Electric pipe fitting butting device

A technology of a docking device and a dragging device, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of workers' technical level and experience having a great influence, low installation accuracy, and high labor intensity, so as to improve labor efficiency. Efficiency, improving work quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

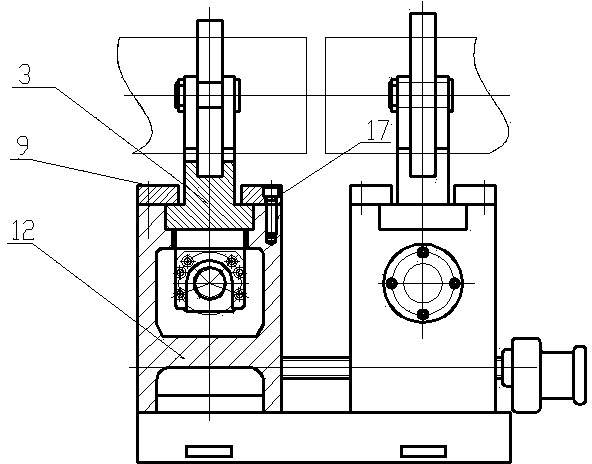

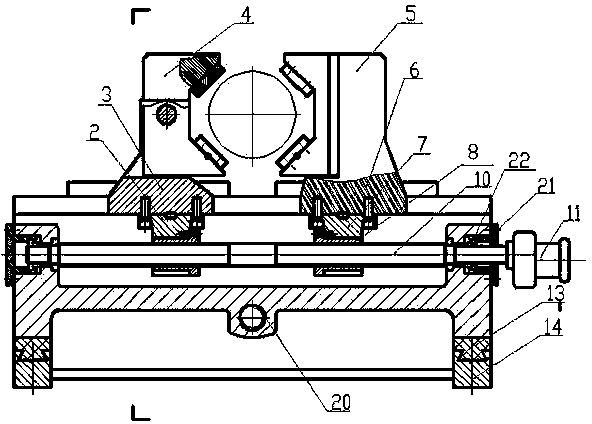

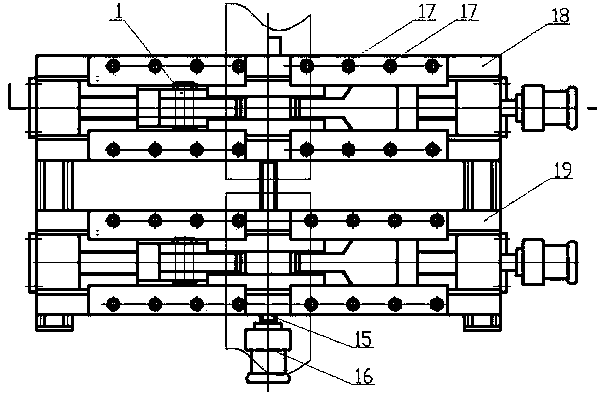

[0020] Such as figure 1 , figure 2 and image 3 As shown, an electric pipe butt joint device includes a first centering clamping device 18 and a second centering clamping device 19 having the same structure as the first centering clamping device, and the two ends of the base along the base The horizontal and longitudinal sides of the seat 12 are respectively provided with a guide rail groove, and the first and second centering clamping devices are respectively installed on the guide rail grooves through the guide rails, and the first centering clamping device 18 and / or the second centering clamping device 18 The device 19 can move along the rail groove 14 . And the first and second centering clamping devices are arranged horizontally along the longitudinal direction, the centering clamping device 18 clamps the first pipe, and the second centering c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com