A high-flux polymer separation membrane, preparation method, diluent composition and application

A diluent and porous membrane technology, which is applied in the field of polymer separation membrane preparation, can solve the problem that the microporous membrane is easy to form a closed cell-like pore structure, and achieve the effect of improving the pure water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

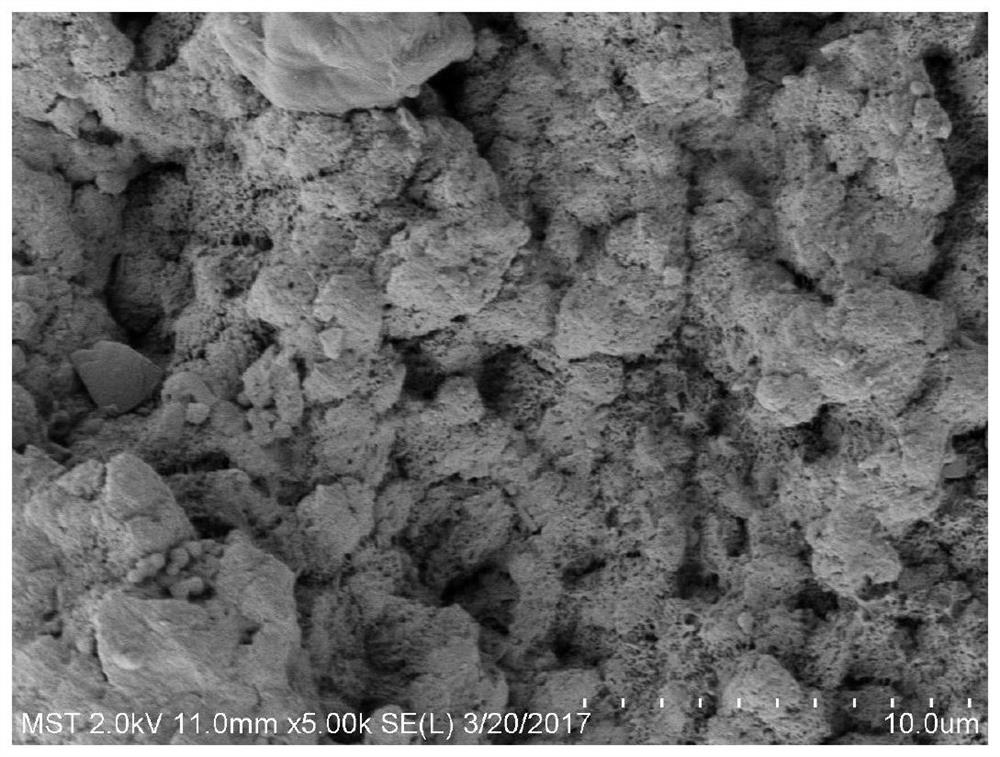

Embodiment 1

[0090] Accurately weigh 70g of diluent (tributyl acetyl citrate: dioctyl terephthalate = 1:1), 30g of ECTFE (Halar® 902), ECTFE mass fraction is 30%, stir well and pour into 500 mL In the high-temperature container, the temperature of the oil bath used was 250 °C, nitrogen was used as the protective gas, and then the solution was stirred with an electric stirrer for 4 h, and then left in the oil bath for defoaming for 4 h; the obtained film solution was poured into a self-made mold Medium-press to form a film, then put the mold into a water quenching bath (20-25°C) to solidify to form a film; put the obtained film in an ethanol solution for extraction for a certain period of time, and extract the diluent to obtain an ECTFE porous film.

Embodiment 2

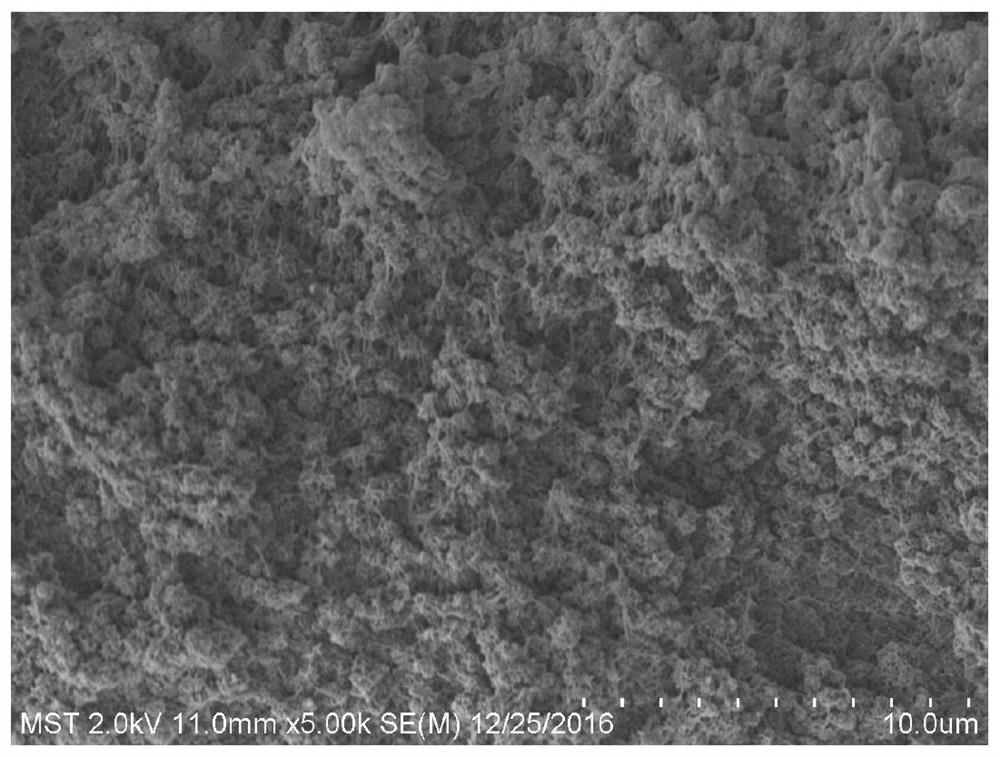

[0092] Accurately weigh 70g of diluent (tributyl acetyl citrate: dioctyl terephthalate = 3:1), 30g of ECTFE (Halar® 902), ECTFE mass fraction is 30%, stir well and pour into 500 mL In the high-temperature container, the temperature of the oil bath used was 250 °C, nitrogen was used as the protective gas, and then the solution was stirred with an electric stirrer for 4 h, and then left in the oil bath for defoaming for 4 h; the obtained film solution was poured into a self-made mold Medium-press to form a film, then put the mold into a water quenching bath (20-25°C) to solidify to form a film; put the obtained film in an ethanol solution for extraction for a certain period of time, and extract the diluent to obtain an ECTFE porous film.

Embodiment 3

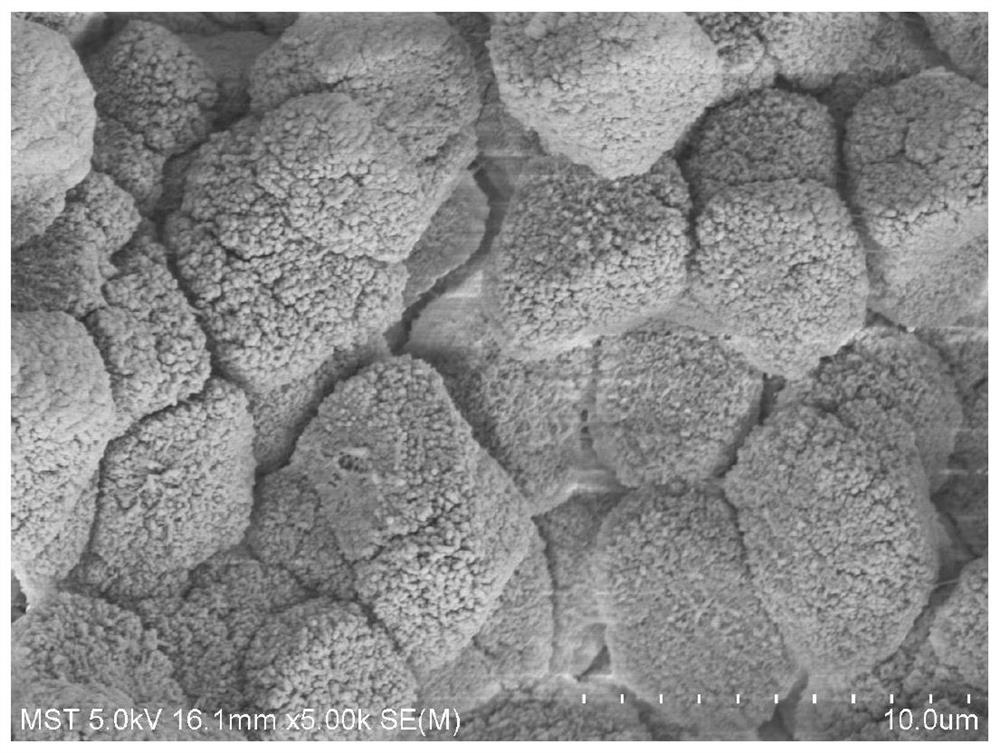

[0094] Accurately weigh 70g of diluent (acetyl tributyl citrate: dioctyl terephthalate = 1:3), 30g of ECTFE (Halar® 902), ECTFE mass fraction is 30%, stir well and pour into 500 mL In the high-temperature container, the temperature of the oil bath used was 250 °C, nitrogen was used as the protective gas, and then the solution was stirred with an electric stirrer for 4 h, and then left in the oil bath for defoaming for 4 h; the obtained film solution was poured into a self-made mold Medium-press to form a film, then put the mold into a water quenching bath (20-25°C) to solidify to form a film; put the obtained film in an ethanol solution for extraction for a certain period of time, and extract the diluent to obtain an ECTFE porous film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com