Fluoropolymer composition

A technology of fluoropolymer and composition, which is applied in the field of fluoropolymer composition, and can solve problems such as long mixing time, high temperature, and uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

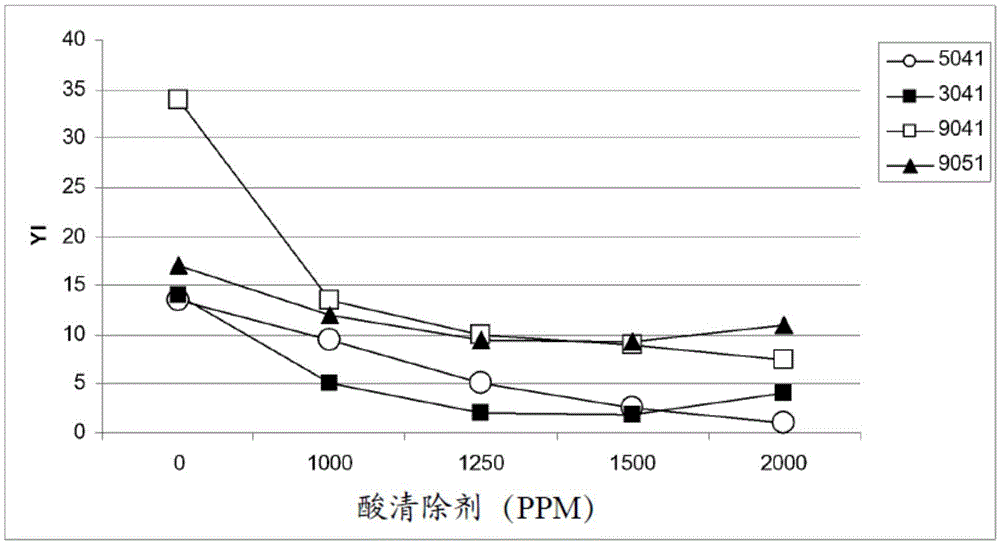

[0110] raw material:

[0111] The following ECTFE polymers were used:

[0112] 5041 ECTFE polymer, 50 / 50 molar ratio E / CTFE with a melt flow rate of 15g / 10min-22g / 10min at 275°C under a piston load of 2.16Kg;

[0113] 3041 ECTFE polymer, 50 / 50 molar ratio E / CTFE with a melt flow rate of 1.5g / 10min-3.0g / 10min at 275°C under a piston load of 2.16Kg

[0114] 9041 ECTFE polymer, 50 / 50 molar ratio E / CTFE with a melt flow rate of 0.8g / 10min-1.3g / 10min at 275°C under a piston load of 2.16Kg

[0115] 9051 ECTFE polymer, about 47 / 53 molar ratio E / CTFE with a melt flow rate of 0.8g / 10min-1.3g / 10min at 275°C under a piston load of 5Kg

[0116] All are commercially available from Solvay Specialty Polymers.

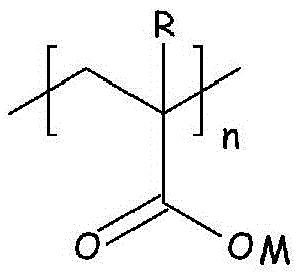

[0117] The following polyelectrolytes (E) were used:

[0118] 270 Sodium polyacrylic acid soluble in water, with M w =3500[hereinafter referred to as polyelectrolyte (E1)];

[0119] K766 Water-soluble sodium polymethacrylate with M w =5000 [hereinafter referred to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com