Scraper conveyor and self-adaptive speed regulating method thereof

A technology of scraper conveyor and speed regulation method, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of inconvenient installation of sensors to detect the amount of coal transported, and no mature and reliable application solutions, etc., to achieve The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

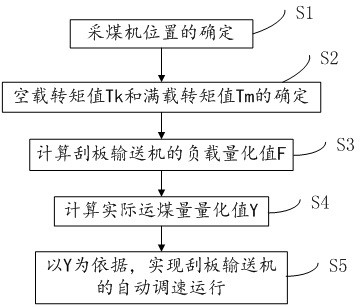

[0034] Such as figure 1 As shown, this embodiment proposes an adaptive speed regulation method for a scraper conveyor, which is specifically described as follows:

[0035] S1. Determination of the position of the shearer:

[0036] Obtain the real-time position of the coal shearer on the scraper conveyor, obtain the length Wm of the scraper conveyor, and the length Wm of the scraper conveyor is a known value.

[0037] According to the real-time position of the shearer and the length of the scraper conveyor, the position of the shearer is quantified as a value X in A-100, where X>0.

[0038] Specifically, the method of quantifying the position of the shearer as a numerical value X is: X=A+Ws×(100-A) / Wm, where A is a set value, and 0

[0039] When Ws is at the tail, Ws=Wm, X=...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that this embodiment uses Y as the basis to realize the automatic speed regulation operation of the scraper conveyor in a different way, and this embodiment is a linear speed regulation method:

[0063] Y=(F*100) / (Tm-Tk), (0≤Y≤100).

[0064] Determine the maximum speed Smax and minimum speed Smin of the scraper conveyor, and the set speed of the scraper conveyor is Sx=Y×(Smax-Smin) / 100 +Smin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com