Irradiation crosslinking modified ECTFE (ethylene chlorotrifluoroethylene) heat shrinkable sleeve and preparation method thereof

A heat-shrinkable sleeve and cross-linking modification technology, used in tubular articles, other household appliances, applications, etc., can solve the problems of insufficient processing adaptability, poor high temperature resistance, etc., and achieve a wide range of processing conditions and excellent applicability. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

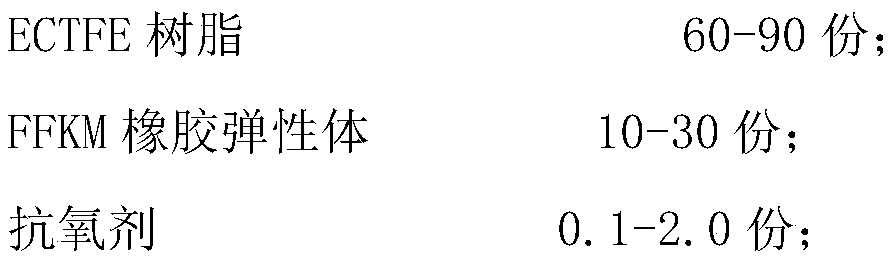

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of described radiation crosslinking modified ECTFE heat-shrinkable sleeve, comprises the following steps:

[0073] (1) Weigh FFKM rubber elastic body, antioxidant, acid absorbing agent, and lubricant and add them to the internal mixer for internal mixing at 170-200°C. During the internal mixing process, turn the material 5-6 times;

[0074] (2) Pour the mixed material in the step (1) into a single-screw extruder, force-feed the material through double pulls, then extrude, pull, cool, and pelletize to obtain the primary mixed pellets;

[0075] (3) Add ECTFE resin and color masterbatch to the initial mixing pellets of step (2) and stir in a mixer for 10-15 minutes together to obtain a blend;

[0076] (4) Adding the blended material to a parallel twin-screw extruder for the first time of melt extrusion, pulling, cooling, and pelletizing to obtain composite pellets;

[0077] (5) Add the composite material granules in step (4) to the homogenization de...

preparation Embodiment 1

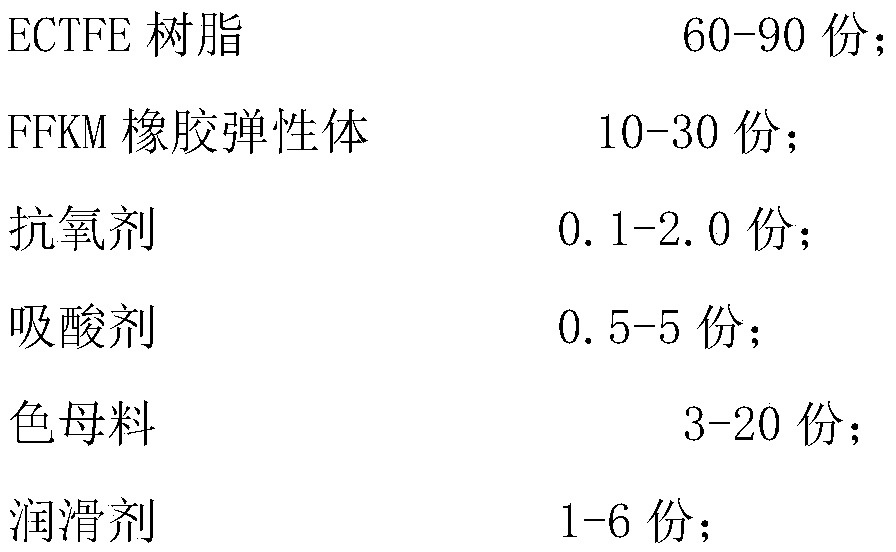

[0089] In this embodiment, a radiation crosslinked modified ECTFE heat shrinkable sleeve is provided, comprising the following components by weight:

[0090]

[0091]

[0092] Described ECTFE resin is ethylene-chlorotrifluoroethylene copolymer;

[0093] The FFKM rubber elastomer is a terpolymer of perfluoromethyl vinyl ether, tetrafluoroethylene and perfluoro-4-carboxymethyl butyl vinyl ether;

[0094] The antioxidant is 2,5-di-tert-butyl hydroquinone;

[0095] The acid absorbing agent is light magnesium oxide;

[0096] The lubricant is a fluoropolymer processing aid PPA (a polymer of 1,1,2,3,3,3-hexafluoro-1-propene and 1,1-difluoroethylene).

[0097] The preparation method of described radiation cross-linking modified ECTFE heat-shrinkable sleeve, comprises the steps:

[0098] (1) Weigh FFKM rubber elastic body, antioxidant, acid absorbing agent, and lubricant and add them to the internal mixer for internal mixing, and turn the material at 175°C, 180°C, 185°C, 190°C, ...

preparation Embodiment 2

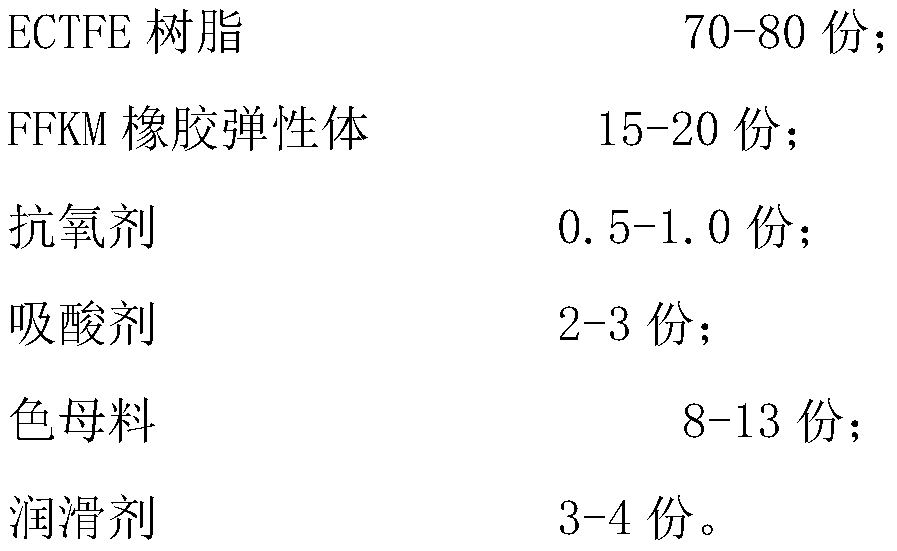

[0109] In this embodiment, a radiation crosslinked modified ECTFE heat shrinkable sleeve is provided, comprising the following components by weight:

[0110]

[0111] Described ECTFE resin is ethylene-chlorotrifluoroethylene copolymer;

[0112] The FFKM rubber elastomer is a terpolymer of perfluoromethyl vinyl ether, tetrafluoroethylene and perfluoro-4-carboxymethyl butyl vinyl ether;

[0113] The antioxidant is 2,5-di-tert-butyl hydroquinone;

[0114] The acid absorbing agent is light magnesium oxide;

[0115] The lubricant is a fluoropolymer processing aid PPA (a polymer of 1,1,2,3,3,3-hexafluoro-1-propene and 1,1-difluoroethylene).

[0116] The preparation method of described radiation cross-linking modified ECTFE heat-shrinkable sleeve, comprises the steps:

[0117] (1) Weigh FFKM rubber elastic body, antioxidant, acid absorbing agent, and lubricant and add them to the internal mixer for internal mixing, and turn the material at 175°C, 180°C, 185°C, 190°C, and 195°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal shock | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com