Energy saving integrated engineering bamboo assembly building system with low cost structure

A low-cost, prefabricated technology, applied in buildings, building structures, etc., can solve the problems of low construction efficiency, poor performance, large space occupation, etc., and achieve the effect of simple and convenient construction, light weight and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

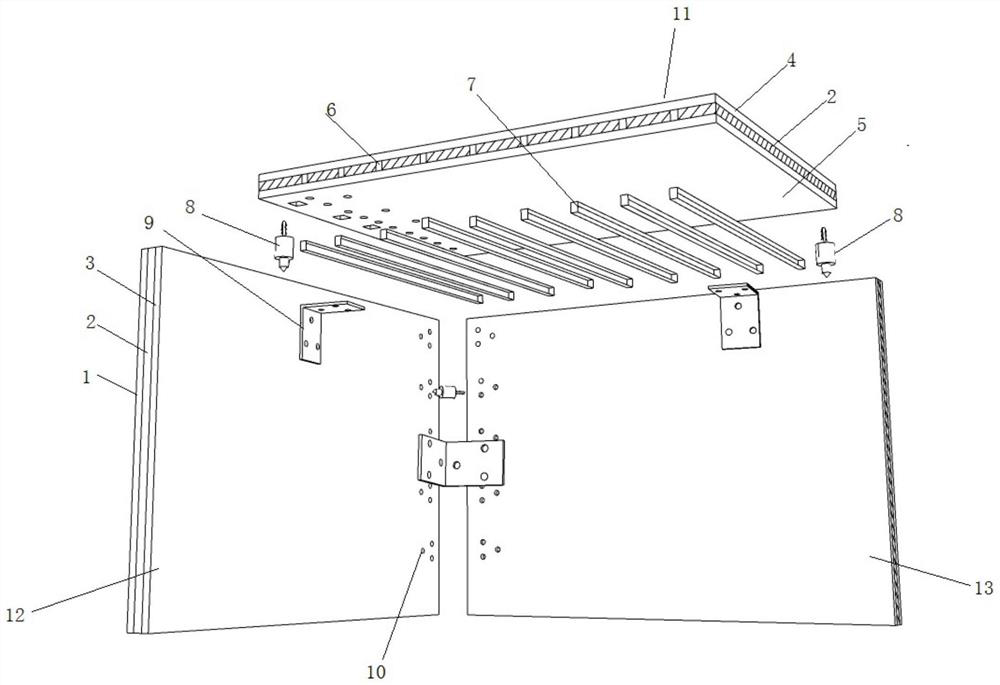

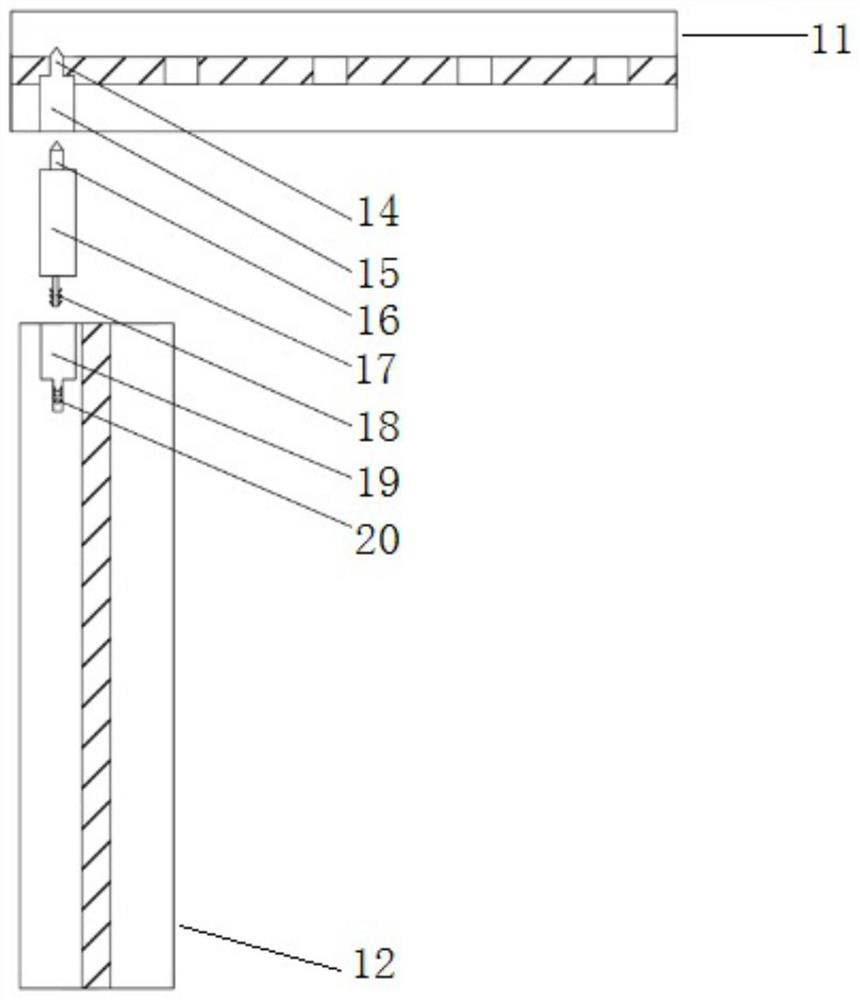

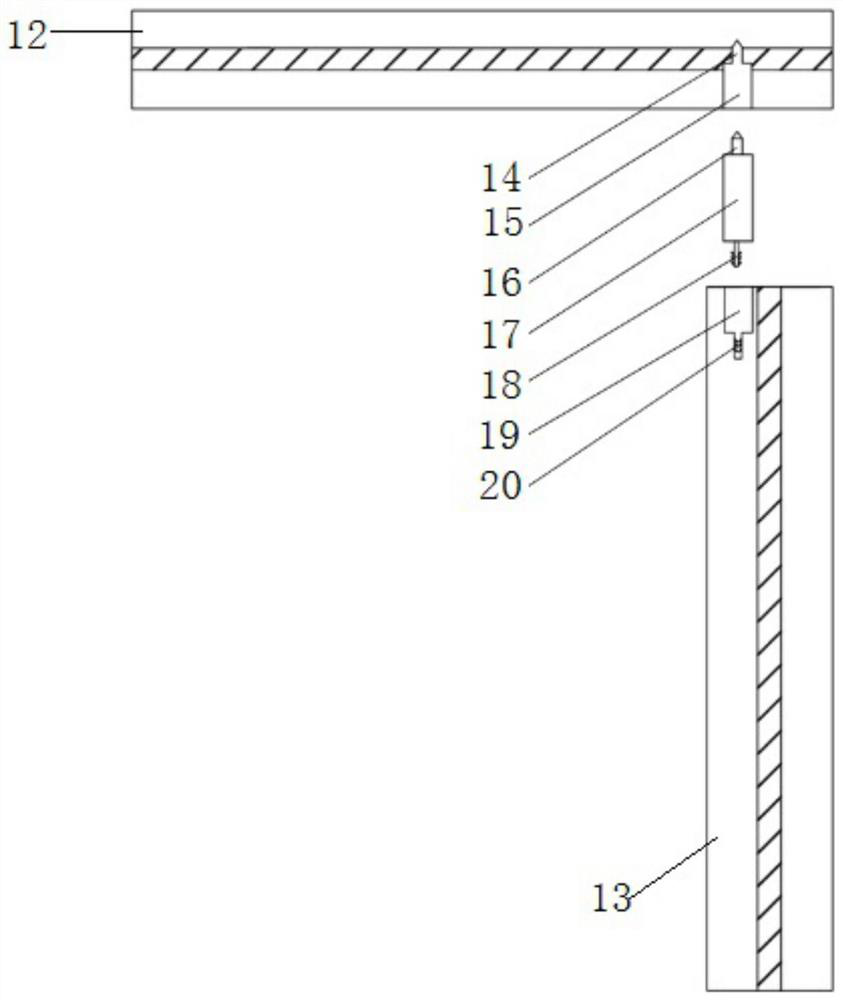

[0029] According to the attached Figure 1-5 The specific embodiment of the present invention is further described:

[0030] A low-cost structural energy-saving integrated engineering bamboo prefabricated building system, such as figure 1 As shown, it includes a main wall panel 12, a side wall panel 13, a roof panel 11, a plurality of stiffeners 7, a plurality of L-shaped angle steel connectors 9 and a plurality of metal connectors 8;

[0031] The main wall panel 12 and the side wall panel 13 have the same structure, and are all formed by sequentially bonding the inner engineering bamboo board 3, the straw board 2 and the outer engineering bamboo board 1; the inner engineering bamboo board 3 and the outer engineering bamboo board 1 are all passed through waterproof treatment;

[0032] The roof slab 11 includes an upper engineering bamboo board 4, a straw board 2, a lower engineering bamboo board 5 and stiffeners 7, and a plurality of straws are bonded between the upper engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com