Production and preparation device for ultraviolet curing organic silicon release agent

A silicon release agent and preparation device technology, which is applied in the field of ultraviolet light curing silicone release agent production and preparation devices, can solve the problems of output speed adjustment, increase the connection force between the mixer and the ground, and fail to output efficiency, etc., to achieve Guaranteed tightness and accelerated mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

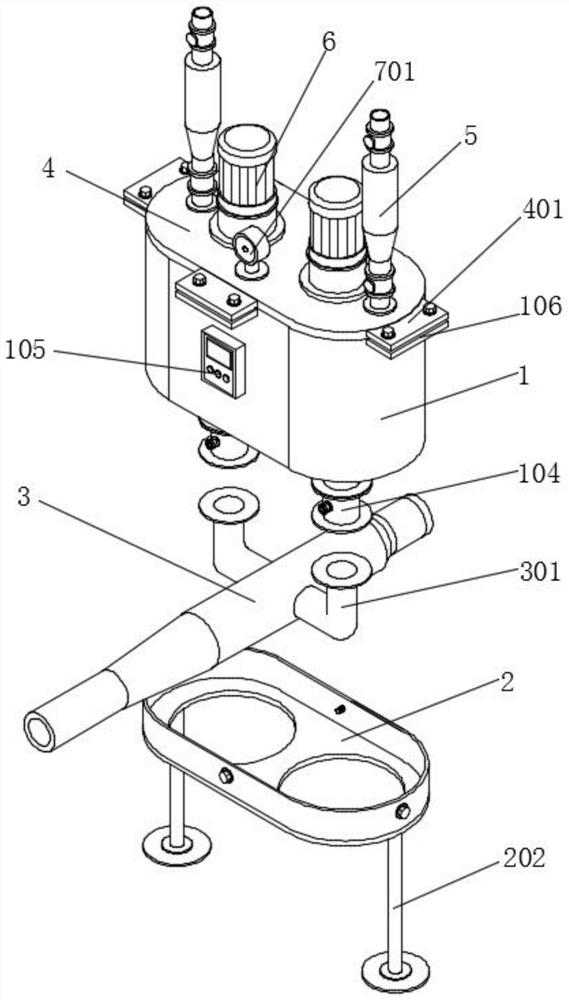

[0042] Embodiment 1 includes a preparation box 1, the top of the outer wall of the preparation box 1 is equipped with a connecting plate 106, the preparation box 1 stores materials, provides space for the mixing of materials, and the preparation box 1 fixes the connecting plate 106 on the outside to ensure The stability of the connecting plate 106, the front of the preparation box 1 is equipped with a controller 105, the operation of the device is controlled by the controller 105, the inner wall of the preparation box 1 is equipped with a heat conduction layer 101, and the inside of the heat conduction layer 101 A heating wire 102 is installed, and the heat conduction layer 101 is fixed on the inner wall of the preparation box 1, and the heat conduction layer 101 fixes the inner heating wire 102, so that the heating wire 102 can be energized and heated up smoothly, and the heat transfer of the heat transfer layer 101 is carried out by the heat conduction layer 101 when the heati...

Embodiment 2

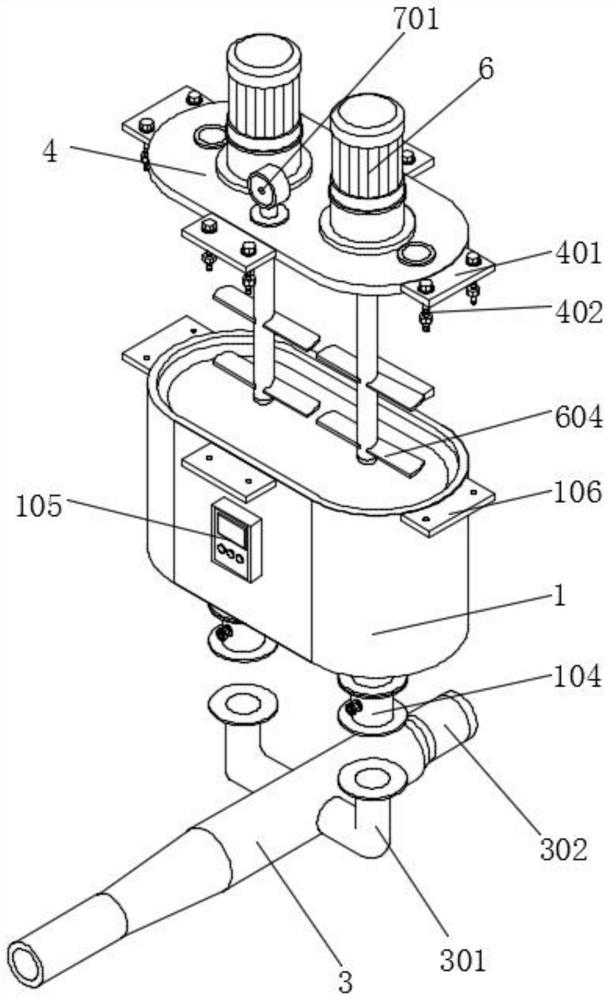

[0044] Embodiment 2 includes a top cover 4, a through plate 401 is installed on the outside of the top cover 4, and a connecting screw 402 is installed on the inside of the through plate 401, and the through plate 401 is connected to the connecting plate 106 through the connecting screw 402, so The top of the preparation box 1 is fitted with a top cover 4, and the outer penetrating plate 401 of the top cover 4 is connected with the connecting plate 106 through the connecting screw 402 to ensure the stability of the top cover 4 and is used to fix the top cover 4. Two sets of motors 6 are mounted symmetrically on the top of the top cover 4, a transmission rod 601 is installed at the output end of the motor 6, a torque sensor 602 is installed at the bottom of the transmission rod 601, and a torque sensor 602 is installed at the bottom of the torque sensor 602. There is a rotating rod 603, and a stirring paddle 604 is installed on the outside of the rotating rod 603. The two sets o...

Embodiment 3

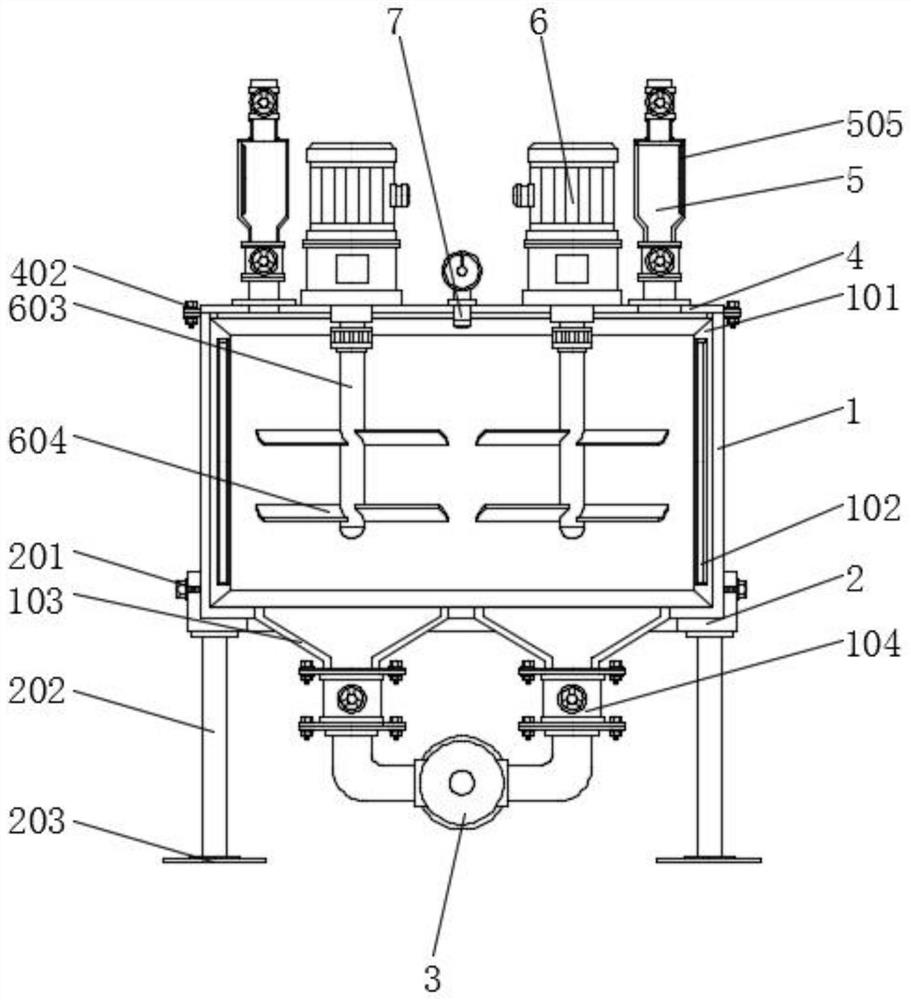

[0046] The third embodiment includes a top cover 4, two groups of flow tubes 501 are symmetrically installed on the top of the top cover 4, and the flow tubes 501 are located on both sides of the two groups of motors 6, and the tops of the flow tubes 501 are installed by bolts There is a first control valve 502, the top of the first control valve 502 is equipped with a quantitative pipe 5 through bolts, the top of the quantitative pipe 5 is equipped with a connecting pipe 503, and the top of the connecting pipe 503 is installed with a The second control valve 504, an infrared detector 505 is installed on the inner wall of the quantitative tube 5, and a connection port 506 is installed on the top of the second control valve 504, and the connection port 506 is connected with the external structure to ensure the tightness of the device connection , to facilitate the conveying device to transport the material to the connection port 506, and then the second control valve 504 is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com