate, and then use a kneader to mix ethylene-chlorotrifluoroethylene, ground diphenyl carbonate and tris(2,4-di-tert-butylphenyl)phosphite evenly to obtain Solid mixed material, then solid material is added in the extruder by artificial feeding mode, and feed rate is 18g / min, and diethyl phthalate is joined in the extruder, and feed rate is 9.7g / min, finally Extrude through the extruder screw at 210°C to completely melt and extrude, the die head temperature is set to 197°C, the core liquid is a diethyl phthalate solution at 80°C, and then the extruded film filament is placed in a water bath at 55°C Cooling to form a film, winding and winding, and finally immersing the film filament in ethanol washed with water for extraction to obtain an et...

Embodiment 3

[0048] Weigh 676g of ethylene-chlorotrifluoroethylene copolymer, 10g of tris(2,4-di-tert-butylphenyl)phosphite, 730g of diphenyl carbonate as the first diluent, dimethyl phthalate as the second diluent Esters 584g. Wherein the first diluent diphenyl carbonate is ground using a ball mill, and ethylene-chlorotrifluoroethylene, the first diluent diphenyl carbonate and tris (2,4-di-tert-butylphenyl) phosphite are mixed using a kneader Mix evenly to obtain a solid mixture, then add the solid mixture and the second diluent dimethyl phthalate into the extruder through manual feeding, and completely melt and extrude through the extruder screw at 220 ° C. The die head temperature at 200°C, with nitrogen as the core fluid, the extruded membrane filaments are cooled in a 55°C water bath to form a film and wound and wound, and finally the membrane filaments are immersed in ethanol washed with water for a period of time to obtain ethylene-chlorotrifluoroethylene copolymer microporous sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com