A kind of ectfe meltblown film and preparation method thereof

A melt-blown and melt-based technology, which is applied in the field of membrane materials, can solve the problems of unsatisfactory filtration accuracy, unresolved technical problems, large pore size of melt-blown membranes, etc., and achieve high elongation at break and uniform pore size distribution , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

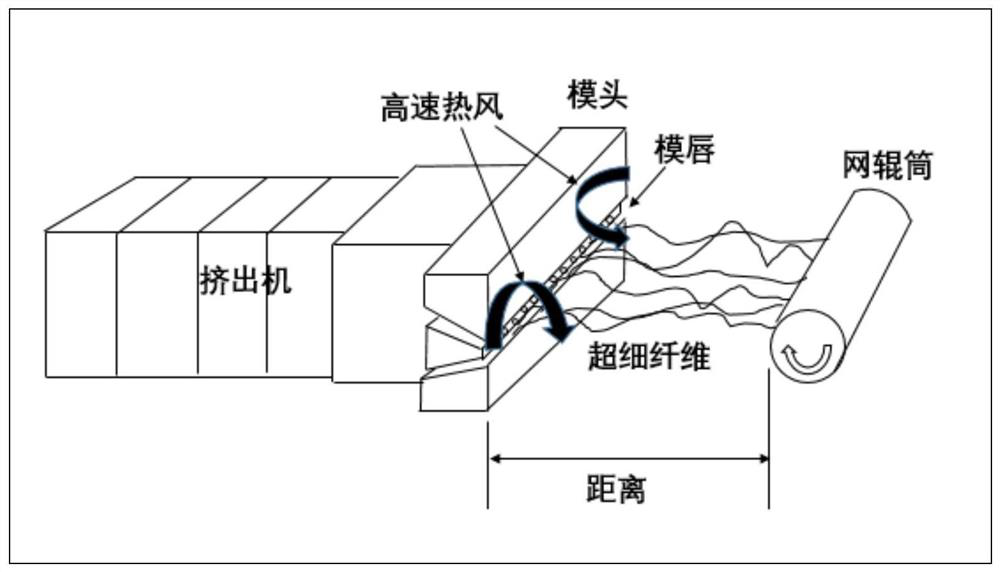

Method used

Image

Examples

Embodiment 1

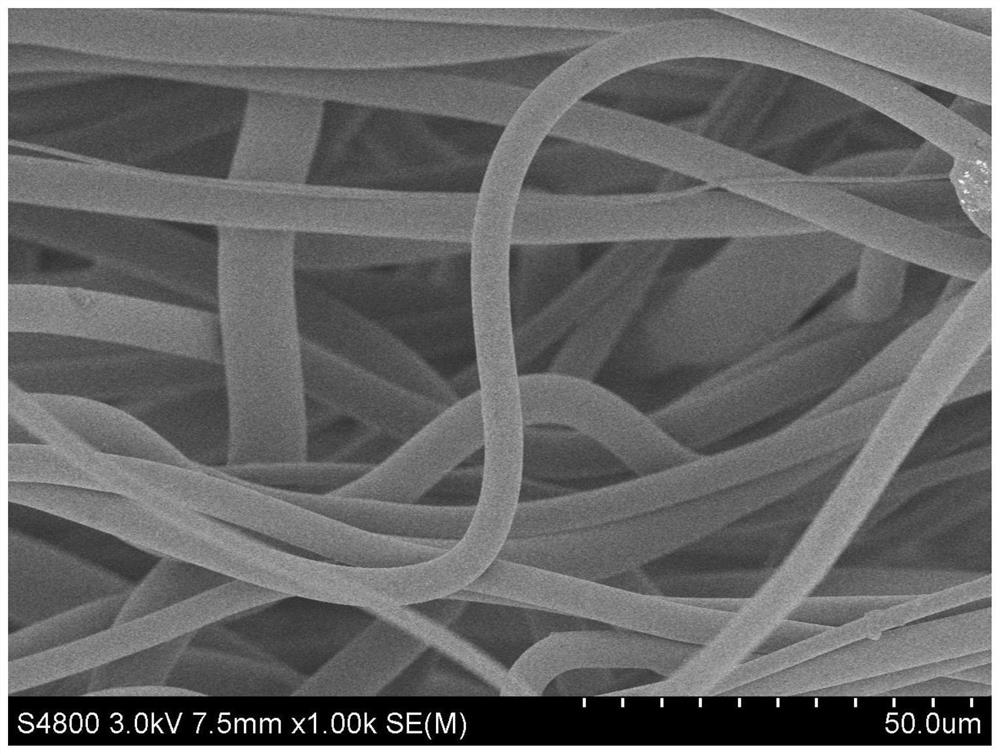

[0034] The ECTFE resin with a melting temperature of 195°C (melt index of 600 g / 10 min, 2.16 kg, 275°C) was melt processed in a twin-screw extruder with a melt processing temperature of 200°C. The hot air temperature of high-speed and high-temperature airflow is 230 °C, the hot air pressure is 0.1 MPa, the temperature of the mesh roller is 30 °C, and the distance between the die lip and the mesh roller is 2 cm, and the diameter of the obtained ECTFE ultrafine fiber is 1.0 μm.

[0035] During hot pressing, the hot pressing temperature was 100°C, the hot pressing pressure was 0.05 MPa, and the hot pressing time was 10s.

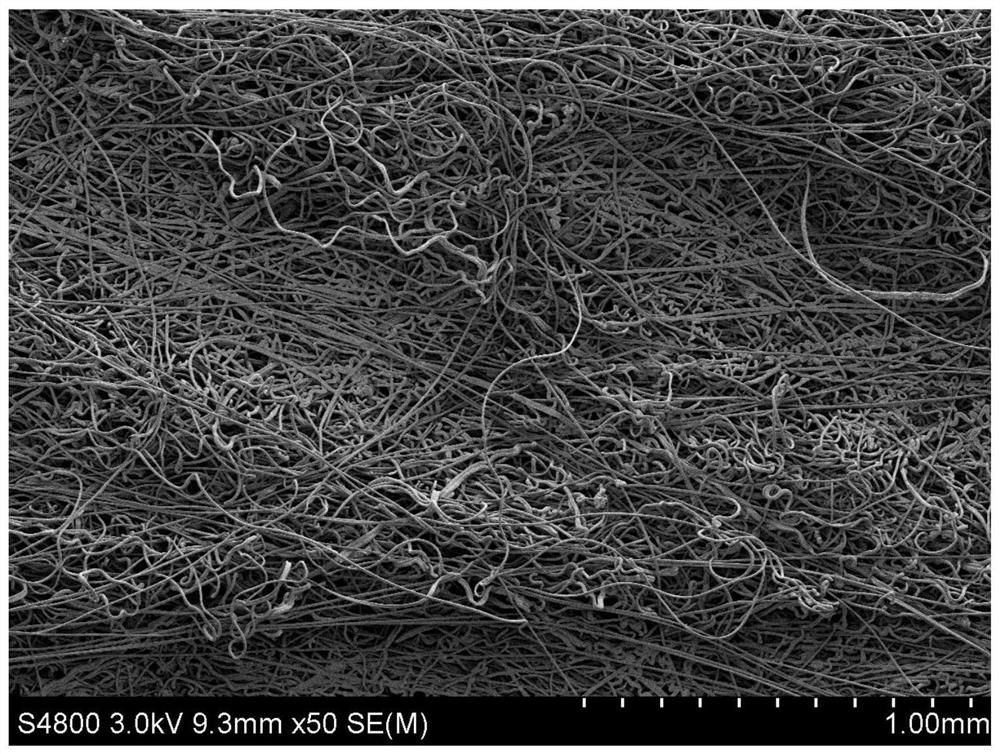

[0036] In the prepared melt-blown film, at least 75% of the melt-blown film has a pore size between 0.3 μm and 0.7 μm, and less than 10% of the melt-blown film has a pore size between 0.1 μm and 0.3 μm, and less than 10% The pore size of the meltblown film is between 0.7 μm and 1.0 μm, and the pore size of the meltblown film less than 5% exceeds 0.1 μm to 1.0 μ...

Embodiment 2

[0039] The operation of this example is the same as that of Example 1, except that the temperature of the mesh roll is 40°C, the distance between the die lip and the mesh roll is 1 cm, and the diameter of the obtained ECTFE ultrafine fibers is 0.5 μm.

[0040] During hot pressing, the hot pressing temperature was 100°C, the hot pressing pressure was 0.05 MPa, and the hot pressing time was 10s. At least 80% of the meltblown film has a pore size between 0.3 μm and 0.7 μm, 10% of the meltblown film has a pore size between 0.1 μm and 0.3 μm, and 5% of the meltblown film has a pore size between 0.3 μm and 0.7 μm. Between 0.7 μm and 1.0 μm, the pore size of 5% of the meltblown film exceeds 0.1 μm to 1.0 μm. The longitudinal tensile strength of the prepared melt-blown film was 2.08 MPa, and the longitudinal elongation at break was 50%; the transverse tensile strength of the melt-blown film was 1.50 MPa, and the transverse elongation at break was 108%.

Embodiment 3

[0042] The operation of this example is the same as that of Example 1, except that the ECTFE resin with a melting temperature of 180°C (melt index of 600g / 10min, 2.16kg, 275°C) was melt-processed in a twin-screw extruder, and the melt-processing temperature is 185°C. The obtained ECTFE ultrafine fibers had a diameter of 0.4 μm.

[0043]The pore size of 85% of the meltblown films prepared by the preparation is between 0.3 μm and 0.7 μm, the pore size of less than 5% of the meltblown films is between 0.1 μm and 0.3 μm, and the pore size of less than 5% of the meltblown films is between 0.1 μm and 0.3 μm. The pore size of the membrane is between 0.7 μm and 1.0 μm, and the pore size of the meltblown film less than 5% exceeds 0.1 μm to 1.0 μm.

[0044] The longitudinal tensile strength of the prepared melt-blown film was 2.13 MPa, and the longitudinal elongation at break was 53%; the transverse tensile strength of the melt-blown film was 1.53 MPa, and the transverse elongation at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com