Preparation method of ECTFE hollow fiber porous membrane for a membrane chemical reactor process

A technology of membrane chemical reactor and porous membrane, which is applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of complex process and difficult control of membrane pore size, and achieve simple process, small pore size and high porosity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

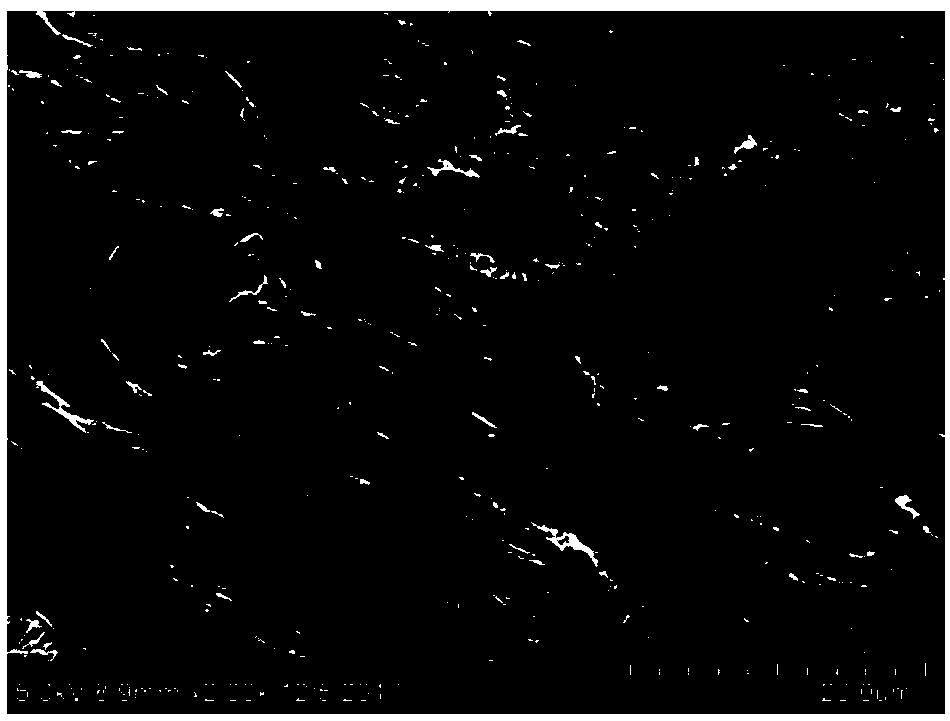

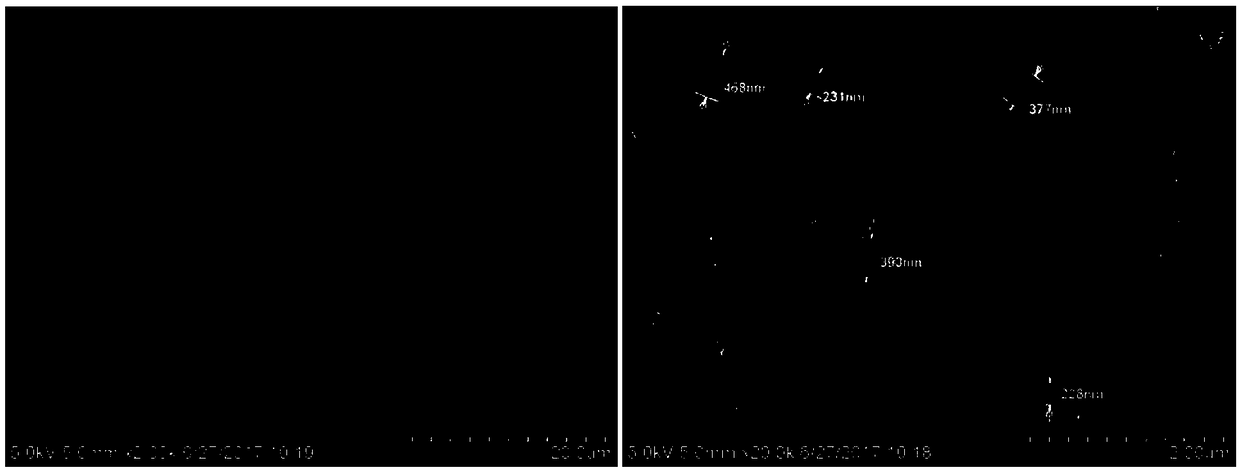

Image

Examples

preparation example Construction

[0026] The present invention provides a method for preparing an ethylene-chlorotrifluoroethylene copolymer hollow fiber porous membrane used in a membrane chemical reactor process, which includes the following steps:

[0027] 1) Add ethylene-chlorotrifluoroethylene copolymer powder and compound diluent to the melting equipment, melt and plasticize to obtain casting liquid; based on the total mass of ethylene-chlorotrifluoroethylene copolymer powder and compound diluent, The mass fraction of ethylene-chlorotrifluoroethylene copolymer powder is 15%-45%; the compound diluent is selected from two of the following diluents: acetyl tributyl citrate, propylene glycol carbonate, and phthalic acid Dibutyl ester, diethyl phthalate, benzophenone, diphenyl carbonate, γ-butyrolactone, sulfolane, glycerol triacetate, diethylene glycol, dioctyl adipate, two sebacate Octyl ester, dioctyl phthalate, diphenylmethane, dibutyl sebacate;

[0028] 2) The casting liquid is extruded through a spinneret a...

Embodiment 1

[0043] 1) Add 1kg of dried ECTFE powder, 2.4kg of diethyl phthalate (DEP), and 1.6kg of dibutyl sebacate (DBS) into a stirred tank and mix;

[0044] 2) After stirring at 260°C for 5 hours, let it stand and degas overnight to obtain a casting solution;

[0045] 3) Extruding the casting liquid through the spinneret, controlling the dry spinning process to 25cm, the drawing speed to 32m / min, and quenching in a water bath at 30°C to obtain the nascent hollow fiber membrane;

[0046] 4) Extract with ethanol at 40°C for 3 hours to obtain ECTFE hollow fiber porous membrane.

Embodiment 2

[0048] 1) Add 2kg of dried ECTFE and a compound diluent composed of 1kg of triacetin (GTA) and 2kg of dioctyl phthalate (DOP) into the twin-screw extruder;

[0049] 2) In a twin-screw extruder, melt and plasticize at 230°C to obtain a casting liquid;

[0050] 3) Extrude the casting liquid through the spinneret, control the dry spinning process to 10cm, the drawing speed to 16m / min, and enter it into a water bath at 10°C for quenching to obtain a nascent hollow fiber membrane;

[0051] 4) Ethanol-n-butanol extraction at 50°C for 4 hours to obtain ECTFE hollow fiber porous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com