Prestressed concrete cylinder pipe with transfer part for being connected with steel pipe

A prestressed steel and concrete pipe technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of affecting the safe operation of pipelines, the welding joints are easy to break, and the diameter is changed, and the structure is simple and convenient On-site construction to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

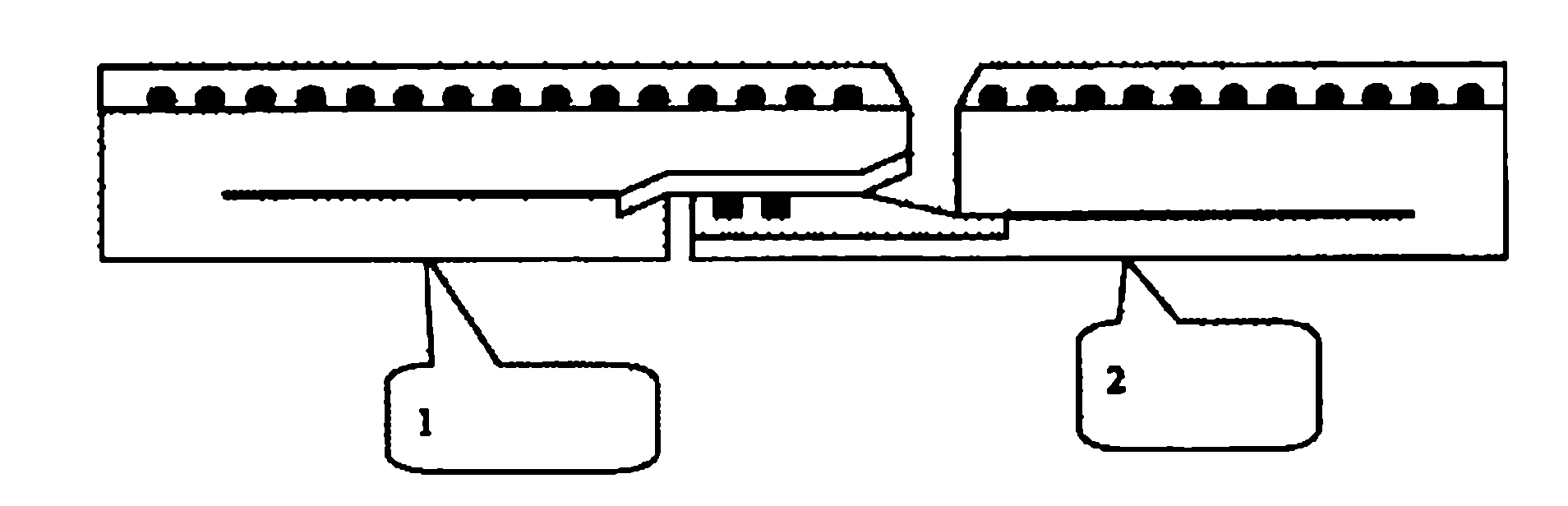

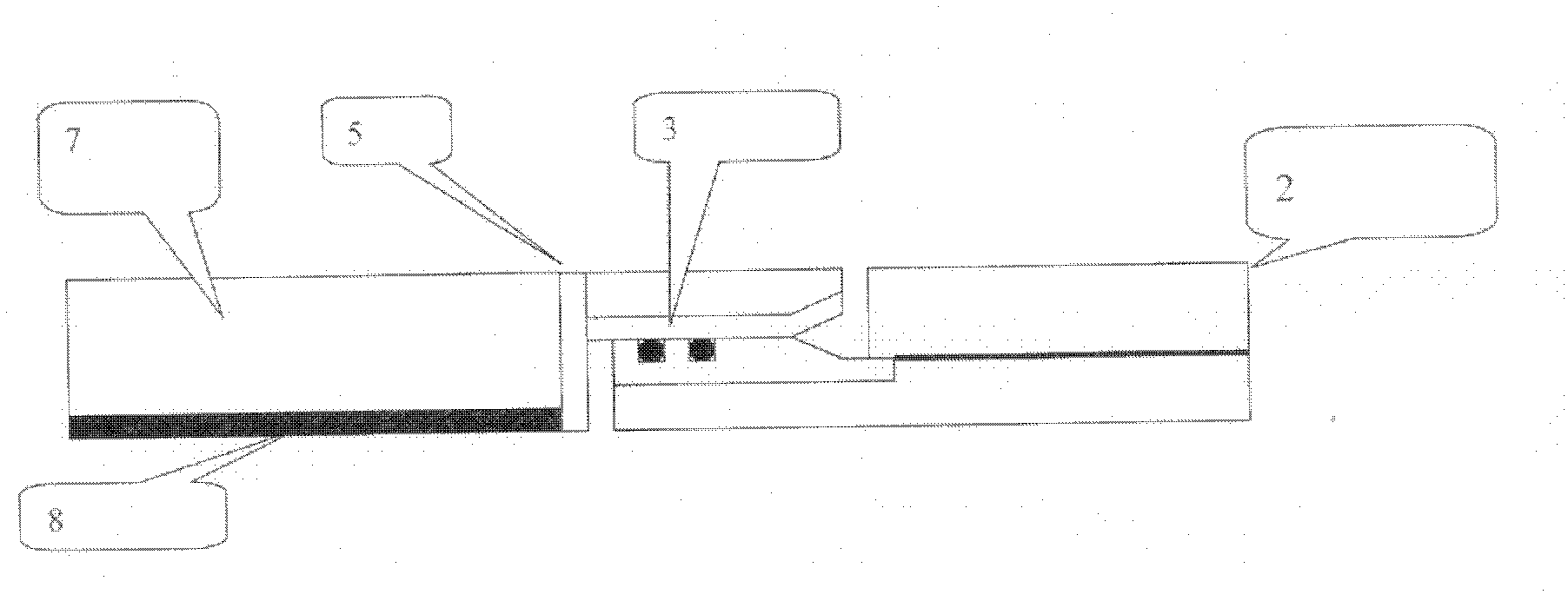

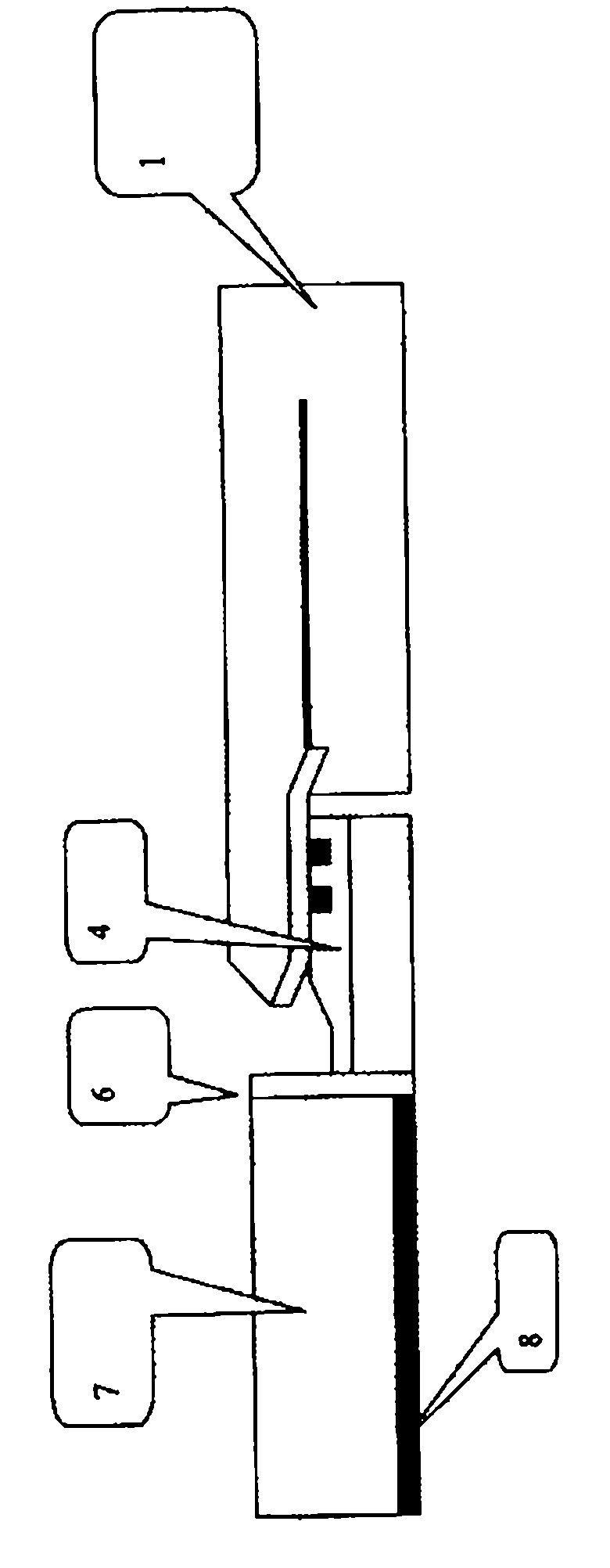

[0015] Such as figure 1 Shown: a prestressed steel cylinder concrete pipe with a conversion piece for connecting steel pipes, with a socket 1 and a socket 2 at both ends of the pipe body, and steel socket rings 3 and 4 on the socket and the socket. Such as figure 2 Shown: flange plate 5 is welded on socket ring 3. Such as image 3 Shown: flange plate 6 is welded on socket ring 4. The size of the above-mentioned flange matches the diameter of the steel pipe connected with the prestressed steel cylinder concrete pipe.

[0016] When using the present invention, first weld the flanges on the socket rings at both ends of the prestressed steel cylinder concrete pipe, and then weld the steel pipe 8 with the mortar protection layer 7 on the flanges, if the project does not have welding conditions , Conversion parts and steel pipes can also be bolted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com