Cast-in-place pile structure passing through karst cave and construction method of cast-in-place pile structure

A construction method and cast-in-place pile technology, which can be used in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as material waste, and achieve the effects of structural durability, simple structure and good structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the implementation steps of the present invention are further described:

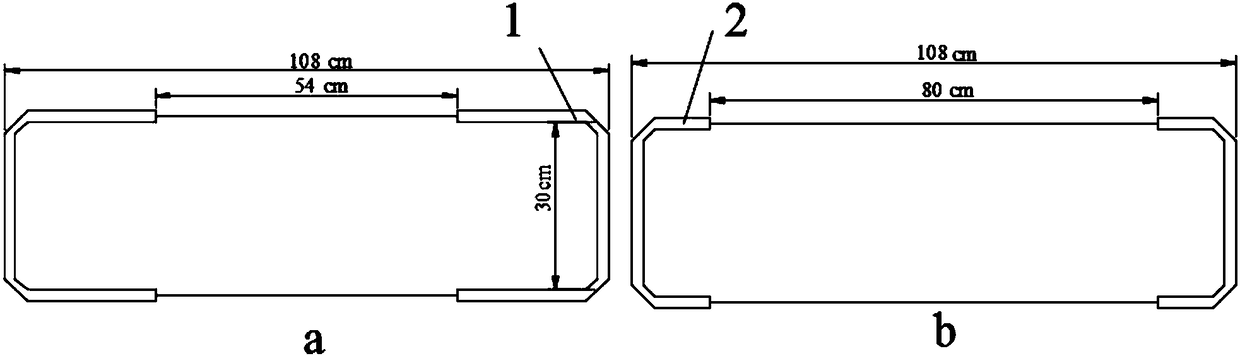

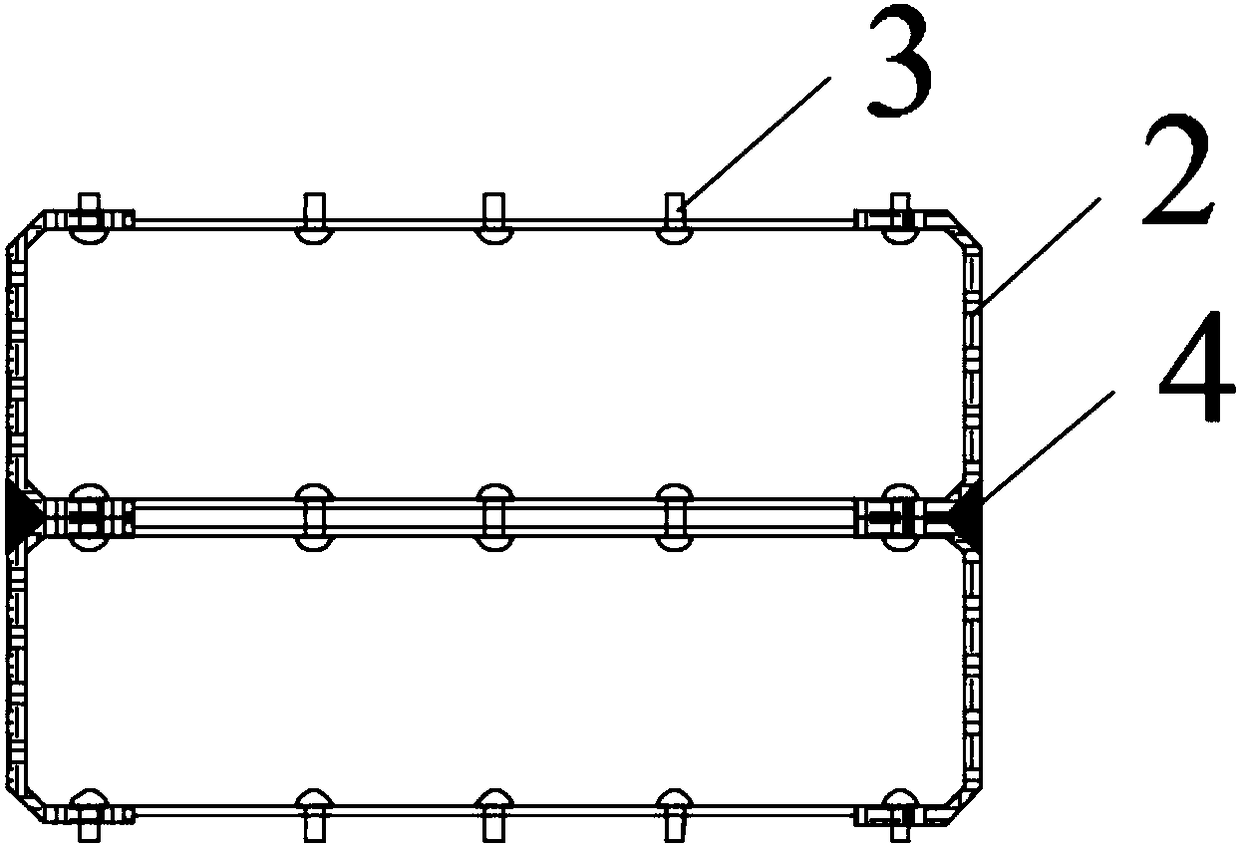

[0039] The structural design of the present invention is suitable for truck waste tires 2 of R22 and above size, and the size of each tire side can be cut according to the pile diameter design size, and can be applied to the pile diameter size of 800mm to 1000mm. The present invention takes the truck waste tire 2 of 295 / 80R22.5 specification as an example.

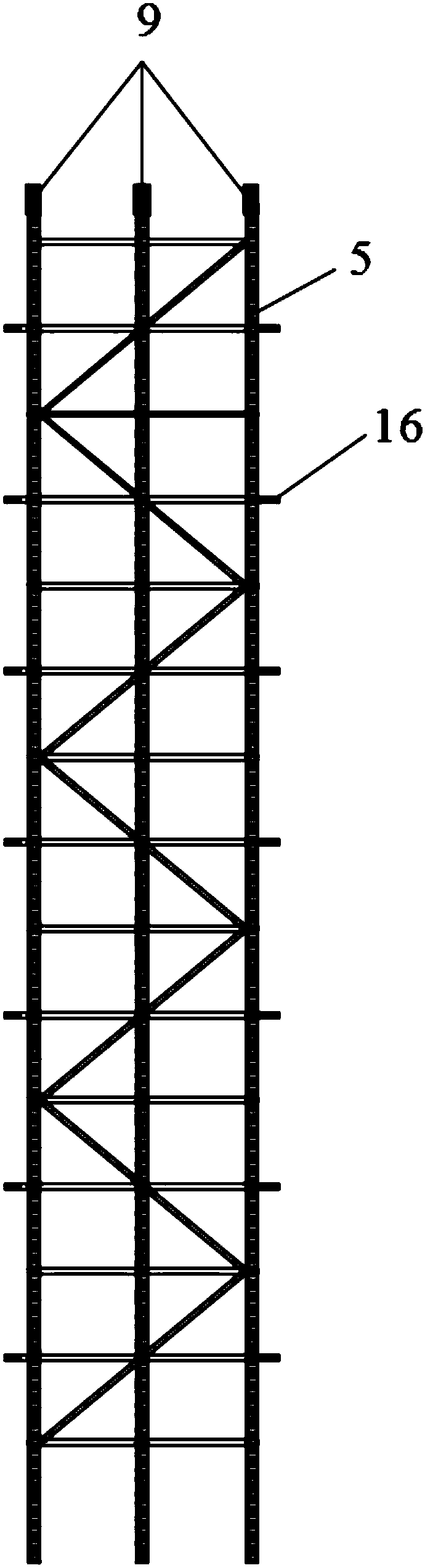

[0040] A cast-in-place pile structure passing through a karst cave, including an upper section pile, a middle section pile and a lower section pile. The upper section pile is located in the top area of the karst cave, and adopts a conventional cast-in-place pile structure; the lower section pile is located in the rock area 11 at the bottom of the karst cave, and is a prefabricated end bearing of reinforced concrete Rock-socketed waterproof pile; the middle pile is located in the karst cave are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com