Patents

Literature

34results about How to "Control output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blocking remover for reservoir of oil well

The invention discloses a blocking remover for a reservoir of an oil well. The blocking remover is applied to the technical field of oil extraction in an oil field, comprises an agent A and an agent B, and is characterized in that the weight percentage of the agent A is 25-35%; the weight percentage of the agent B is 65-75%; the agent A comprises the following components by weight: 45-50% of petroleum mixed xylene, 1-2% of nonyl phenol polyoxyethylene (4) ether, and the balance of 0# diesel oil; the agent B comprises the following components by weight: 6-10% of glacial acetic acid or sulfamic acid, 2-2.5% of ammonium bifluoride, 2% of ammonium chloride, 1-2% of citric acid, 1.5-2% of corrosion inhibitor 7801, 3-5% of tertiary butanol, 0.5-1% of octyl phenol polyoxyethylene (10) ether and the balance of water. The blocking remover has the following effects that: the agent A and the agent B are respectively prepared so as to be beneficial to storing the blocking remover for a long time, the agent A of the blocking remover has strong dissolving capacity on crude oil heavy components, such as wax colloid asphalt, and the washing oil efficiency on oil sand is more than 90%. The dissolving rate of the agent B of the blocking remover on carbonate is more than 80%, and the corrosion speed on N80 steel is low and is smaller than 2 g / m<2>.h.

Owner:PETROCHINA CO LTD

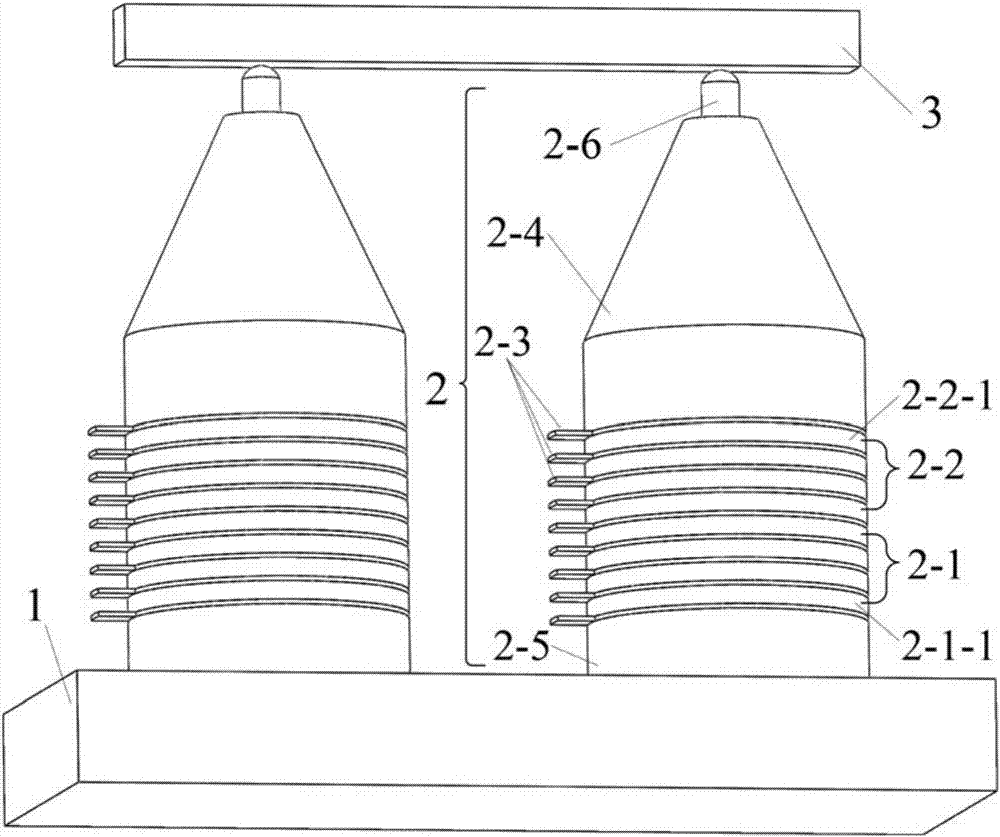

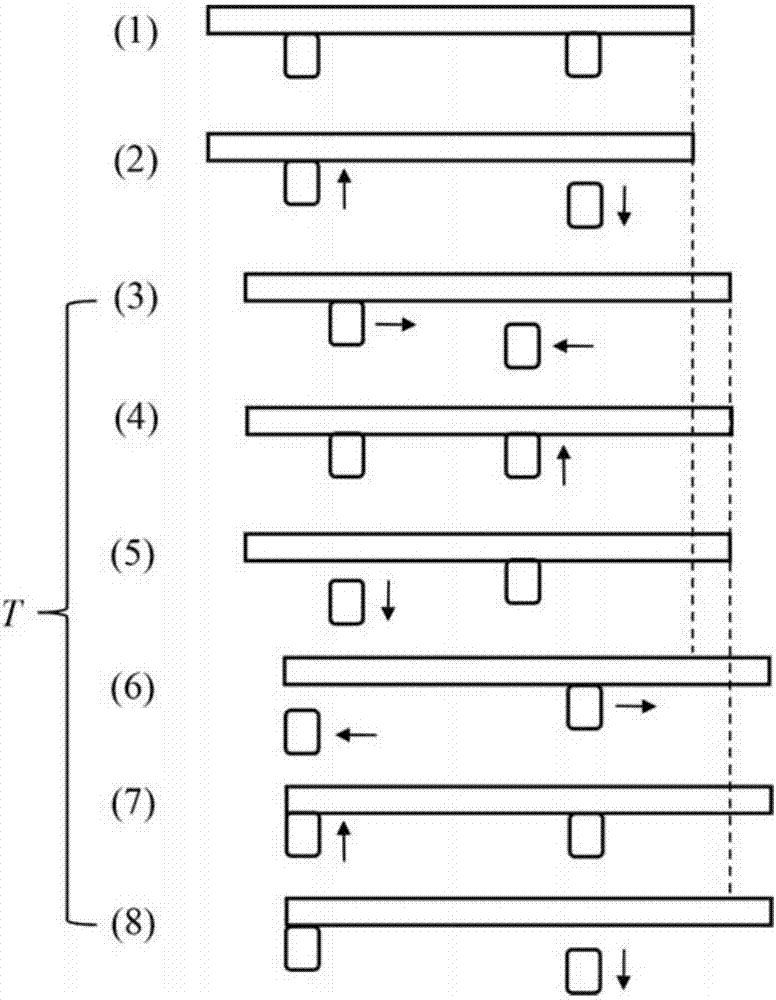

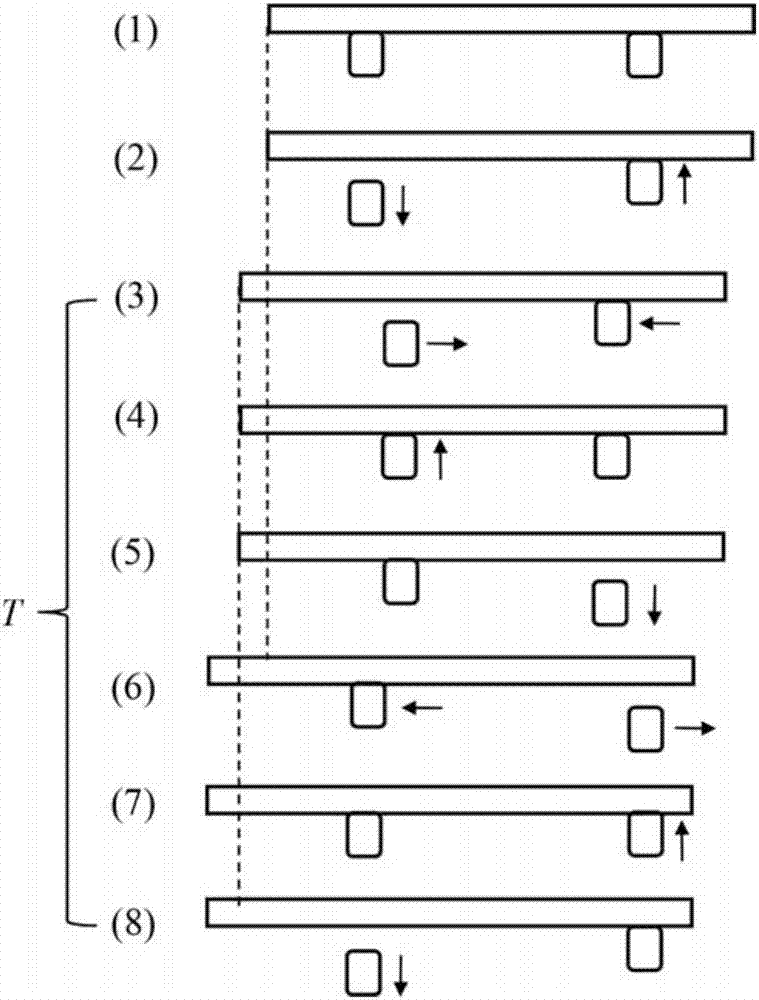

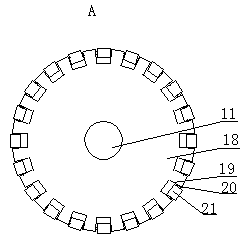

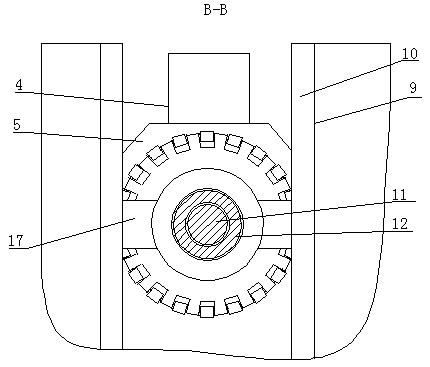

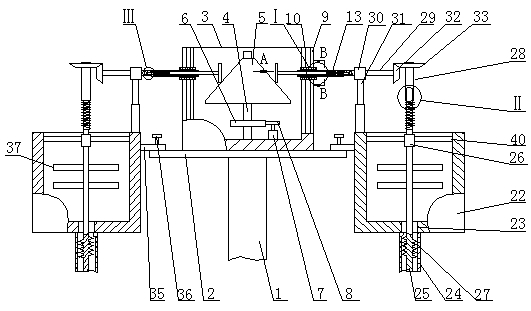

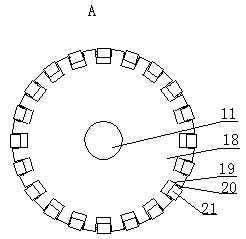

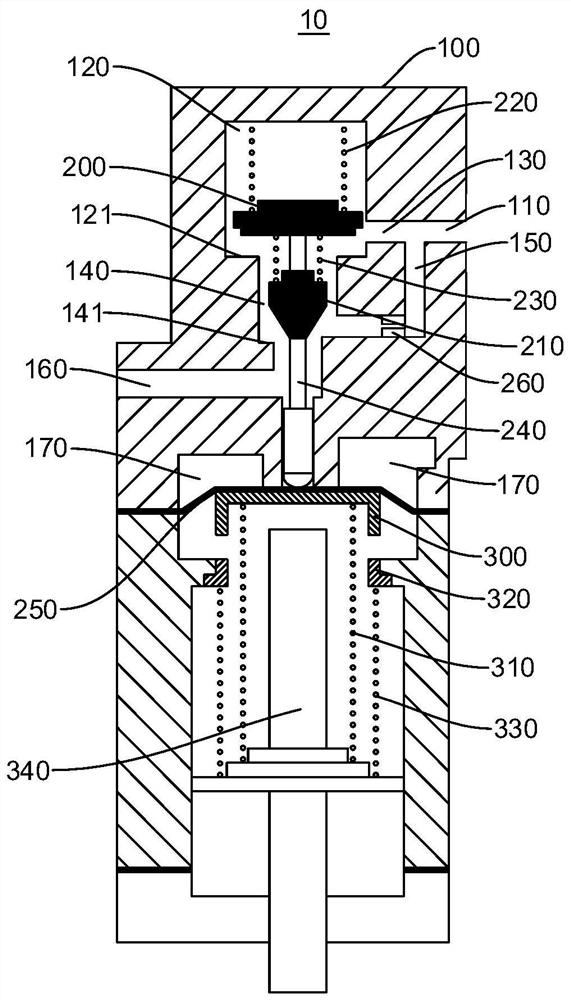

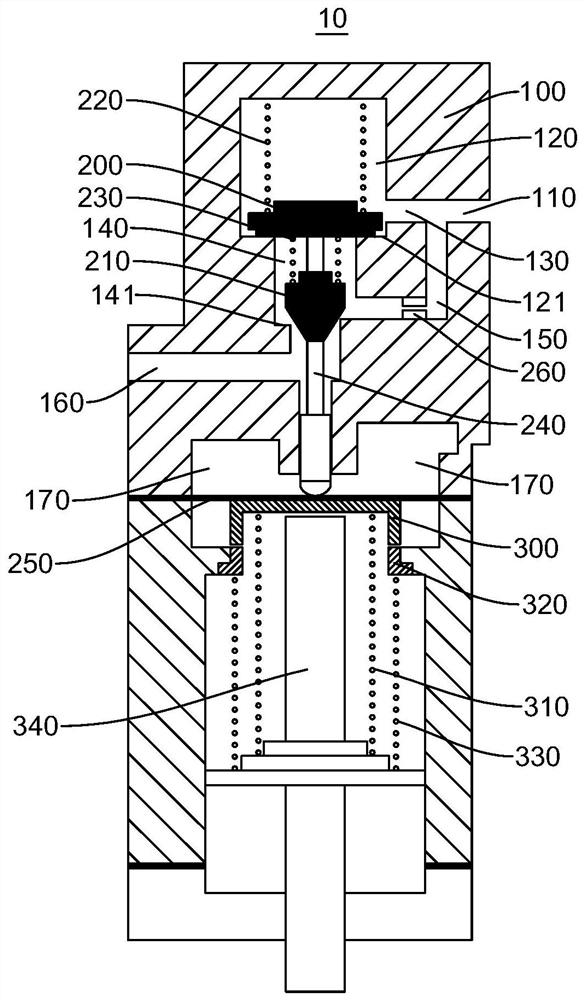

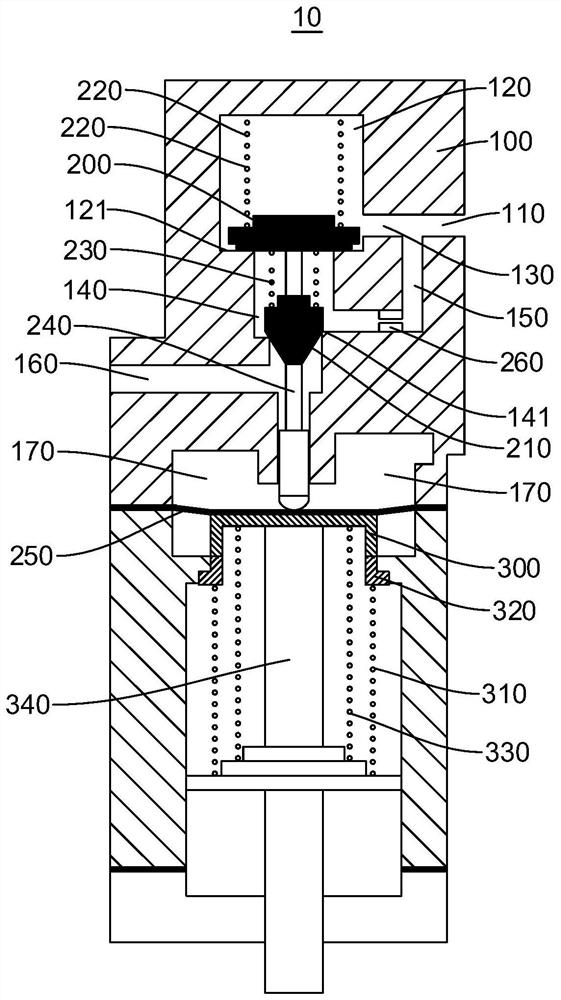

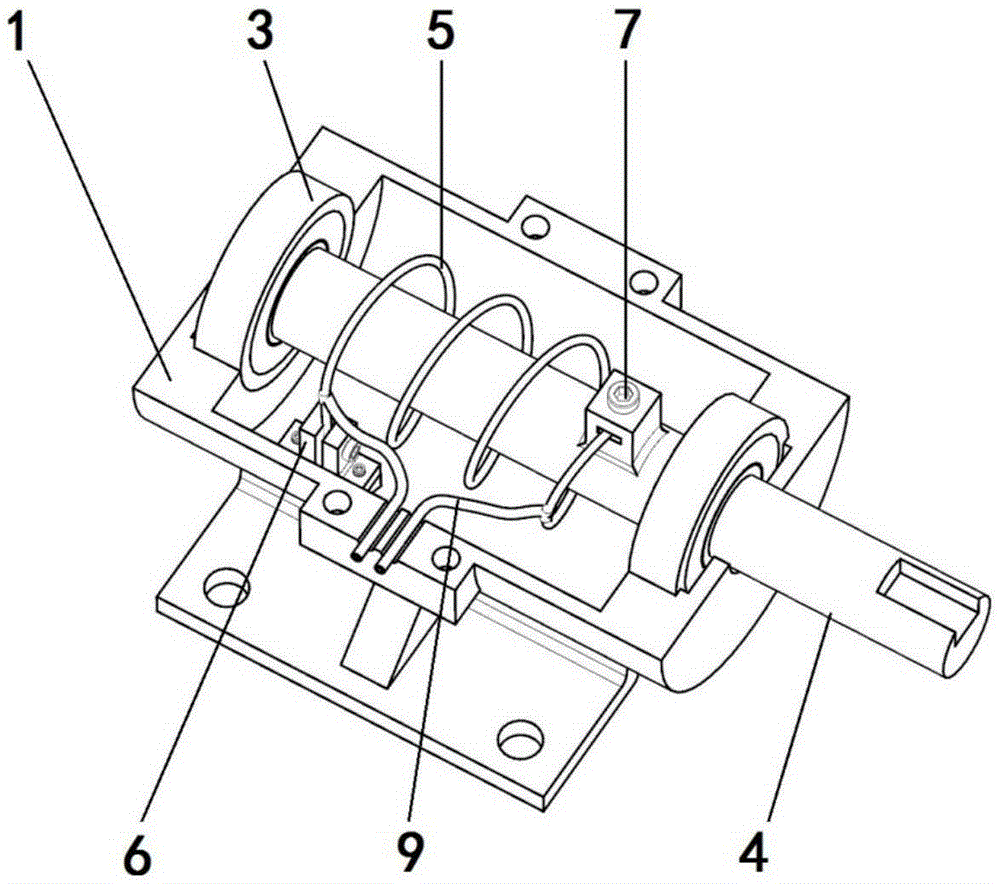

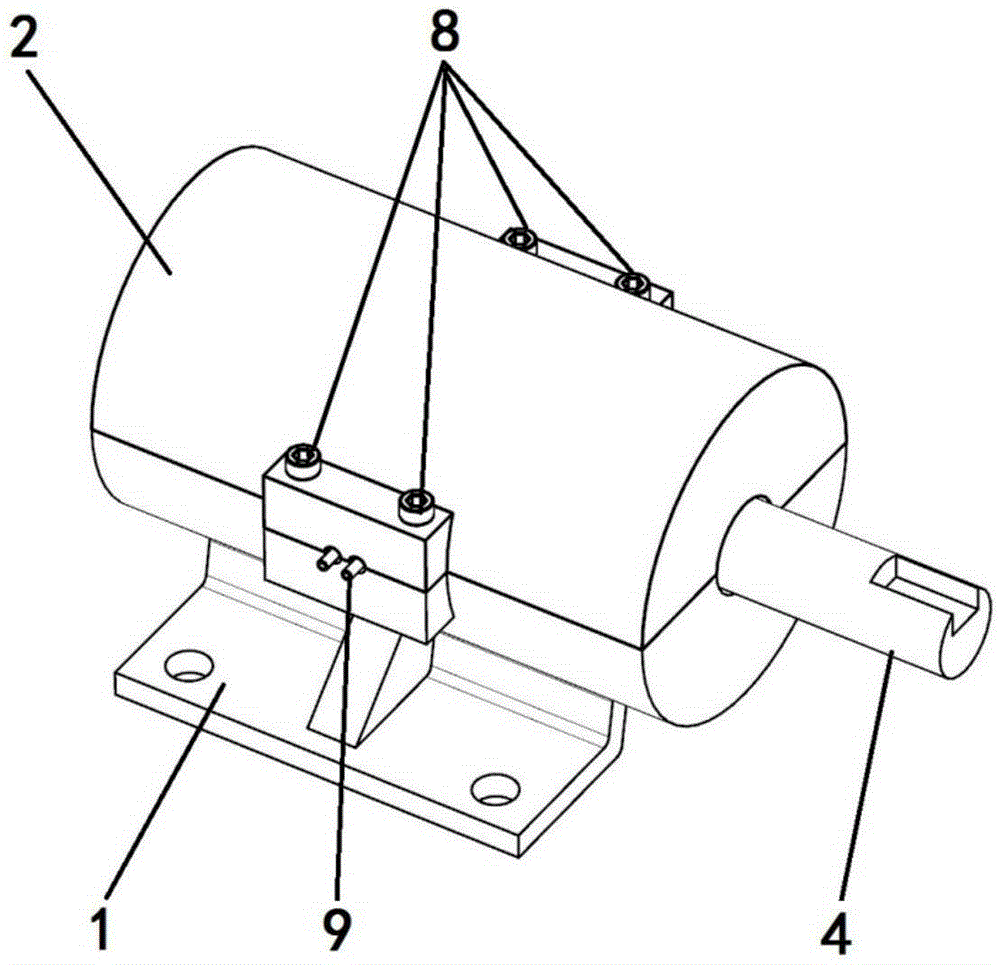

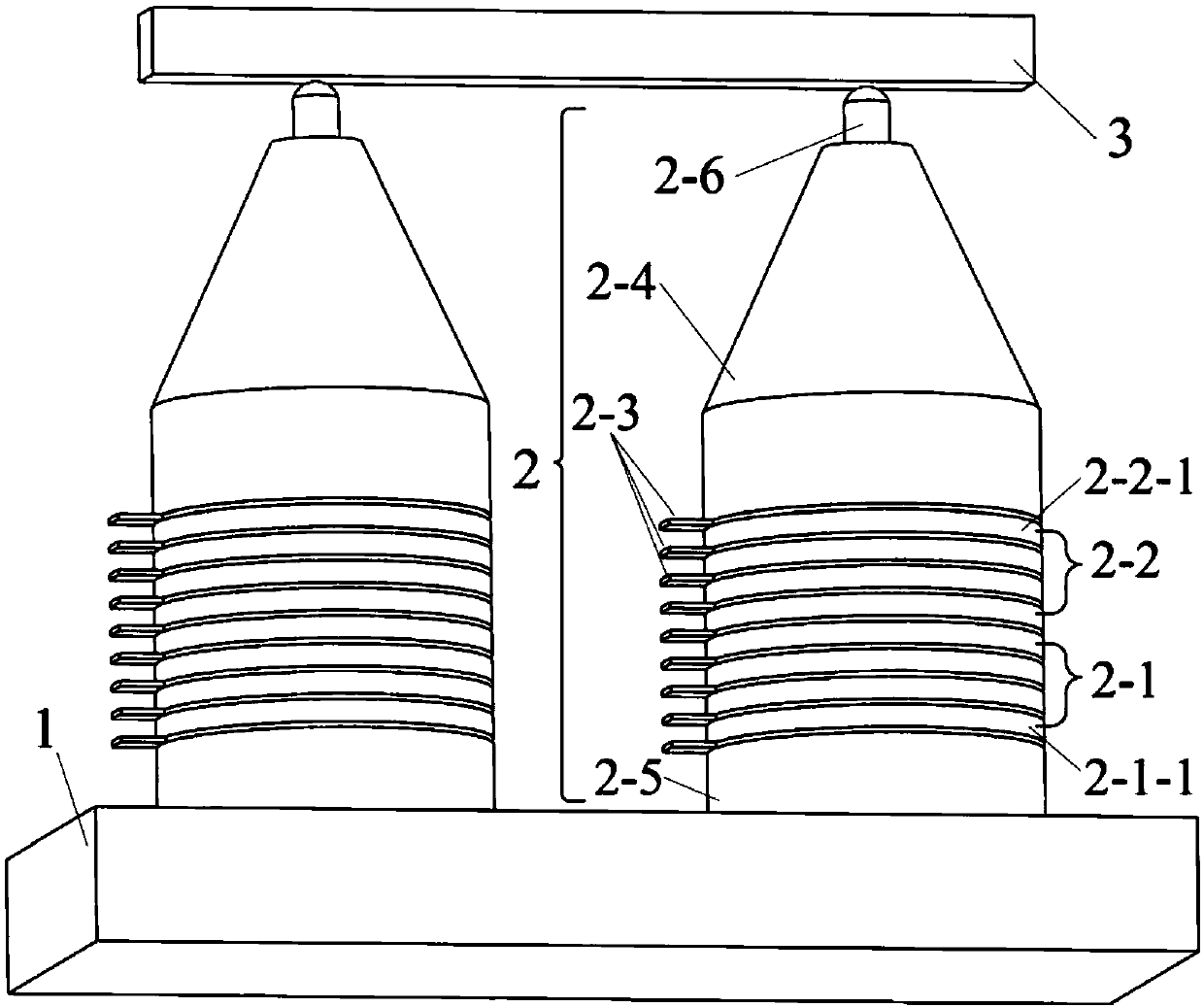

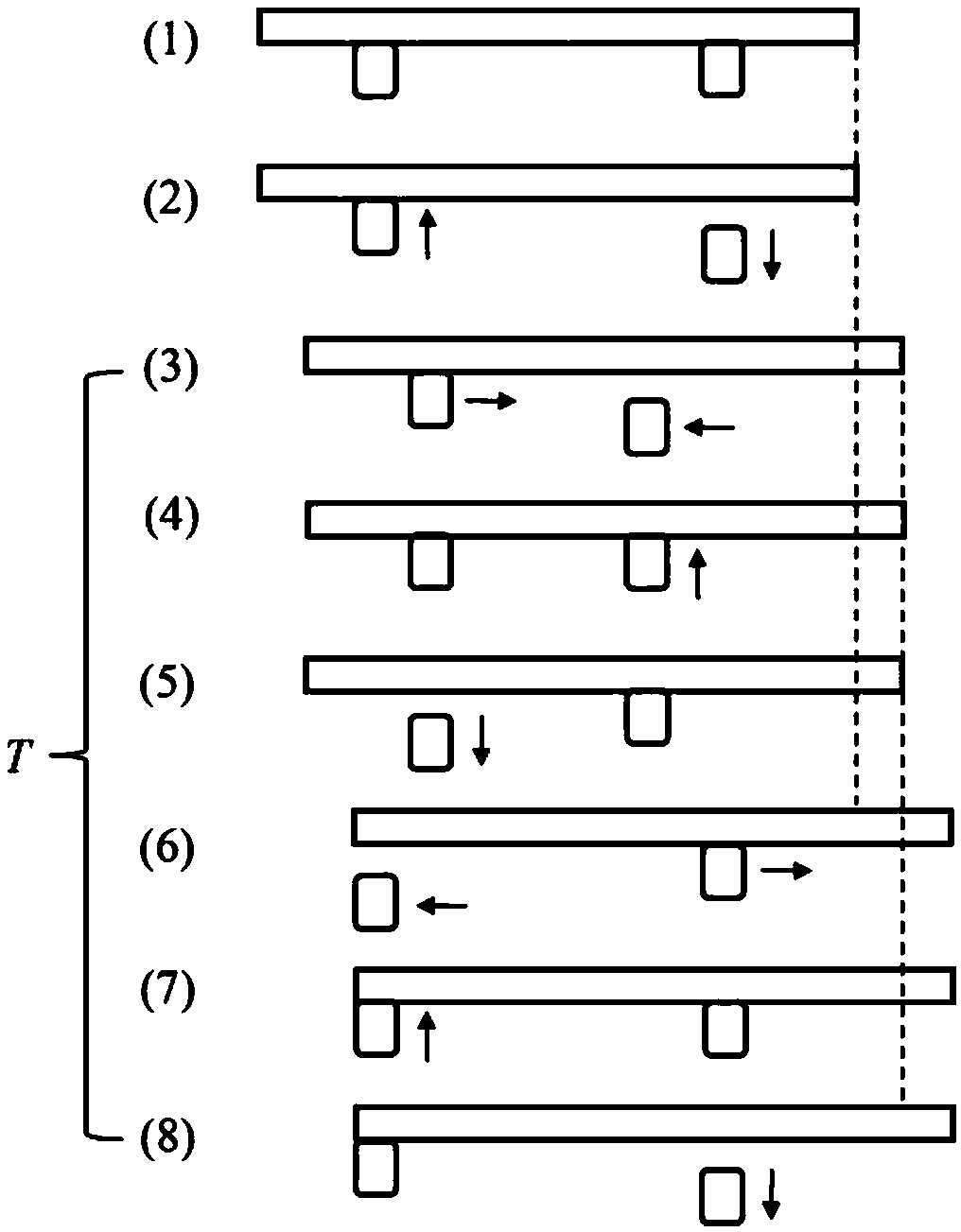

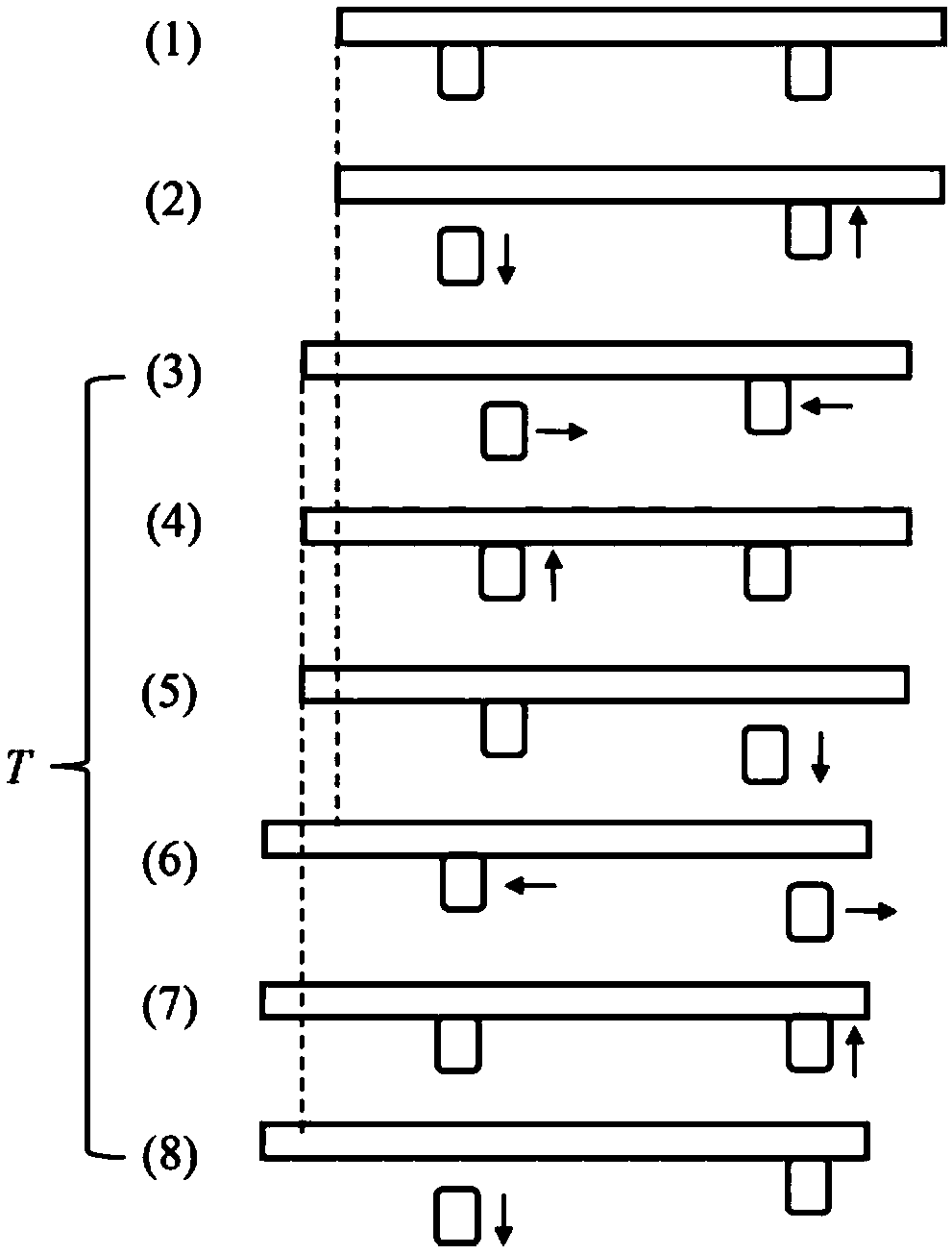

Longitudinal-bending composite peristaltic precision piezoelectric driver and excitation method thereof

ActiveCN106953539AAchieve continuous motion outputEffective stepper drivePiezoelectric/electrostriction/magnetostriction machinesAviationElectricity

The invention discloses a longitudinal-bending composite peristaltic precision piezoelectric driver and an excitation method thereof, and relates to the technical field of piezoelectric driving. The invention aims to solve a problem that an existing piezoelectric driver cannot have the properties of rapid movement, nanometer-scale positioning, strong power output and large-range movement stroke. The longitudinal-bending composite peristaltic precision piezoelectric driver is characterized in that a ceramic group formed by a bending vibration ceramic group and a longitudinal vibration ceramic group is arranged on a rear clamping body, n rear clamping bodies are arranged on a fixed base in parallel or arranged on a base body along the circumferential direction of the base body, a front clamping body is arranged at the front surface of each ceramic group, and each front clamping body is contacted with a linear rotor or a rotary rotor through a driving foot; the longitudinal vibration ceramic groups perform telescopic deformation so as to control contact / separation of the corresponding driving feet and the rotor, the bending ceramic groups perform bending deformation so as to realize stepping driving for the rotor, and continuous driving is realized through coordinately setting the operating process of a plurality of energy converters. The longitudinal-bending composite peristaltic precision piezoelectric driver has the advantages of large stroke, high positioning precision, adjustable output speed and output power and the like, and has good application prospects in the fields such as intelligent robots, aviation and aerospace and high-end equipment manufacturing.

Owner:HARBIN INST OF TECH

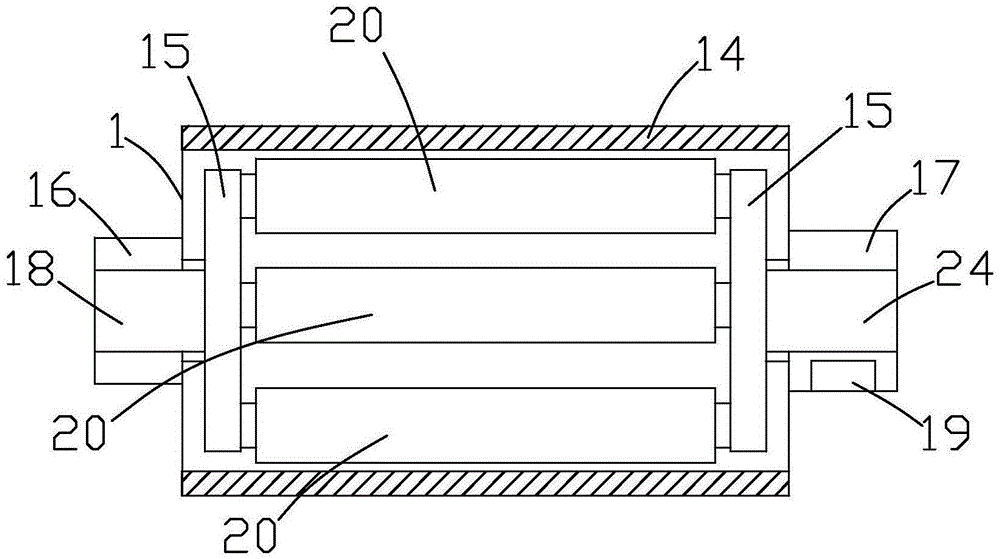

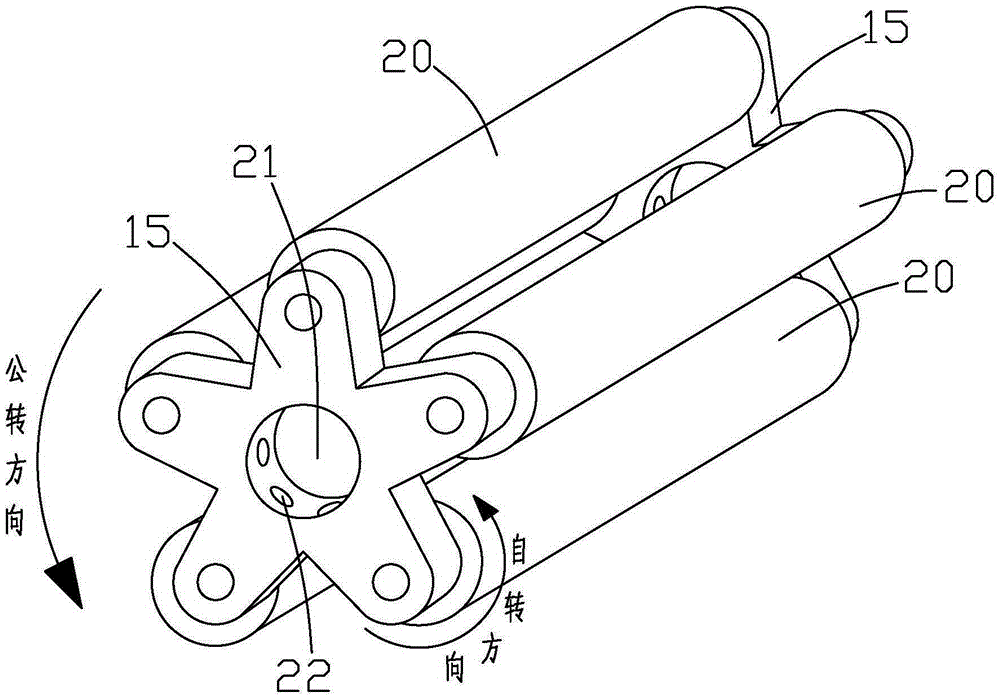

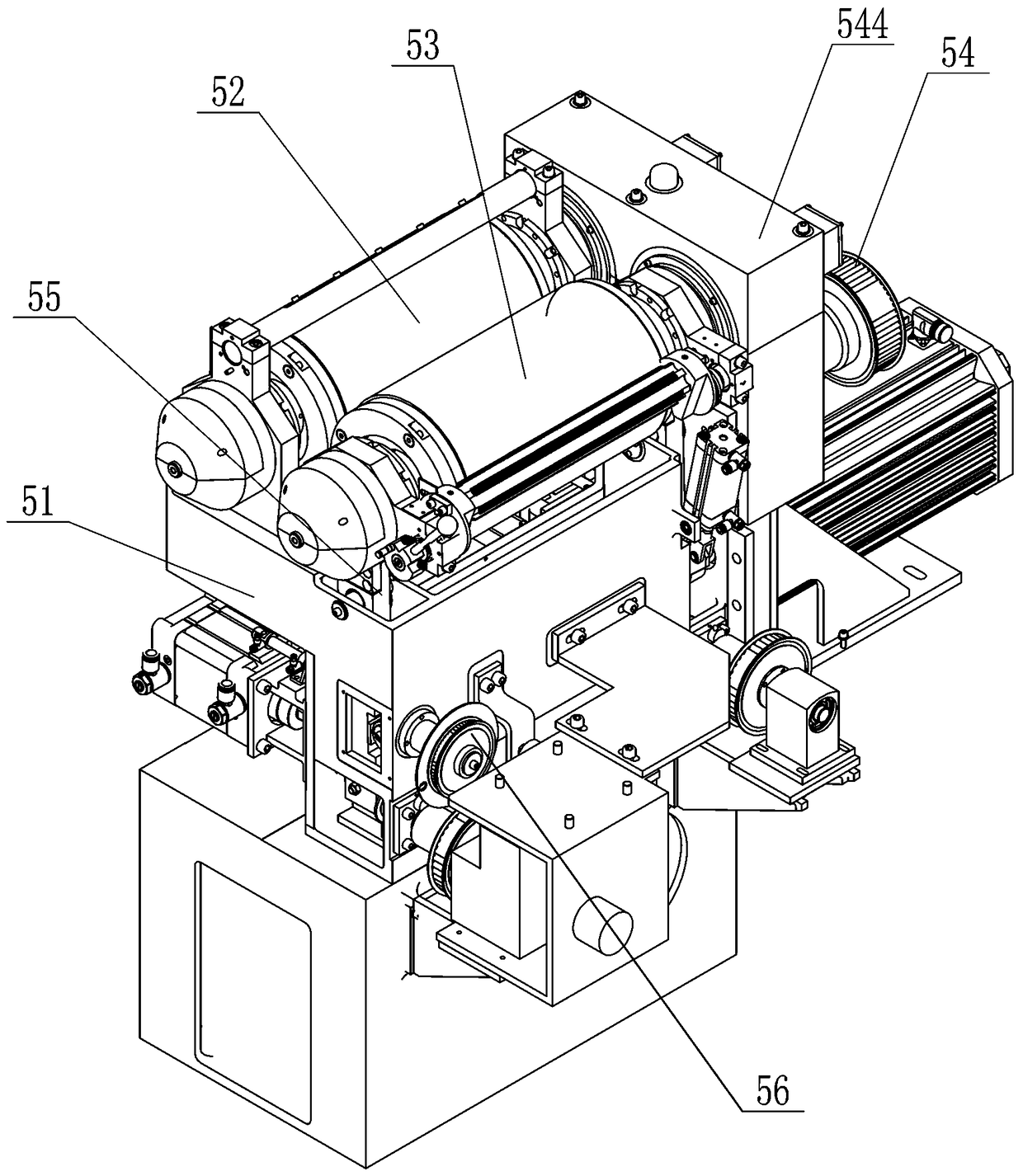

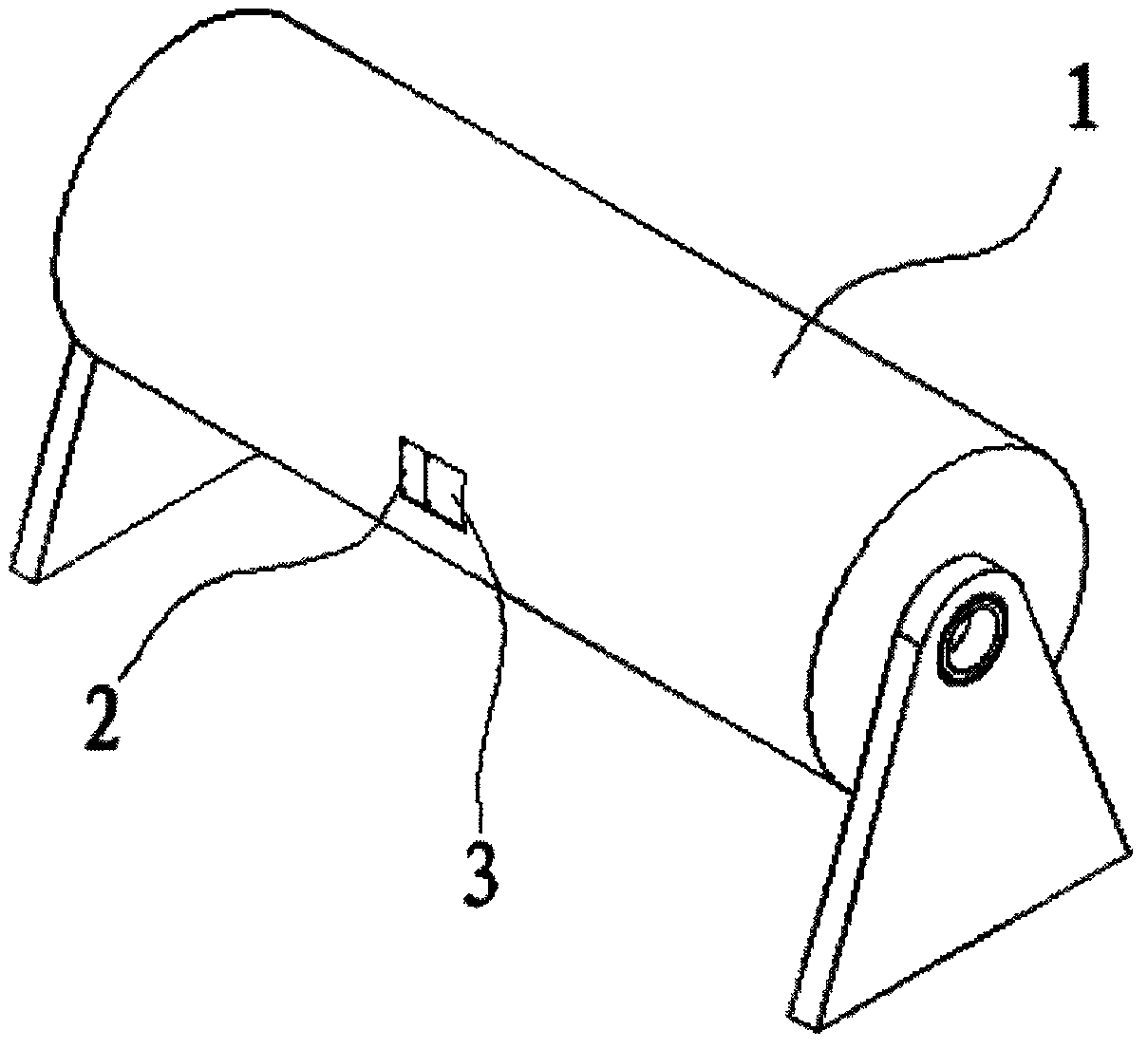

Ball mill used for producing graphite powder

InactiveCN105413813AExcellent crushing speedReduce crushing timeGrain treatmentsSynchronous motorGraphite

The invention discloses a ball mill used for producing graphite powder. The ball mill comprises a roller, a power drive device, a feeder and a dumping device, wherein two star brackets which are parallel to each other are arranged on the inner part of the roller; material distributing tubes are uniformly arranged on the inner parts of the star brackets; five cylindrical ball-milling tanks which are parallel to each other are uniformly distributed between the two star brackets; the two ends of each cylindrical ball-milling tank are provided with supporting tube racks; a synchronous motor is arranged on the inner parts of the star brackets; the cylindrical ball-milling tanks realize autoroatation around the star brackets; the two ends of the roller are respectively provided with a front positioning bearing and a rear positioning bearing; and the cylindrical ball-milling tanks realize rotation around the front positioning bearing and the rear positioning bearing. The ball mill is simple in structure, high in practicability, not only can realize autoroatation and rotation of the cylindrical ball-milling tanks and improve material crushing efficiency and material crushing quality, but also can pre-heat and crush materials, so that the materials are guaranteed to have certain temperature while being output, and therefore, crushing requirements of different materials are met.

Owner:SHENGZHOU SIGMA TECH

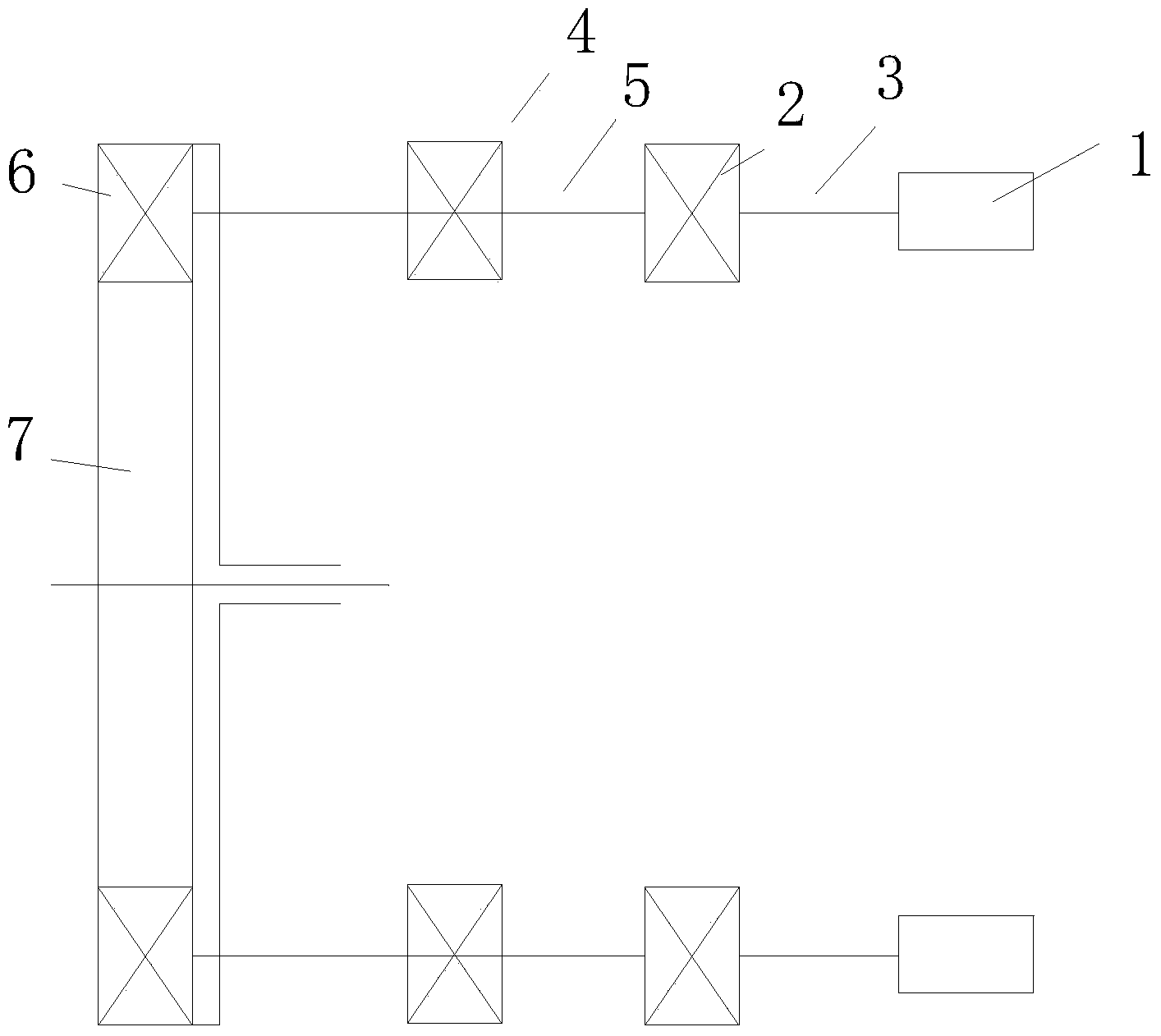

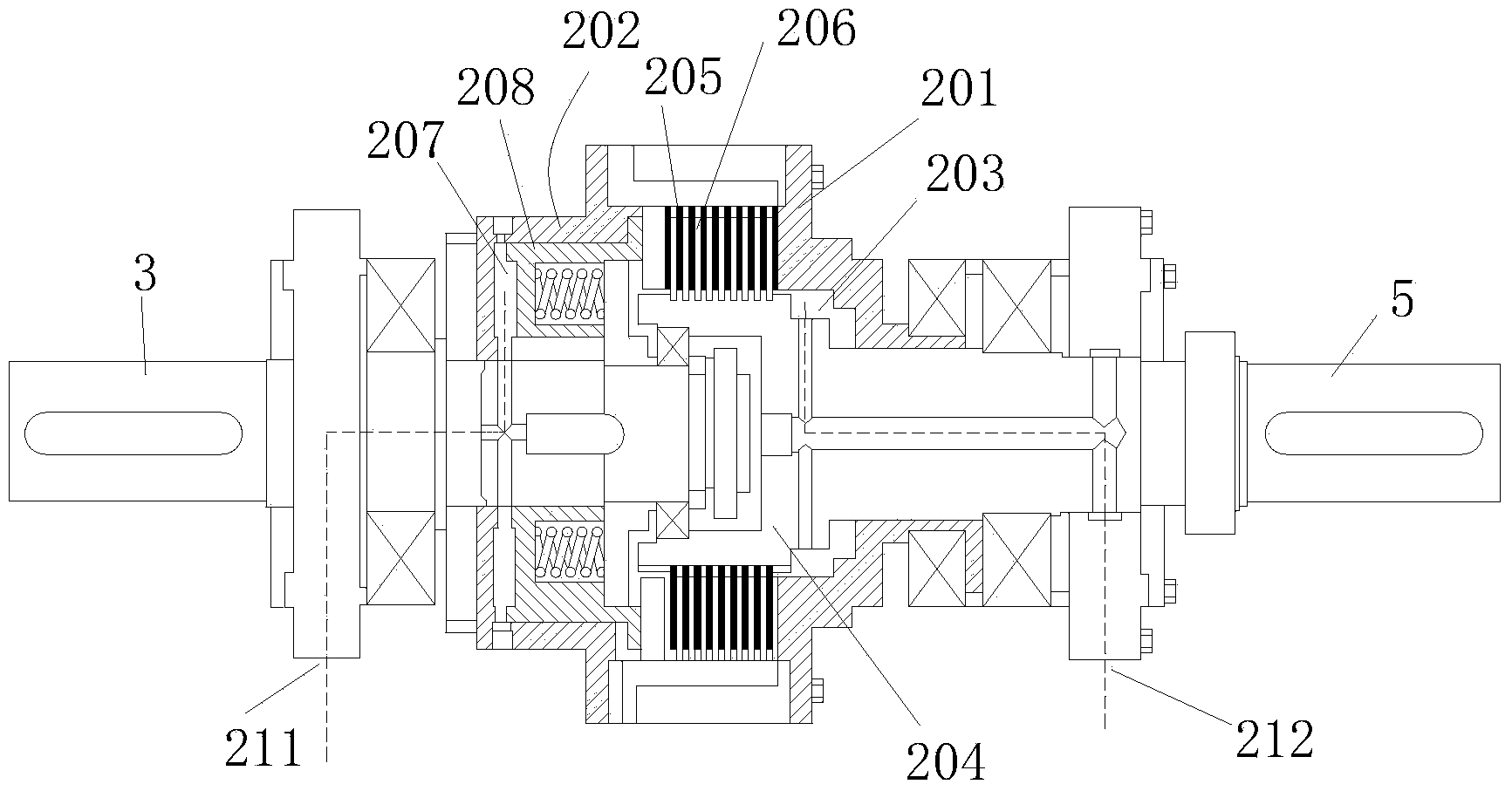

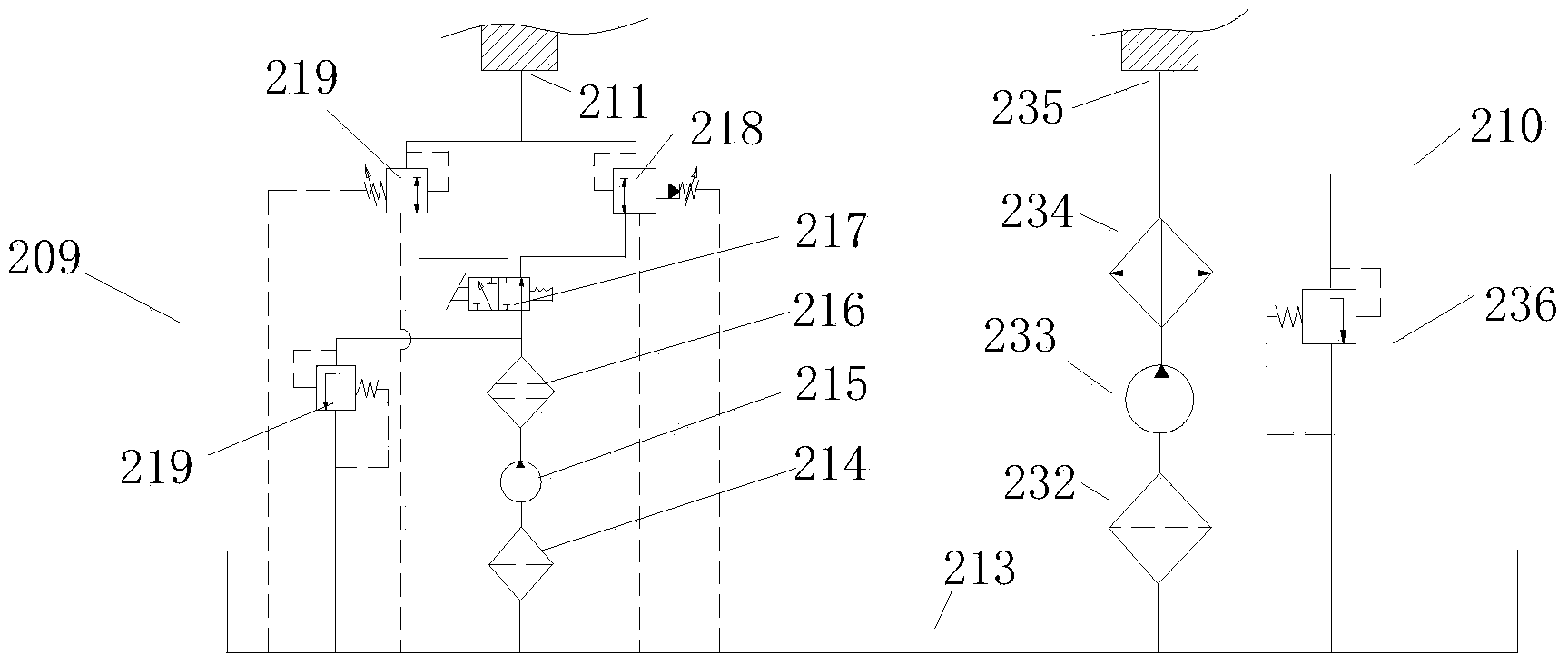

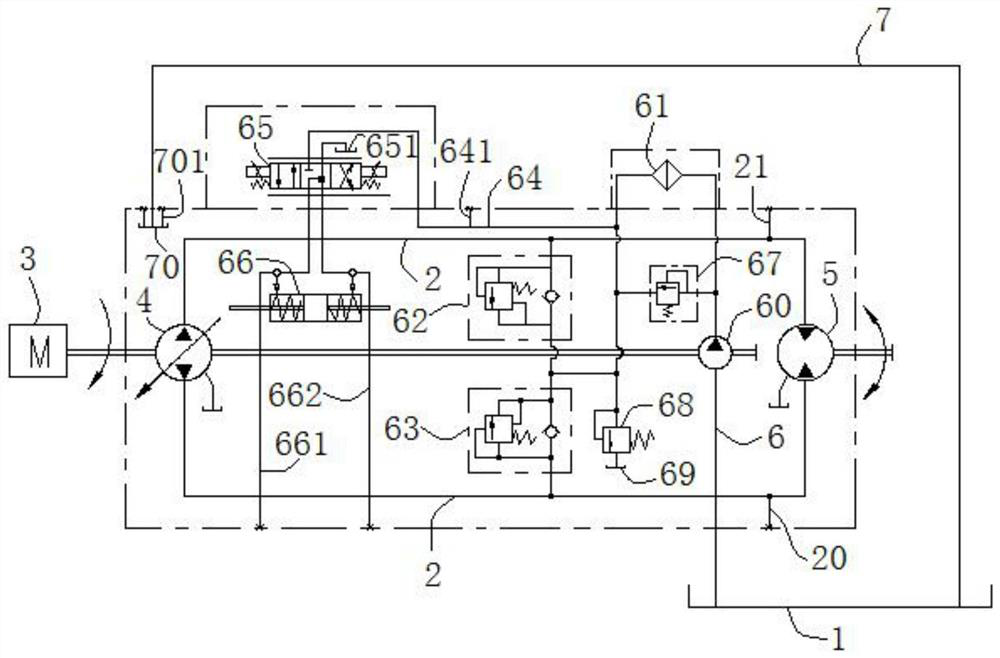

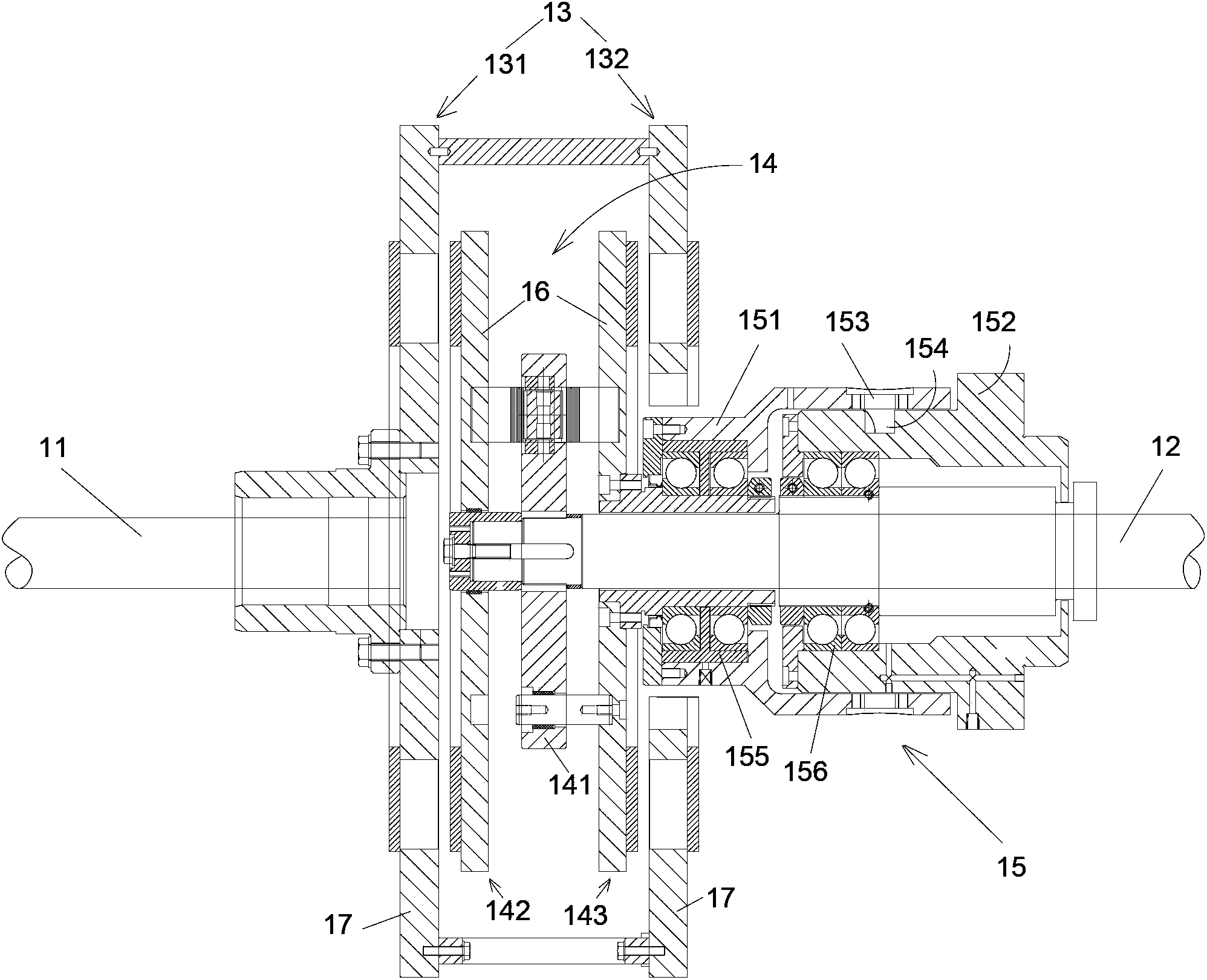

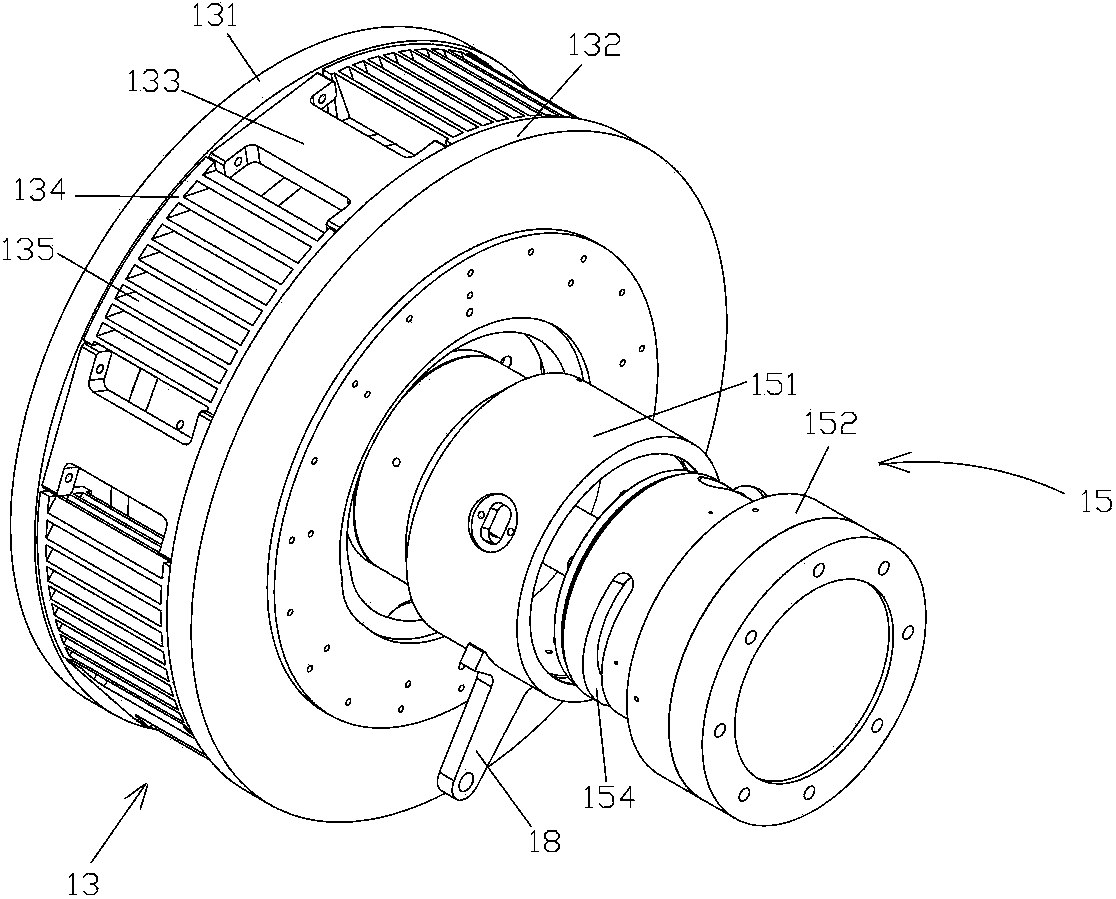

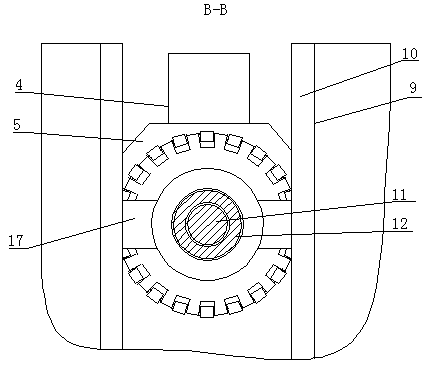

Shield tunneling machine cutterhead driving system based on hydro-viscous drive

The invention discloses a shield tunneling machine cutterhead driving system based on hydro-viscous drive. The shield tunneling machine cutterhead driving system comprises multiple groups of driving mechanisms. Each group of driving mechanism is connected with a transmitting mechanism through an input shaft, the transmitting mechanism is connected with a cutterhead driving small gear with planetary deceleration through an output shaft, and the cutterhead driving small gear is in meshed transmission with a cutterhead driving large gear to drive a cutterhead to rotate. The shield tunneling machine cutterhead driving system is characterized in that a hydro-viscous drive mechanism comprises a driving drum fixed to the input shaft and a driven drum fixed to the output shaft. The driving drum is connected with multiple groups of main friction plates through splines, the driven drum is connected with multiple groups of auxiliary friction plates through splines, and the main friction plates and the auxiliary friction plates are arranged in a cross mode. A piston cavity is formed in the driving drum, a piston is arranged in the piston cavity, and the piston can drive the main friction plates to adjust the gaps between the main friction plates and the auxiliary friction plates. The shield tunneling machine cutterhead driving system based on the hydro-viscous drive has the advantages of being stepless in speed regulation, large in driving power, excellent in impact resistance and good in overload protection performance.

Owner:ZHEJIANG UNIV

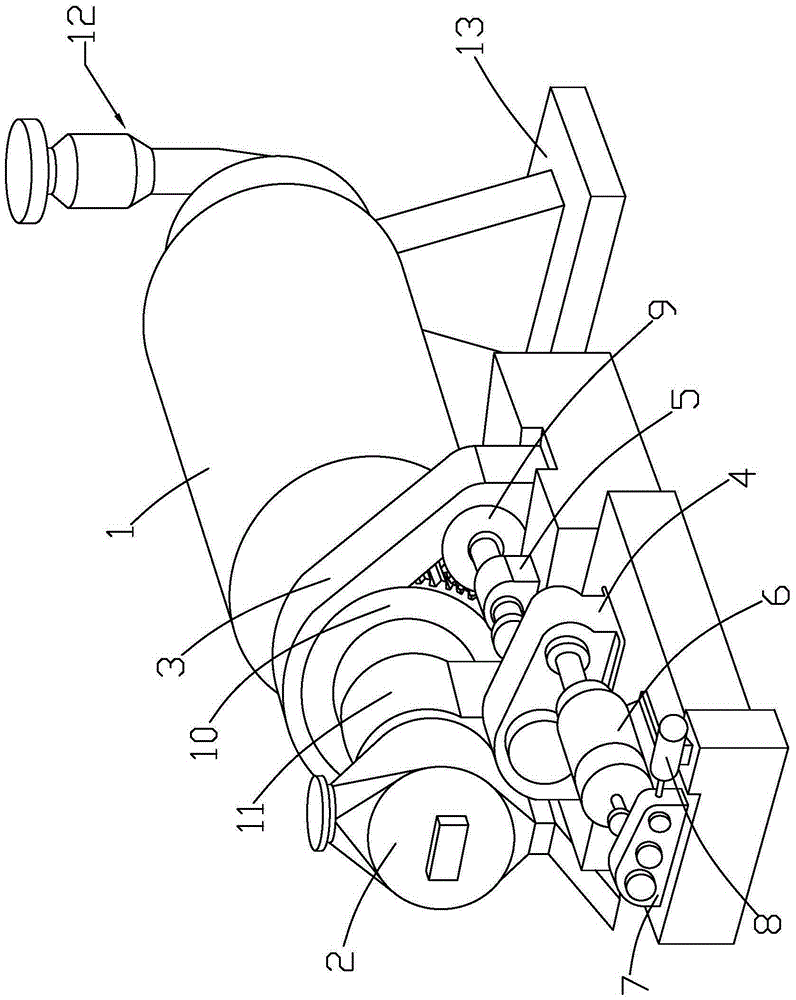

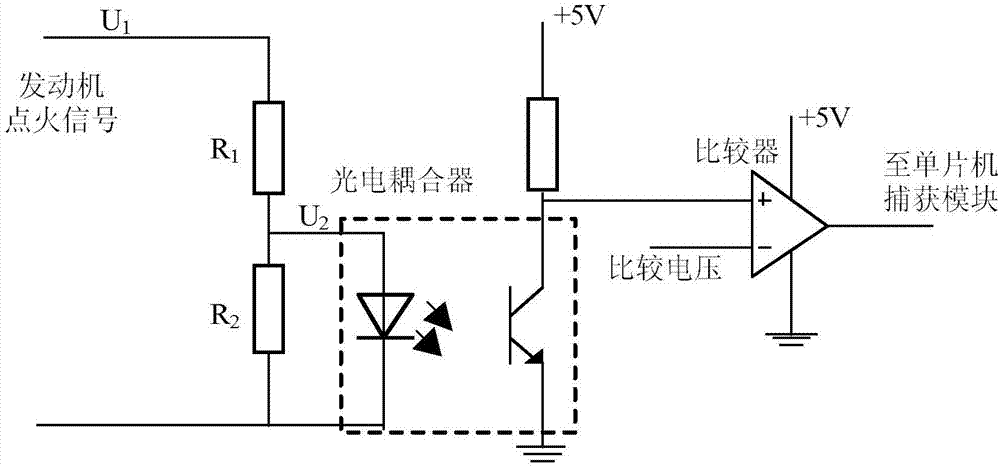

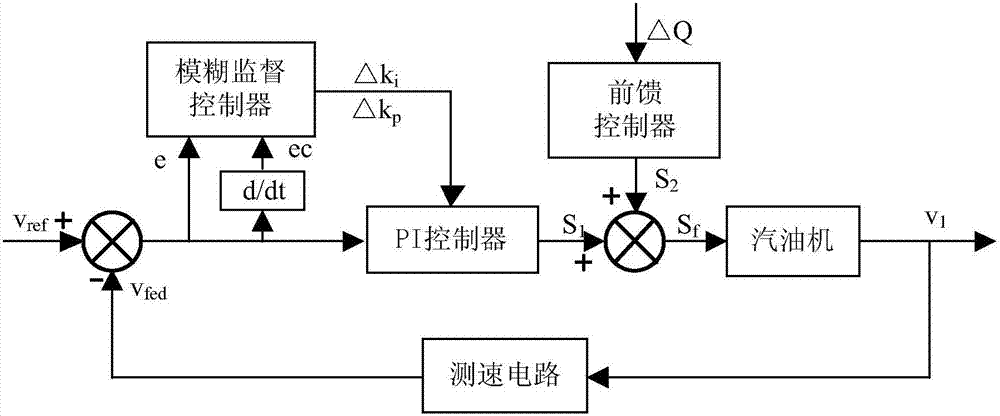

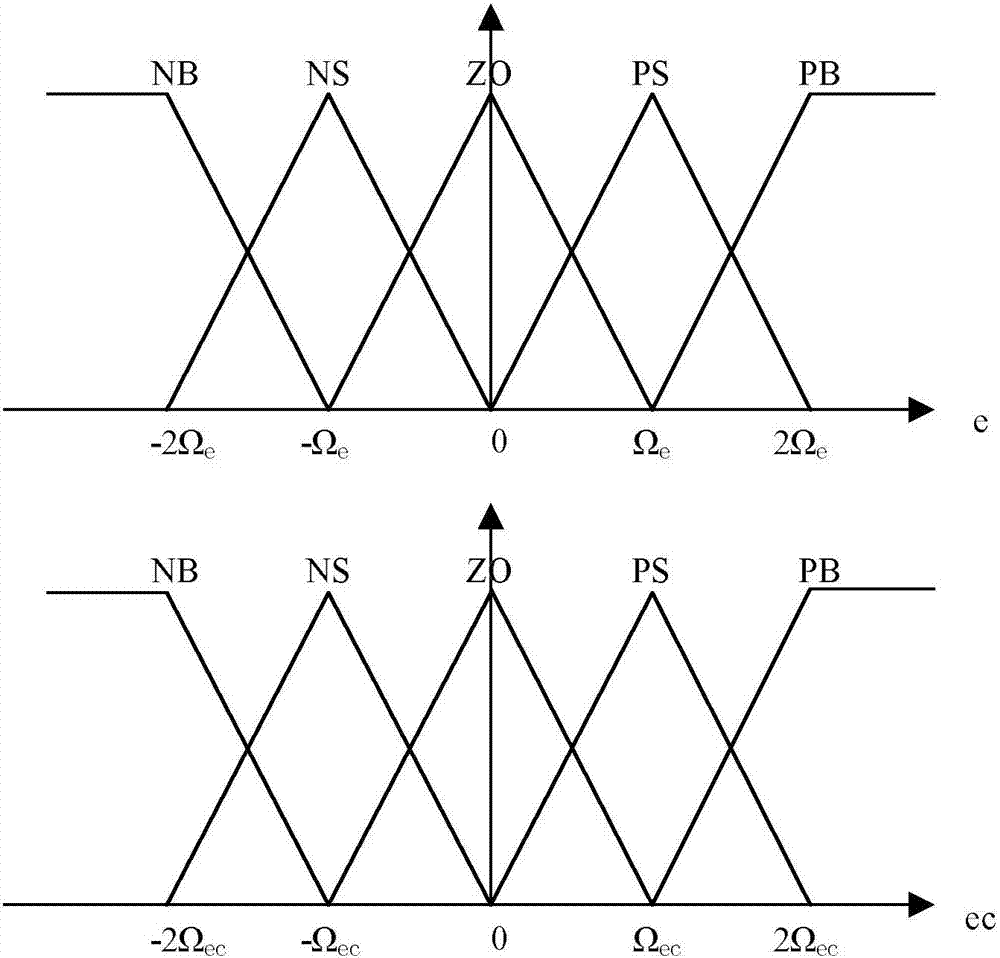

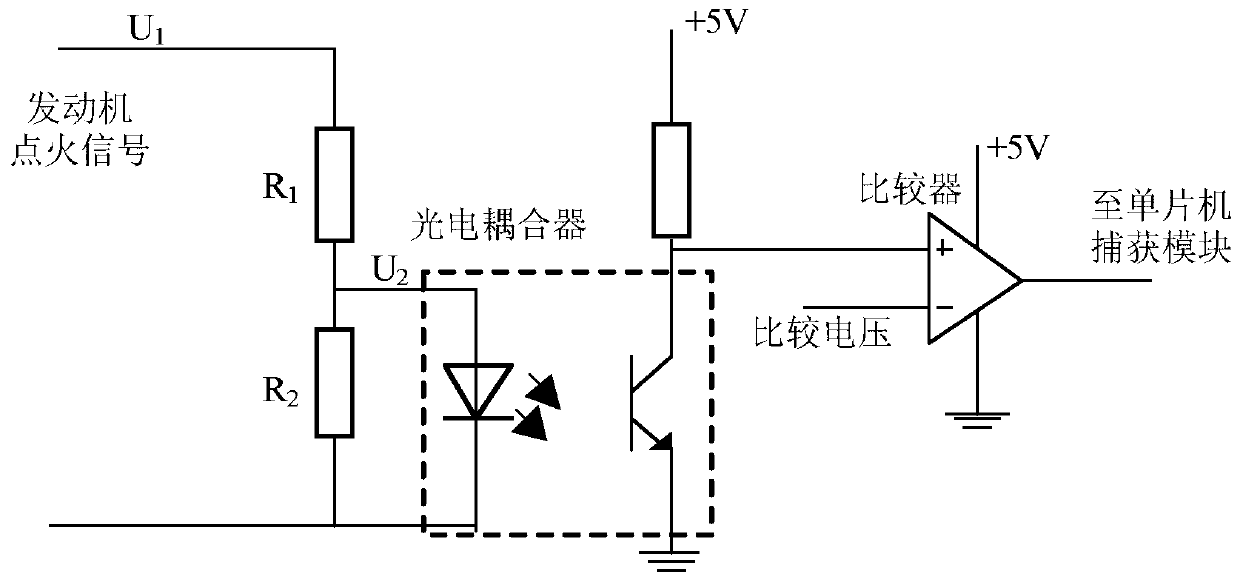

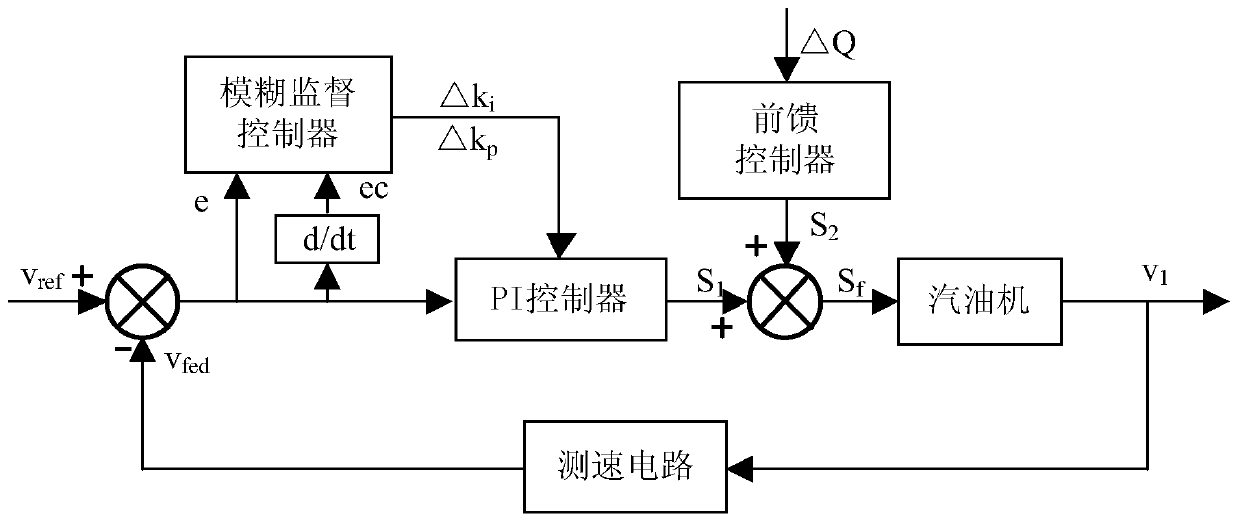

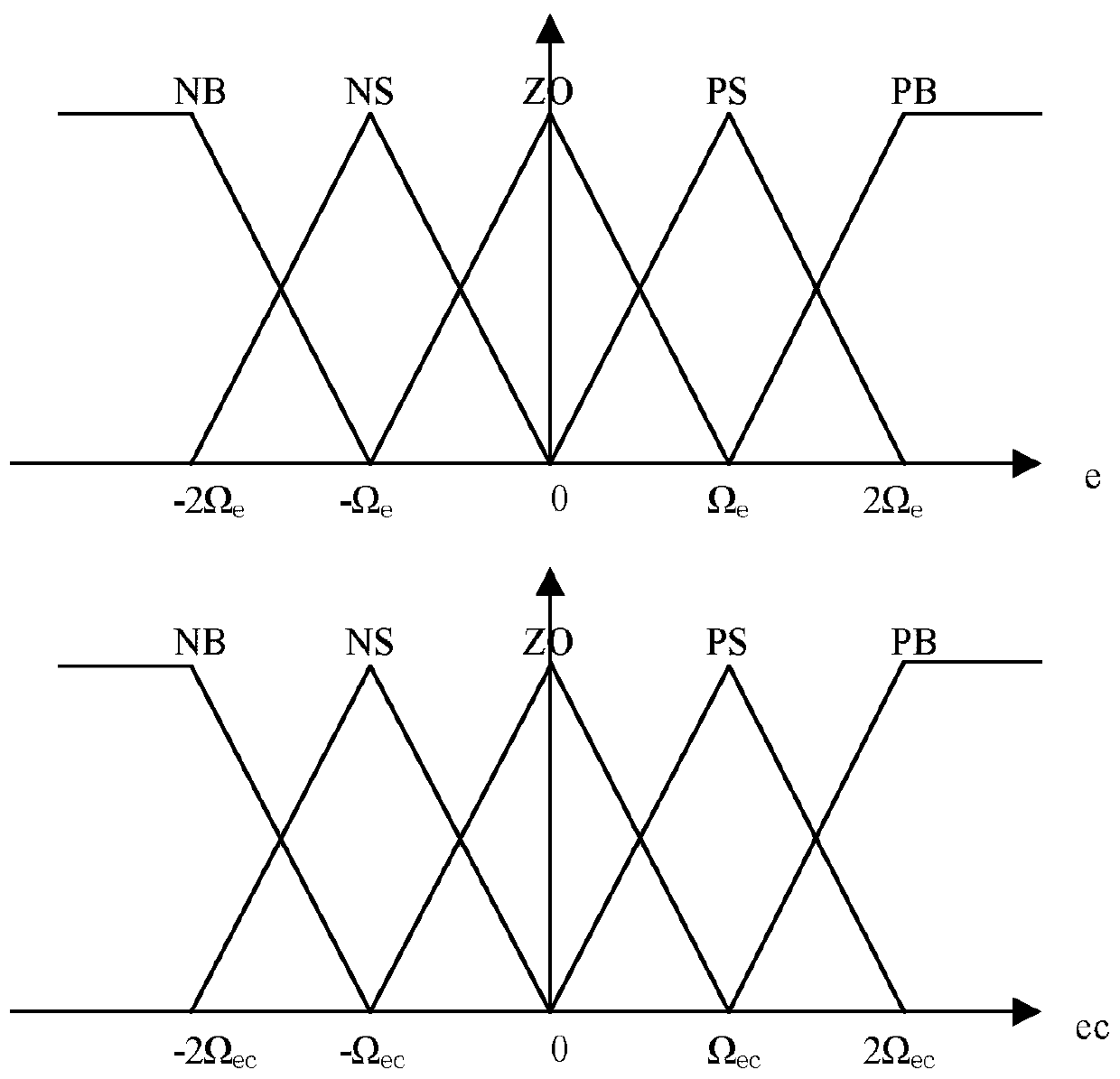

Servo control method for gasoline engine speed in hydraulic system of legged robot

ActiveCN106870181AStable speedReduce speed fluctuationElectrical controlSpeed sensing governorsLegged robotGasoline

The invention provides a servo control method for the gasoline engine speed in a hydraulic system of a legged robot. The servo control method comprises the following steps: (1) calculating the engine speed error e and the engine speed error change rate ec; (2), after the fuzzy logic calculation of e and ec, outputting the proportionality coefficient increment delta kp and the integral coefficient increment delta ki; (3) calculating the proportionality coefficient and the integral coefficient according to the following formulas correspondingly: kp = kp0 + delta kp and ki = ki0 + delta ki; (4) calculating the accelerator opening degree according to the following formula: S1 = S1_old + kp*ec + ki*e; (5) calculating the accelerator opening degree change caused by the hydraulic oil flow rate change according to the following formula: S2 = kQ*detal Q; and (6) calculating the final accelerator opening degree Sf = S1 + S2, wherein the rotation of a steering engine is controlled through the accelerator opening degree in the PWM form, the air inlet volume is controlled by controlling the opening degree of an engine throttle valve through an accelerator cable, and finally the engine speed is controlled. The servo control method provided by the invention has the advantages that the feedforward control is adopted, so that the stable engine speed can be guaranteed well under the circumstance that the flow rate changes suddenly; parameters are modified online by adoption of fuzzy self-tuning, so that the different control requirements can be met; and accordingly, the hydraulic system can have the good dynamic property and static property.

Owner:SHANDONG UNIV

Wastewater filtering and purifying device

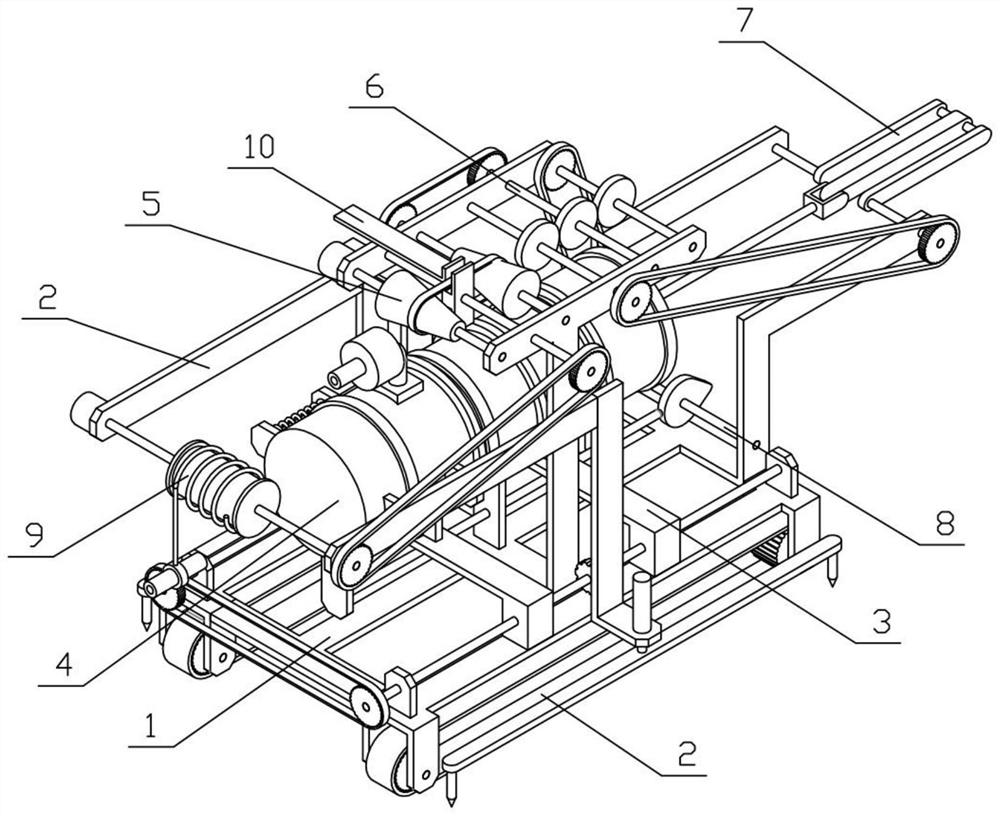

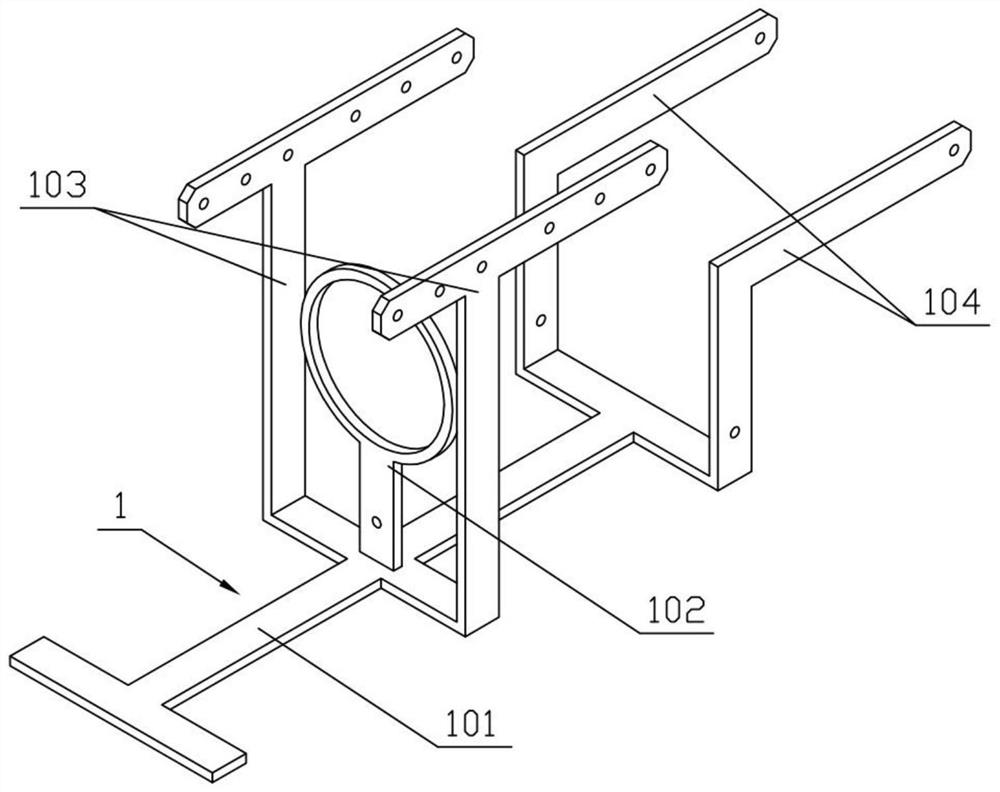

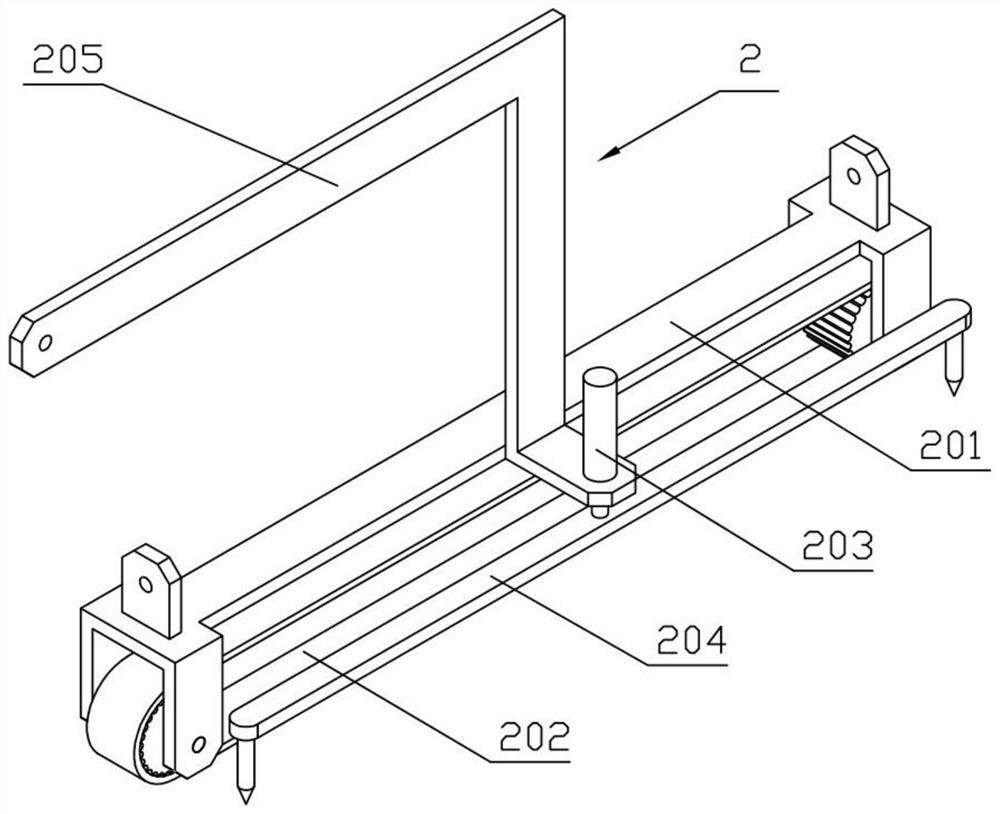

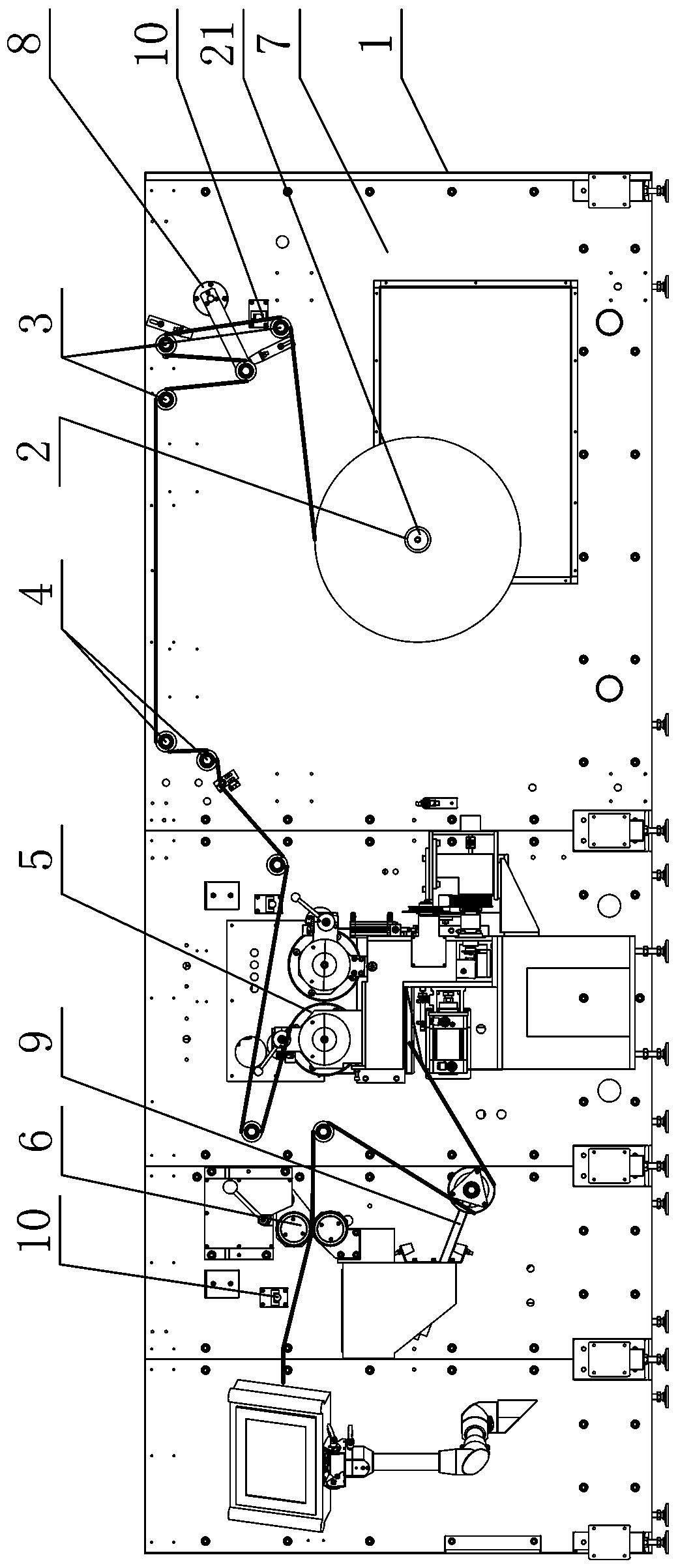

InactiveCN112604362AControl output speedControl work speedFiltration separationWastewaterEnvironmental protection

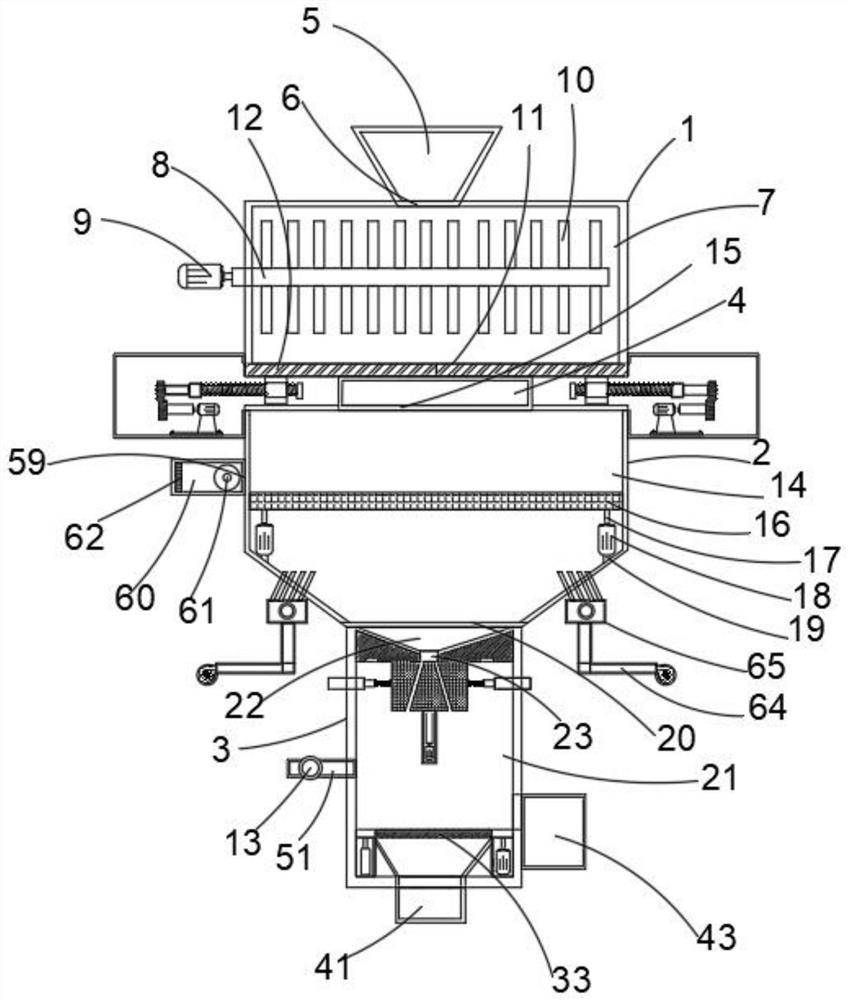

The invention relates to a purifying device, in particular to a wastewater filtering and purifying device, which comprises a device support, a moving mechanism, a detaching mechanism, a purifying mechanism, a power mechanism, a transmission mechanism, an extruding mechanism, a pushing mechanism, a retracting and releasing mechanism and a speed changing mechanism. The transmission mechanism can be driven by the power mechanism to move, the transmission mechanism drives the extruding mechanism and the pushing mechanism to move, the extruding mechanism extrudes pollutants in the purification mechanism to separate insoluble pollutants from water, and when the pushing mechanism moves to the front end limit position, the pushing mechanism pushes the purification mechanism to be opened, so that the pollutants separated in the purification mechanism are discharged out of the purification mechanism. The retracting and releasing mechanism releases the water pumping pipeline to different depths, then the speed change mechanism is controlled to move, the speed change mechanism controls the output speed of the power mechanism, then the working speed of the extruding mechanism and the pushing mechanism is controlled, and therefore the use requirement for increasing insoluble substances in waste water in deep water is met.

Owner:HARBIN UNIV

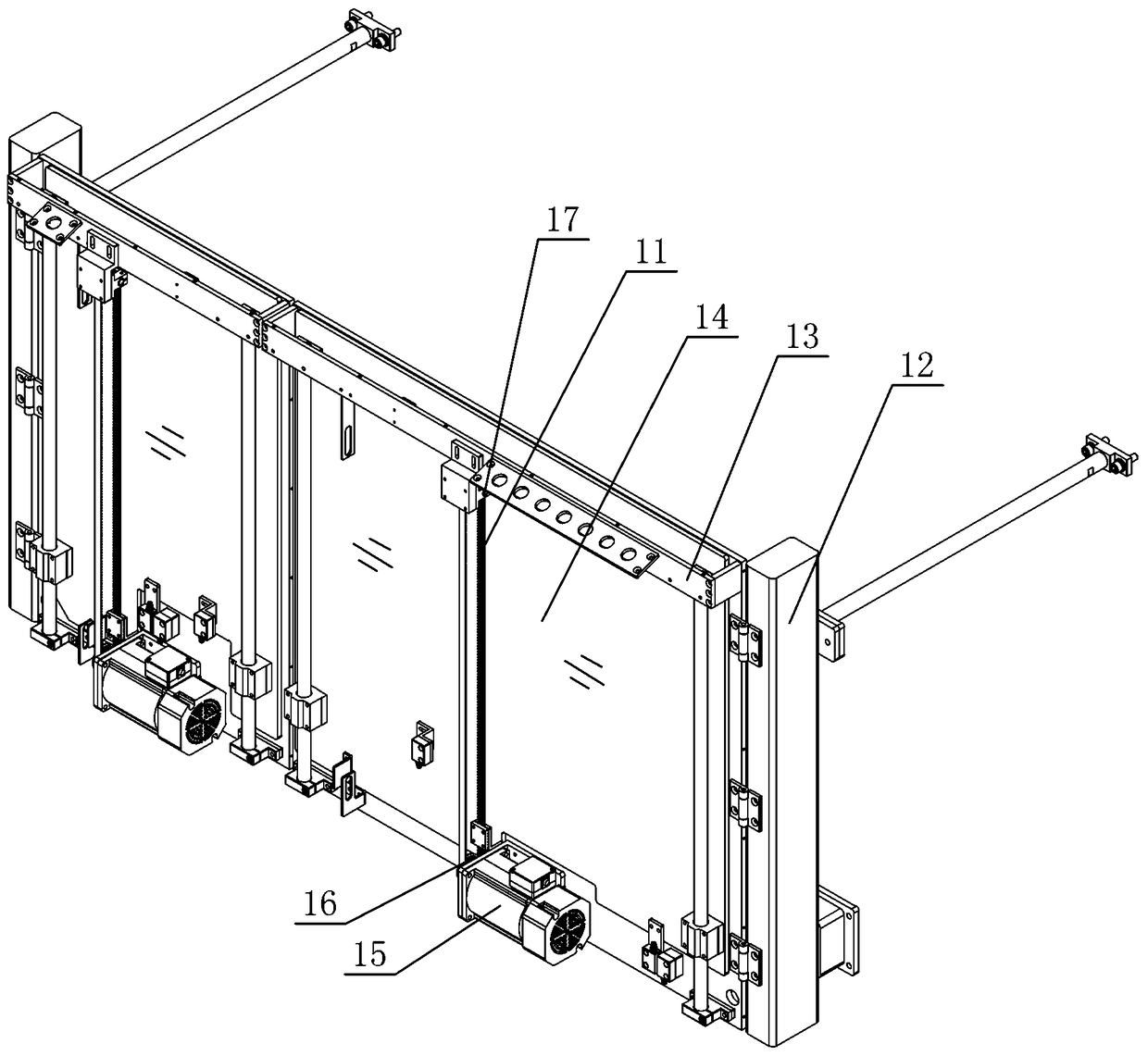

Sheet PLA composite press cutting machine

ActiveCN108657852AMeet the needs of the cooling sectionWon't cut offTobacco smoke filtersElectrostatic chargesCombustionCoil procedure

The invention provides a sheet PLA composite press cutting machine comprising a box, a safety door, an uncoiling device, a conveying roller group, a reversing roller group, a forming device and an outputting roller group. Continuous uncoiling action of a sheet PLA composite is achieved through the uncoiling device. The sheet PLA composite is conveyed to the forming device through the conveying roller group. The forming device cuts the sheet PLA composite into strips which are apparently separated but actually connected, or the forming device presses strip-shaped indentations on the sheet PLA composite, or the forming device wrinkles the sheet PLA composite to be zigzag; and the sheet PLA composite is made to meet the demand of a cooling section of a cigarette free of combustion at low temperature. The formed sheet PLA composite is output through the outputting roller group, and conditions are provided for follow-up coiling procedure.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD +2

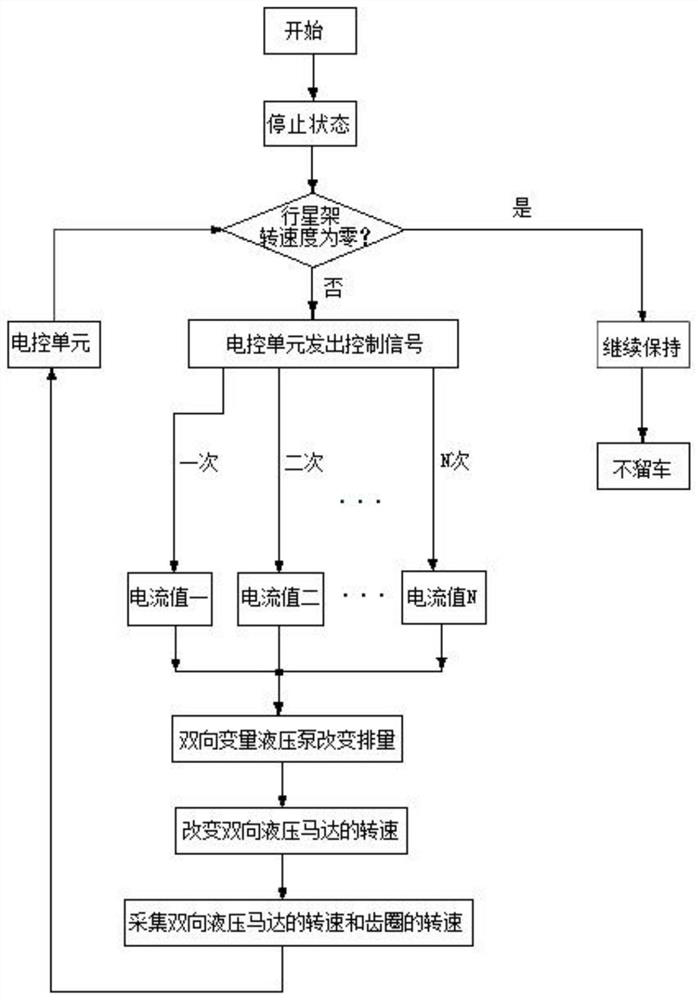

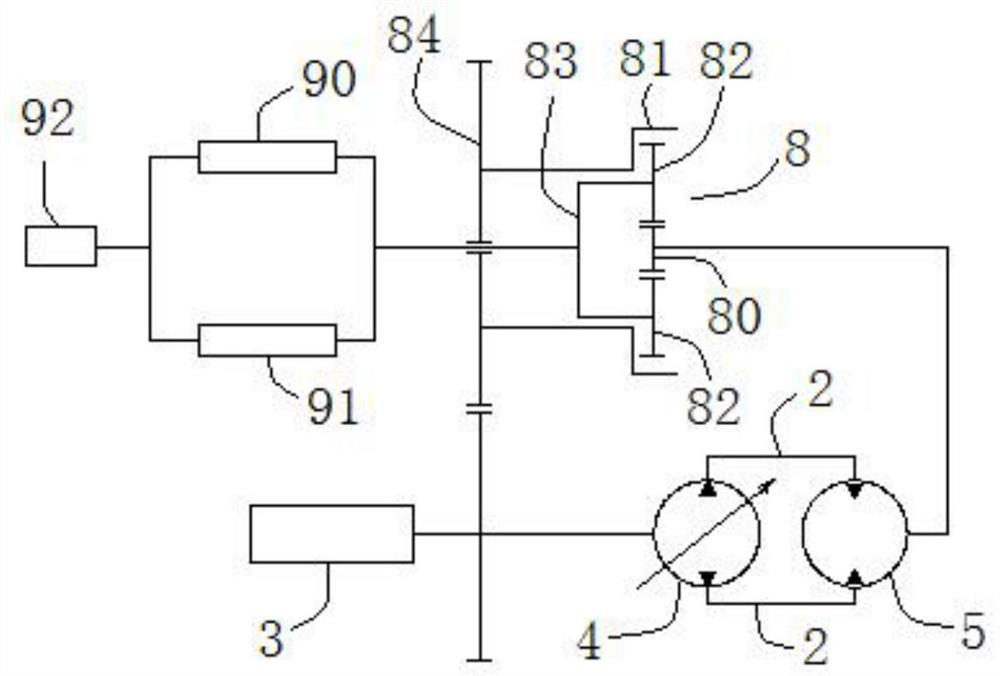

Sliding-preventing method and sliding-preventing hydraulic control system for traveling device

PendingCN111946681APrevent rolling phenomenonControl output speedServomotor componentsMowersHydraulic motorControl system

The invention discloses a sliding-preventing method and sliding-preventing hydraulic control system for a traveling device, and belongs to the technical field of hydraulic control systems. The sliding-preventing method for the traveling device includes the following steps that the hydraulic control system is arranged on the traveling device, the hydraulic control system comprises a hydraulic mainoil way, a bidirectional variable hydraulic pump, a bidirectional hydraulic motor, an electric control unit and a planet gear transmission mechanism, the planet gear transmission mechanism comprises agear ring, a sun gear, a planet gear and a planet carrier, and the gear ring, the sun gear and the planet carrier are arranged coaxially and rotationally; when the traveling device stops, the electric control unit collects the rotating speed of the bidirectional hydraulic motor and the rotating speed of the gear ring and automatically calculates the output rotating speed of the planet carrier, and if the output rotating speed of the planet carrier is not zero, the electric control unit sends a control signal to the bidirectional variable hydraulic pump to change the displacement of the bidirectional variable hydraulic pump until the output rotating speed of the planet carrier is zero. According to the sliding-preventing method for the traveling device, the mechanical zero point can be accurately controlled, and sliding of the traveling device can be effectively prevented.

Owner:LOVOL HEAVY IND CO LTD

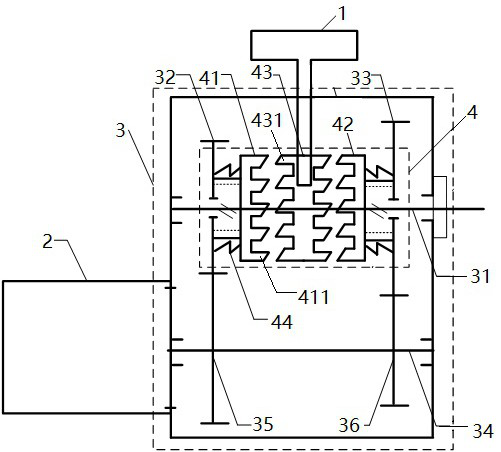

Eddy speed changer

InactiveCN103427589ASolve wasted energy consumptionEnergy rationalizationAsynchronous induction clutches/brakesEngineeringCam

The invention discloses an eddy speed changer which comprises a first rotating shaft, a second rotating shaft, a rotating outer frame, an inner rotor assembly with a central pivot turntable, a driving mechanism, two conducting rings and two magnetic rotors. The driving mechanism comprises an outer sleeve and an inner sleeve which are arranged on the second rotating shaft in a sleeved mode, a cam is arranged on the inner side of the outer sleeve, a groove is formed in the peripheral face of the inner sleeve, the inner sleeve is sleeved with the outer sleeve, the cam extends into the groove, the cam slides in the groove to drive the outer sleeve to move in the axial direction of the second rotating shaft, therefore, a fourth disk position is driven to make axial movement, finally, a third disk position and the fourth disk position on the outer side of the inner rotor assembly are made to move relative to a first disk position and the third disk position to change the size of a gap, and the output rotating speed is controlled. The conducting rings and the magnetic rotors are arrayed in different disk positions, so that the eddy speed changer can further meet different filed installation requirements.

Owner:SHANGHAI POTEVIO

Rice milling device for rice processing and working method thereof

InactiveCN112871251AStir wellPrevent overflowGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention discloses a rice milling device for rice processing. The rice milling device comprises a feeding mechanism, a screening mechanism and a rice milling mechanism, wherein the feeding mechanism is connected with the screening mechanism through a first feeding channel; the rice milling mechanism is arranged below the screening mechanism; the feeding mechanism comprises a feeding groove; the lower portion of the feeding groove is fixedly connected with the feeding groove through a first feeding port; a stirring shaft is transversely fixed to the interior of the feeding groove; the left end of the stirring shaft penetrates through the left side wall of the feeding groove and then is fixedly connected with a rotating motor; and a plurality of stirring blades are fixed to the stirring shaft. When the discharge flow needs to be reduced, a driving motor drives a driving wheel to rotate in the opposite direction, so that a fixed block moves towards the inner side, and a gap between two discharging plates is reduced; and the feeding speed and flow are controlled by controlling the gap between the two discharging plates, so that quantitative feeding is achieved, the overflow of brown rice is prevented, the blockage of the brown rice is avoided, and the rice milling processing quality of the brown rice is effectively guaranteed.

Owner:寿县昱奕米业股份有限公司

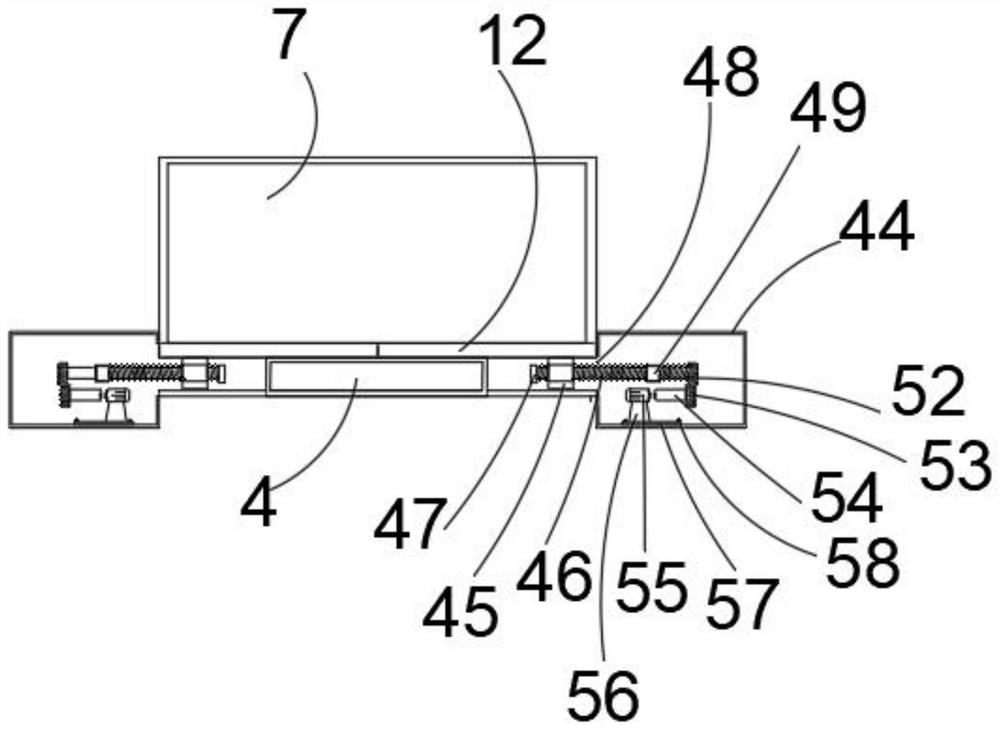

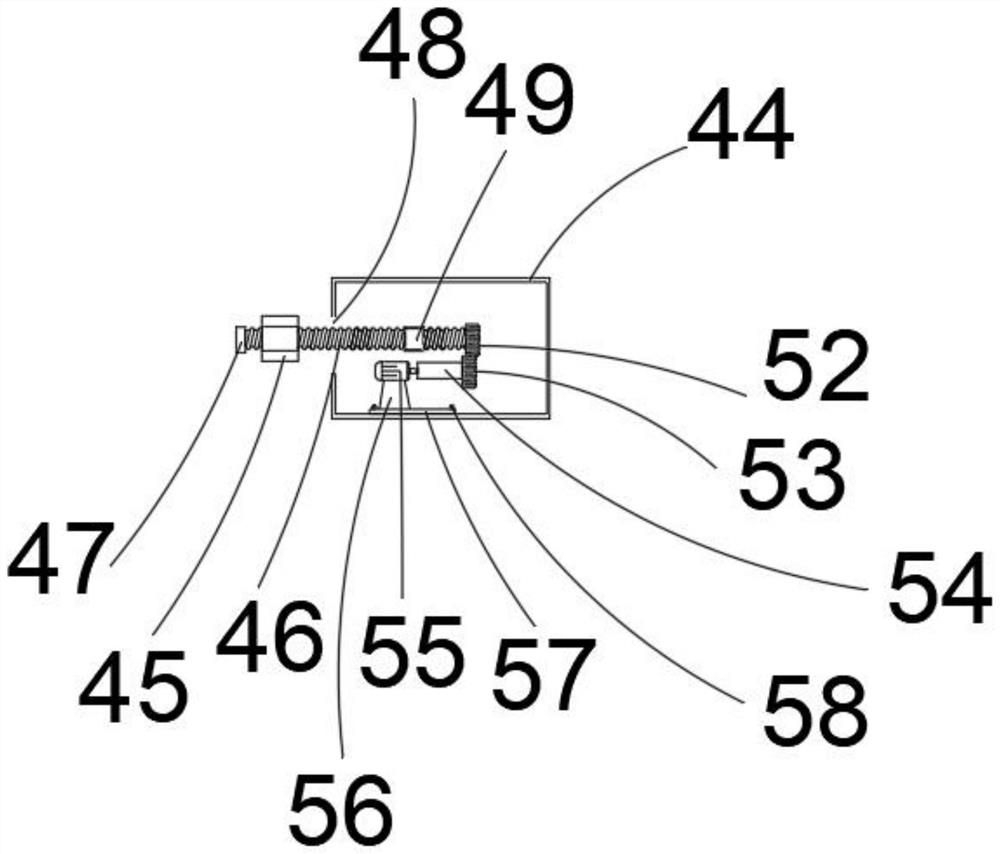

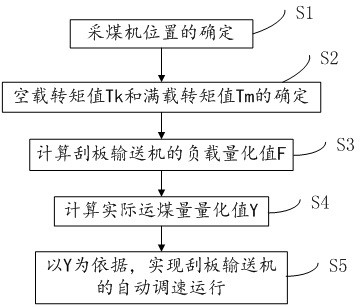

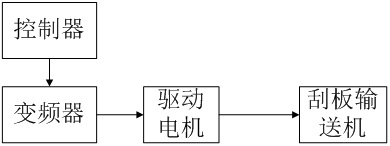

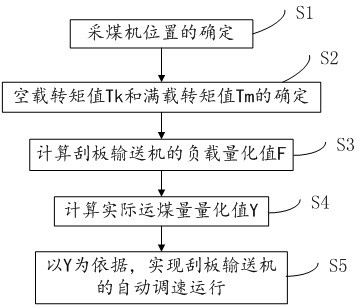

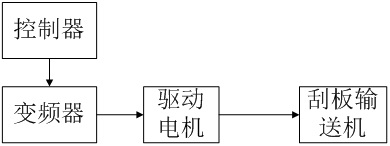

Scraper conveyor and self-adaptive speed regulating method thereof

ActiveCN111689170AImprove reliabilityControl output speedConveyorsControl devices for conveyorsSelf adaptiveProcess engineering

The invention provides a scraper conveyor and a self-adaptive speed regulating method thereof. The method comprises the steps as follows: acquiring a real-time position value of the scraper conveyor when a shearer runs; reading and recording a running torque value of a frequency converter of the scraper conveyor, and obtaining a no-load torque value and a full-load torque value of the scraper conveyor through data analysis; simulating the current coal conveying capacity of the scraper conveyor by related calculation of torque, speed and shearer position of the frequency converter; and adjusting given speed of the scraper conveyor according to the calculated coal transportation amount. Any auxiliary sensors are not required to participate in the whole speed regulation process, and reliability is higher.

Owner:QINGDAO CCS ELECTRIC CORP

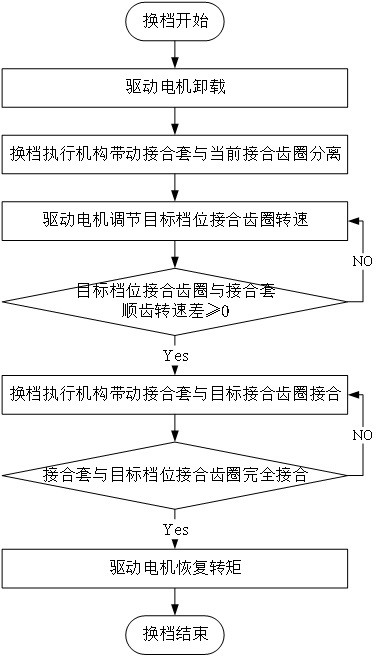

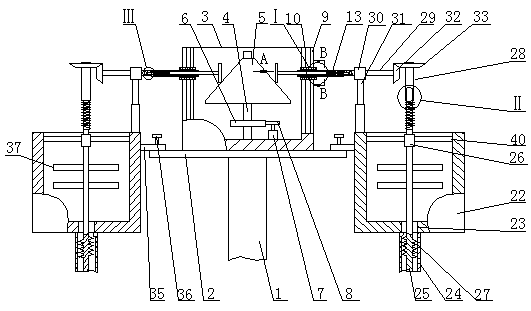

Transmission system with one-way self-adaptive joint device and gear shifting control method of transmission system

InactiveCN114877035AControl output speedShift quicklyToothed gearingsGearing controlGear driveControl engineering

The invention relates to a transmission system with a one-way self-adaptive joint device and a gear shifting control method thereof.The transmission system comprises a gear shifting executing mechanism, a driving motor, a mechanical transmission and the one-way self-adaptive joint device, and the mechanical transmission comprises a power input unit with a change gear and a power output unit; the one-way self-adaptive joint device comprises a first joint gear ring, a second joint gear ring and a joint sleeve, the joint gear ring is in transmission connection with a speed change gear corresponding to the power output unit, and the joint sleeve is fixedly connected with the power output shaft and is pushed by the gear shifting execution mechanism to be jointed with the first joint gear ring or the second joint gear ring. The gear shifting control method comprises the steps of unloading, gear disengagement, gear engagement and torque recovery of the driving motor. The driving motor can control the joint gear ring to be matched with the rotating speed of the target gear, and then the gear shifting executing mechanism pushes the joint sleeve to be in butt joint with the joint gear ring at the rotating speed of the target gear, so that rapid gear shifting is achieved, and impact force of gear shifting is effectively buffered.

Owner:TSINGHUA UNIV

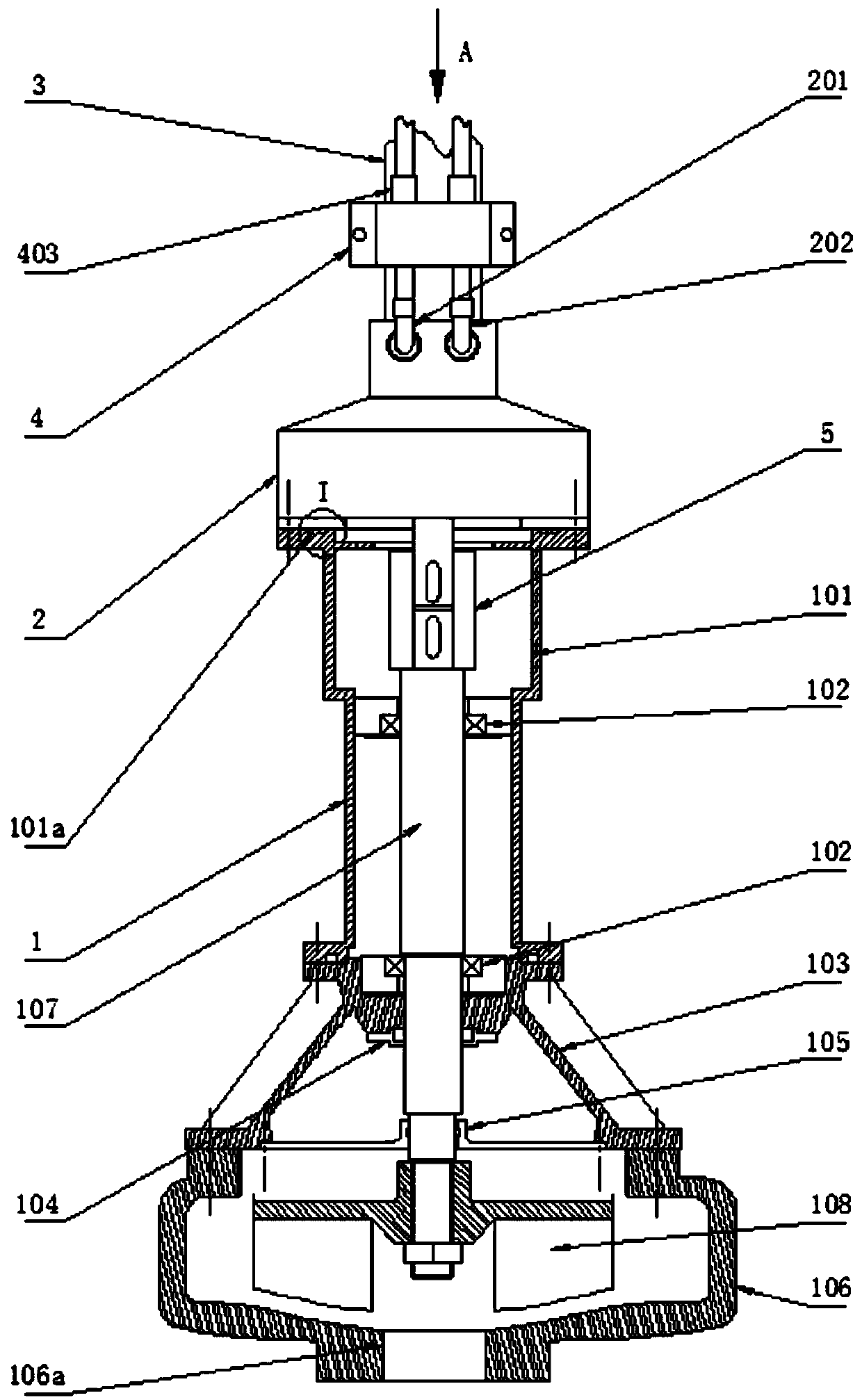

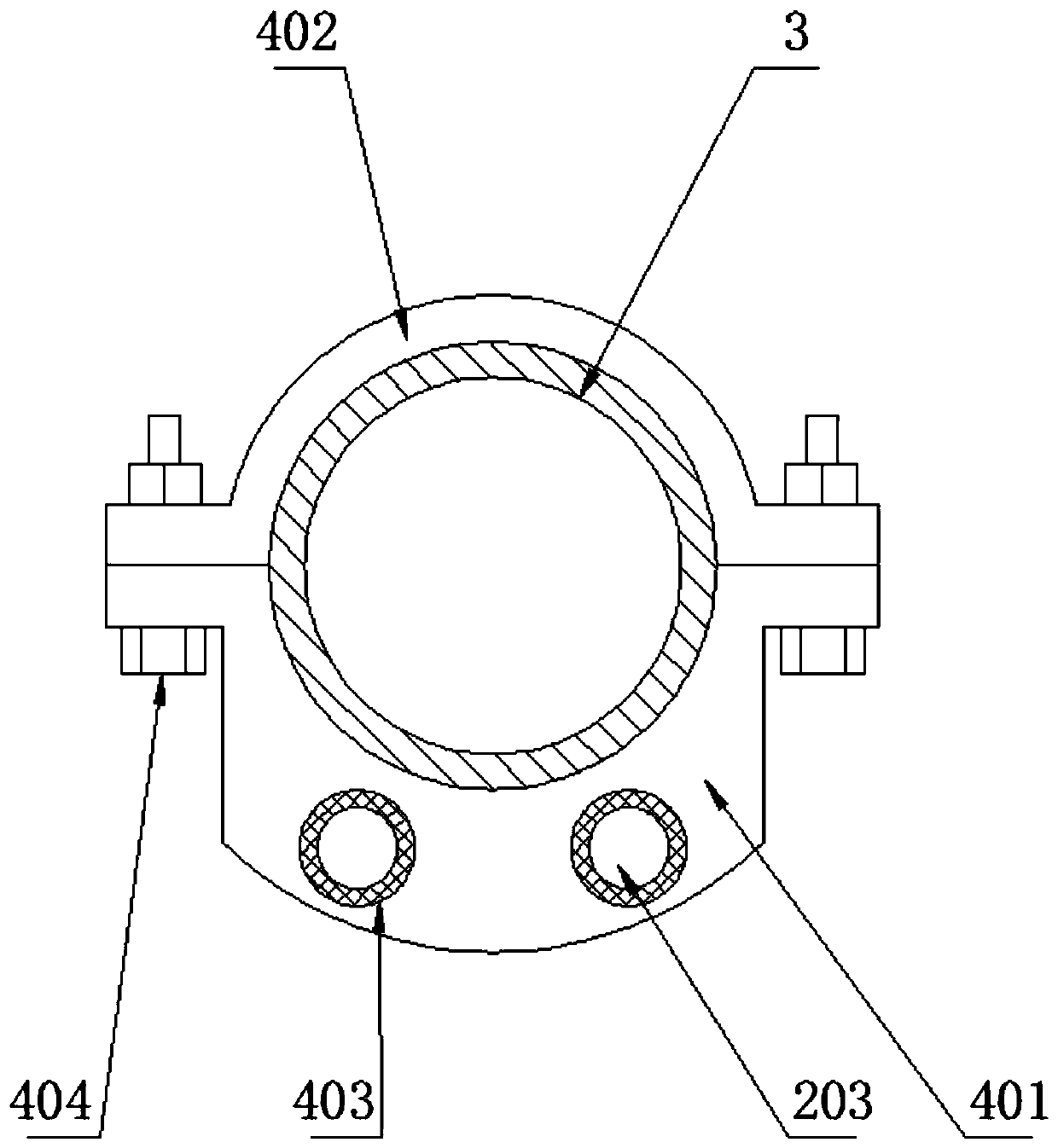

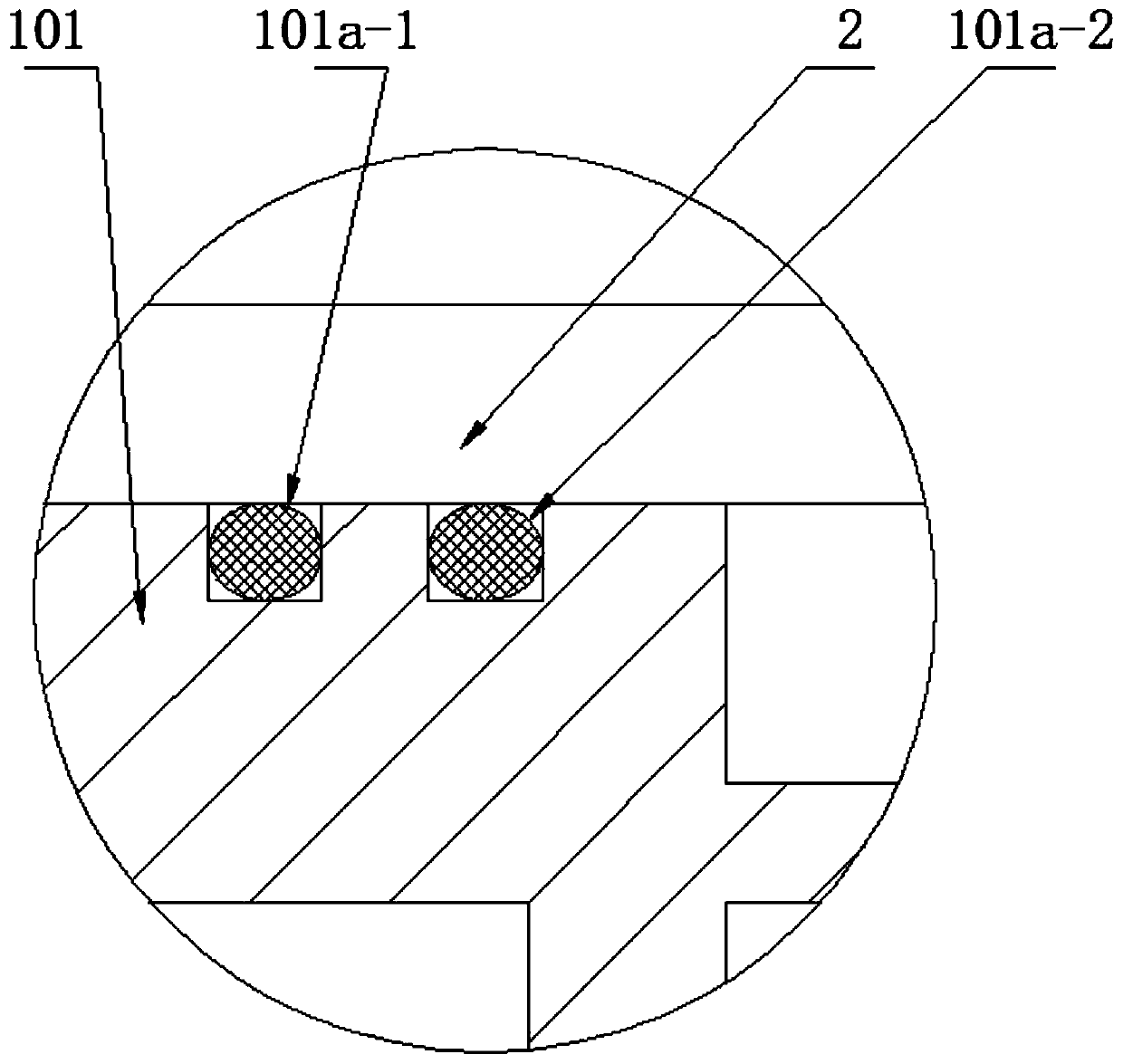

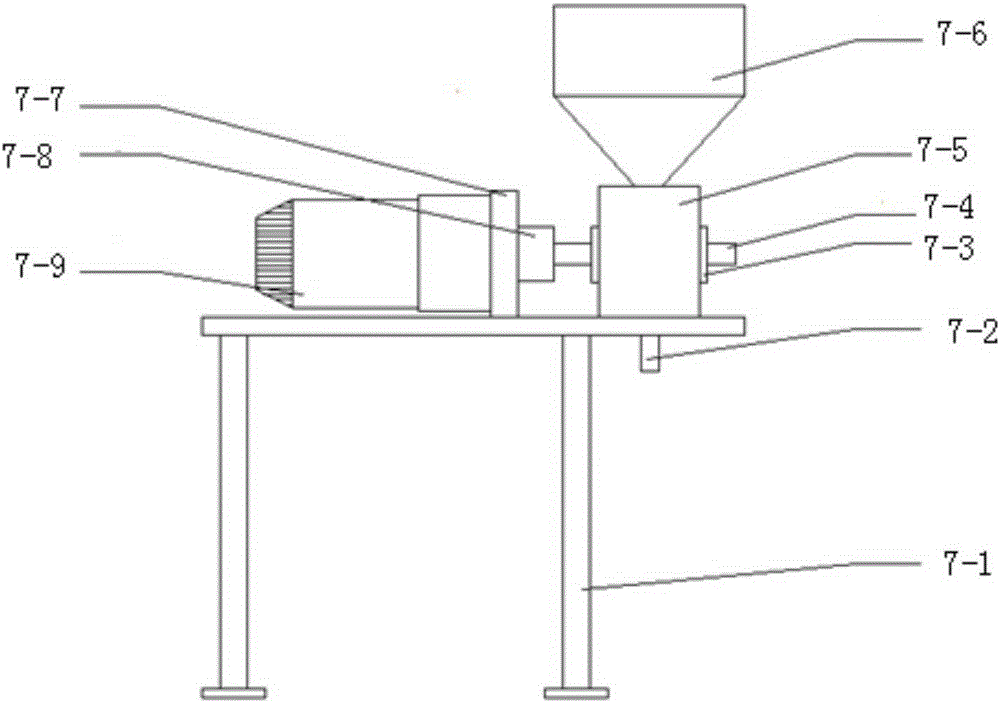

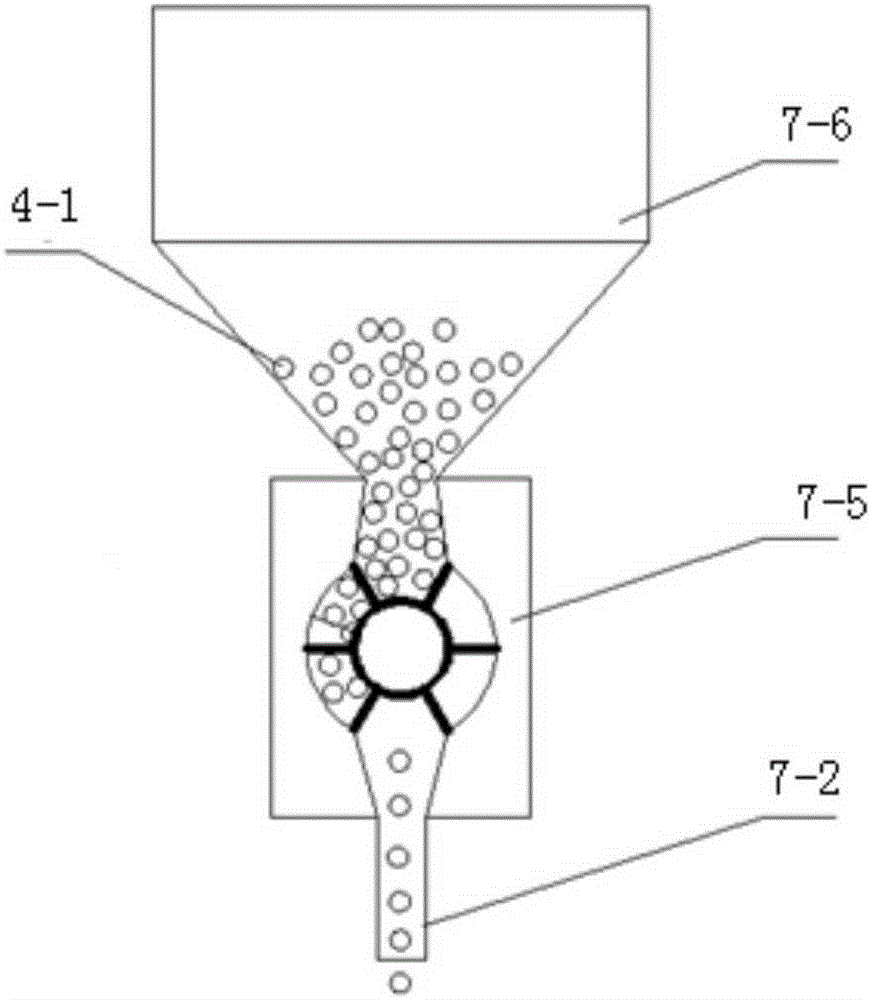

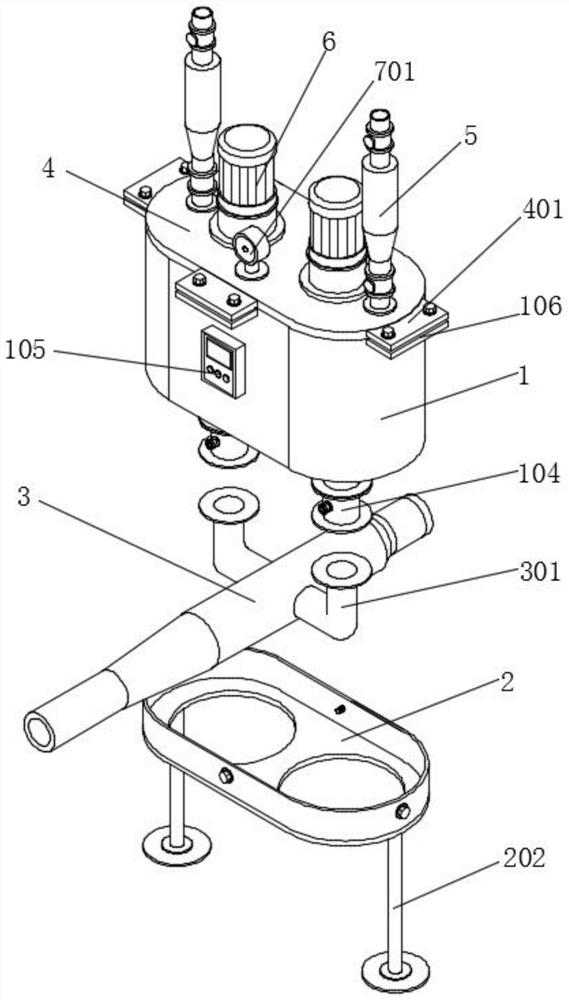

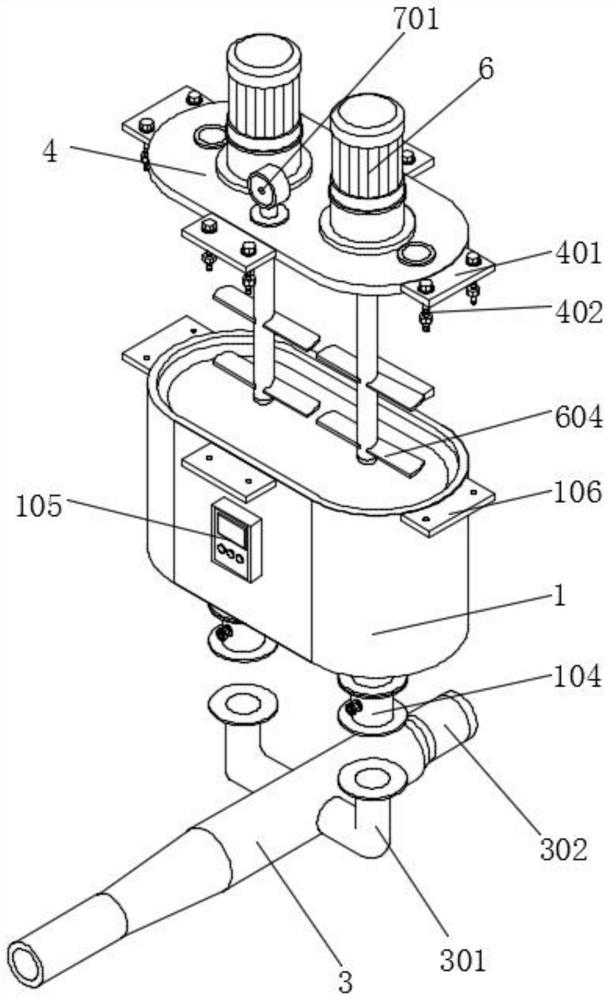

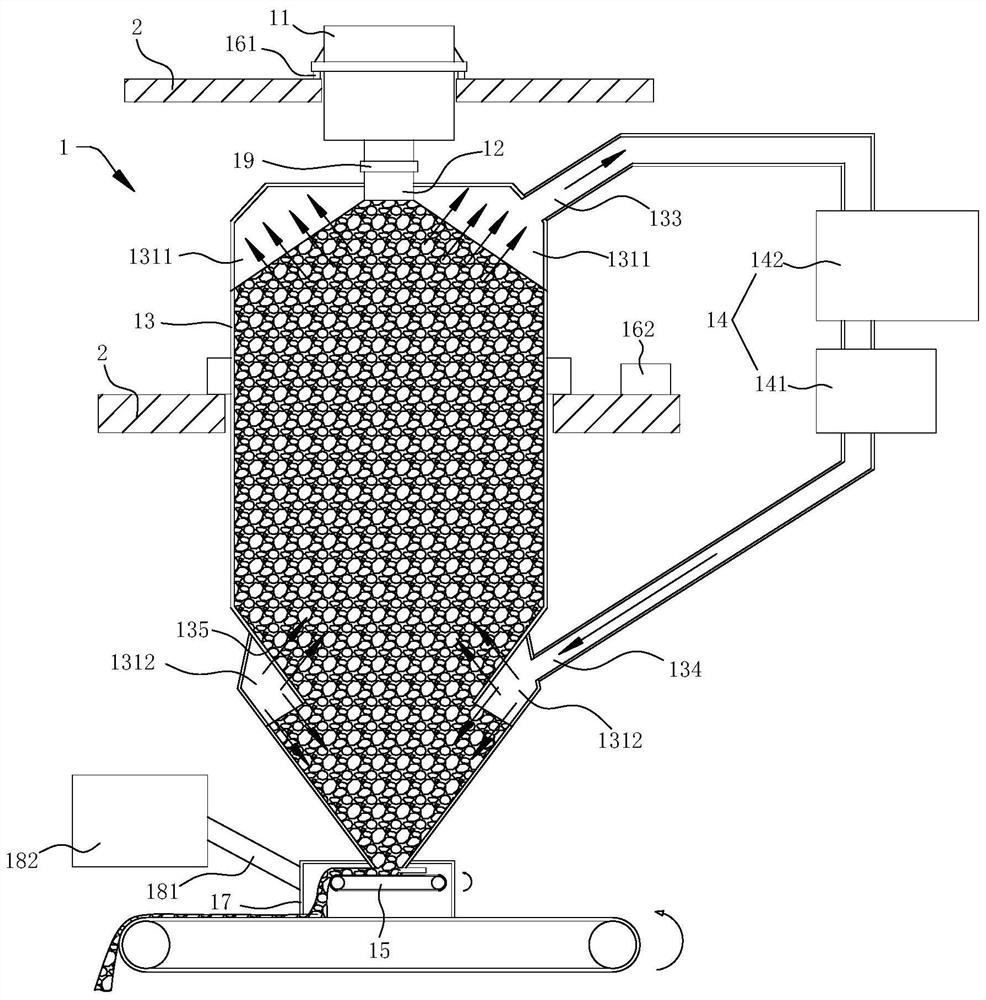

Auxiliary material supply synchronizing mechanism of metal powder additive manufacturing equipment

The invention discloses an auxiliary material supply synchronizing mechanism of metal powder additive manufacturing equipment. The auxiliary material supply synchronizing mechanism comprises a frame body, a disc-shaped transverse mounting plate is fixedly installed on the upper portion of the frame body, a barrel body is fixedly installed in the middle of the top of the mounting plate, a first vertical shaft is installed in the middle of the bottom of the barrel body, the lower end of the first vertical shaft is movably connected with a bottom bearing in the barrel body, a conical roller fixedly sleeves the position, close to the upper end, of the first vertical shaft, the small-diameter end of the conical roller faces upwards, the lower end of the first vertical shaft is fixedly sleeved with a driven gear, the inner bottom of the barrel body is fixedly provided with a vertical power motor, an output shaft of the power motor is fixedly provided with a driving gear, and the driving gearis matched with the driven gear in a meshed mode. According to the auxiliary material supply synchronizing mechanism, the output speeds of metal powder particles in different material cylinders can be linearly controlled through adjustment of corresponding electric telescopic rods, and the whole mechanism only needs one power motor to provide the power; and therefore, the auxiliary material supply synchronizing mechanism is simple in structure and convenient to use.

Owner:HUNAN UNIV OF SCI & TECH

An auxiliary material supply synchronization mechanism for metal powder additive manufacturing equipment

The invention discloses an auxiliary material supply synchronizing mechanism of metal powder additive manufacturing equipment. The auxiliary material supply synchronizing mechanism comprises a frame body, a disc-shaped transverse mounting plate is fixedly installed on the upper portion of the frame body, a barrel body is fixedly installed in the middle of the top of the mounting plate, a first vertical shaft is installed in the middle of the bottom of the barrel body, the lower end of the first vertical shaft is movably connected with a bottom bearing in the barrel body, a conical roller fixedly sleeves the position, close to the upper end, of the first vertical shaft, the small-diameter end of the conical roller faces upwards, the lower end of the first vertical shaft is fixedly sleeved with a driven gear, the inner bottom of the barrel body is fixedly provided with a vertical power motor, an output shaft of the power motor is fixedly provided with a driving gear, and the driving gearis matched with the driven gear in a meshed mode. According to the auxiliary material supply synchronizing mechanism, the output speeds of metal powder particles in different material cylinders can be linearly controlled through adjustment of corresponding electric telescopic rods, and the whole mechanism only needs one power motor to provide the power; and therefore, the auxiliary material supply synchronizing mechanism is simple in structure and convenient to use.

Owner:HUNAN UNIV OF SCI & TECH

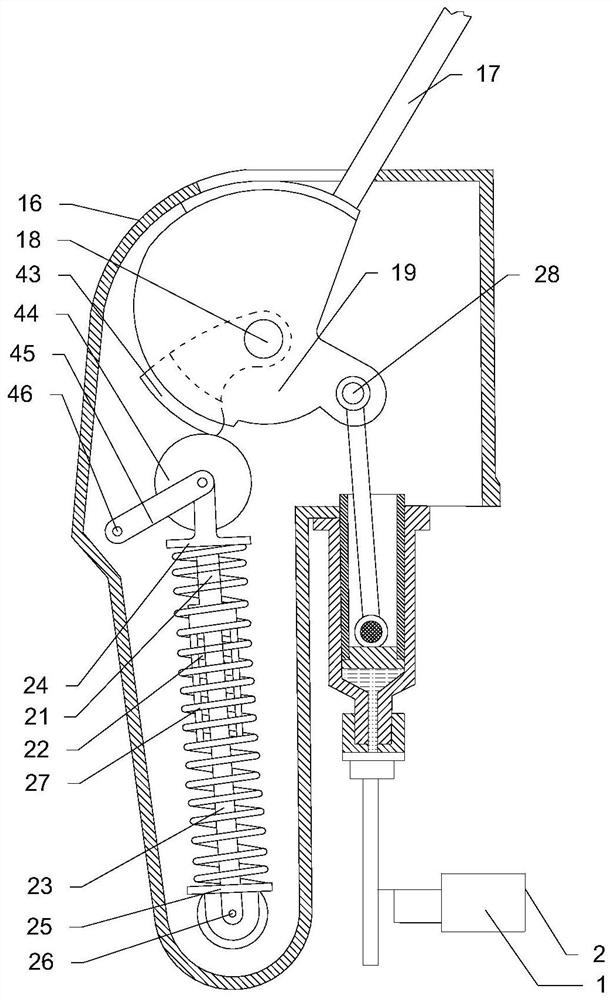

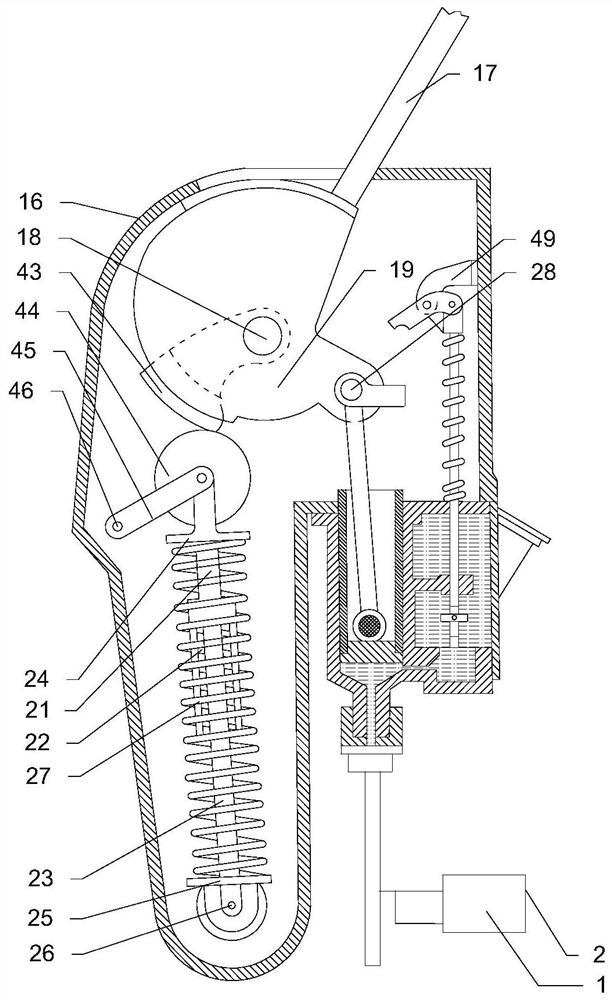

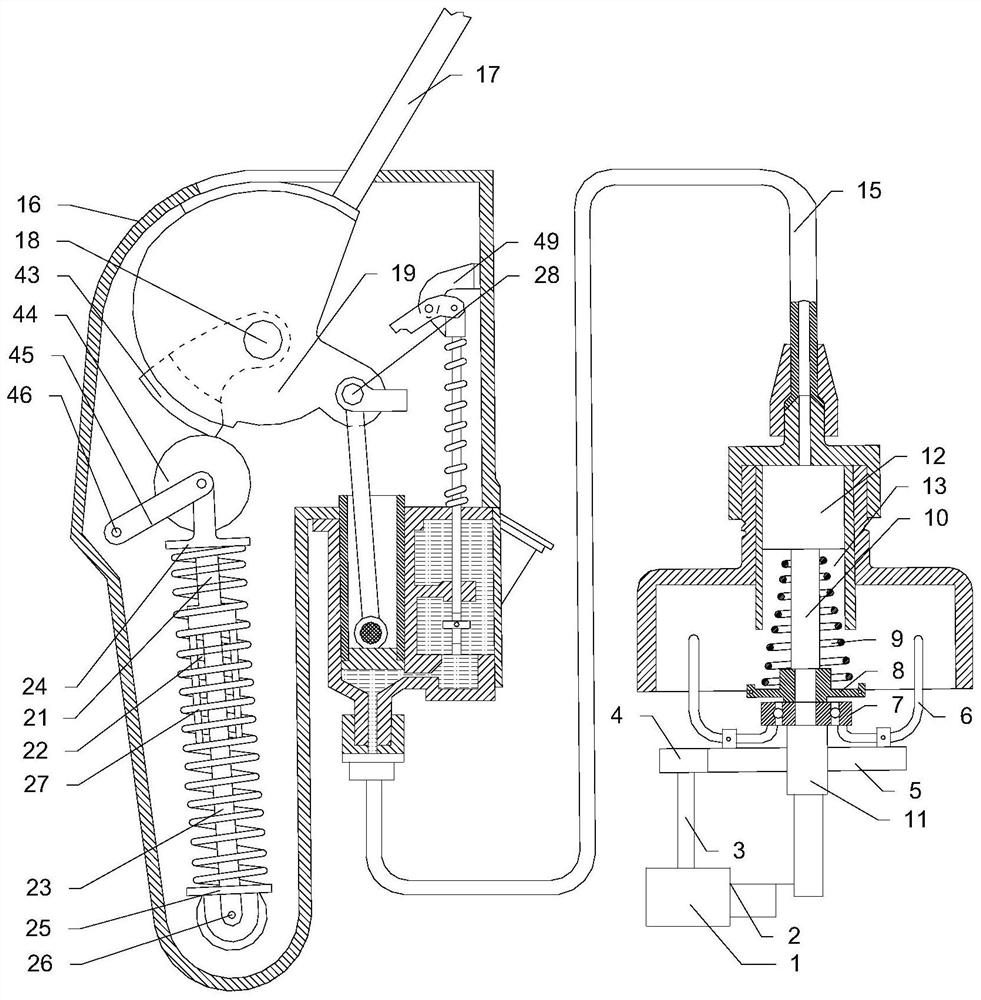

Jump pressure limiting mechanism and air braking system

ActiveCN113581148AFast outputControl output speedBraking action transmissionApplication and release valvesAir brakeEngineering

The embodiment of the invention provides a jump pressure limiting mechanism and an air braking system, and relates to the field of air braking systems. The problem that a pressure limiting structure needs to adopt a combination of two valves, and the size is large is solved. The jump pressure limiting mechanism comprises a valve body, a jump valve, an inflation valve and a pressure limiting piece; the valve body is provided with an air inlet, a first cavity, a second cavity and an air outlet; the jump valve is arranged in the first chamber; and the inflation valve is arranged in the second cavity, the jump valve and the inflation valve are both connected with the pressure limiting piece, and the pressure limiting piece is used for driving the jump valve and the inflation valve to move in the pressure change process in the pressure limiting cavity. The air braking system comprises a jump pressure limiting mechanism. When the first chamber and the second chamber are opened at the same time, the air outlet can quickly output pressure air; when the first chamber is closed and the second chamber is opened, the output speed of the air outlet can be controlled; and the first cavity and the second cavity are closed at the same time, the current pressure state of the air outlet can be kept, and therefore switching of the three pressure limiting states is achieved.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Discharging width limiting door for ball grinding mill

The invention discloses a discharging width limiting door for a ball grinding mill. The outer barrel wall of the ball grinding mill is provided with an output opening. The width limiting door which can be used for adjusting the width of the output opening in a sliding way is arranged in the output opening. After the ball grinding mill is stopped, materials and steel balls in the ball grinding mill are output together through the output opening. The width limiting door is capable of adjusting the size of the output opening, and controlling the output speed and the output quantity of the materials and the steel balls, so that stable output of the steel balls of various specifications is ensured.

Owner:TAIZHOU BOYANG AUTOMATIC EQUIP

Pneumatic pump for dredging water sump and working method of air driven pump

PendingCN110454402AEasy to control output powerControl output speedPump componentsPump installationsImpellerEngineering

The invention discloses a pneumatic pump for dredging a water sump and a working method of the pneumatic pump, and belongs to the technical field of dredging equipment. The pneumatic pump comprises amain pump body, a pneumatic motor and a coupler, wherein the pneumatic motor is fixedly mounted at the top of the main pump body through a flange, an output shaft of the pneumatic motor is connected with a main shaft of the main pump body through the coupler, and impellers used for stirring, centrifuging and outputting fluid are mounted at the tail end of the main shaft. According to the technicalscheme, the pneumatic pump can be used under the relatively complicated working conditions of the water sump, and cannot be limited by using above or below water.

Owner:河南海光兰骏矿山技术有限公司

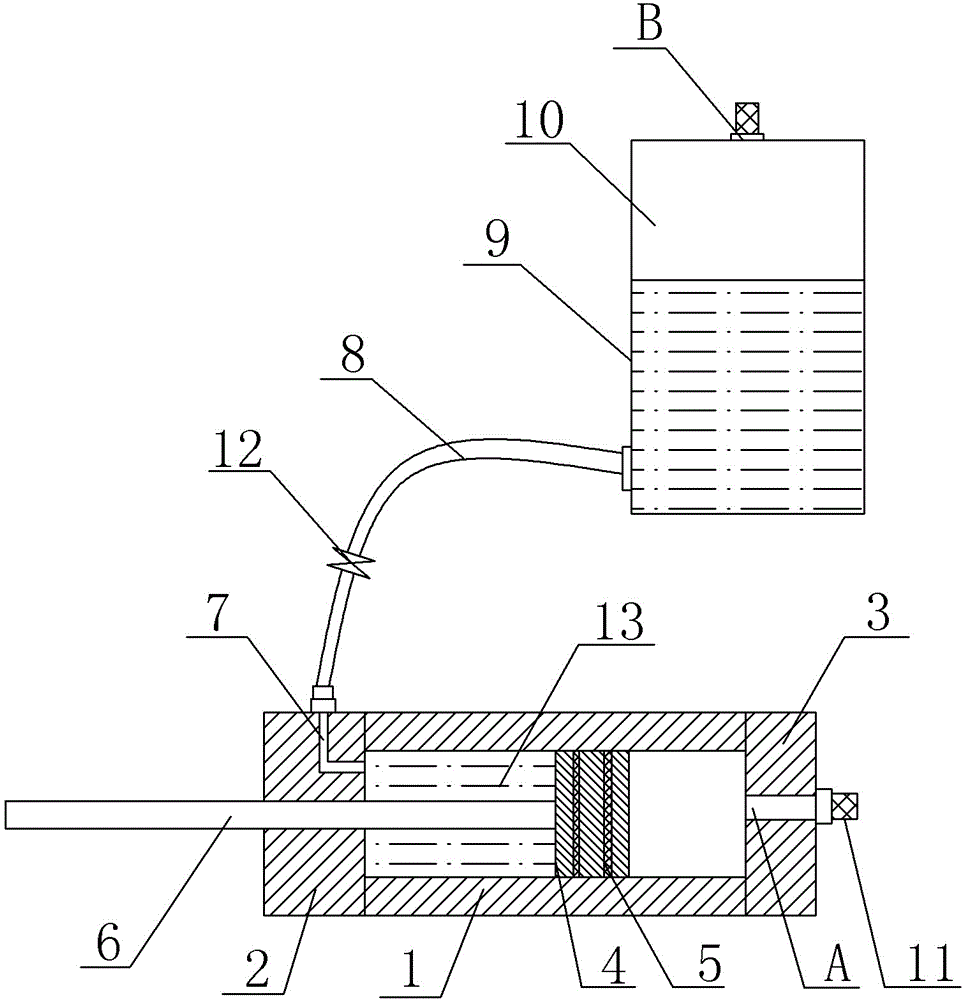

Welding manipulator driving device

InactiveCN104389828ASolve the unstable outputAdjust output speedServomotorsWelding/cutting auxillary devicesEngineeringCylinder block

The invention relates to a welding manipulator driving device, which belongs to the technical field of fluid braking devices. The welding manipulator driving device comprises an air cylinder, wherein the air cylinder is divided into a front cover, a cylinder body and a back cover, a piston cavity is formed in the cylinder body, a piston is installed in the piston cavity, a piston rod which is connected with the piston penetrates through the front cover, and a first air port is formed in the back cover. The welding manipulator driving device is characterized in that a hydraulic oil port which is communicated with the piston cavity is formed in the front cover, the hydraulic oil port is connected with the bottom of an oil tank outside the air cylinder through an oil inlet pipeline, and a speed regulating valve is installed on the oil inlet pipeline; hydraulic oil is contained in the oil tank, an air chamber is left in the upper part of the oil tank, and a second air port which is communicated with the air chamber is formed in the top of the oil tank. The welding manipulator driving device has the advantage of simple structure, only one oil tank needs to be arranged on the original air cylinder, and compared with an existing gas-liquid damping type air cylinder, the air cylinder is lower in the cost, but the problem of unstable output of the air cylinder can be solved.

Owner:CHONGQING XIHUA BELT PULLEY MACHINERY MFG CO LTD

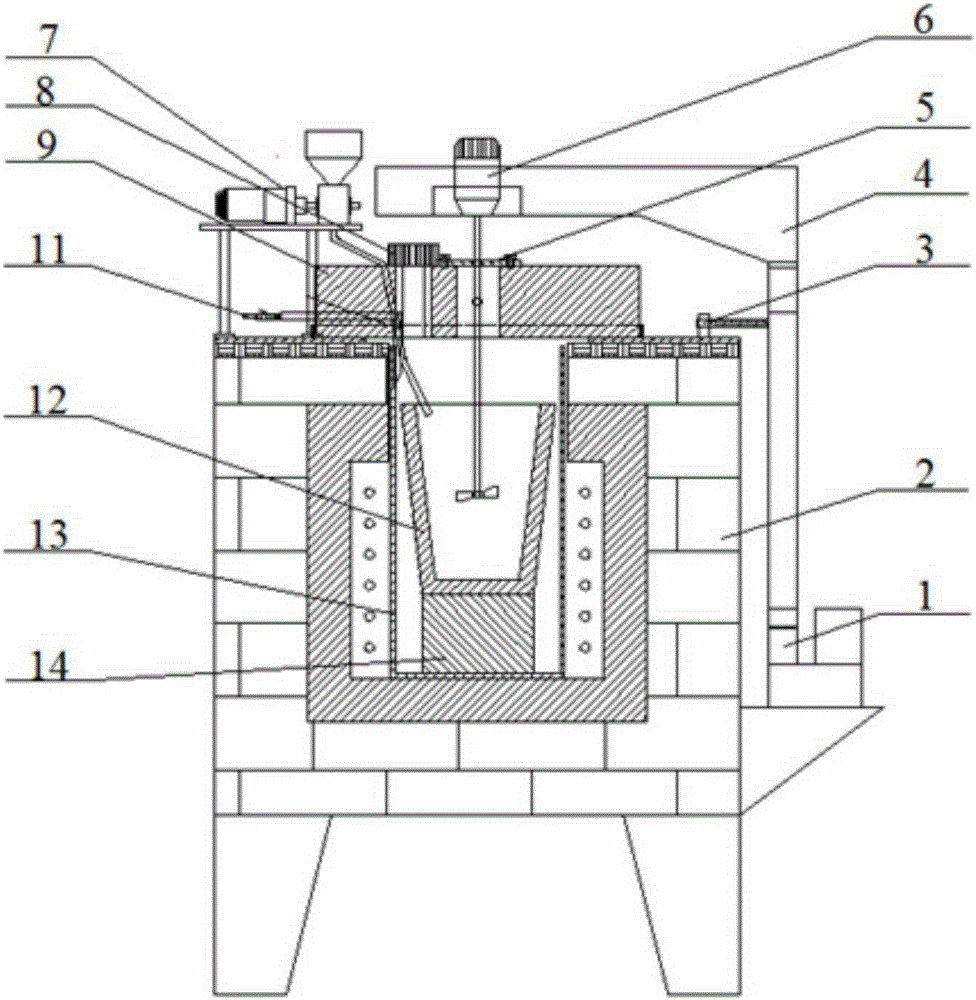

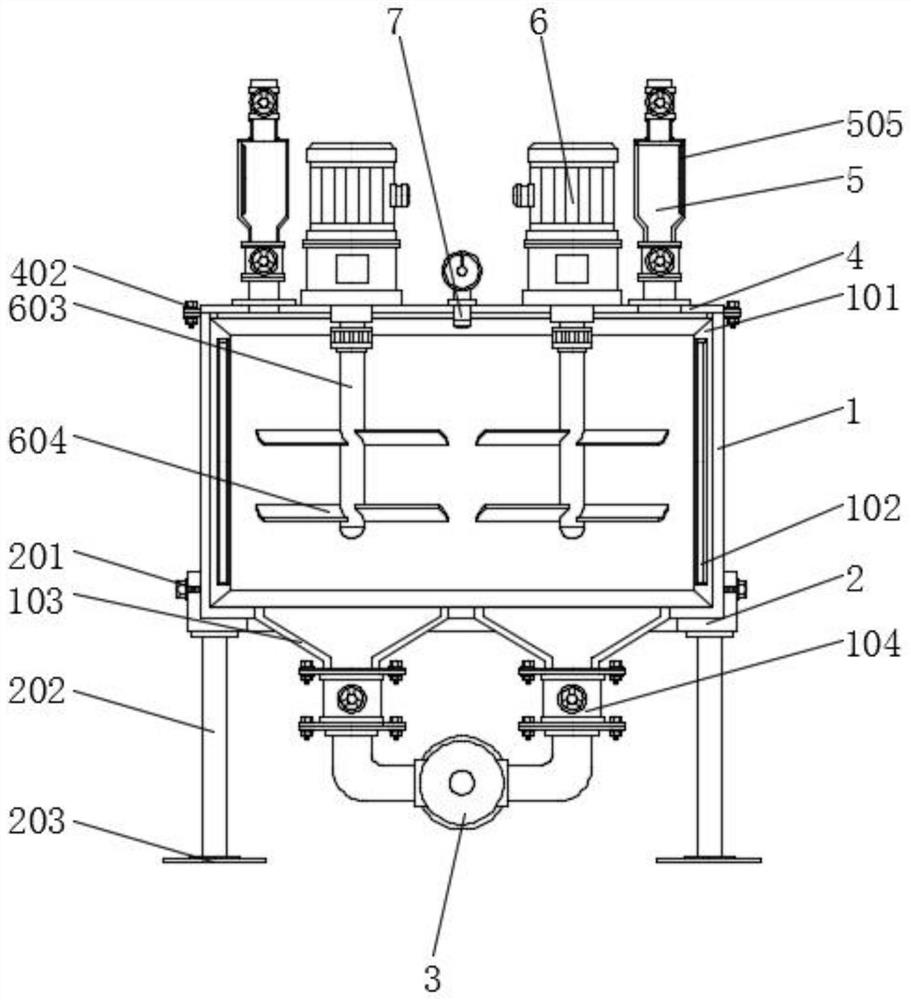

Preparation device and method for stirring casting of particle reinforced aluminum matrix composite material

Owner:SOUTH CHINA UNIV OF TECH

A scraper conveyor and its adaptive speed regulation method

ActiveCN111689170BControl output speedImprove reliabilityConveyorsControl devices for conveyorsTransverterLoad torque

The invention provides a scraper conveyor and its self-adaptive speed regulation method, which can obtain the real-time position value of the scraper conveyor when the shearer is running; read and record the running torque value of the frequency converter of the scraper conveyor, Through data analysis, the no-load torque value and full-load torque value of the scraper conveyor are obtained; through the relevant calculation of the frequency converter torque, speed, and shearer position, the current coal transportation volume of the scraper conveyor is simulated; according to The calculated coal volume is used to adjust the given speed of the scraper conveyor; the entire speed regulation process does not require the participation of any auxiliary sensors, and the reliability is higher.

Owner:QINGDAO CCS ELECTRIC CORP

A variable helical shape memory alloy rotating motor

ActiveCN103647369BSimple structureEasy to controlMachines/enginesMechanical energy handlingMemory effectShape-memory alloy

Owner:BEIHANG UNIV

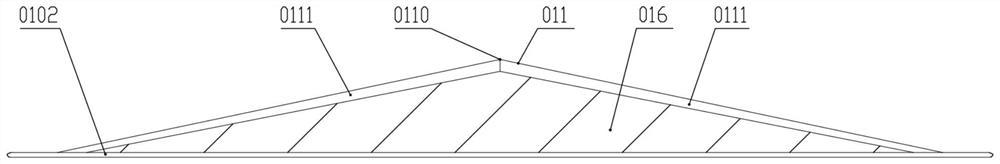

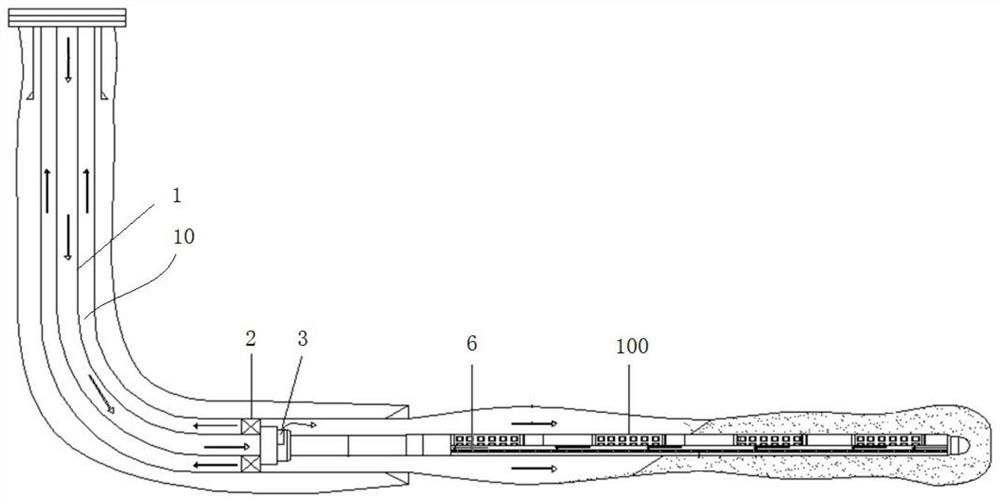

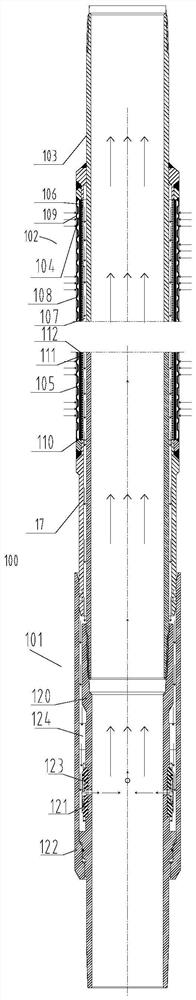

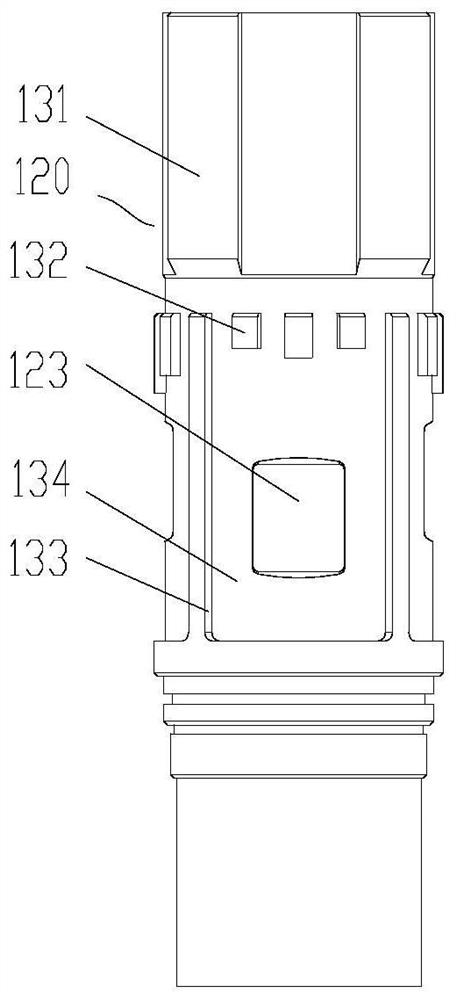

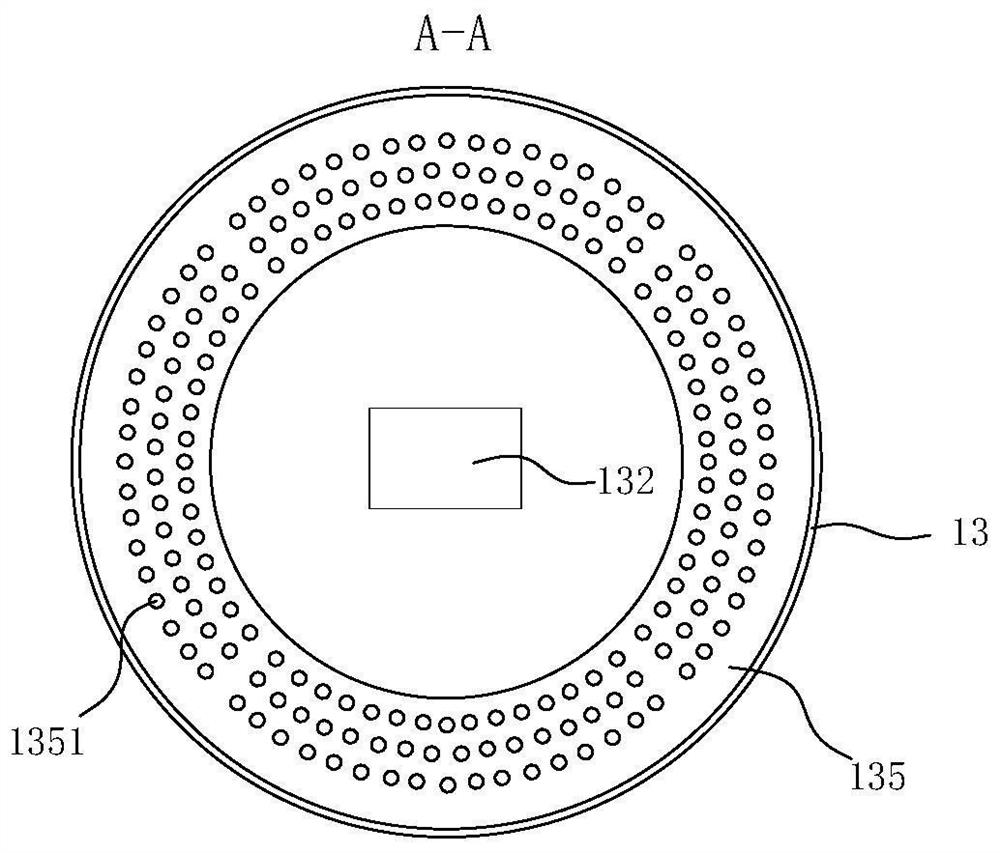

An oil control and profile control device

ActiveCN109138945BDelay time of water breakthroughIncrease flow resistanceFluid removalSealing/packingHorizontal wellsWater flow

The present invention proposes an oil control profile control device, which includes an outer cylinder; a base pipe interferingly arranged in the outer cylinder; the base pipe and the outer cylinder form an annular space with an open upstream end and a blocked downstream end; A flow hole for connecting the inner cavity of the annulus space and the base pipe is arranged on the upper part; and a filter assembly communicated with the upstream of the annulus space. Using this device can increase the flow resistance of the fluid in the reservoir, thereby controlling the production rate of fluid in the reservoir corresponding to different sections of the horizontal well, and then adjusting the fluid production profile of the horizontal well, thereby inhibiting the edge-bottom water coning and delaying the flow of water. The water breakthrough time of flat wells can achieve the purpose of increasing single well production and recovery.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production and preparation device for ultraviolet curing organic silicon release agent

PendingCN114247320AWell mixedIncrease mixing speedFlow mixersRotary stirring mixersEngineeringMechanical engineering

The invention discloses an ultraviolet curing organic silicon release agent producing and preparing device which comprises a preparing box, a discharging hopper is installed at the bottom of the preparing box, a discharging valve is installed at the bottom of the discharging hopper through a bolt, a flow guide pipe is installed at the bottom end of the discharging valve through a bolt, an output pipe is installed at one end of the flow guide pipe, and an output pipe is installed at the other end of the flow guide pipe. A supporting bracket is mounted on the outer side of the bottom of the preparation box, and a supporting column is mounted at the bottom of the supporting bracket; and a top cover is mounted at the top of the preparation box in an embedded manner. The two motors are installed and operate at the same time to drive the transmission rod to rotate, the transmission rod rotates to drive the torsion sensor and the rotating rod at the bottom end to rotate, the rotating rod rotates to drive the stirring paddle on the outer side to rotate, the stirring paddle mixes and stirs materials, vortexes can be generated around the two stirring structures, and therefore the materials are mixed and stirred. The two groups of vortexes collide with each other, so that the materials can be more sufficiently mixed together, and the mixing speed of the device is increased.

Owner:江苏双冠新材料科技有限公司

Servo Control Method of Gasoline Engine Speed in Legged Robot Hydraulic System

ActiveCN106870181BStable speedReduce speed fluctuationElectrical controlSpeed sensing governorsLegged robotGasoline

Owner:SHANDONG UNIV

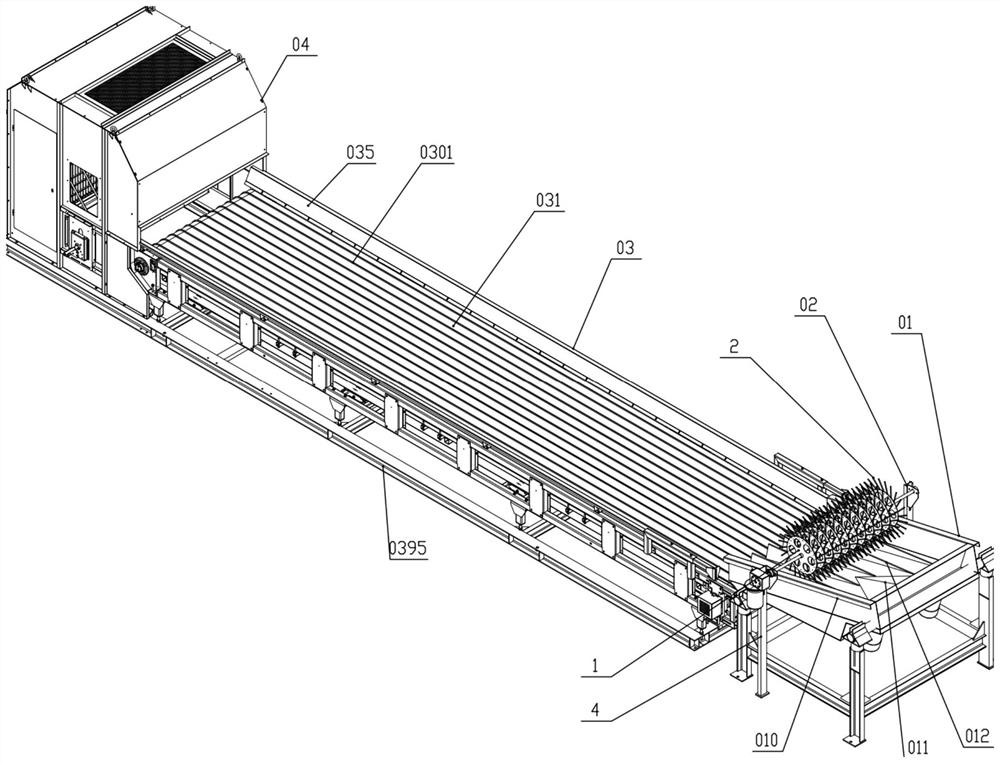

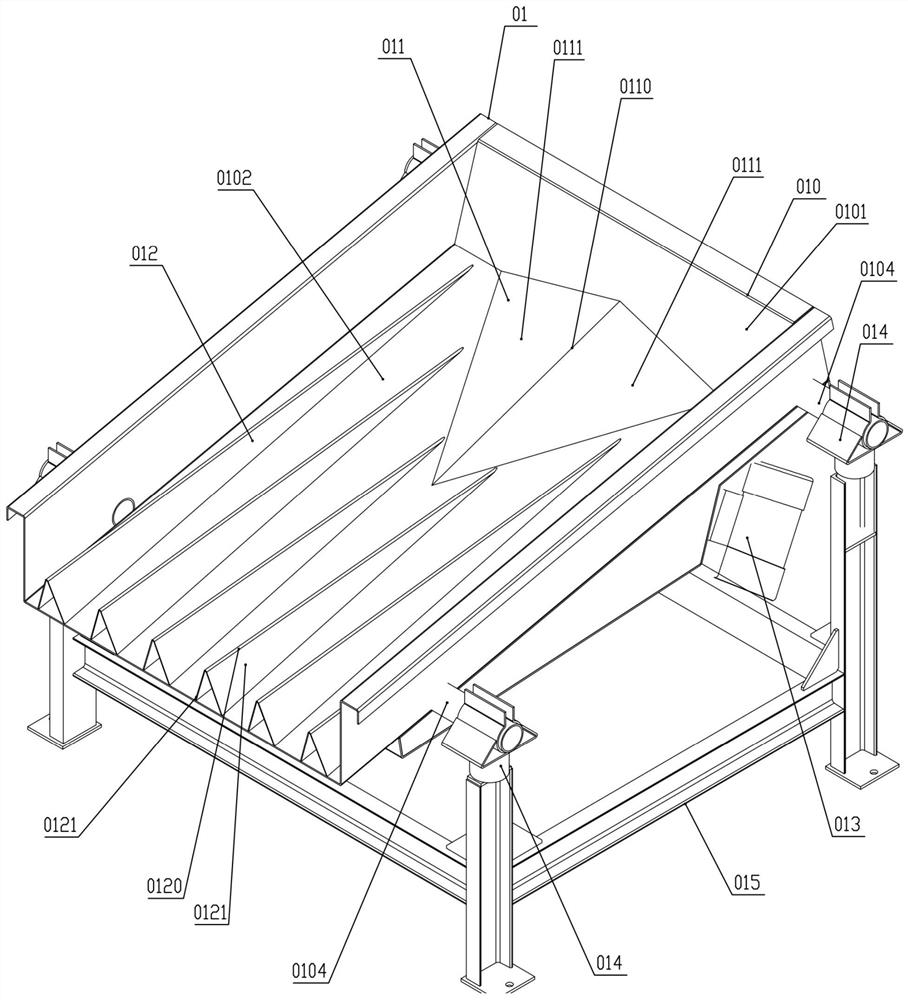

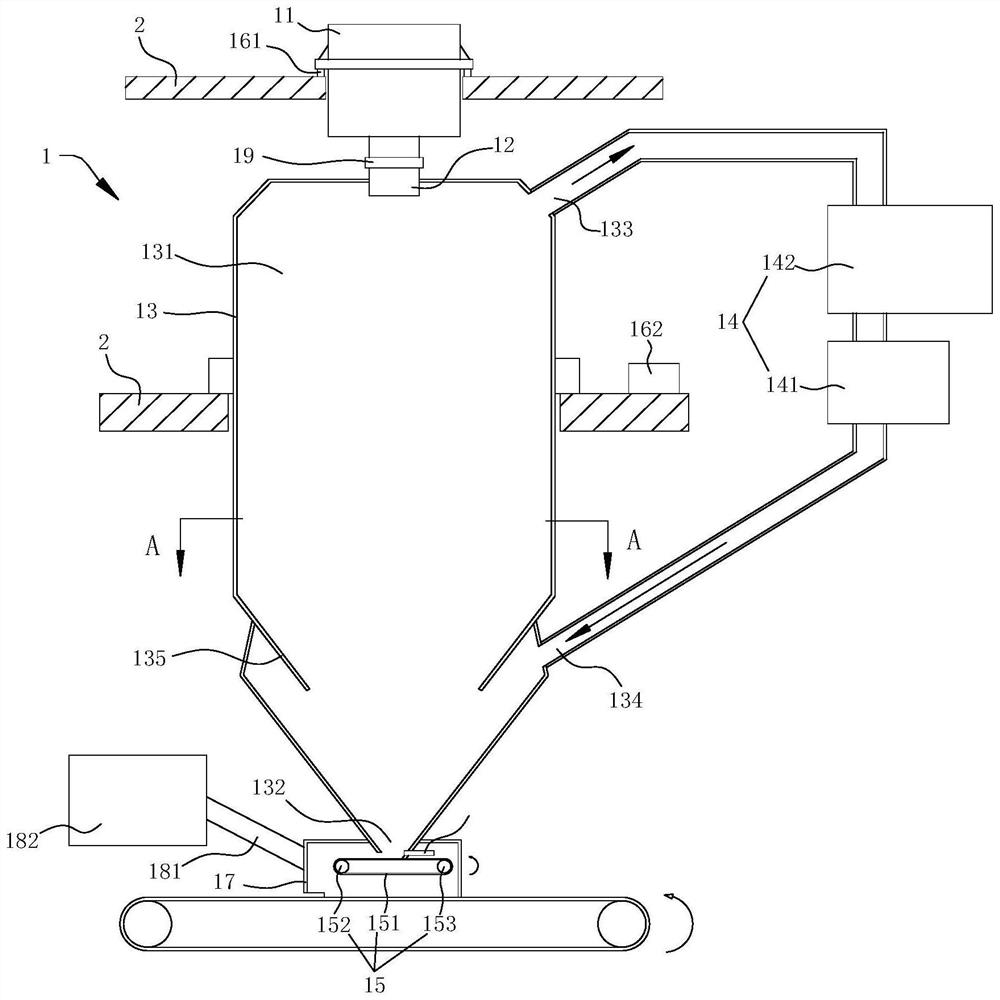

Visual sorting line for directionally feeding bottle garbage

PendingCN114433499AUniform feeding speedImprove material movement speedSortingElectrical and Electronics engineeringBottle

The invention discloses a visual sorting line for directionally feeding bottle garbage. The visual sorting line for the bottle garbage comprises a directional vibrating feeder, a bottle shifting machine, a guide belt conveyor and a high-speed jet-propelled light sorting machine, a material uniformizing plate is mounted in the middle of the feeding end of the lower cavity wall of a hopper of the directional vibration feeder, and a plurality of flow guide strips are symmetrically distributed at the discharging end; a stirring soft finger of the bottle stirring machine is positioned in the hopper and is positioned above the material uniformizing plate; a lifting adjusting assembly of the bottle shifting machine controls the height of a shifting soft finger so as to control the output flow of the bottle; a plurality of transverse barrier strips are longitudinally distributed on the upper surface of a wide guide belt of the guide belt conveyor at equal intervals, each transverse barrier strip right faces one flow guide plate left and right, the transverse barrier strips and the flow guide strips limit longitudinal movement of light materials, and the left end of the wide guide belt right faces a feeding port of a sorting bin body of the high-speed jet-propelled light sorting machine. The sorting device has the advantages of being uniform in longitudinal distribution, capable of guiding transverse movement, uniform in feeding speed, good in sorting effect and high in sorting speed.

Owner:GUANGDONG GONGYE TECH CO LTD

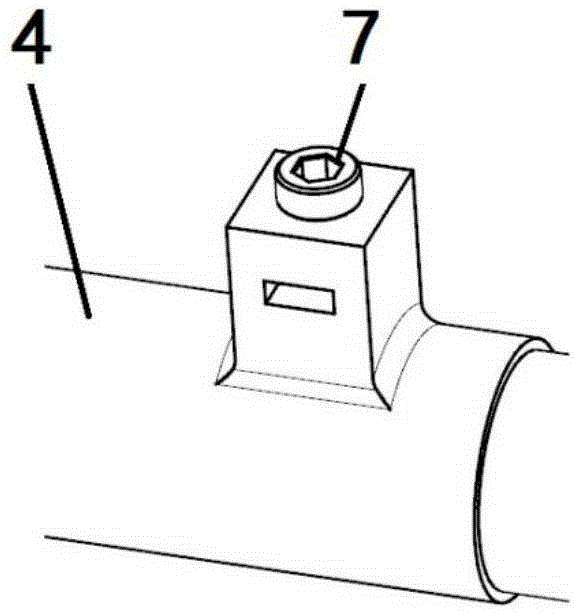

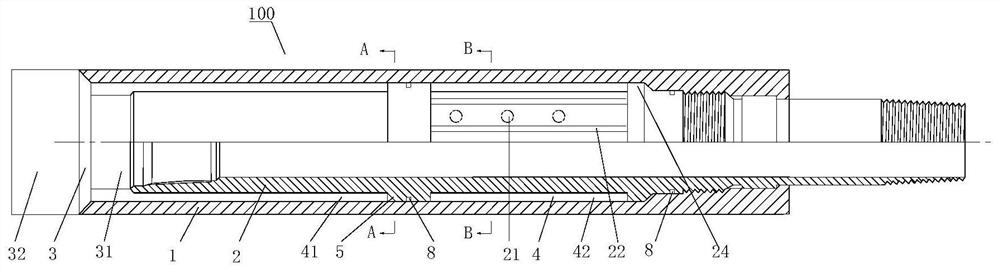

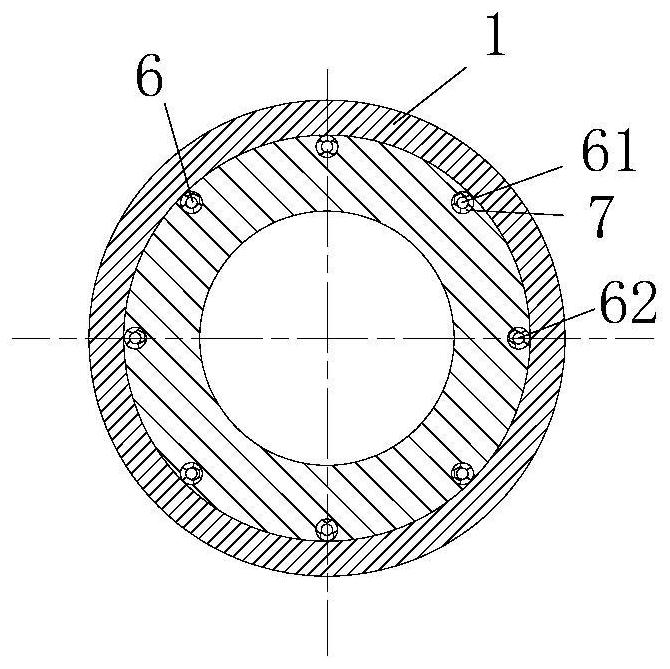

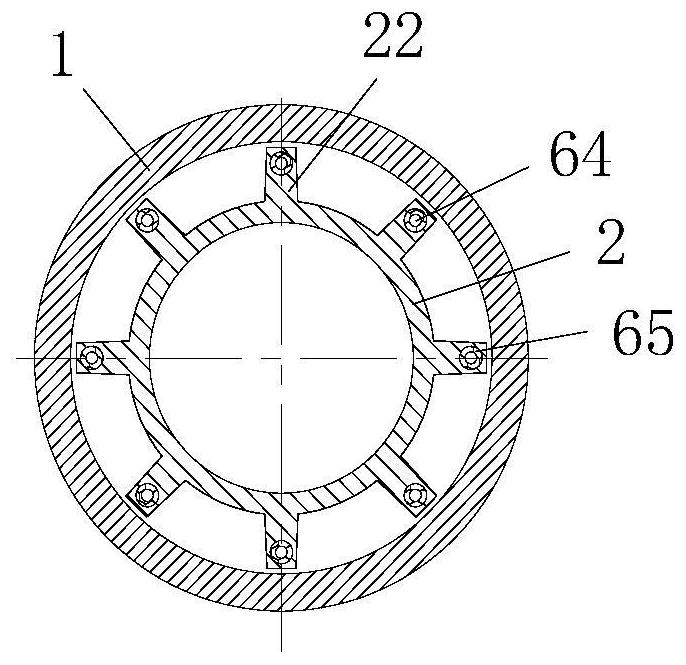

Flow regulation and water control device, pup joint, pipe string and secondary water control completion method

ActiveCN109138938BDelay time of water breakthroughIncrease flow resistanceFluid removalHorizontal wellsRotational flow

The invention provides a flow-regulating water control device, a pipe nipple, a pipe string and a secondary water-control completion method. The flow-regulating water control device comprises a base pipe, a rotational flow controller and a protecting barrel, wherein a mounting groove is formed in the outer wall of the downstream end of the base pipe, the rotational flow controller is arranged at the mounting groove; and the protecting barrel is arranged outside the base pipe in a sleeving mode, and an annulus cavity with the downstream end blocked is formed by the protecting barrel and the base pipe. After fluid enters the annulus cavity, the fluid enters an inner cavity of the base pipe through the rotational flow controller. By using the flow-regulating water control device, the liquid production section of a horizontal well can be balanced, the waterline coning speed is decreased, and the purposes of stabilizing oil and controlling water are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Control device for hydraulic motor

InactiveCN112228415AControl output speedSimple structureOperating means/releasing devices for valvesServomotor componentsHydraulic motorAuto regulation

The invention belongs to the technical field of mechanical equipment, and provides a control device for a hydraulic motor. The control device comprises the hydraulic motor, wherein the hydraulic motoris connected with a manual speed regulating device, the manual speed regulating device is connected with a valve control device, and the valve control device is connected with an oil inlet of the hydraulic motor; and the manual speed regulating device can also be connected with an automatic regulating device. According to the control system for the hydraulic motor, control over the output speed of the hydraulic motor is achieved through a pure mechanical structure, and the control system has the advantages of being simple in structure and low in production cost; the hydraulic motor works without depending on a circuit, so that the fault probability is low; an automatic speed regulating device is matched with the manual speed regulating device, when one device goes wrong, the other deviceis started to work, so that the situation that the hydraulic motor cannot normally regulate the speed is avoided, and the working efficiency is not affected; and the speed regulating device of the mechanical structure has the advantages of being simple in troubleshooting, convenient to maintain and the like.

Owner:天津市航昊机电设备有限公司

Cooling furnace and material cooling method

ActiveCN112964072AControl contentControl output speedCharge manipulationIncreasing energy efficiencyThermodynamicsMechanical engineering

The invention relates to the technical field of cooling equipment, and particularly discloses a cooling furnace and a material cooling method. The cooling furnace comprises a storage bin, a feeding cylinder, a furnace body, a baffle, a waste heat recovery device and a discharging device, the feeding cylinder is arranged at the bottom of the storage bin, a containing cavity is formed in the furnace body, the feeding cylinder communicates with the storage bin and the containing cavity, the width of a cylinder opening of the feeding cylinder is smaller than the width of the bin wall of the storage bin and smaller than the width of the cavity wall of the containing cavity, the baffle is arranged at an angle relative to the side wall of the containing cavity, the baffle is located between the feeding cylinder and a discharging port of the containing cavity and inclines towards the discharging port, an air inlet and an air outlet are formed in the side wall of the containing cavity in a penetrating mode, the air inlet communicates with a first cavity and the waste heat recovery device, the air outlet communicates with a second cavity and the waste heat recovery device, a discharging device is arranged at the discharging port, and the discharging device is used for adjusting the material releasing speed of the discharging port. The cooling furnace is simple in structure, the equipment failure rate can be reduced, and the waste heat recovery efficiency is high.

Owner:SGIS SONGSHAN CO LTD

Longitudinal-bending compound peristaltic precision piezoelectric actuator and its excitation method

ActiveCN106953539BAchieve continuous motion outputEffective stepper drivePiezoelectric/electrostriction/magnetostriction machinesAviationElectricity

The invention discloses a longitudinal-bending composite peristaltic precision piezoelectric driver and an excitation method thereof, and relates to the technical field of piezoelectric driving. The invention aims to solve a problem that an existing piezoelectric driver cannot have the properties of rapid movement, nanometer-scale positioning, strong power output and large-range movement stroke. The longitudinal-bending composite peristaltic precision piezoelectric driver is characterized in that a ceramic group formed by a bending vibration ceramic group and a longitudinal vibration ceramic group is arranged on a rear clamping body, n rear clamping bodies are arranged on a fixed base in parallel or arranged on a base body along the circumferential direction of the base body, a front clamping body is arranged at the front surface of each ceramic group, and each front clamping body is contacted with a linear rotor or a rotary rotor through a driving foot; the longitudinal vibration ceramic groups perform telescopic deformation so as to control contact / separation of the corresponding driving feet and the rotor, the bending ceramic groups perform bending deformation so as to realize stepping driving for the rotor, and continuous driving is realized through coordinately setting the operating process of a plurality of energy converters. The longitudinal-bending composite peristaltic precision piezoelectric driver has the advantages of large stroke, high positioning precision, adjustable output speed and output power and the like, and has good application prospects in the fields such as intelligent robots, aviation and aerospace and high-end equipment manufacturing.

Owner:HARBIN INST OF TECH

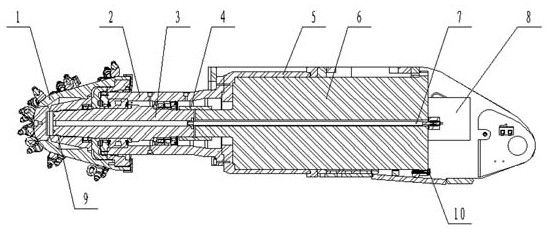

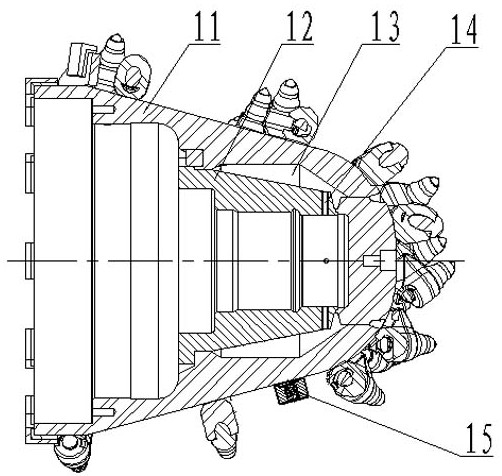

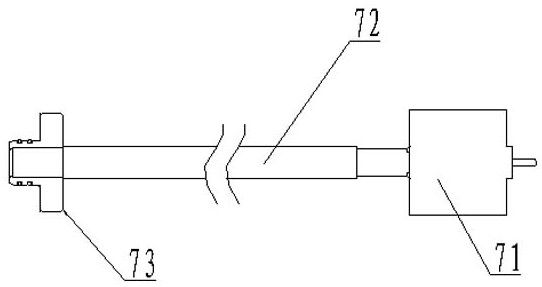

Cantilever type heading machine cutting mechanism adopting permanent magnet synchronous motor

PendingCN112627816AEasy to adjustImprove work efficiencyAC motor controlDriving meansFrequency changerControl engineering

The invention discloses a cantilever type heading machine cutting mechanism adopting a permanent magnet synchronous motor. The method comprises the following steps that: a permanent magnet variable-frequency motor and a servo frequency converter are arranged in a motor box body, and are connected through a circuit; a cutting main shaft is connected with an output shaft of the motor through a spline sleeve; the cutting main shaft and the output shaft of the motor are hollow shafts; a cutting head is tightly connected with the cutting main shaft, and includes a cutting head body and an inner spline sleeve; a nozzle is arranged on the cutting head body; the inner spline sleeve is fixedly connected with the cutting head body; a water accommodating cavity is formed between the inner spline sleeve and the cutting head body, and communicates with the nozzle; a small hole is formed in the inner spline sleeve, and communicates with the water accommodating cavity; an inner spraying system is mounted in the hollow parts of the output shaft of the motor and the cutting main shaft; one end of a water pipe is tightly connected with the cutting main shaft, and the other end of the water pipe is tightly mounted on the motor. The cantilever type heading machine cutting mechanism can realize stepless speed adjustment of the cutting head, and is higher in working efficiency; and the spraying system is simple in water way, high in pressure and excellent in dust removing effect.

Owner:山西汾西华益实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com