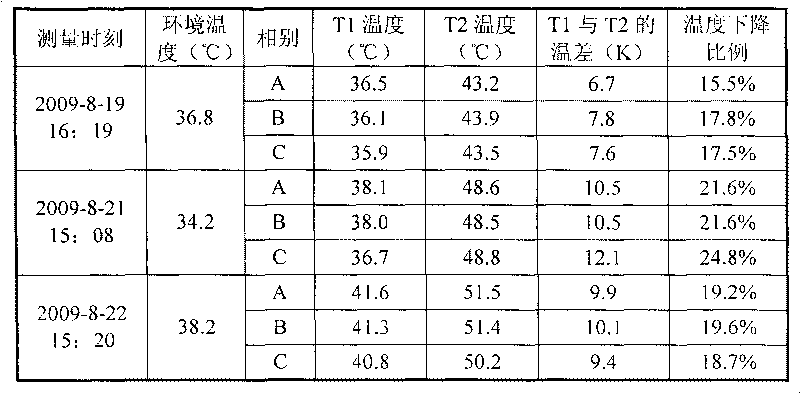

Patents

Literature

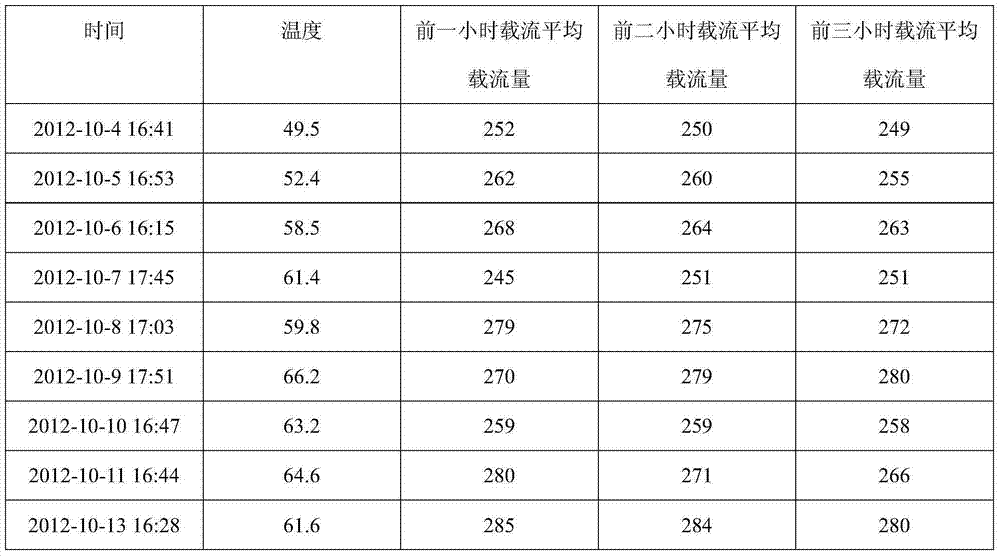

94results about How to "Easy on-site construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

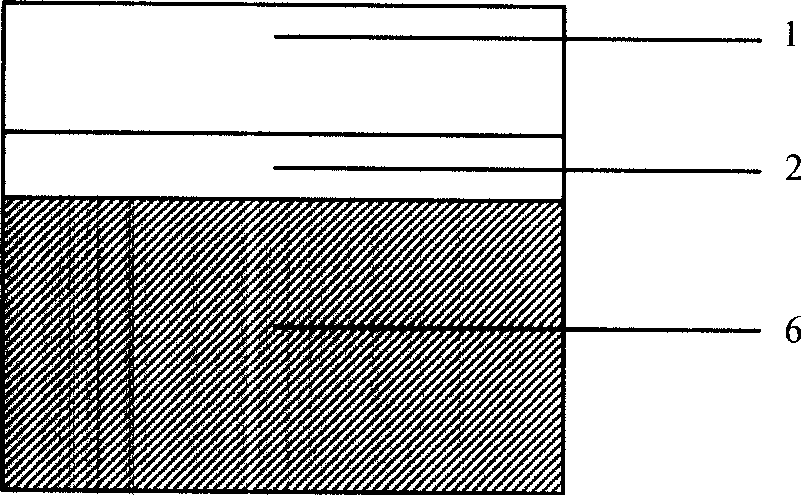

Novel phase change-heat preservation composite wall structure

InactiveCN101413299AImprove peak clipping delay effectImprove thermal inertiaWallsHeat proofingInsulation layerThermal insulation

The invention relates to a novel phase change and heat insulation composite wall structure, which is applied to the heat insulation of a wall and mainly comprises a heat insulation layer, a figurate phase change layer and a wall base body to form an integrative composite structure. The heat transmission resistance of the composite wall structure can be evaluated according to the material and the thickness of the wall base body so as to figure out the material thickness of the heat insulation layer and ensure that the heat transmission resistance of the wall base body is equal to that of the heat insulation layer, so that the despicking delay effect of the phase change layer to the temperature variation is improved to the utmost extent. The composite wall structure gives full play to the heat insulation effect of the heat insulation layer and the heat storage and temperature regulation effect of the phase change layer to improve the thermal inertia of the wall body greatly. The composite wall structure has stable performance and is convenient in construction and energy-saving reconstruction of old buildings to achieve the effects of high efficiency and environmental protection.

Owner:武汉科华高新材料发展有限公司

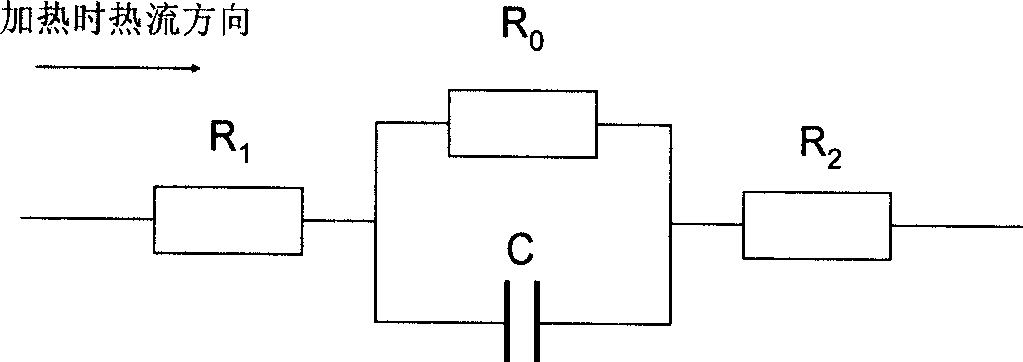

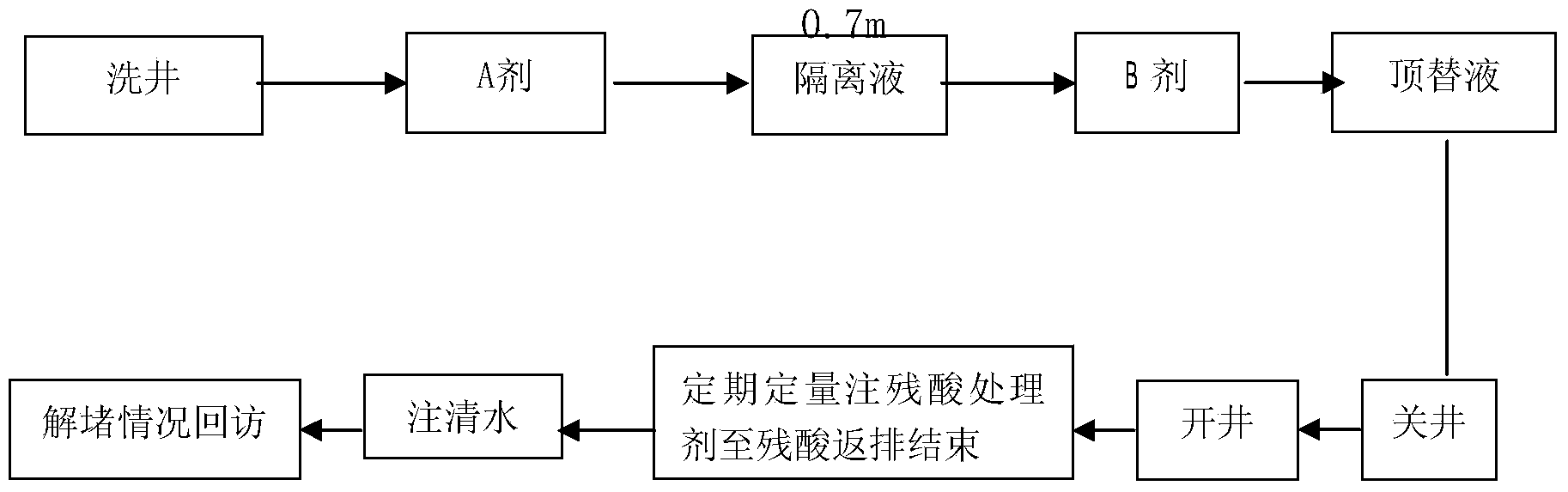

Carbon dioxide acidification blocking remover and process of not reversely discharging raffinate after acidification

ActiveCN103937475AEasy to store and absolutely safeEasy to transport and absolutely safeCleaning apparatusFluid removalActive agentSurface-active agents

The invention relates to a carbon dioxide acidification blocking remover and a process of not reversely discharging raffinate after acidification. The blocking remover comprises a reagent A which is prepared by directly mixing hydrochloric acid, hydrofluoric acid, glacial acetic acid, polyoxyethylene alkyl phenol ether, citric acid, a corrosion inhibitor, a mutual solvent and a clay stabilizer to form a homogeneous solution and a reagent B prepared by mutually mixing carbonate, a surfactant, an iron ion complexing agent, a demulsifier and clean water which are stirred for 1 hour at normal temperature. The process of not reversely discharging raffinate after acidification comprises the following steps: when an oil well is deblocked, first, injecting a medicament A into an oil layer; then, isolating the clean water by layers; then, injecting a medicament B into the oil layer; and finally, injecting clean water to extrude a mixture in a shaft to the stratum, then, injecting an acidizer into a loop space to a perforated interval, closing the well for 4-6 hours, opening the well, observing the pH value (control range from 6-7), periodically injecting the acidizer till raffinate is fully discharged out of the stratum, and finally, injecting clean water to extrude the mixture in the shaft into a dryline.

Owner:DAQING ZHONGYOU TAIKE PETROLEUM TECH SERVICE

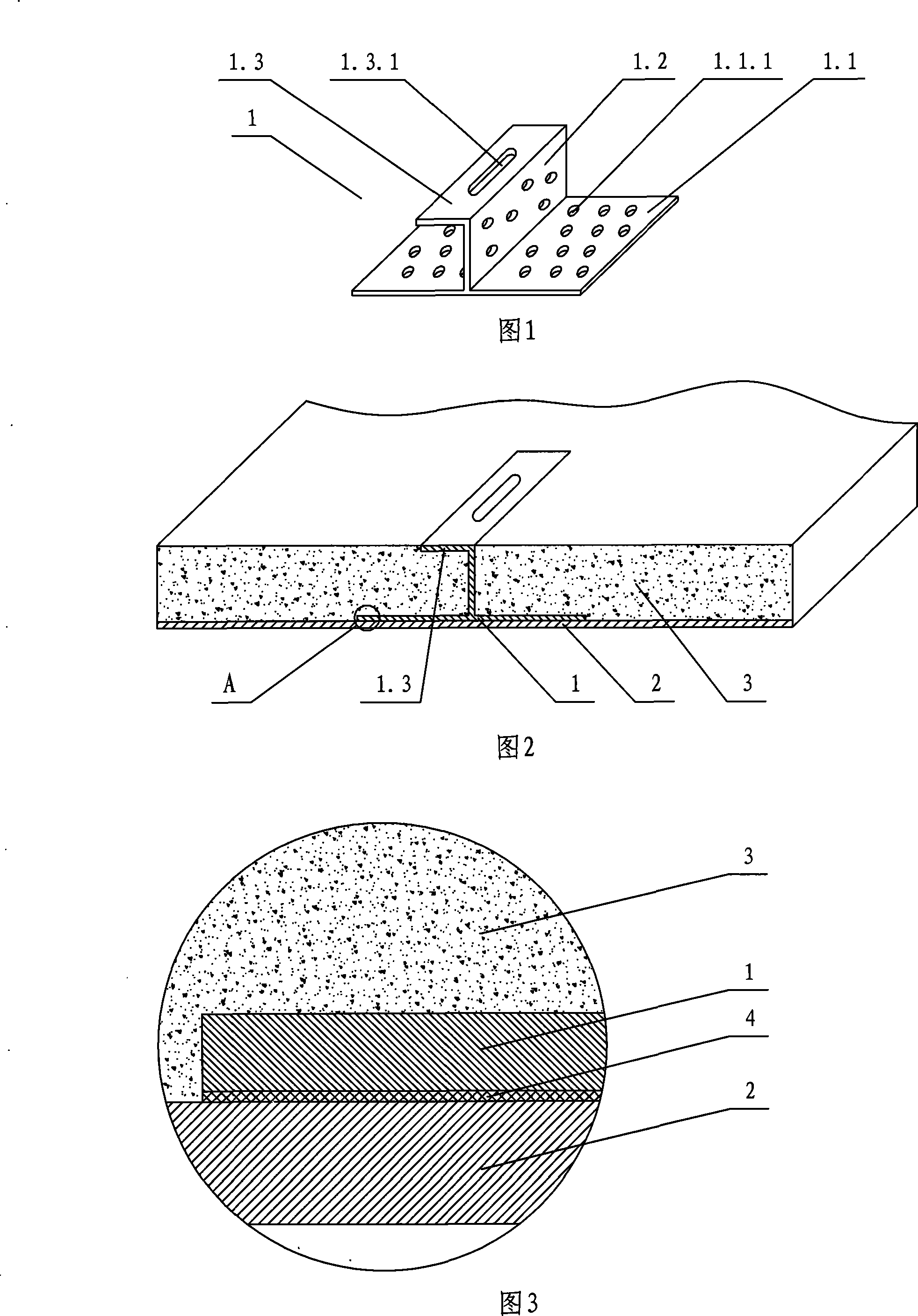

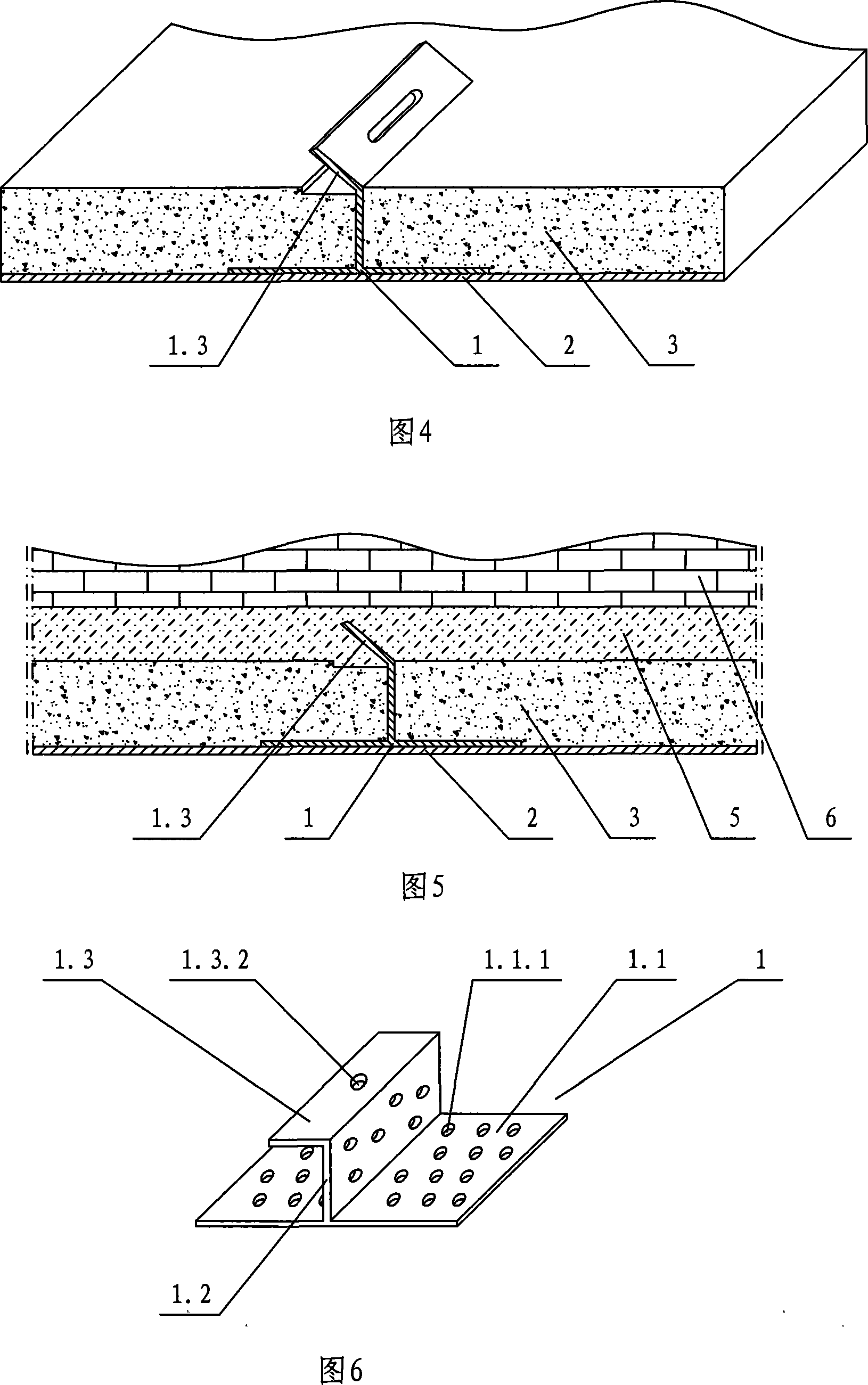

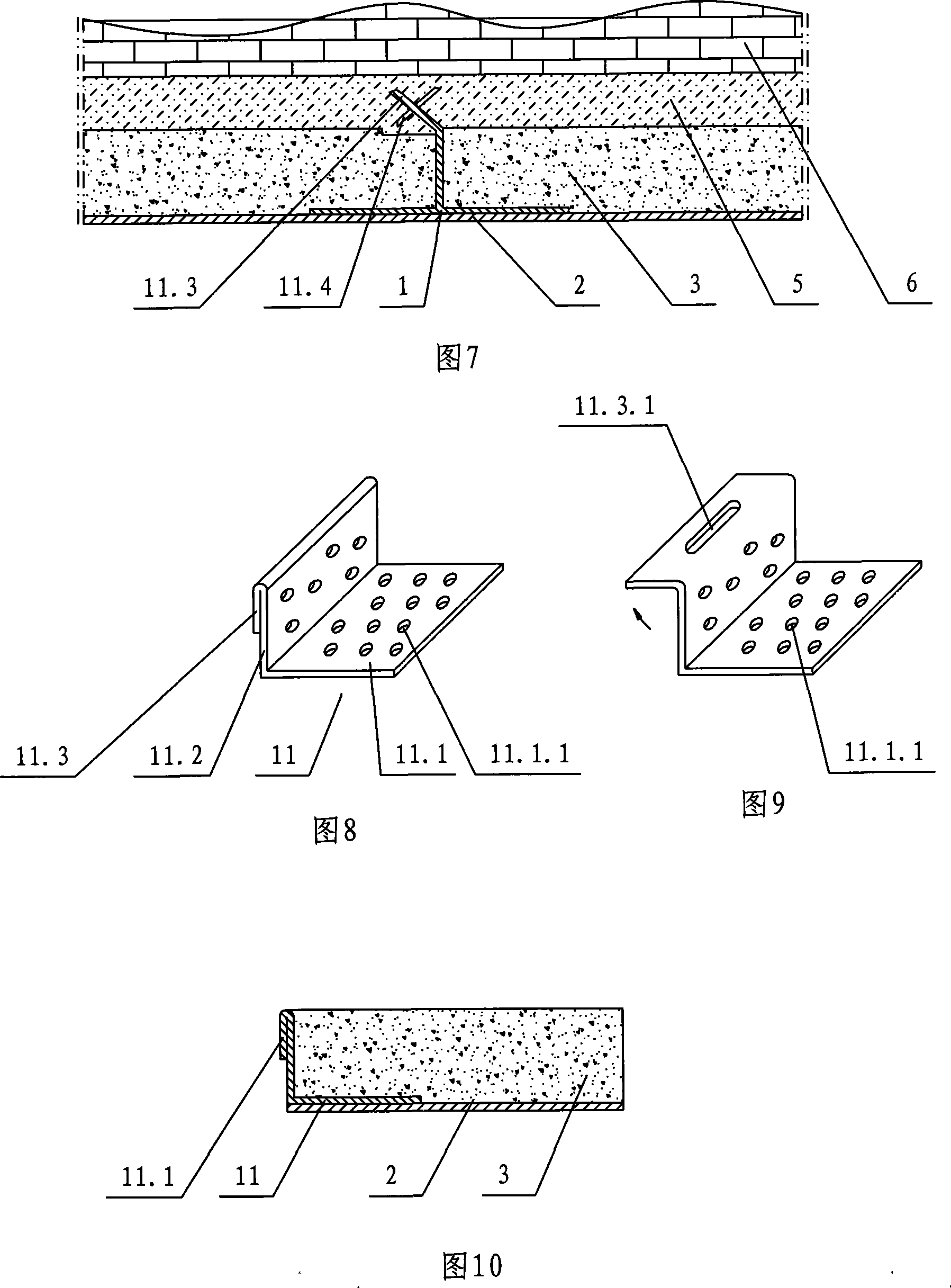

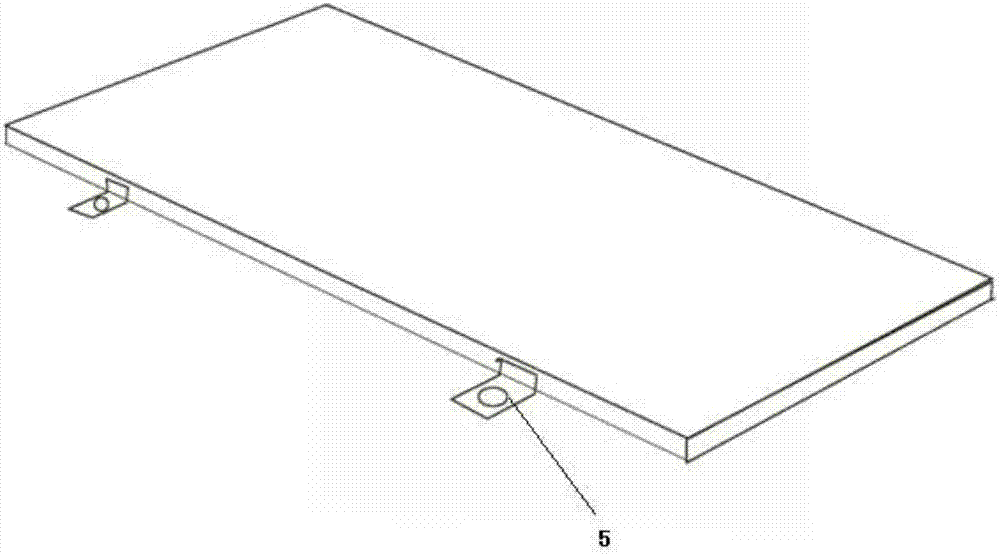

Heat insulation decoration board and its connecting component on site construction method

InactiveCN101215917AImprove the decorative effectSimple structureCovering/liningsThermal insulationEngineering

The invention relates to a field construction method of a thermal insulation decorative sheet and a connecting piece of the thermal insulation decorative sheet, one or more than one connecting pieces with thin wall are inserted on the thermal insulation decorative sheet, the thermal insulation decorative sheet comprises a polyurethane coating which is arranged on a decorative base slab, wherein the lower end of the connecting piece is clung with the decorative base slab, the top is level to the upper surface of the polyurethane coating, the connecting piece comprises a transverse base slab, a vertical slab and a transverse edge fold, wherein a locating hole is arranged on the transverse edge fold. The connecting piece is a first connecting piece, the first connecting piece comprises a first vertical slab which is arranged on a first transverse base slab, a first transverse edge fold is arranged on the top of the first vertical slab, the first transverse edge fold and the first vertical slab are arranged in a right angle, the top surface of the first transverse edge fold is level to the upper surface of the polyurethane coating, a first locating hole is arranged on the first transverse edge fold, and the first locating hole is a strip-shaped hole or a round hole. The invention has the advantages of factory prefabrication, low fabricating cost, simple field construction and good wall surface decorative effects.

Owner:瞿浩荣

Cable low heat resistance protection medium and preparing method thereof

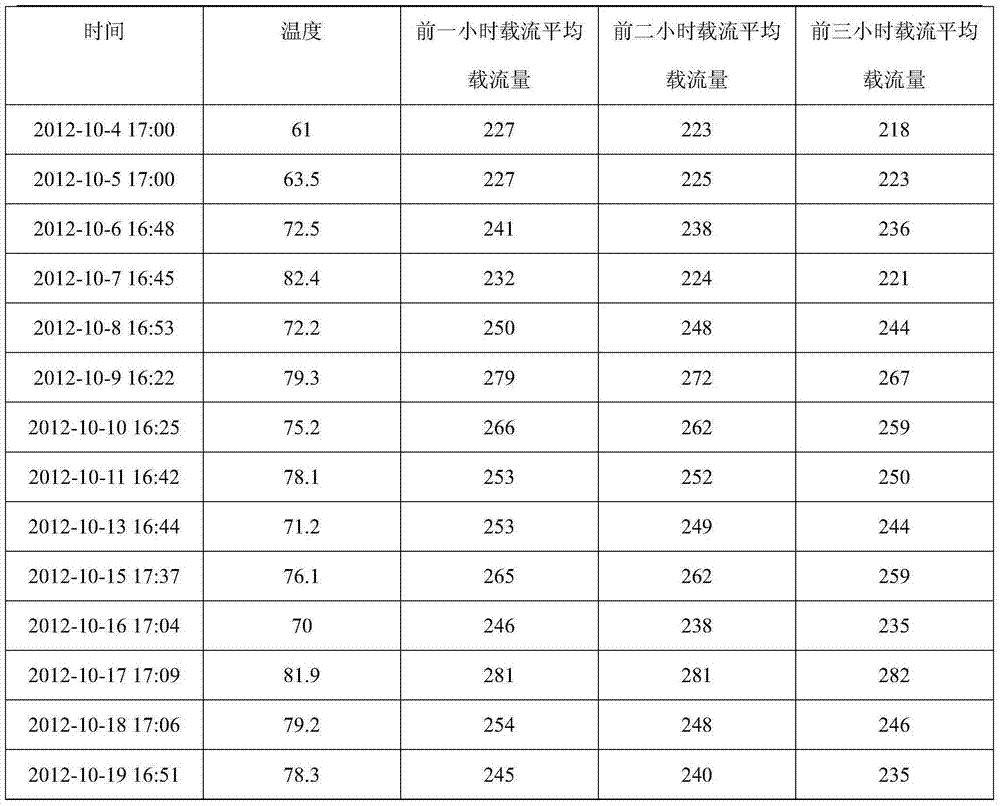

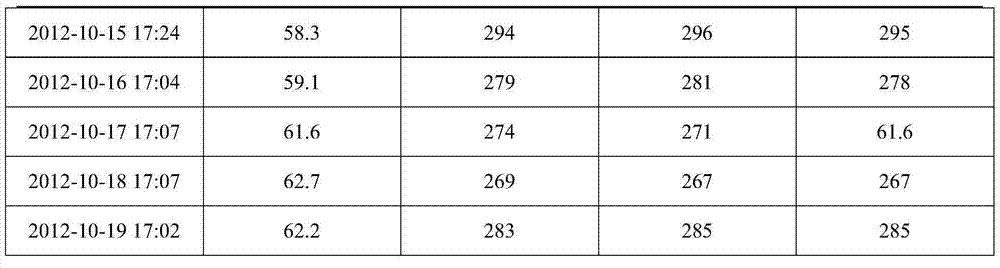

ActiveCN101764384AReduce thermal resistanceIncrease thermal resistanceCable installations on groundAlkalinityElectrical conductor

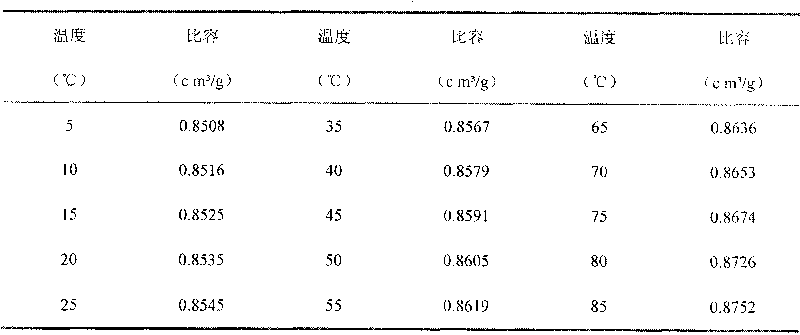

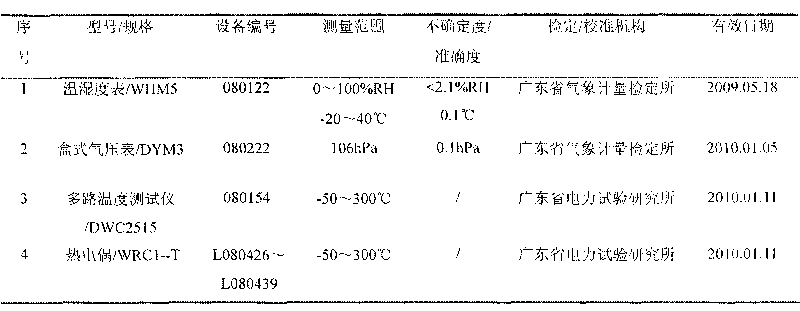

The invention discloses a cable low heat resistance protection medium with high water content, high stability, low heat resistance, environment protection and effective prevention of termite damage, and a preparation method thereof. The filling medium is prepared by mixing bentonite, fine quartz sand, water and cement, and using a small amount of tartaric acid and sodium sesquicarbonate as additives. As accounted by 100% of mass fraction, the filling medium is preferably prepared by 54%-57% of bentonite, 24%-28% of fine quartz sand, 14%-16% of water, 2.5-3.5% of cement, 0.24%-0.26% of tartaric acid and 0.24%-0.26% of sodium sesquicarbonate. Before condensation, the filling medium has the advantages of better initial liquidity, moderate alkalinity, low bleeding rate and the like. After condensation, compared with traditional material, the filling medium has the advantages of high water content and high stability, and enables the surroundings of the cable to maintain low heat resistance for long term, the heat resistance is smaller than that of soil, and the hardness is higher, therefore the current carrying amount of the cable is improved, or the running temperature of the cable conductor is reduced.

Owner:广州骏拓电力科技有限公司

Large scale ship booster supporting compartment manufacture and installation method

ActiveCN101008176AImprove construction efficiencyIntegrity guaranteedVertical ship-liftingEngineeringWater level

The invention relates to a method for producing and installing large shift-lift support compartment used in the dam of hydraulic power plant. The invention based on the structure, the character and the transportation demand of compartment utilizes the floating method; divides the support compartment into nut beam floating unit, the main longitudinal floating unit, and the bottom plate embed unit, to be produced in factory, floated to the dam and into the compartment; adjusts the water level of compartment, positions the pier and assembles and welds the units, to connect them integrally. The invention can build the compartment via assembling units on site, to improve the accuracy, quality and reduce the cost.

Owner:WUCHANG SHIPBUILDING IND

Aquatic floating and transportation method of ultra-large type component

ActiveCN1927653AReduce draftGuaranteed uptimeConveyorsWaterborne vesselsPower stationMarine engineering

The invention relates to waterborne floating transporting method used when construct super sized component such as dams for the power stations and bridges. Its program is: detecting fairways, forming sealed compartment with the cross beam and / or the longitudinal beam of trunk section of super sized component, forming inflatable air chamber with the within web of said cross and longitudinal beam; connecting the inflatable air chamber with compressed air source, putting the super component in waterborne fairways; aerifying the inflatable air chamber and forming air cushion between it and the surface and leading to the giant component floating on the water; regarding the towboat as power and driving the super component into waterways to floating and transporting. Its features are: installing independent ballast water tank on the both ends of longitudinal beam on the both sides of super component, ballast water tank is linked with the ballast pumping system to adjusting the ballast water of each ballast water tanks. The adaptability to component structure of the invention is better, adjustment and balance is easy and convenient to completing when in water run-time, so the overall floating and transporting performance of super component is more perfect.

Owner:WUCHANG SHIPBUILDING IND

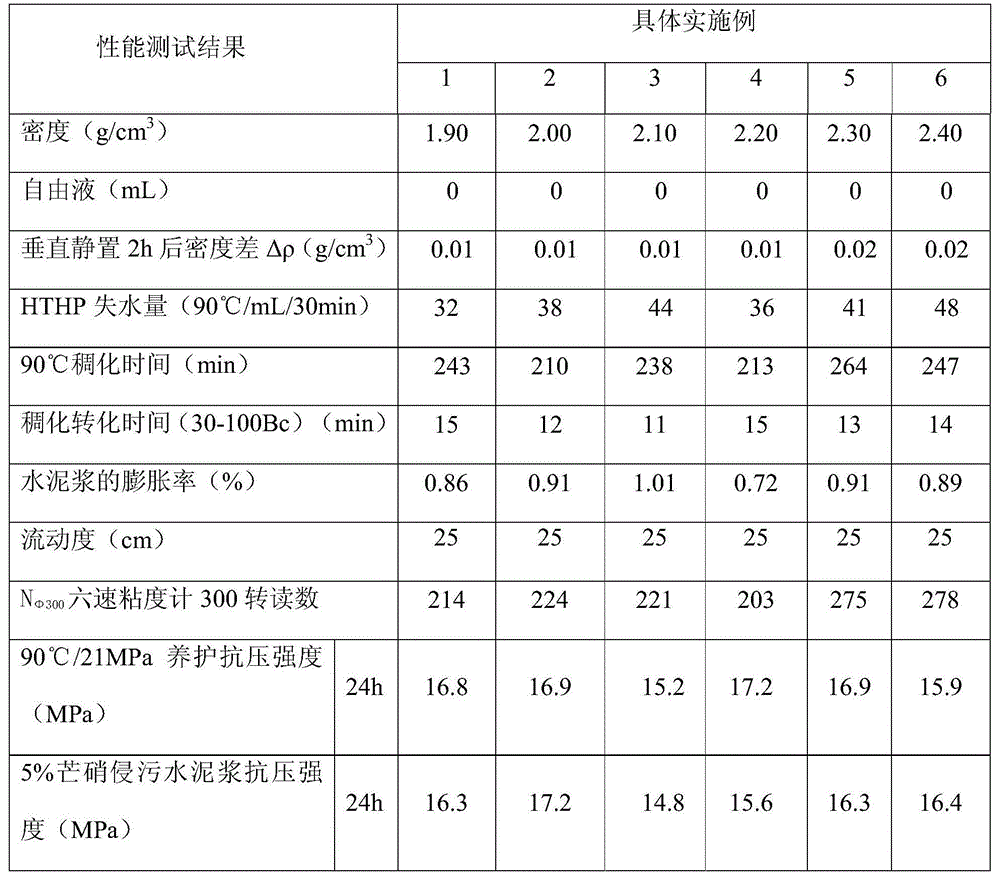

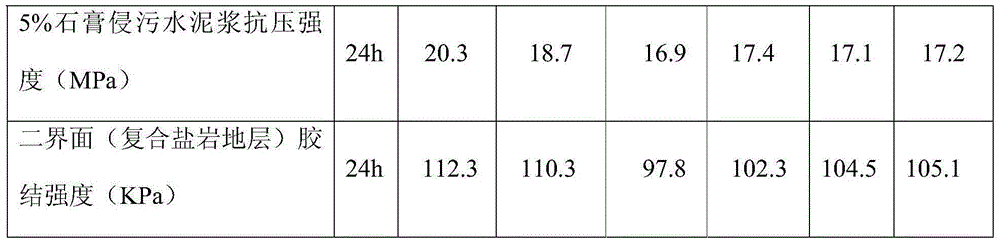

Supersaturated potassium chloride cement paste for well cementation

InactiveCN104610949AThickening time controllableSimple recipeDrilling compositionMirabiliteHigh pressure

The invention discloses supersaturated potassium chloride cement paste for well cementation. The cement paste is prepared from the following components: high sulfate-resistant G-grade cement, a salt-bearing fluid loss reducer, a preservative, a retarder, water, potassium chloride, a reinforced anti-migration additive, an expanding agent and a weighting agent. The supersaturated potassium chloride cement paste has the effects of stabilizing a well wall and improving the well wall strength; supersaturated potassium chloride assists a cement paste to resist the influence of mirabilite, gypsum, sodium, potassium, magnesium and other halite in an evaporite bed; the technology is reliable; the field construction is simple and convenient; the well cementation effect is good; the requirements on well cementation in the evaporite bed, a high-pressure deep well evaporite bed and a super-thick evaporite bed and other complex conditions can be met; the supersaturated potassium chloride cement paste has favorable application prospect particularly for the exploration and development of a potassium bittern water well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

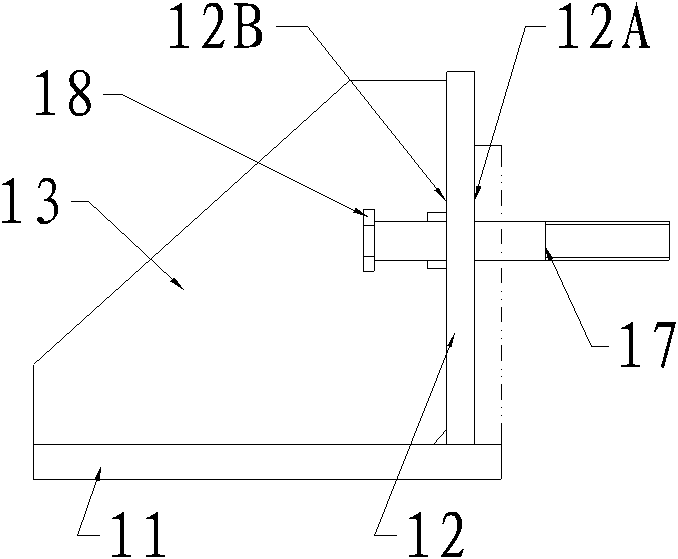

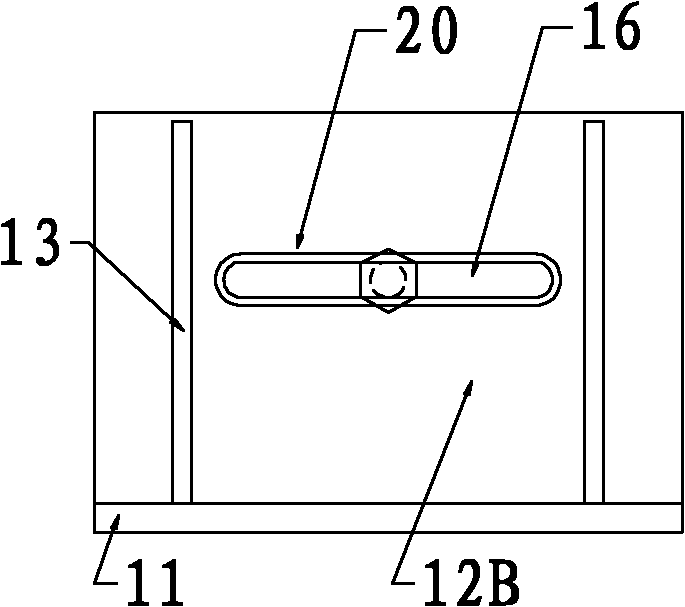

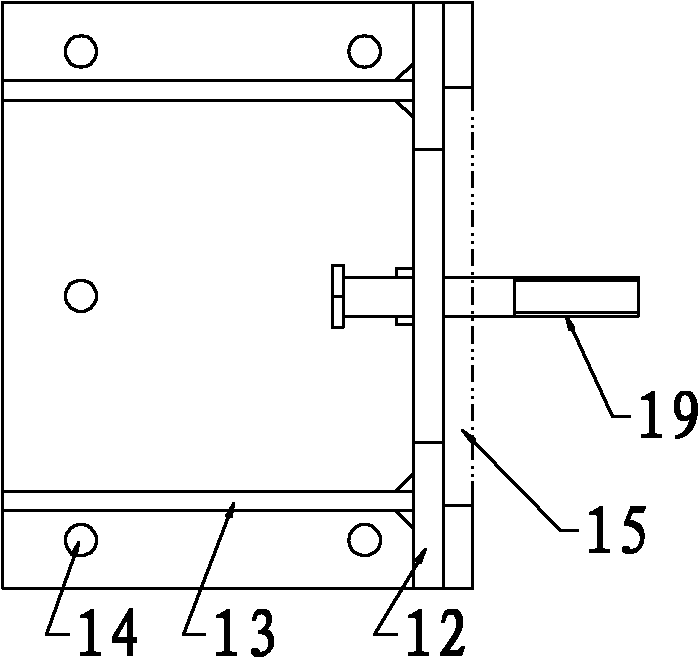

Exterior wall fireproof composite board with built-in keel

PendingCN107401258AEnhanced wind load resistancePrevent collapseCovering/liningsFlooringInsulation layerChinese characters

The invention relates to an exterior wall fireproof composite board with a built-in keel. The exterior wall fireproof composite board successively comprises a backboard layer, a heat-insulation layer and a surface decoration layer outwardly from an exterior wall, the keel is embedded in the heat-insulation layer, and the backboard layer, the heat-insulation layer and the surface decoration layer are bonded with each other to form the composite board. The exterior wall fireproof composite board also comprises wall anchoring members for fixing and connecting the composite board to the wall. The keel is an aluminum alloy keel of a structure shaped like a Chinese character 'jing', 'tian', 'wang', or 'shi'. The exterior wall fireproof composite board has the advantages that through building the aluminum alloy keel in the heat-insulation layer, wind load anti-compression performance of the whole composite board is largely enhanced, and collapse and deformation of the whole composite board are effectively prevented; and service lifetime of exterior wall heat-insulation materials is effectively prolonged, and heat-insulation lifetime of the exterior wall can be prolonged to be over 10-15 years.

Owner:江贤梁 +1

Steel anti-vibration block

InactiveCN102277838AEasy constructionBeautiful structureBridge erection/assemblyBridge strengtheningPre embeddingEngineering

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

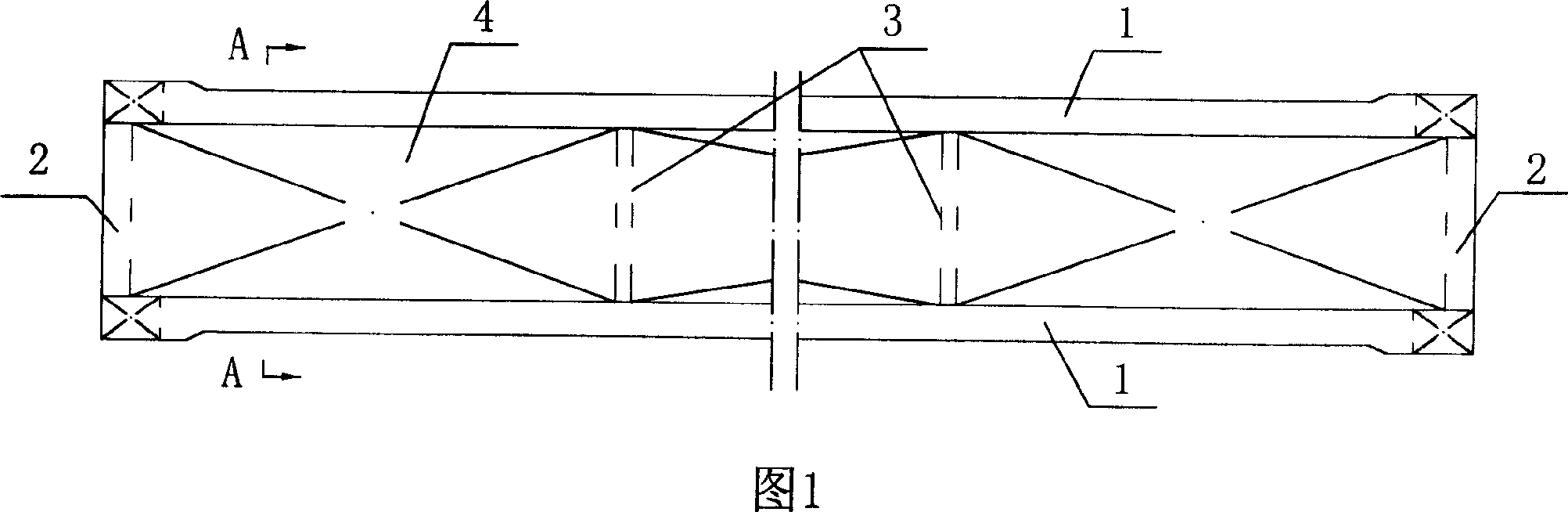

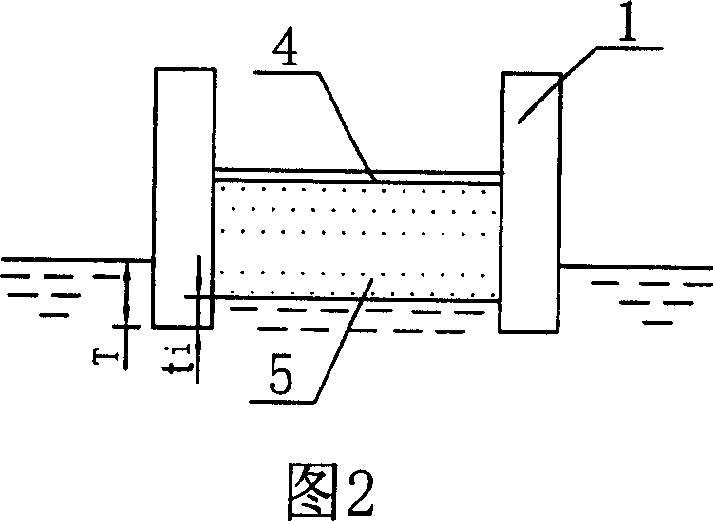

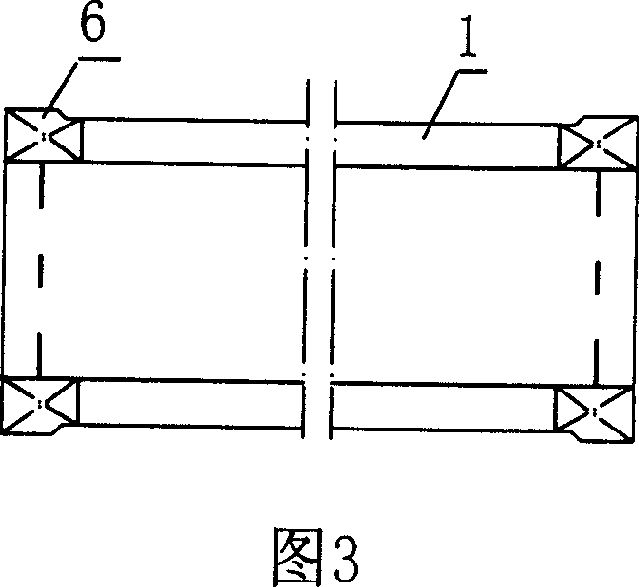

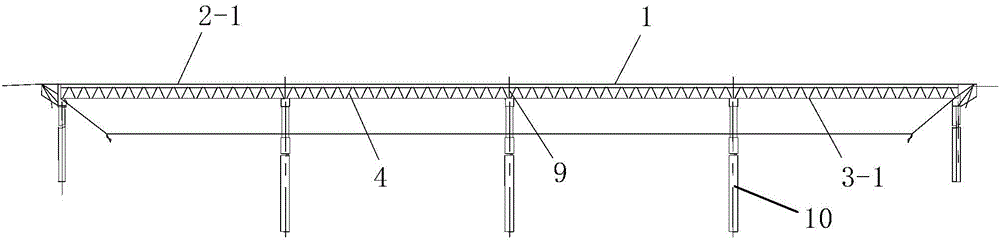

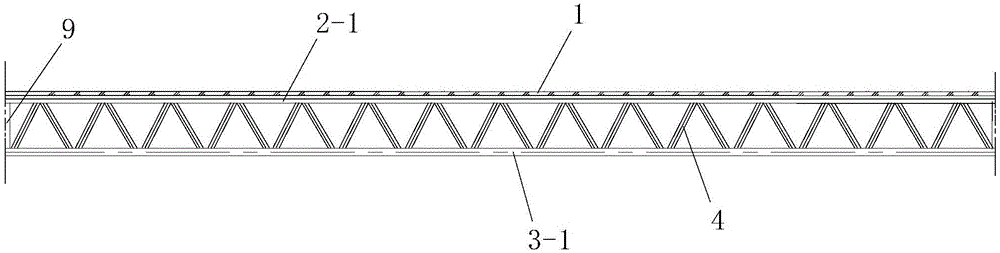

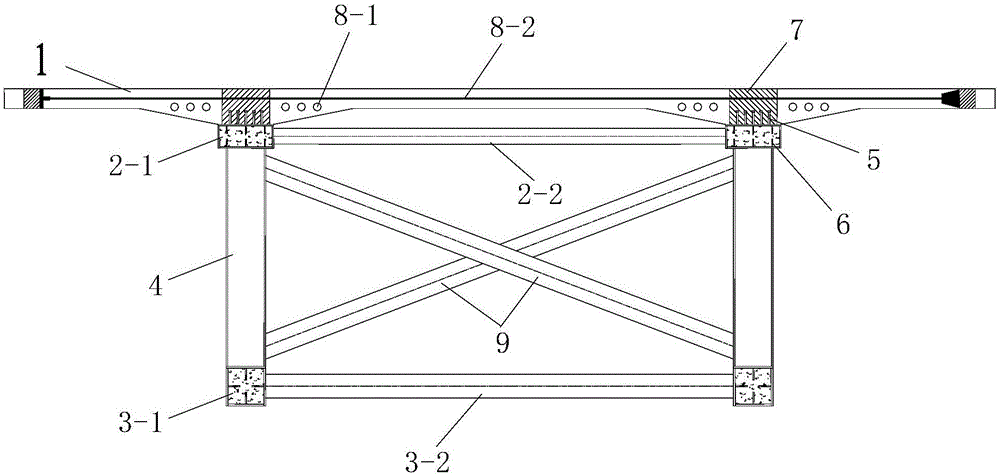

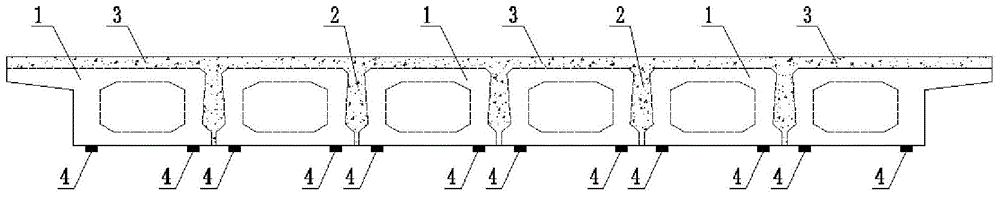

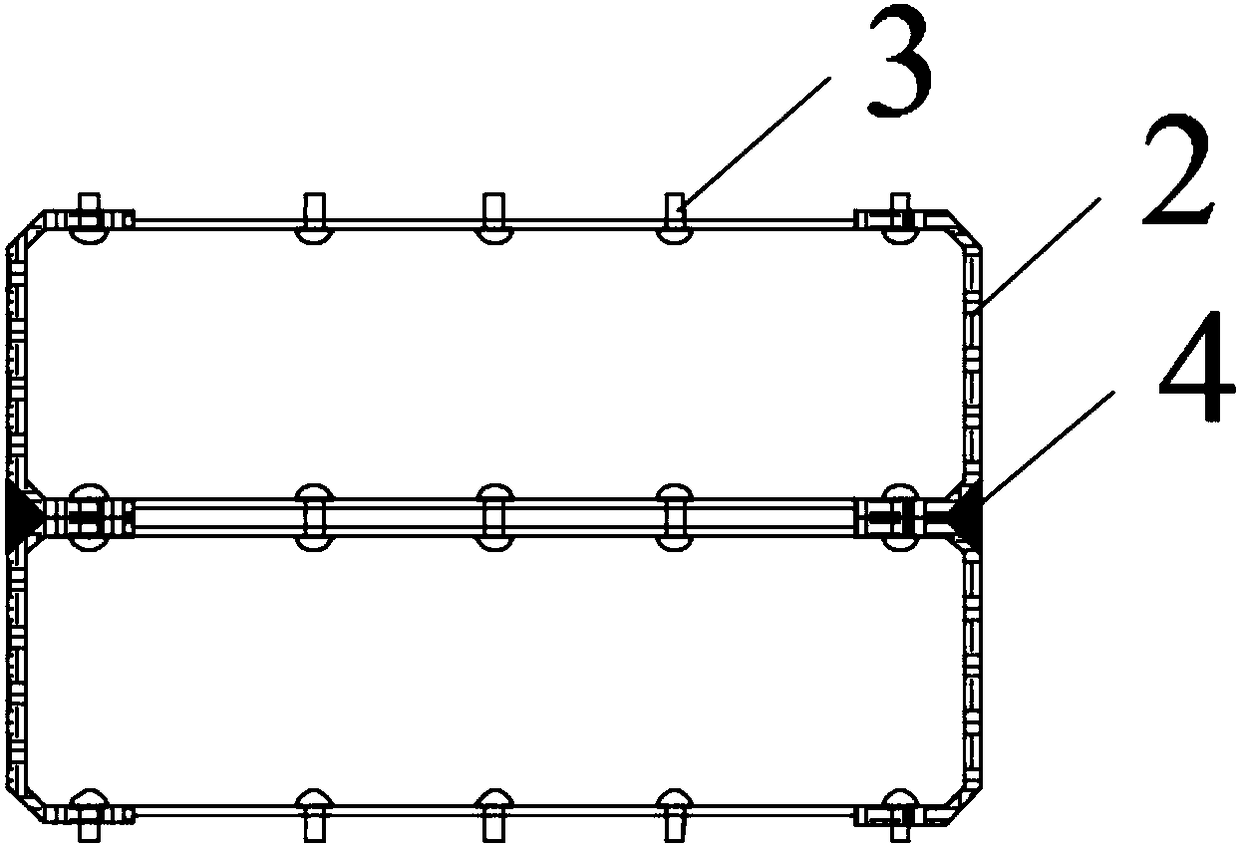

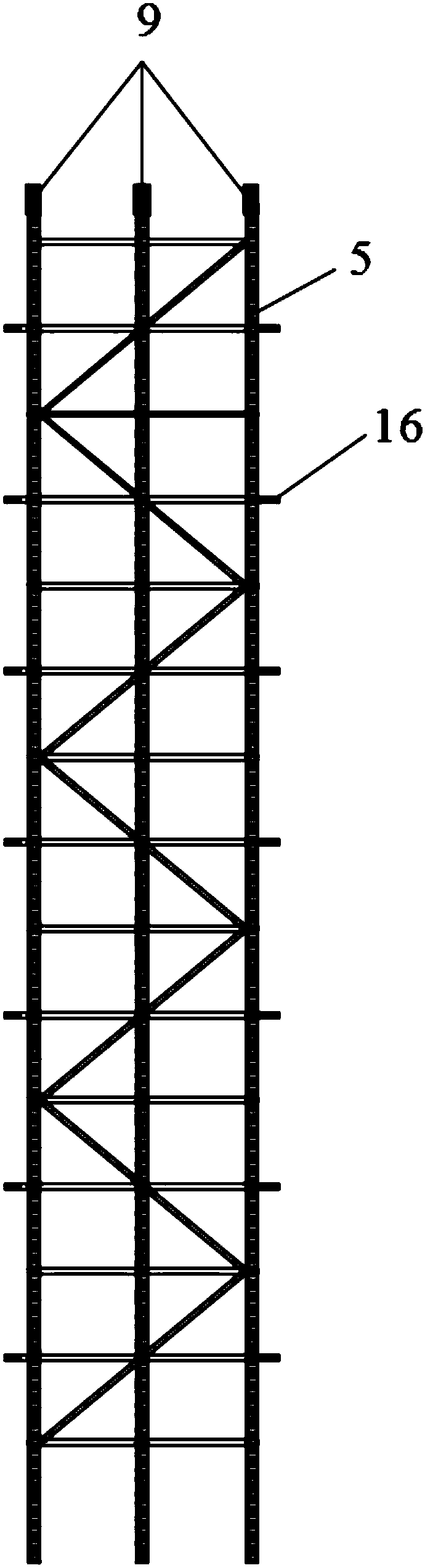

Assembly type rectangular concrete-filled steel tube composite truss girder bridge and construction method thereof

ActiveCN106223183ASimple structureEasy on-site constructionTruss-type bridgeBridge structural detailsSteel tubeGirder bridge

The invention discloses an assembly type rectangular concrete-filled steel tube composite truss girder bridge and a construction method thereof. The truss girder bridge comprises girder lower supporting structures, an assembly type girder and a prefabricated bridge panel which is connected with the assembly type girder through a shear key. The assembly girder is a rectangular concrete-filled steel tube composite truss and is formed by splicing a plurality of longitudinal trusses. Each longitudinal truss is composed of an upper chord member, a lower chord member and a web member. A horizontal bridge direction supporting structure composed of two inclined struts arranged in a crossed mode is arranged over each girder lower supporting structure, and the rectangular concrete-filled steel tube composite truss is formed by assembling a plurality of truss sections. The construction method comprises the first step of construction of the girder lower supporting structures, the second step of erecting of the assembly type girder, and the third step of mounting of the prefabricated bridge panel. The assembly type rectangular concrete-filled steel tube composite truss girder bridge is reasonable in design, easy and convenient to construct, good in using effect, capable of fully performing the advantage of the combination of steel and concrete materials, good in stress performance, high in construction speed, low in construction cost, capable of achieving the standard and batch production of the girder and the bridge panel.

Owner:CHANGAN UNIV

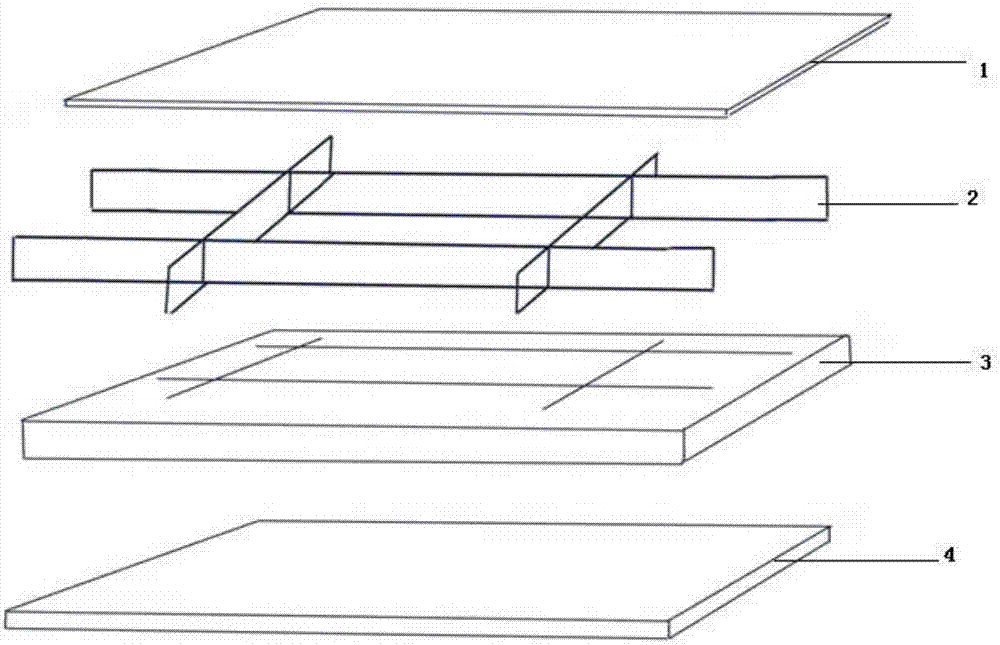

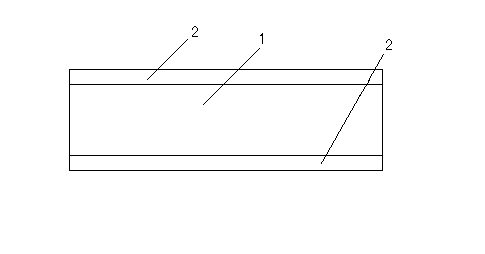

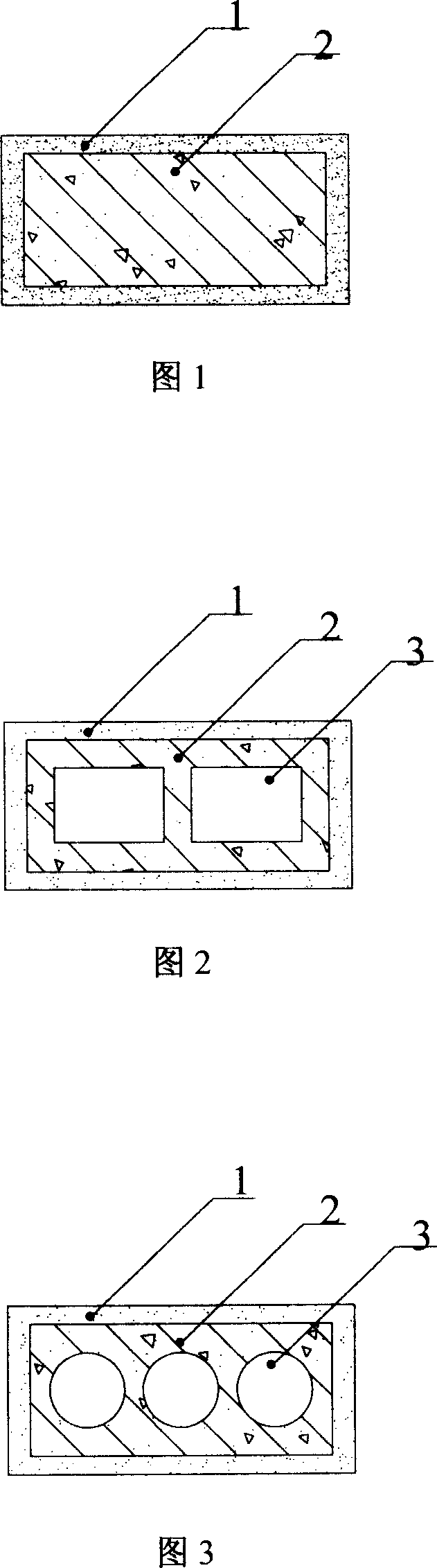

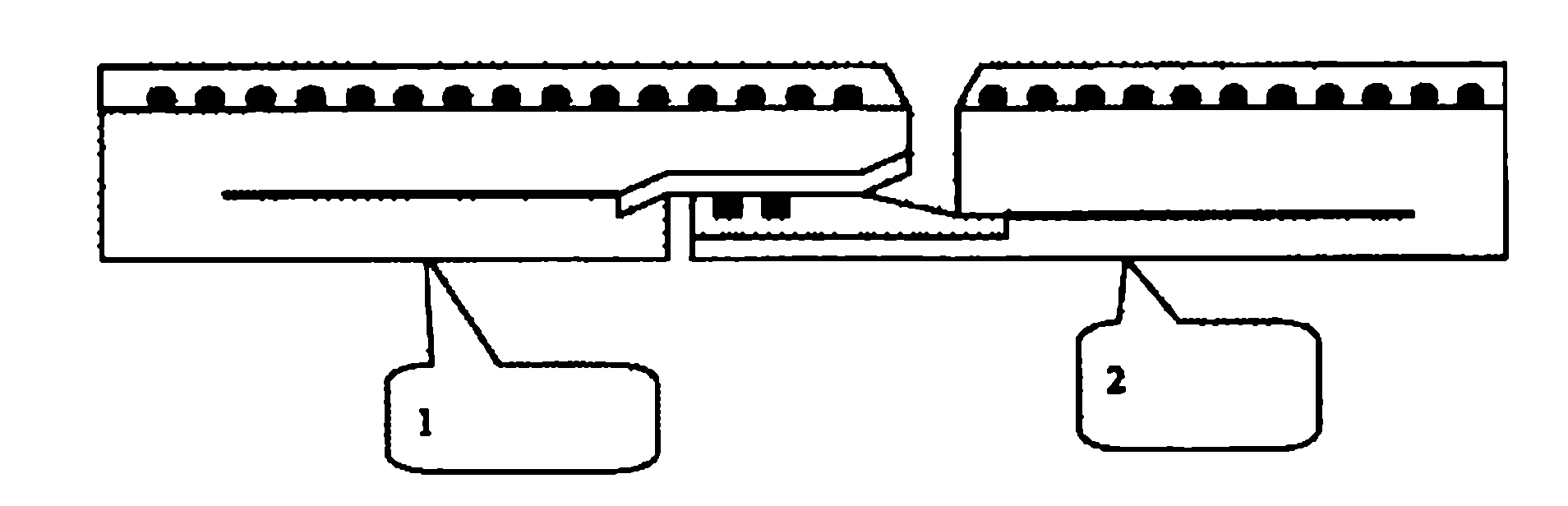

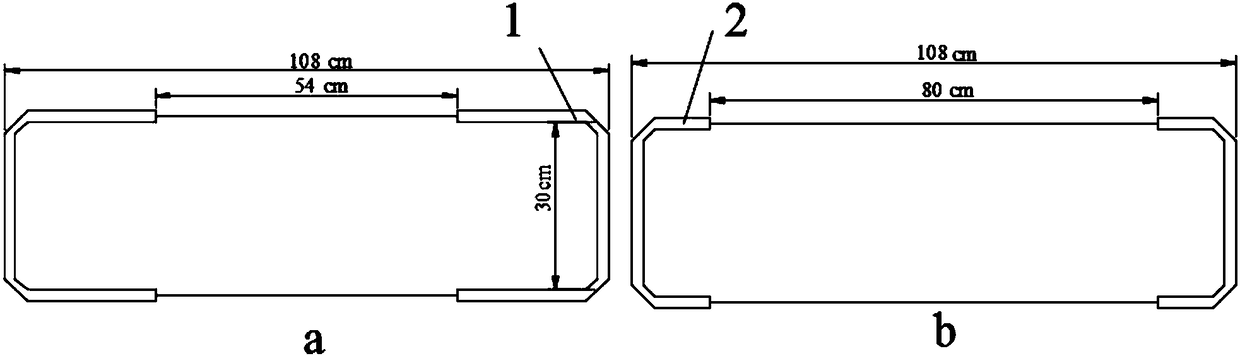

Microvesicle glass fireproofing insulation board and production method thereof

InactiveCN103104047AImprove surface strengthImprove water resistanceLaminationLamination apparatusFiberFireproofing

The invention discloses a microvesicle glass fireproofing insulation board and a production method thereof. The microvesicle glass fireproofing insulation board is characterized by comprising a mixed layer (1). The mixed layer (1) is formed by glass foam materials and binding materials in a mixing mode, or is formed by the glass foam materials, short fiber and the binding materials. Surface protective layers (2) are arranged on the upper surface and the lower surface of the mixed layer (1). The production method of the microvesicle glass fireproofing insulation board comprises the following steps: adding the glass foam materials and short fiber to a mixed device to be mixed with the binding materials; coating and laying the mixed materials on the surface protective layers; adding a surface protective layer on the surface of the mixed materials, carrying out lamination after entering a lamination machine, drying, solidifying, and then carrying out cutting and packing after molding. According to the microvesicle glass fireproofing insulation board and the production method thereof, technical formula design is reasonable, a small amount of binding materials and reasonable binding conditions are selected to be used on the premise that binding strength is ensured, the fact that existing thermal resistance of the glass foam materials is not reduced is ensured, and the made insulation board is noncombustible materials with grade A and can be used for a building energy conservation exterior wall external insulation project.

Owner:YANTAI FUHAO BUILDING MATERIALS CO LTD

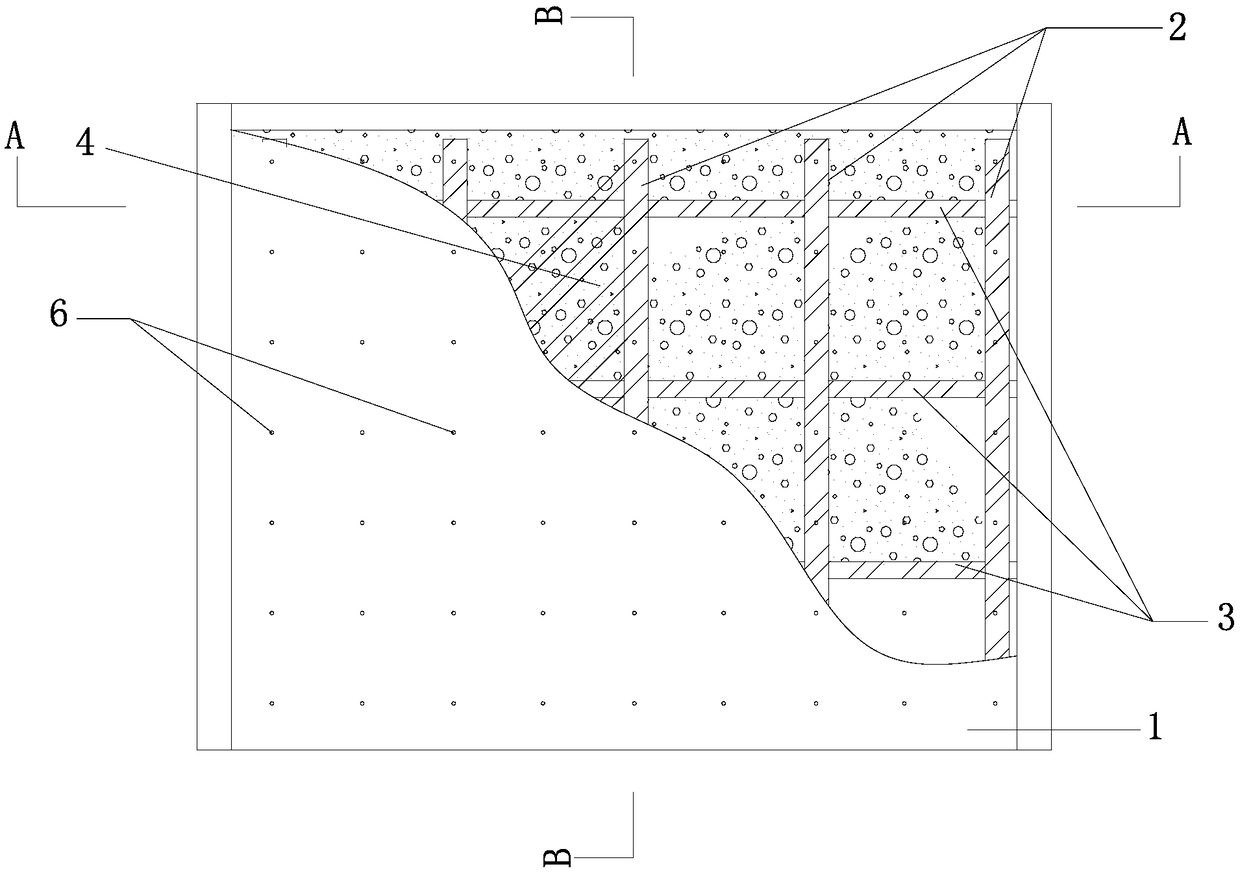

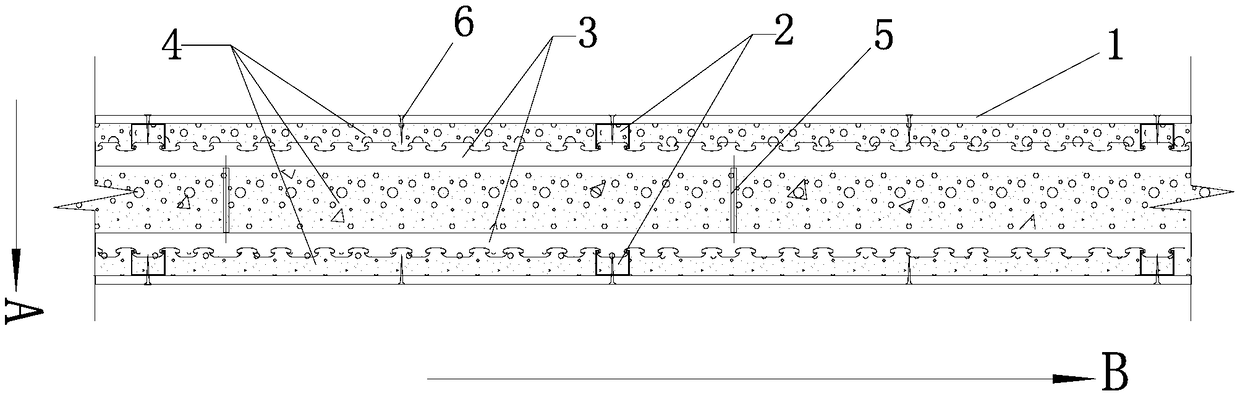

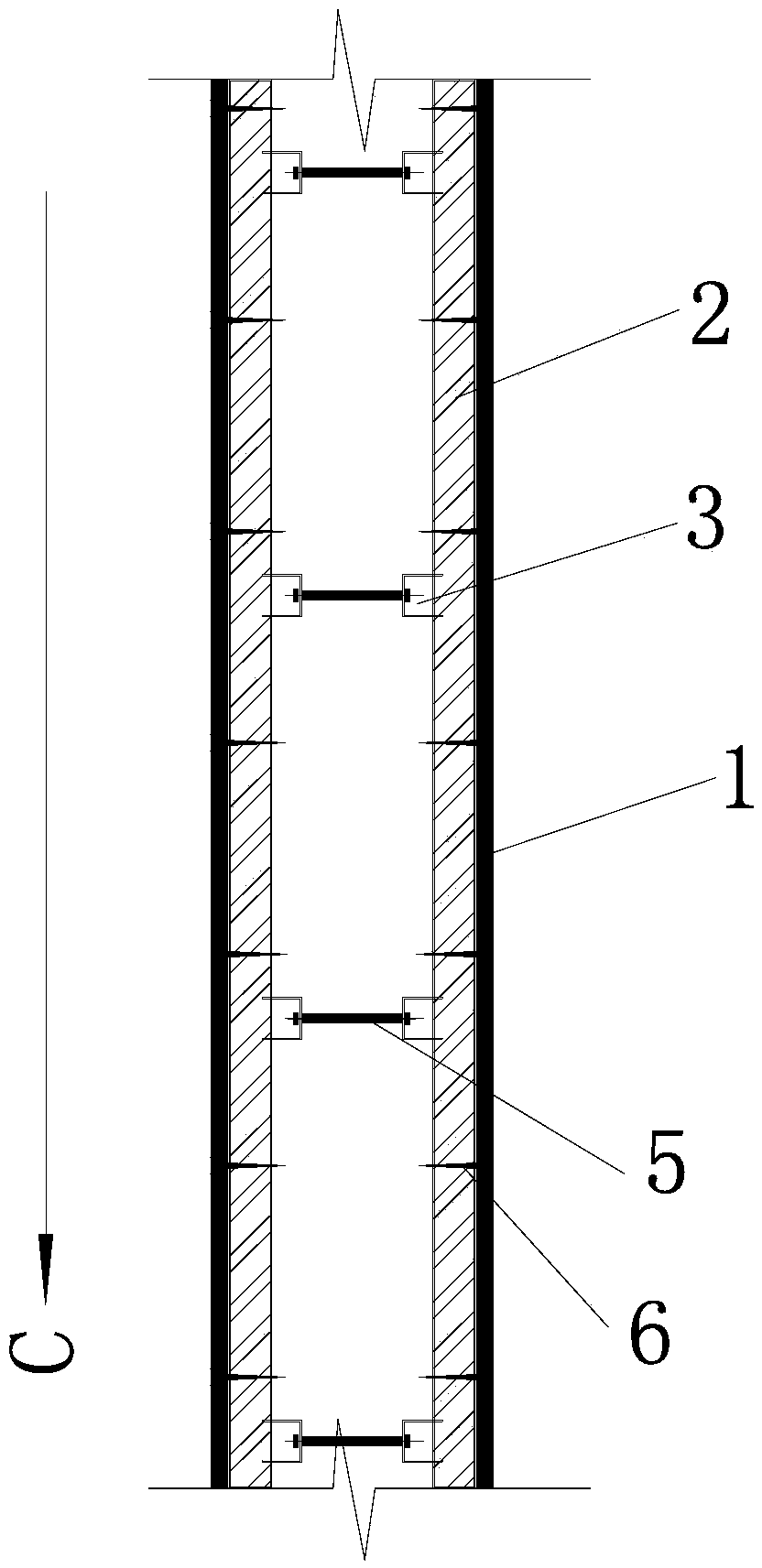

Foamed concrete thermal insulation composite wall

The invention discloses a foamed concrete thermal insulation composite wall. The foamed concrete thermal insulation composite wall comprises two wall skeletons arranged in the direction of the thickness of the wall at intervals, wherein the two wall skeletons are both fixed to a building main structure. The wall skeletons comprise panels and keel assemblies, a pouring space is formed between the inner surfaces of the two panels and the outer surface of the building main structure, and the keel assemblies are arranged in the pouring space. The keel assemblies include a plurality of vertical keels and a plurality of transverse keels, the vertical keels are fixedly erected on the building main structure, the vertical keels are sequentially arranged at intervals in the length direction of thewall, and the panels are fixed to the corresponding vertical keels. The transverse keels are vertically connected with the corresponding vertical keels and arranged parallel to the corresponding panels, and the transverse keels are sequentially arranged at intervals in the height direction of the wall. Foamed concrete is poured into the pouring space so that the foamed concrete, the two panels andthe keel assemblies form the integrated foamed concrete thermal insulation composite wall. The composite wall has the advantages of good thermal insulation performance, high degree of industrialization, high universality, easy assembly and the like.

Owner:湖南睿盾新材料科技有限公司

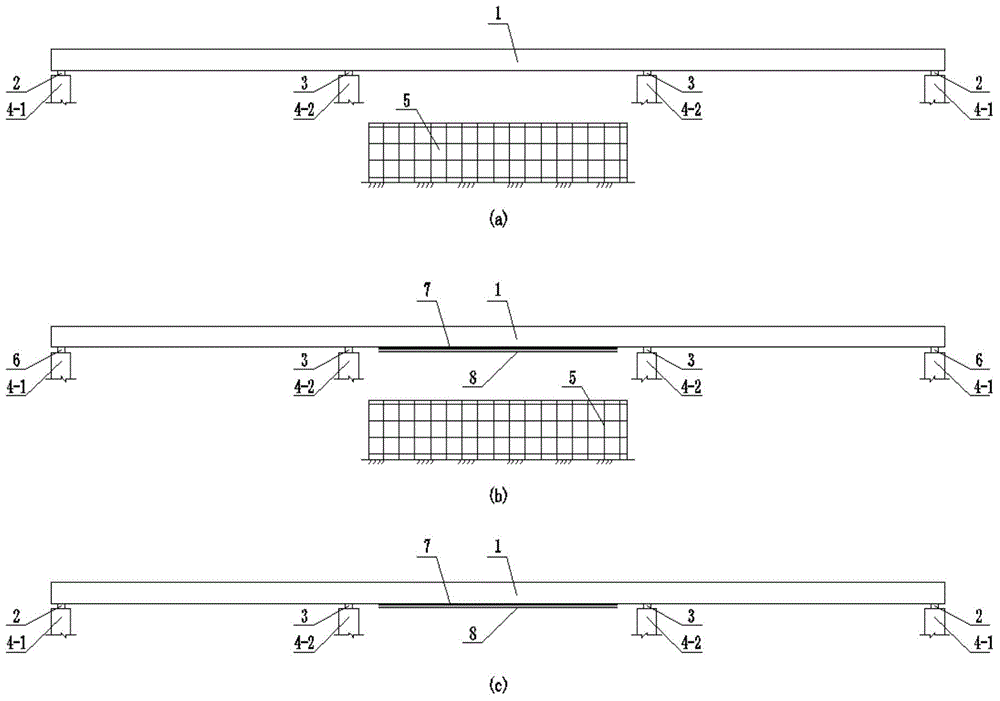

Method for reinforcing midspan of ordinary three-span steel continuous beam bridge

ActiveCN104652296AImprove the bending capacitySolve the problem of relative lag of stress and strainBridge erection/assemblyBridge strengtheningContinuous beamEngineering

The invention discloses a method for reinforcing a midspan of an ordinary three-span steel continuous beam bridge. The method comprises the following steps: building a construction operation platform; treating the surface of a midspan bottom plate; jacking up two side spans by virtue of a jack and then dismantling a side span support seat; lowering the jack to be lower than the side span support seat; calculating to obtain the lowered value of the jack relative to the side span support seat; unloading dead load bending moment of the midspan, and then pasting and fixing with a steel plate; jacking up the edge spans by virtue of the jack, and reinstalling the dismantled side span support seat at the original position; and lowering the jack, relocating the edge spans on the side span support seat, and then shifting out the jack. According to the method, by unloading the dead load bending moment of the midspan and then pasting and fixing with the steel plate, the steel plate can participate into the activities of bearing the load of a car and then adding dead load, can also participate into the activity of bearing the dismantled dead load bending moment; the bending bearing capacity of the main girder can be effectively improved; meanwhile, the material properties of reinforcing steel plate can be put into a relatively full play; and the bridge safety is not affected by lowering the jack in the construction process.

Owner:广州展亚土木工程技术有限公司

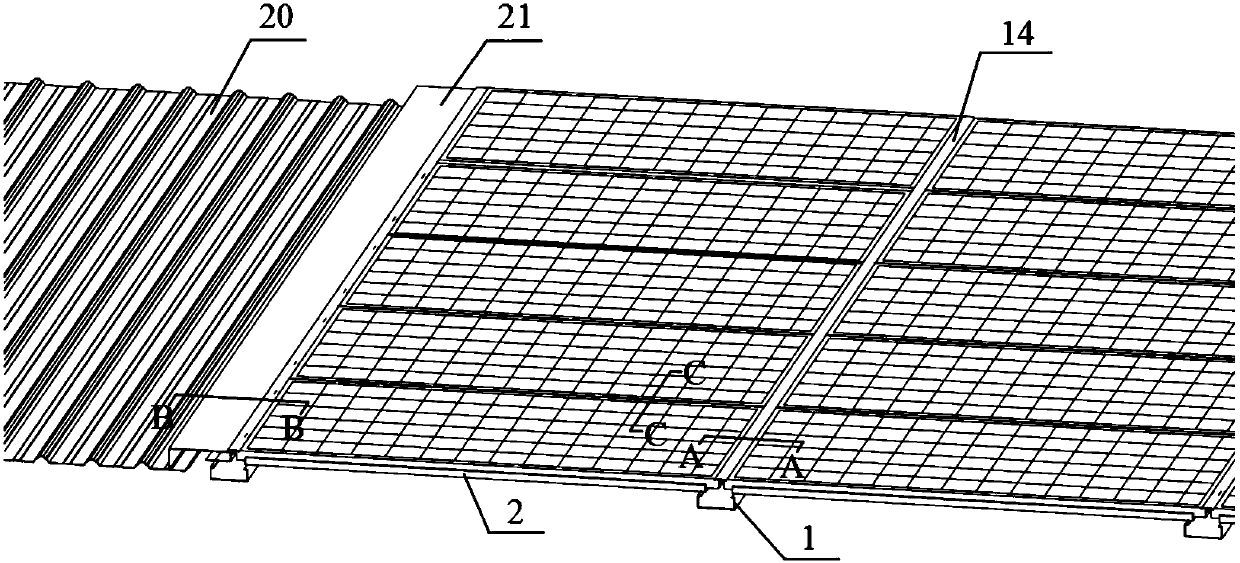

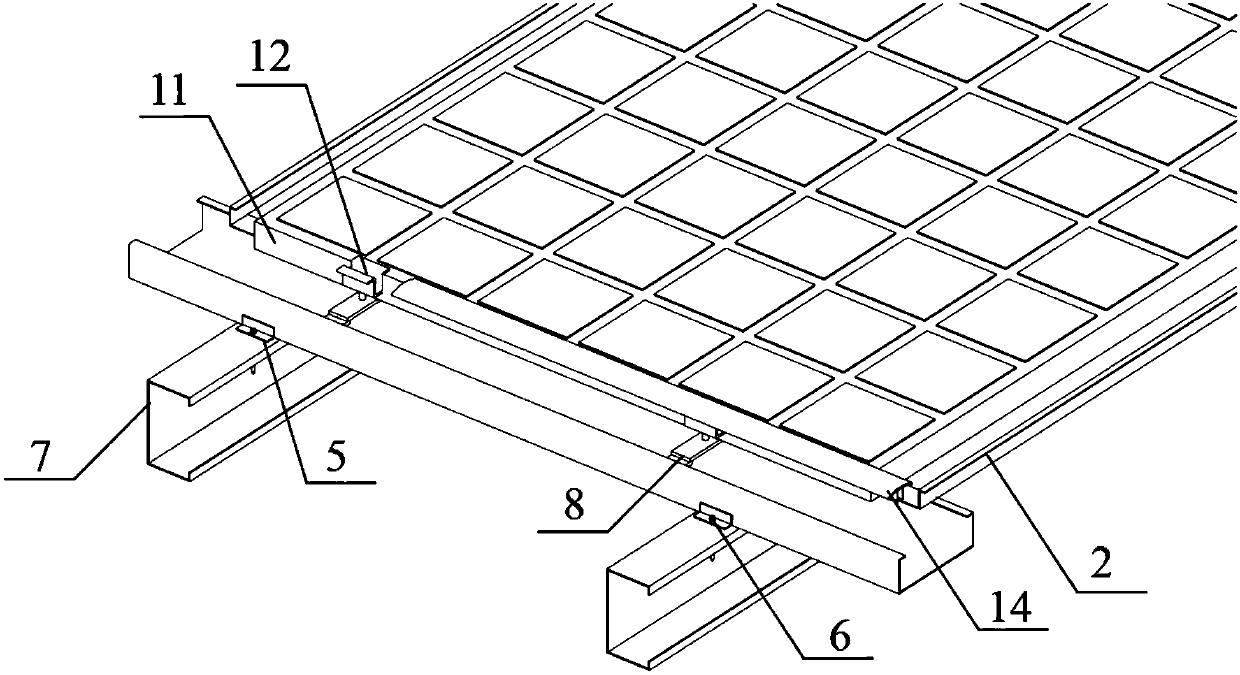

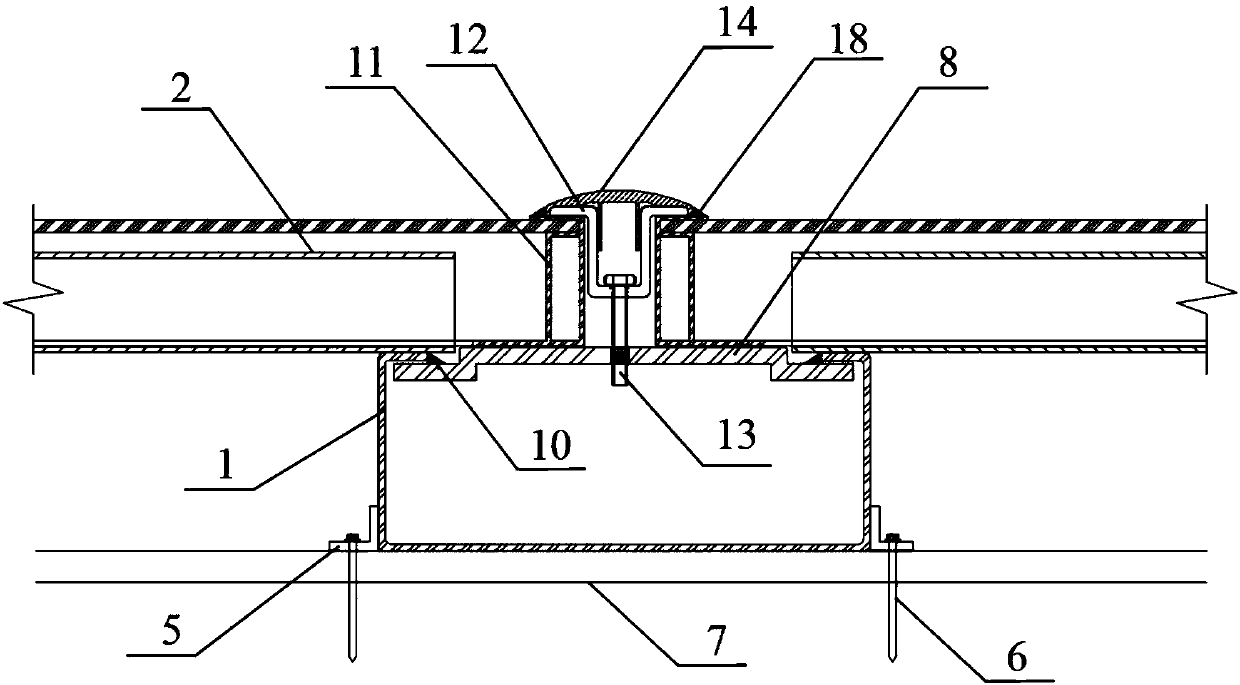

Integrated-type steel structure roof photovoltaic system

PendingCN107938955AIncrease displacementEasy on-site constructionPhotovoltaic supportsRoof covering using slabs/sheetsWater dischargeInverted-T shape

The invention relates to an integrated-type steel structure roof photovoltaic system. The integrated-type steel structure roof photovoltaic system comprises main beams, secondary beams, pieces of angle steel, purlines, supporting blocks, electric weld pieces, assembly frames, pressing blocks, pressing strips, sealants, waterproof adhesive tapes, color steel tiles, lateral cover plates and photovoltaic plates. The secondary beams are vertically erected on the two sides of the main beams correspondingly, the main beams are each in a U shape, and the two sides of the main beams are provided withmain beam shoulders, wherein the directions of the main beam shoulders are inward. Semicircular notches are pressed in the main beam shoulders, and the pieces of angle steel are welded to the outer sides of the bottoms of the main beams correspondingly and connected with the purlines through first screws. The integrated-type steel structure roof photovoltaic system has the beneficial effects thatthe main beams with the U-shaped sections, the inverted-T-shaped supporting blocks and certain compression components are adopted to constitute the integral mounting system, on-site construction is easy and convenient, materials are saved, and the roof water discharge is also greatly increased; and compared with a traditional building photovoltaic integrated system, the main beams are fixed to thepurlines through the pieces of angle steel on the outer side, inner cavities of the main beams do not need to be punched through, and water in the main beams is prevented from entering a building.

Owner:ZHEJIANG JINGGONG ENERGY TECH GRP CO LTD

Gas-added self heat-insulation composite weight-bearing build brick of concrete

InactiveCN1978837AWith self-insulation functionReduced self-holding functionConstruction materialClimate change adaptationLand resourcesCompressive strength

The invention discloses concrete air entraining self heat preservation compound bearing building block compounded by concrete and air entraining concrete. It includes concrete core block and external insulating layer. The former is set in the building block as bearing material. The air entraining concrete is set at the periphery of the core block as the external insulating layer. The two inorganic materials are made into the building block with of the functions of self heat preservation and bearing which can replace the common clay brick and has the advantages of saving limit land resource, greatly improving wall body useful life, simple processing, convenient construction, compressive strength that over 10MPa.

Owner:TONGJI UNIV

Insulation puncture cable connecting device

InactiveCN104377526AEasy on-site constructionImprove installation efficiencyLine/current collector detailsContact members penetrating/cutting insulation/cable strandsEngineeringMechanical engineering

The invention discloses an insulation puncture cable connecting device which comprises a pressure application portion, a cable containing portion, at least one penetrating portion and at least one anvil portion. The cable containing portion is used for containing a cable to be connected. The pressure application portion is used for providing push force for the cable. The anvil portions are arranged in the cable containing portion and used for clamping the cable together with the pressure application portion in the direction of the push force. The penetrating portions are arranged on the anvil portions and / or the pressure application portion and used for penetrating through an insulation layer of the cable. Containing ducts are formed, torque bolt are pushed to penetrate through the insulation layer of the cable in an extruded mode, site construction is easier and more convenient, and mounting efficiency is improved.

Owner:JIANGSU JIAMENG ELECTRICAL EQUIP

Preparation method of timed-released bird repellents special for electric power and high-speed rails

ActiveCN103858878AVolatile release speed is adjustableOptimal Control StructureBiocidePest repellentsCross-linkElectric power system

The invention discloses a preparation method of timed-released bird repellents special for electric power and high-speed rails. The preparation method comprises the following steps: firstly, dissolving musk-T, cinnamamide, 1-naphthol, bisphenol A, a preservative and an antifreeze agent into N-alkyl substituted acrylamide at certain weight parts, mixing and stirring to obtain uniform dispersion liquid; and secondly, adding a cross-linking agent and an initiator into the dispersion liquid in the step I, standing for polymerization cross-linking reaction for 0.5-24h at 0-60 DEG C. The low-toxicity bird repellent composition is in-situ embedded and uniformly implanted into a gel system in a polymerization cross-linking reaction process of the N-alkyl substituted acrylamide, and the preparation method solves the technical problems that the existing universal bird repellents have high cost, low efficiency and poor weather resistance.

Owner:STATE GRID CORP OF CHINA +2

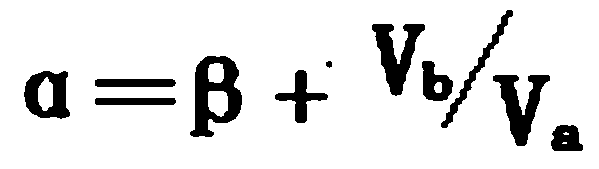

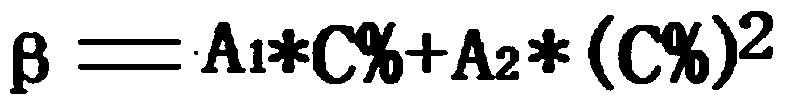

Method for enhancing network volume fracturing effects of complex hydrocarbon reservoirs

ActiveCN109653723AIncrease the volume of the transformationIncrease extension pressureFluid removalWorking fluidGeomorphology

The invention relates to the technical field of oil field fracturing and acidizing, particularly to a method for enhancing network volume fracturing effects of complex hydrocarbon reservoirs. The method comprises the following steps of, firstly, flat network modification, secondly, tackifying branch fracture formation, thirdly, artificial fracture formation, fourthly, three-dimensional network modification, fifthly, artificial fracture sand filling, and lastly, displacement liquid filling, well shutting, well opening for drainage, and reservoir yield measurement. The method for enhancing the network volume fracturing effects of the complex hydrocarbon reservoirs can maximize network volume fracturing modification around perforation points and to the maximum degree improve the durability ofmodification volume and flow conductivity of fractures and prolong the post-fracturing stable production period, save working fluid by 10-30%. Meanwhile, the method for enhancing the network volume fracturing effects of the complex hydrocarbon reservoirs increases common planar small-thickness irregular ellipsoidal network volume fracturing effects to high-three-dimensional-degree network volumefracturing effects, is simple and practical in field construction, reduces consumption of slick water and is applicable to ready-to-use integrated construction.

Owner:克拉玛依科美利化工有限责任公司

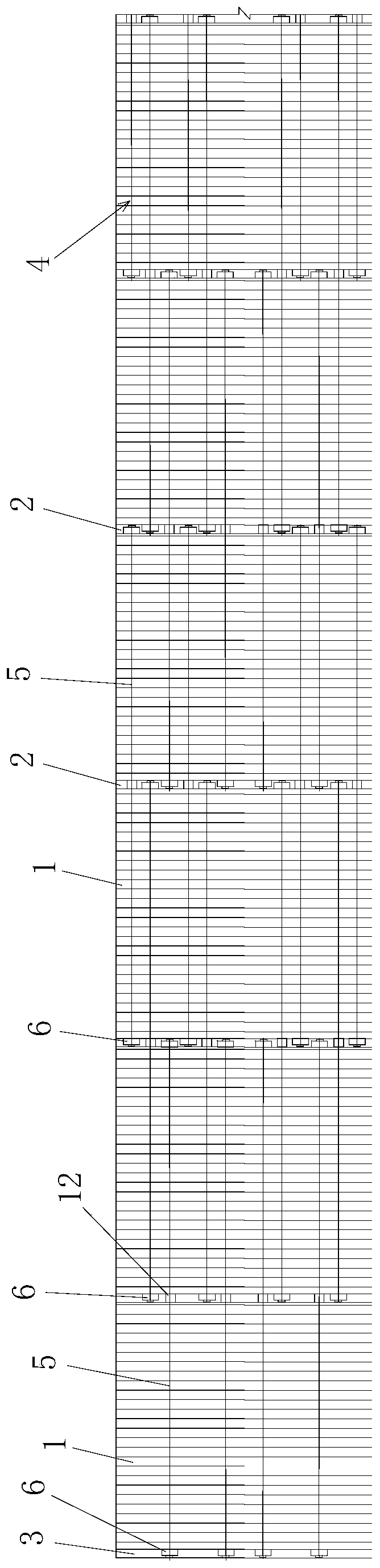

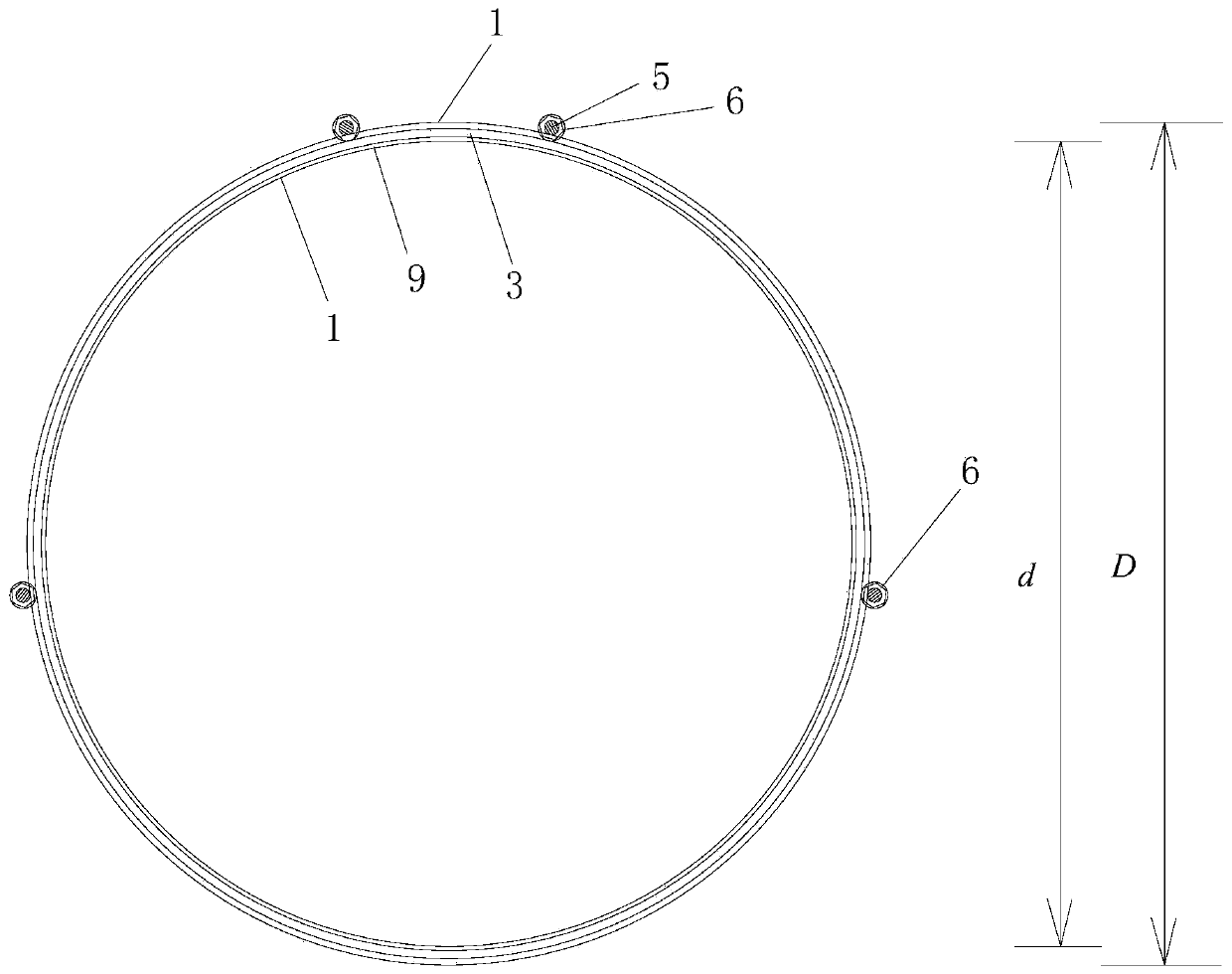

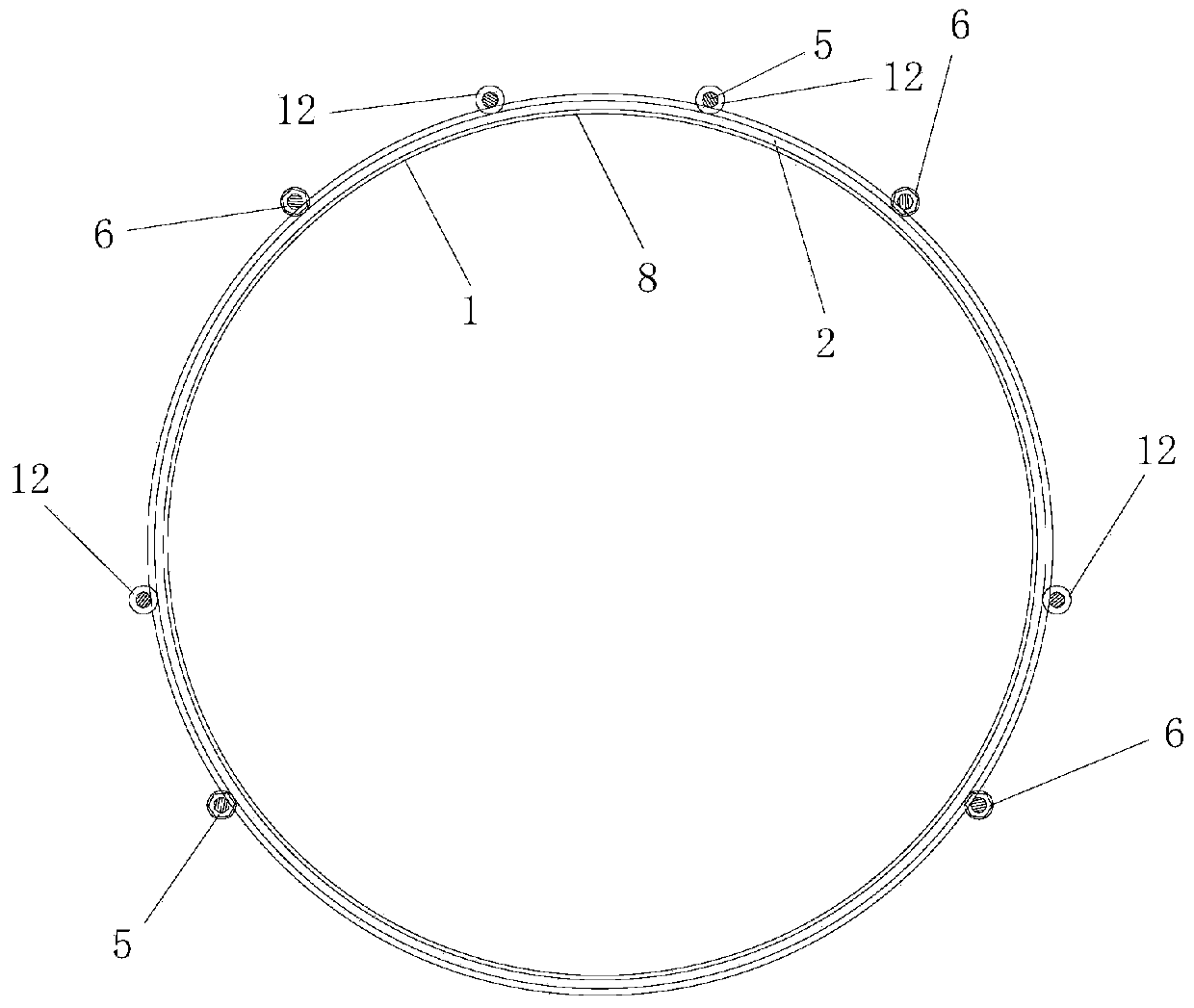

Construction method of corrugated steel pipe culvert

ActiveCN110685234AReasonable structural designEasy to processGround-workPre stressArchitectural engineering

The invention discloses a construction method of a corrugated steel pipe culvert. The method is used for respectively carrying out splicing construction on a plurality of pipe culvert splicing segments from rear to front and comprises the following steps of A1, carrying out splicing construction on a rear-end splicing segment; A2, carrying out splicing construction on a next splicing segment; A3,repeating the step A2 repeatedly until splicing construction processes of all pipe culvert splicing segments on the rear side of a front-end connection segment are completed; and A4, carrying out splicing construction on the front-end connection segment. The construction method of the corrugated steel pipe culvert is reasonable in design, simple and convenient to construct and excellent in using effect; a pre-stressed reinforcing structure is used for carrying out segmental integral reinforcement on the spliced corrugated steel pipe culvert; structures and arrangement positions of all pre-stressed reinforcing steel bar sets in the pre-stressed reinforcing structure are limited; the pipe culvert splicing segments are synchronously subjected to pre-stressed reinforcement in stages in the splicing process; meanwhile, all the pipe culvert splicing segments in the pipe culvert body are integrally reinforced by the pre-stressed reinforcing structure; the integrality and the stress performance of the constructed and formed pipe gallery can be effectively improved; and the durability of the pipe gallery can also be effectively prolonged.

Owner:ZHENGPING ROAD & BRIDGE CONSTR CO LTD +4

Cable high-thermal-conductivity backfilling material

ActiveCN104261785AIncrease thermal resistanceReduce thermal resistanceSolid waste managementElectrical conductorAdhesive

The invention discloses a cable high-thermal-conductivity backfilling material which comprises slag stone, calcium oxide, polyvinyl acetate adhesive, water and sodium silicate. The cable high-thermal-conductivity backfilling material is proportionally prepared from the slag stone, calcium oxide, polyvinyl acetate adhesive, water and sodium silicate by a special technique. The cable high-thermal-conductivity backfilling material has the technical characteristics of favorable initial flowability, moderate alkalinity, low bleeding rate and the like before solidifying. After solidifying, the cable high-thermal-conductivity backfilling material has the advantages of high water content, high stability, smaller thermal resistance ratio than soil, favorable heat dissipation property and higher hardness, and can keep the periphery of the cable at lower thermal resistance for a long time, thereby enhancing the current capacity of the cable or lowering the working temperature of the cable conductor. Compared with the cable with the same specification in the prior art, the current capacity is increased by 15-28%, thereby greatly lowering the project investment cost. The cable using the backfilling material has the advantages of low thermal resistance, environment friendliness, no harm or toxicity and long service life, and can protect the filling medium.

Owner:广州骏拓电力科技有限公司

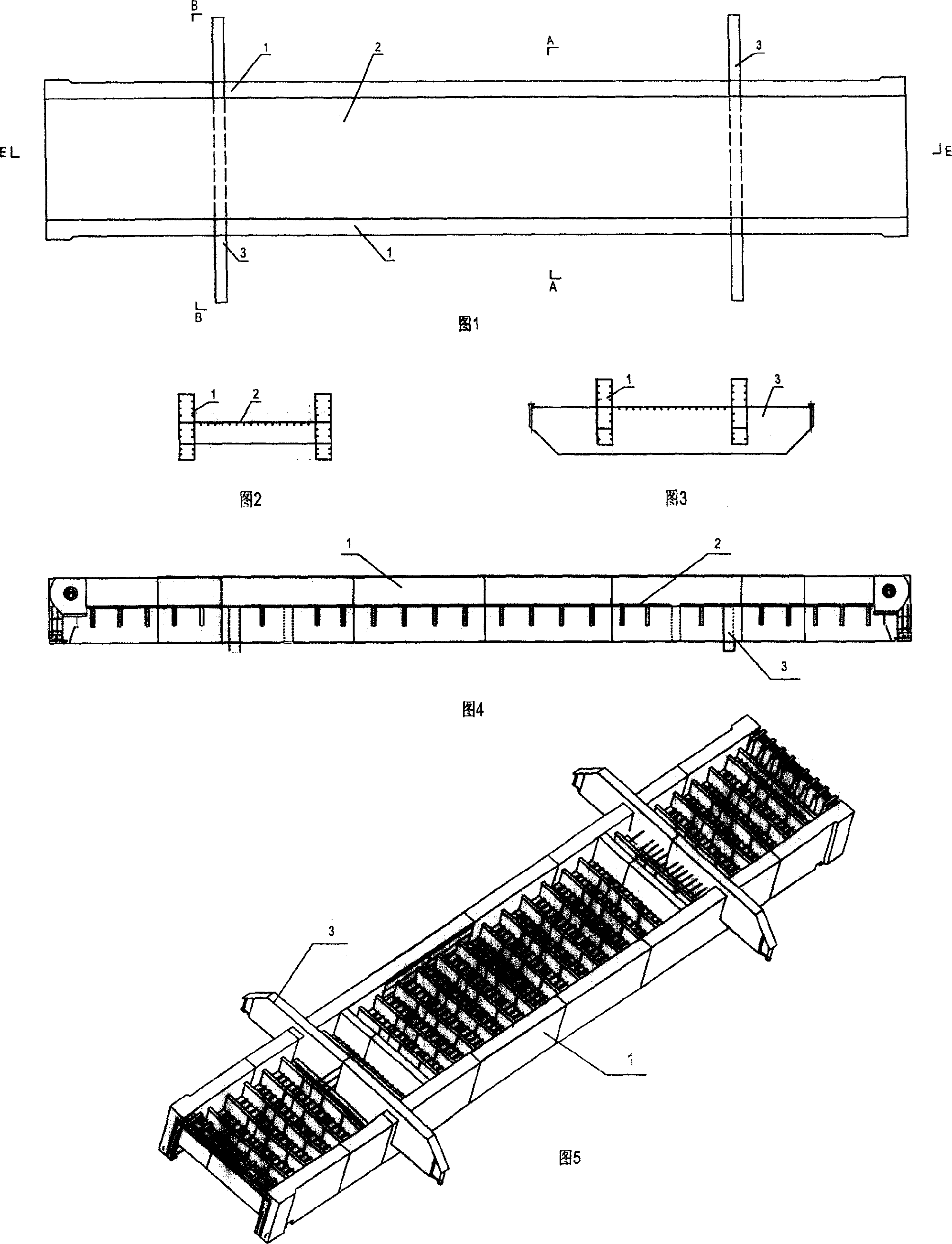

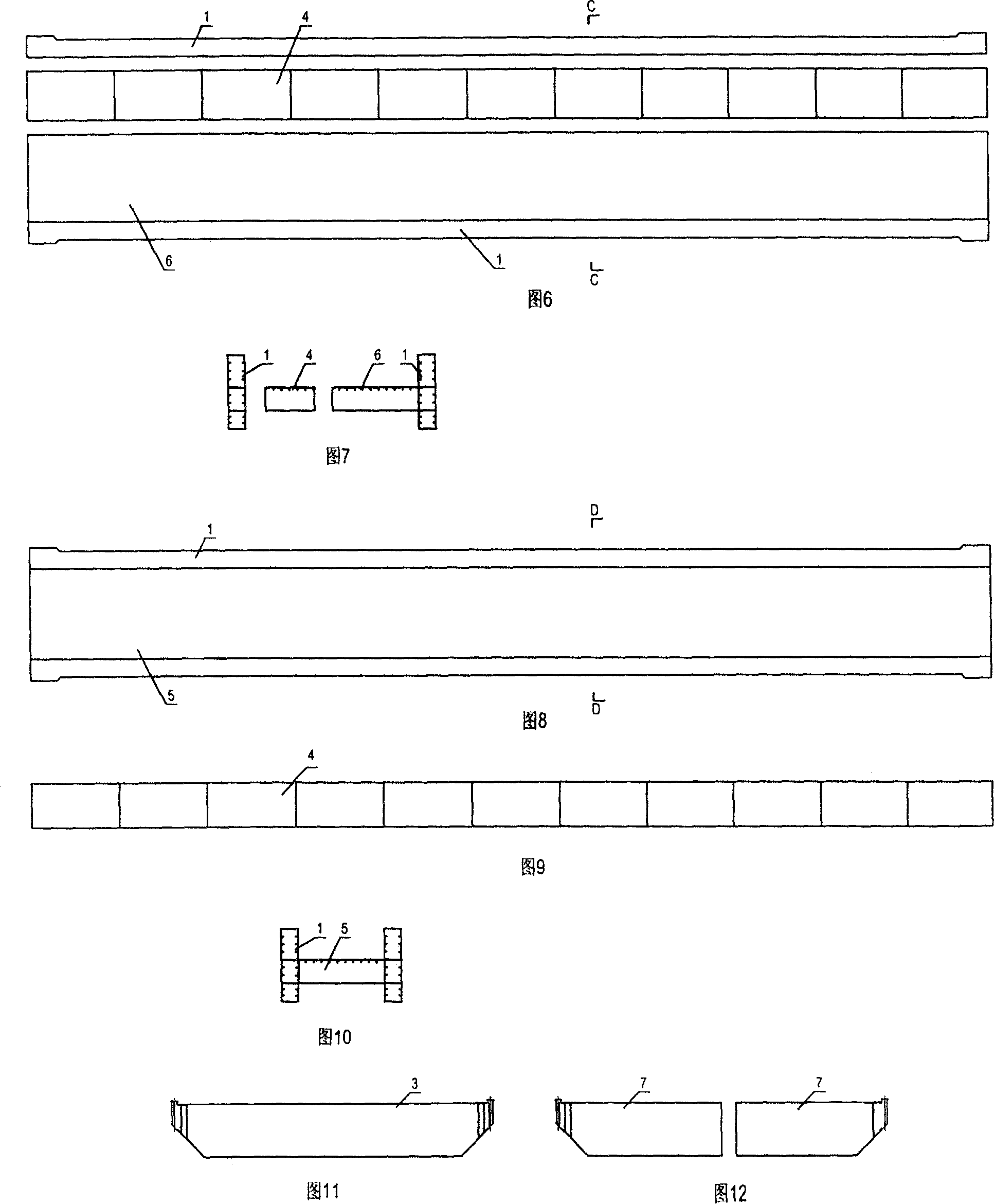

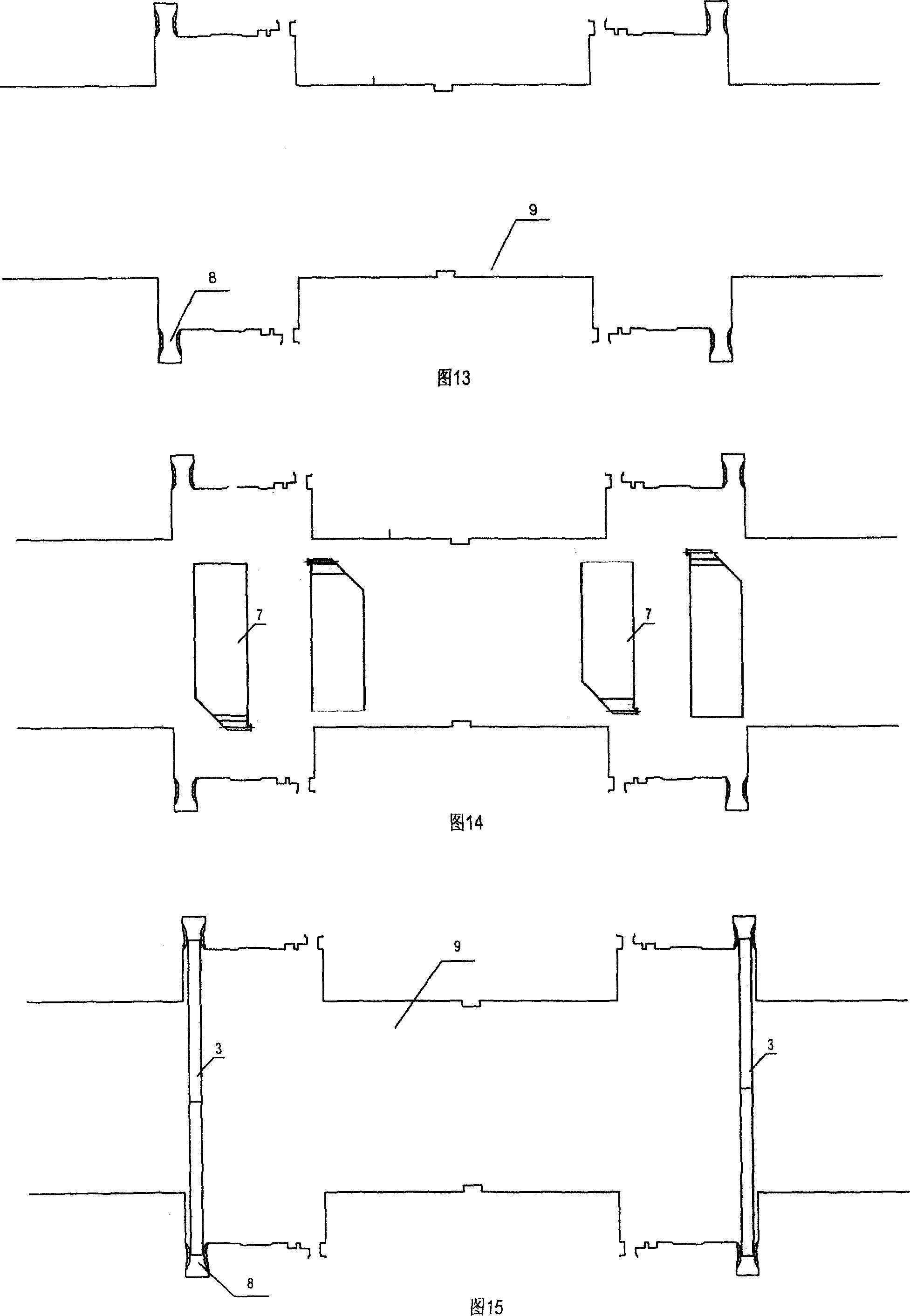

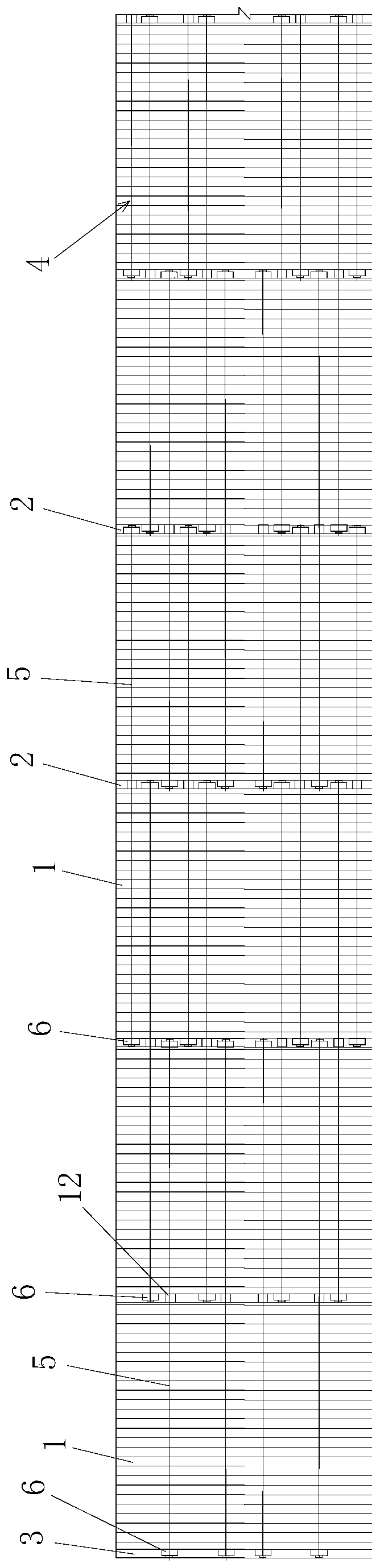

Reinforced concrete prefabricated drainage ditch and construction method

PendingCN110792148AImprove construction qualityImprove construction efficiencySewer pipelinesReinforced concreteArchitectural engineering

The invention provides a reinforced concrete prefabricated drainage ditch and a construction method, and belongs to the technical field of building construction. Temporary drainage of different drainage sections within the construction period in a construction site where terraces on the two sides of the drainage ditch have difference of heights is met. A plurality of prefabricated ditch body basicsections are used for being assembled on the construction site to form the prefabricated drainage ditch, the construction quality of the prefabricated drainage ditch can be effectively improved, integrity and stability of the prefabricated drainage ditch can be effectively improved, the overall construction efficiency of a basement with the drainage ditch can be effectively improved, on-site construction is simple and convenient, and the construction period can be effectively shortened. Each of the ditch body basic sections includes an ordinary plate member, a folded plate member, and a non-standard plate member, the non-standard plate member can adjust the elevation of the bottom of the ditch on both sides of the drainage ditch, and thus the application range is expanded.

Owner:SHANGHAI NO 7 CONSTR

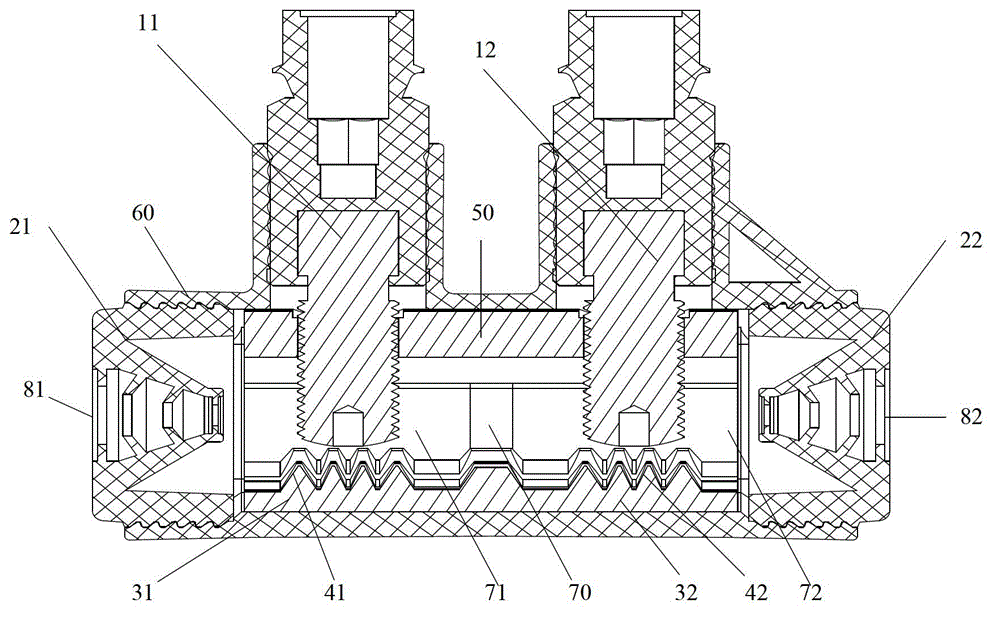

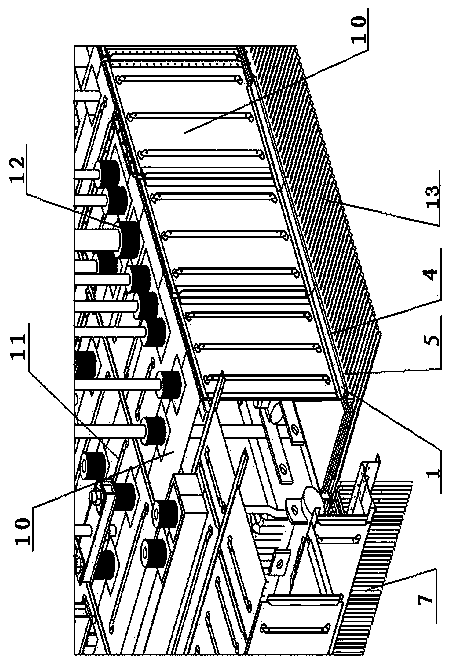

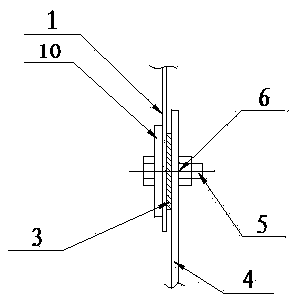

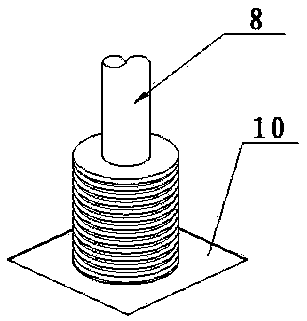

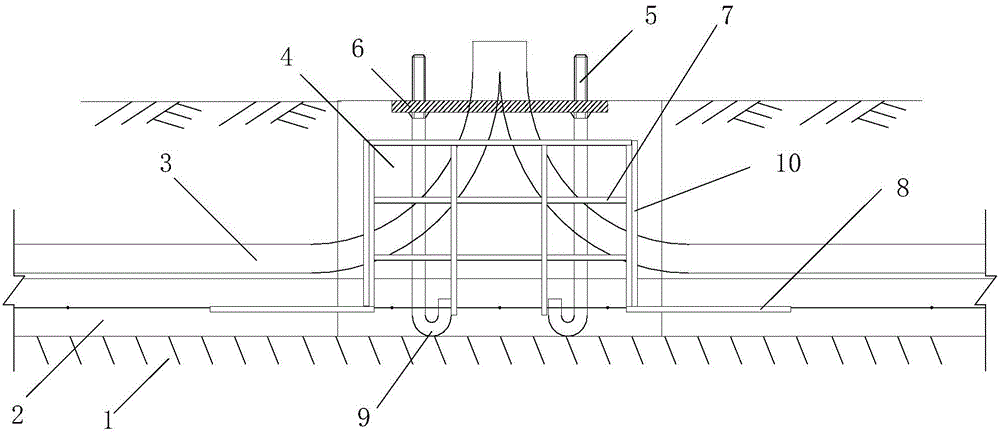

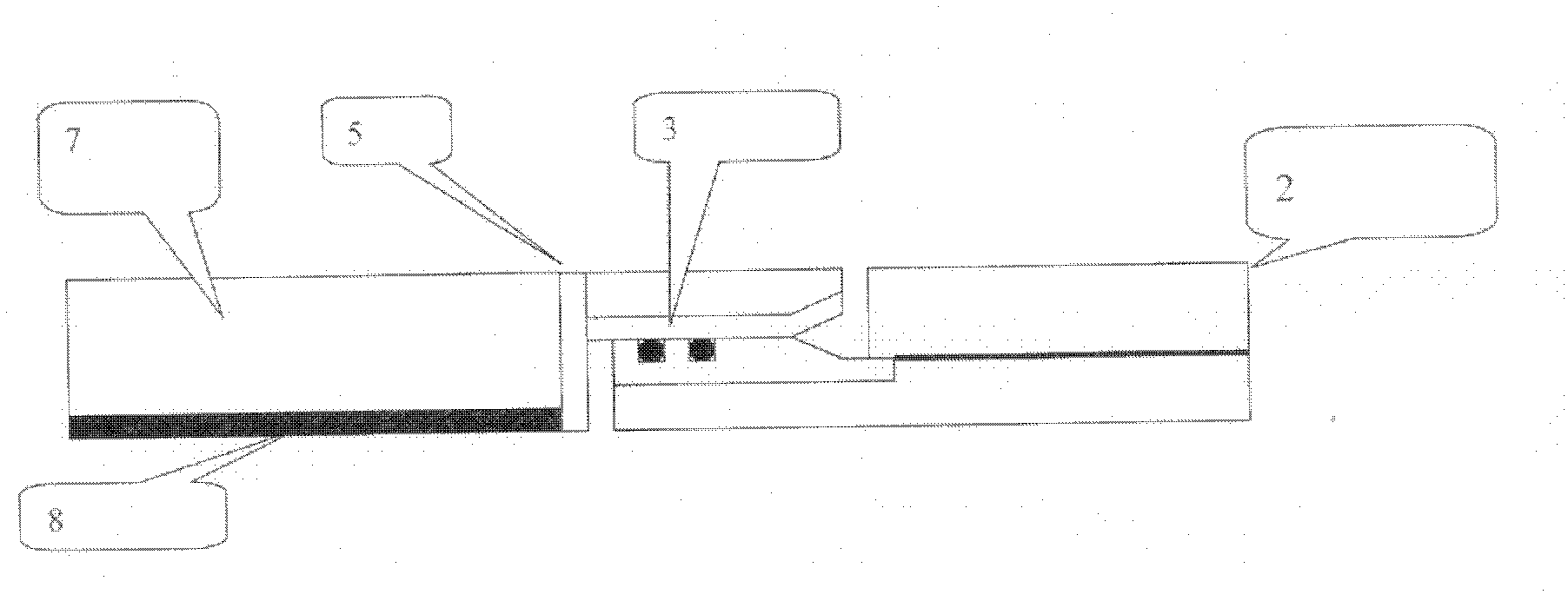

Boiler roof expansion joint sealing device

The invention relates to an expansion joint sealing device of a boiler ceiling. Conventional steel plate sealing cannot realize free expansion between components, and the components are easily pull-cracked. The expansion joint sealing device consists of ceiling pipes (13), guard plates(10), comb-shaped plates (4), ripple expansion joints (1), circular expansion joints (12), pressing plates (2) and ceramic fiber paper (3). Connection forms comprise that a ceiling membrane type wall, peripheral membrane type walls, and pipelines (9) and hanging rods (8), which penetrate through a furnace roof are connected with the guard plates, wherein the ceiling membrane type wall, and the peripheral membrane type walls are connected with the guard plates in the manner that the comb-shaped plates are welded to the ceiling pipes and a water-cooled wall (7), the ripple expansion joints are additionally arranged between the guard plates and the comb-shaped plates, and the ceramic fiber paper is padded between the comb-shaped plates and the ripple expansion joints; the ripple expansion joints and the guard plates are in welding connection. The expansion joint sealing device disclosed by the invention is applied to the expansion joint sealing device of the boiler ceiling.

Owner:HARBIN BOILER

Anti-capsizing street lamp base used for bridge

ActiveCN105040576ANo displacementImprove firm performanceBridge structural detailsCapsizingBridge deck

The invention relates to an anti-capsizing street lamp base used for a bridge. The anti-capsizing street lamp base comprises a road surface embedding groove, and a bearing base layer is arranged inside the road surface embedding groove. The anti-capsizing street lamp base is characterized in that a plate beam top assembly is arranged on the bearing base layer and connected with a steel bar frame. Meanwhile, a limiting assembly is arranged at the top of the steel bar frame, embedded pipelines are arranged inside the steel bar frame in a penetrating mode, and a filling layer is further arranged inside the steel bar frame, wherein foundation bolts are arranged inside the filling layer in a penetrating mode. In this way, the position of a whole foundation can be made unchanged. While the requirement for overall firmness of the foundation is met, the gravity center is moved downwards, and therefore the anti-capsizing capacity is improved. Through the road surface embedding groove, the requirements for hilling heights on different bridge decks can be met, and protruding exposing will not occur. In addition, the anti-capsizing street lamp base is simple in overall structure and easy to manufacture and construct on site.

Owner:苏州同尚工程设计咨询有限公司

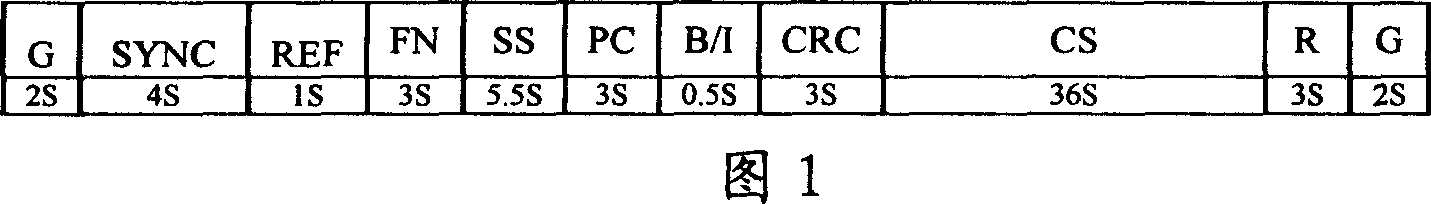

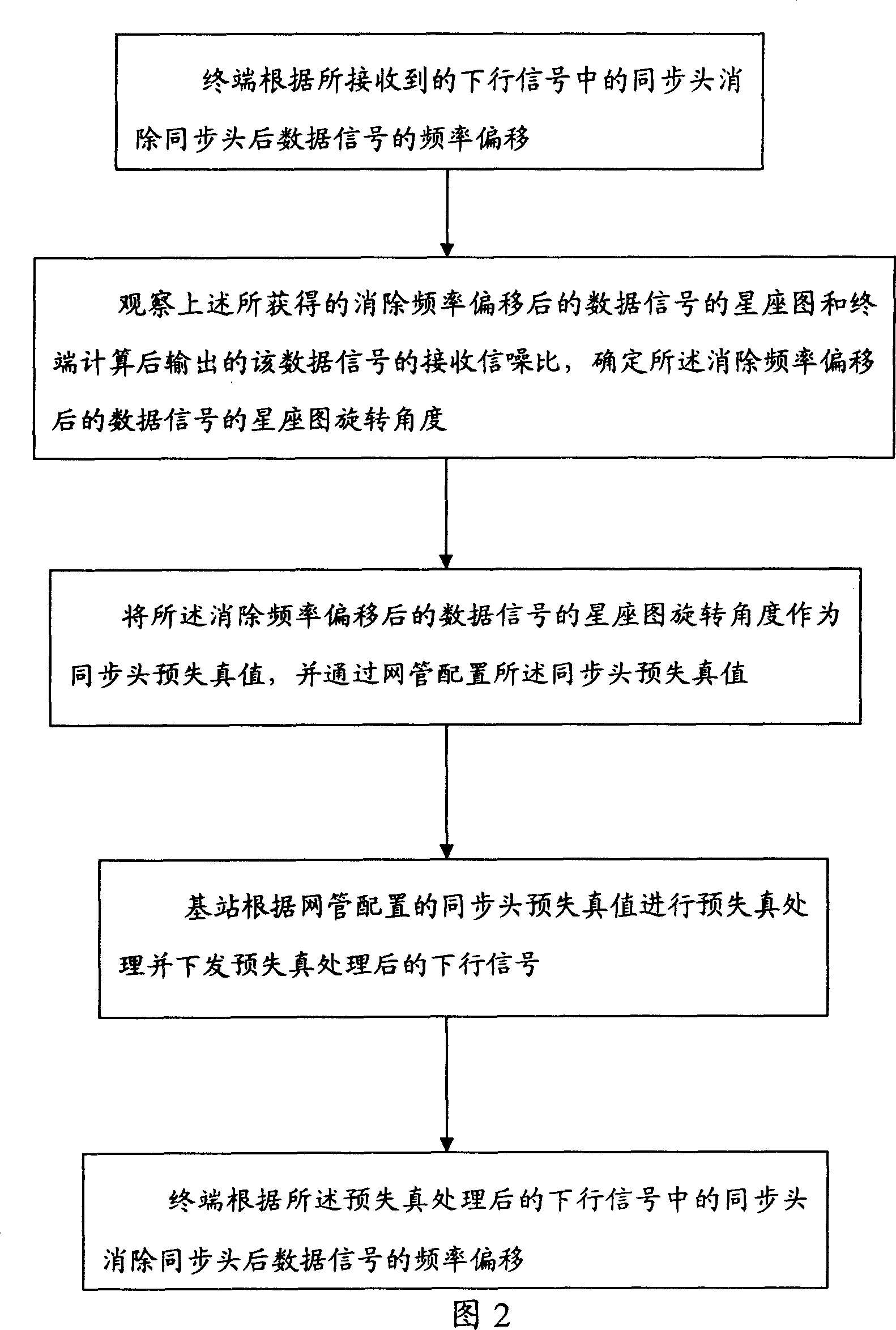

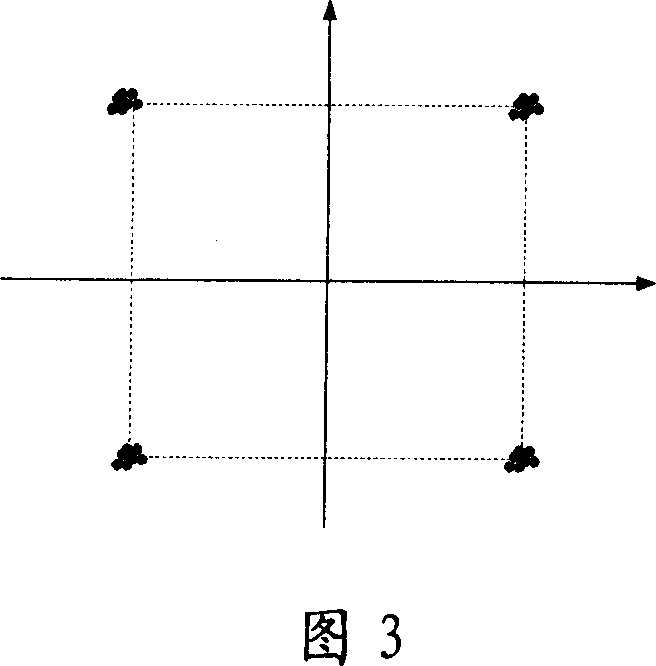

A method for utilizing the synchronization header pre-distortion to eliminate frequency deviation in communication system

InactiveCN101079858AEliminate frequency offsetEasy on-site constructionMulti-frequency code systemsOrthogonal multiplexCommunications systemSignal-to-noise ratio (imaging)

The invention relates to a method for removing the frequency deviation in the communication system with synchronous head predistortion, which comprises the following steps: (1) removing the frequency deviation of the synchronous head data signal according to the received synchronous head by the terminal; (2) determining the constellation chart rotating angle of the data signal after removing the frequency deviation by observing the constellation chart of the data signal acquired by the procedure (1) and the receiving signal-to-noise ratio of the data signal outputted after the calculation of the terminal; (3) regarding the constellation chart rotating angel of the data signal removed the frequency deviation as the synchronous head predistortion value and configuring the synchronous head predistortion value by the network controller; (4) proceeding with the predistortion process according to the synchronous head predistortion value configured by network controller by the base station; (5) removing the frequency deviation of the synchronous head data signal according to the predistortion synchronous head by the terminal. The method can remove the frequency deviation accurately and effectively in the communication system, which guarantees the normal operation of the system.

Owner:BEIJING XINWEI TELECOM TECH

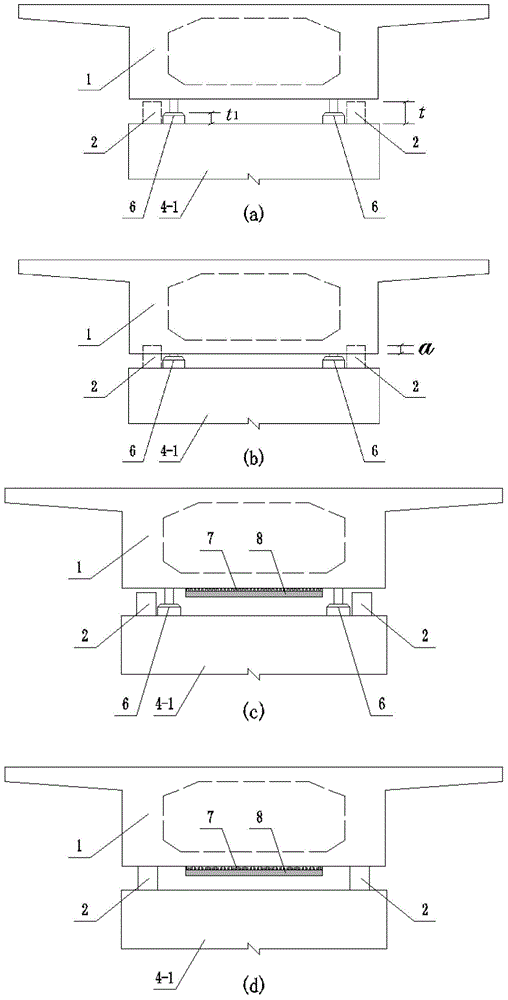

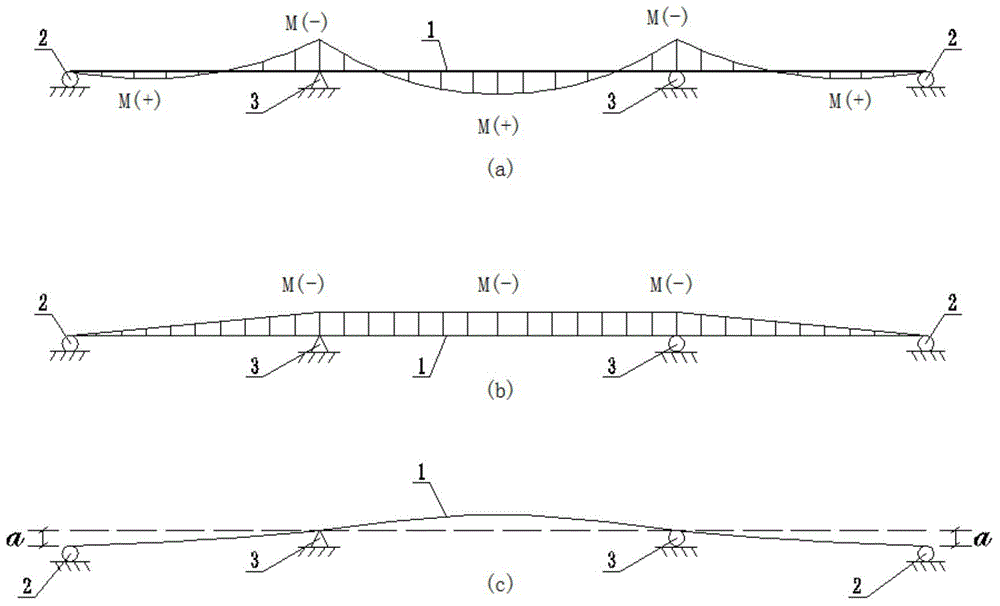

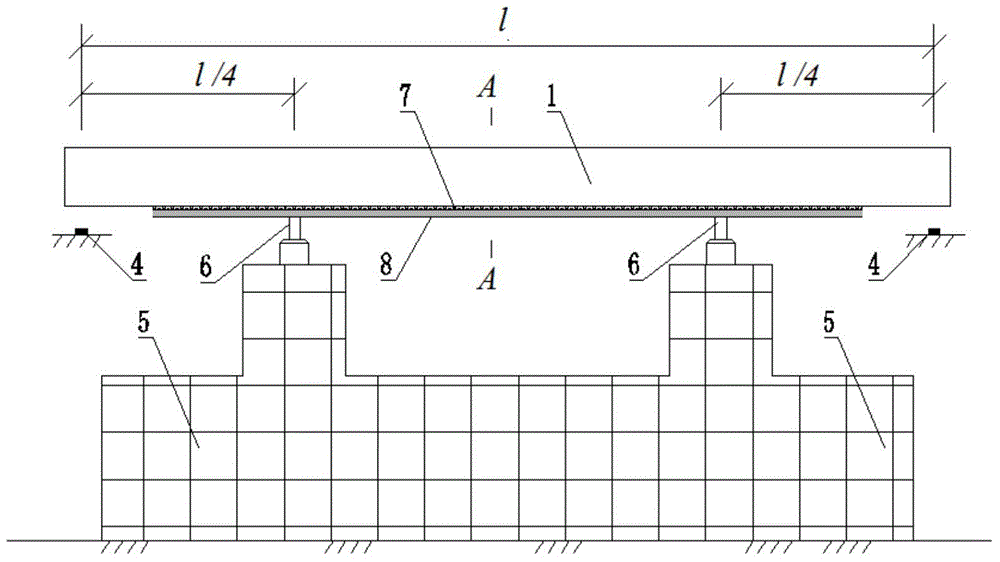

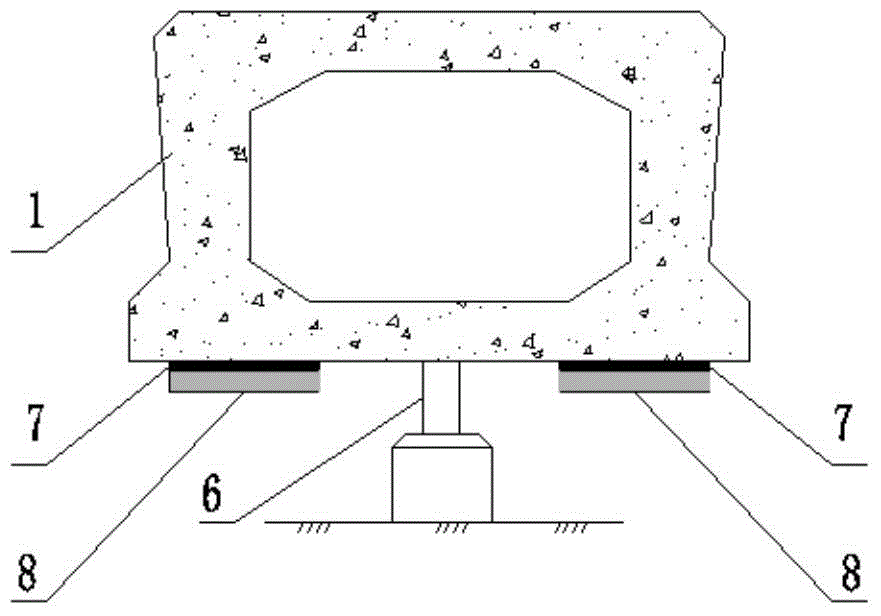

Simply supported hollow plate girder bending resistance reinforcement method

ActiveCN104818678AImprove the bending capacityIncrease profitBridge erection/assemblyBridge strengtheningRebarSteel plates

A simply supported hollow plate girder bending resistance reinforcement method has the construction steps of demounting ancillary facilities of a bridge deck, chiseling hinge joints between girders and a bridge deck cast-in-situ layer, and retaining the girders; setting up operation platforms used for construction to carry out surface treatment on the girders; jacking the girders through jacks under the precondition that safety of the girders is guaranteed; removing mid-span bending moments of dead load of the girders; sticking steel plates after the bending moments of dead load of the girders are removed; pouring concrete to the hinge joints and the bridge deck cast-in-situ layer; synchronously uninstalling the jacks after the curing time is reached, so that the girders are located on supports, and then removing the jacks; pouring concrete to the hinge joints and the bridge deck cast-in-situ layer; restoring the ancillary facilities of the bridge deck, and completing the bending resistance reinforcement of the girders. The simply supported hollow plate girder bending resistance reinforcement method has the beneficial effects that the steel plates are stuck after the mid-span bending moments of dead load of the girders are removed, thus the steel plates can not only participate in the bearing of the load of automobiles and later-imposed dead load, but also participate in the bearing of the removed bending moments of dead load, so that the bending resistance bearing capacity of the girders can be improved; the steel plates are stuck when the strain stress of rebars at mid-span tensile regions of the girders is decreased, so that the material performance of the reinforcing steel plates can be fully exerted better.

Owner:广州展亚土木工程技术有限公司

Splicing construction method of corrugated steel pipe gallery

ActiveCN110629792AReasonable structural designEasy to processArtificial islandsUnderwater structuresPre stressBuilding construction

The invention discloses a splicing construction method of a corrugated steel pipe gallery. The splicing construction of a plurality of splicing sections of the pipe gallery is conducted from back to front, the splicing construction method comprises the steps that A1, the splicing construction of the rear splicing section is conducted; A2, the splicing construction of the next splicing section is conducted; A3, the step A2 is repeated for many times until the splicing construction of all splicing sections of the pipe gallery behind the front connecting section is completed; and A4, the splicingconstruction of the front connecting section is conducted. According to the splicing construction method, the design is reasonable, the using effect is good, the splicing corrugated steel pipe gallery is integrally strengthened in sections by adopting a prestressed reinforcement structure, the structure and layout position of each prestressed reinforcement group in the prestressed reinforcement structure are limited, during the splicing process of the splicing sections of the pipe gallery, the prestressed reinforcement is conducted in synchronous sections, all the splicing sections of the pipe gallery in a pipe gallery body is integrally reinforced through the prestressed reinforcement structure, the integrity and mechanical performance of the constructed and formed pipe gallery can be effectively improved, and the durability of the pipe gallery can be effectively prolonged.

Owner:ZHENGPING ROAD & BRIDGE CONSTR CO LTD +4

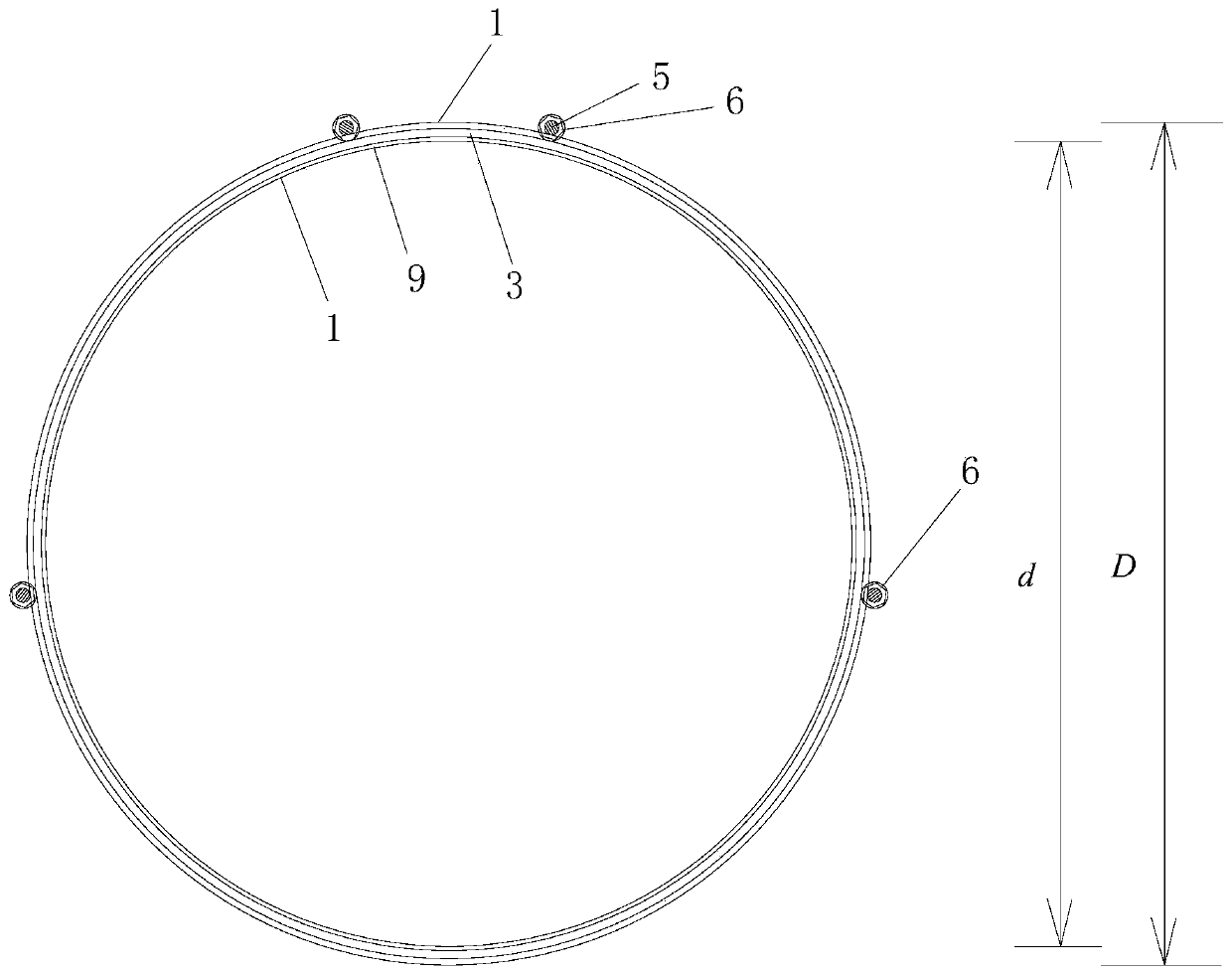

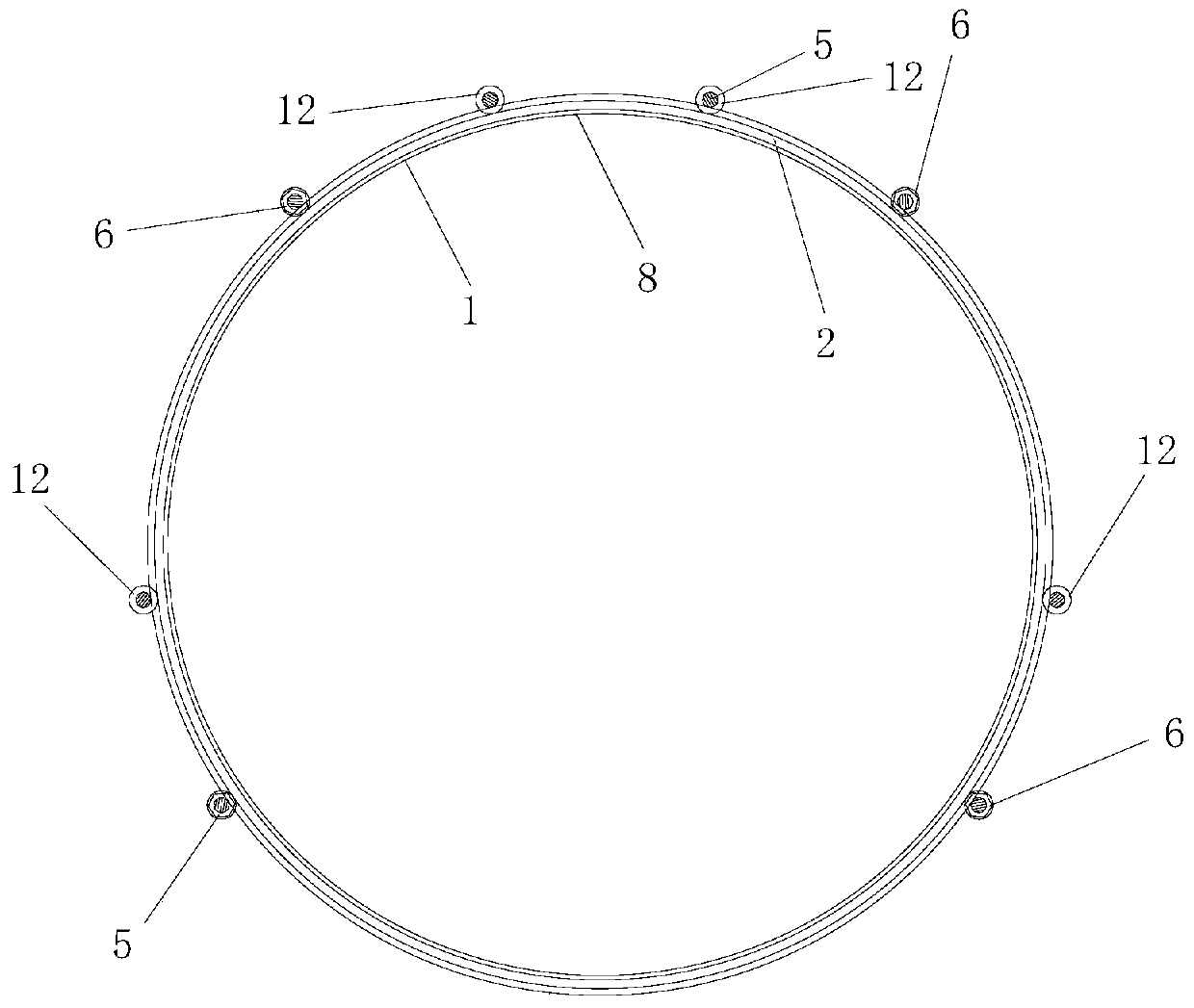

Two-component polyurethane composition for concrete modification and preparation method thereof

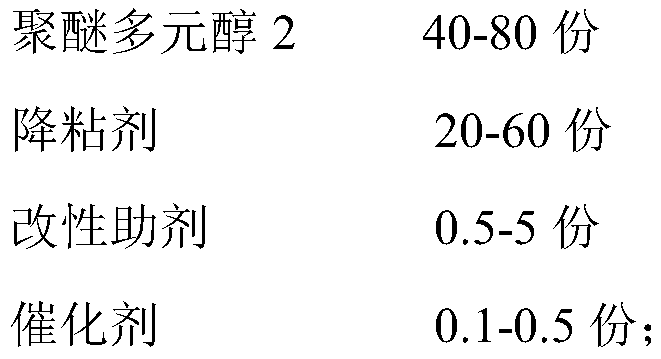

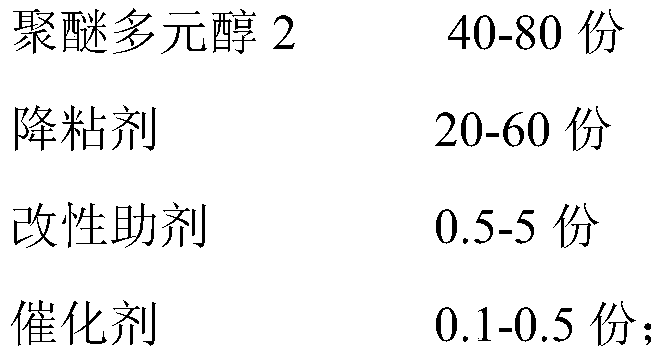

The invention belongs to the technical field of polyurethane elastomers and particularly relates to a two-component polyurethane composition for concrete modification and a preparation method thereof.The double-component polyurethane composition for concrete modification is prepared from a component A and a component B. The component A is formed by polymerizing the following raw materials in parts by mass: 5-20 parts of polyether polyol 1 and 80-100 parts of isocyanate. The component B is prepared from the following raw materials in parts by mass: 40 to 80 parts of polyether polyol 2, 20 to 60 parts of a viscosity reducer, 0.5 to 5 parts of a modification auxiliary agent and 0.1 to 0.5 part of a catalyst. The mixing mass ratio of the component A to the component B is 1: (1-4). The two-component polyurethane composition for concrete modification has the advantages of low viscosity, high permeability, hydrolysis resistance, controllable operation time, high strength and easy construction and operation, concrete materials are modified, and the mechanical properties of the concrete materials are improved. The invention also provides a preparation method of the composition.

Owner:SHANDONG INOV POLYURETHANE

Prestressed concrete cylinder pipe with transfer part for being connected with steel pipe

The invention relates to a prestressed concrete cylinder pipe with a transfer part for being connected with a steel pipe. Steel bell and spigot rings at both ends of a pipe body are fixedly connected with flange plates capable of being connected with the steel pipe. The prestressed concrete cylinder pipe has the advantages that 1, the aim that an abutted joint of the prestressed concrete pipe and the steel pipe is a flexible joint can be fulfilled, so that the phenomenon of a break port generated due to the differential settlement of a foundation is avoided and the normal operation of a pipeline is ensured; 2, the transfer part and the steel pipe can be connected in a welding mode or through a bolt, so that the construction of engineering is convenient to carry out; 3 due to the adoption of the transfer part, functions of diameter reducing, turning or folding and the like of the pipeline, which cannot be realized by a concrete pipe, can be realized; and 4, the prestressed concrete cylinder pipe has a simple structure, the investment of large-scale processing equipment is not required, the factory production can be realized, the field construction is simplified, the construction cost is saved, and the actual application value is very high.

Owner:TIANJIN ZEBAO CEMENT PROD

Cast-in-place pile structure passing through karst cave and construction method of cast-in-place pile structure

ActiveCN108360505AIncrease project cost and construction periodWide variety of sourcesBulkheads/pilesRebarKarst

The invention discloses a cast-in-place pile structure passing through a karst cave and a construction method of the cast-in-place pile structure. The cast-in-place pile structure comprises an upper pile segment, a middle pile segment and a lower pile segment. The lower pile segment is an end support rock-socketed waterproof pile prefabricated through reinforced concrete. Junked tires are stackedand fixedly connected to form a sleeve structure, a middle pile segment reinforcement cage and the end support rock-socketed waterproof pile are connected, sleeves are arranged on the middle pile segment reinforcement cage in a sleeving manner, and the sleeves and the middle pile segment reinforcement cage are hoisted together to be placed in a pre-driven pile hole. The end support rock-socketed waterproof pile is arranged in a bearing hole, located in a rock area, of the bottom of the karst cave, then the middle pile segment is cast under protection of the sleeves, then the clearance betweenthe top of the middle pile segment and the pile hole is blocked off, then the upper pile segment is cast according to a conventional method, and construction of the whole cast-in-place pile structureis completed. According to the cast-in-place pile structure, the characteristics that the junked tires are good in water-resisting property and structure strength, not prone to being corroded and widein source are fully utilized, and through combination with the drilling cast-in-place pile structure, the novel environment-friendly anti-corrosion drilling cast-in-place pile structure and the construction method are provided.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com