Discharging width limiting door for ball grinding mill

A technology of ball mill and width-limiting door, which is applied in the field of material-discharging width-limiting door, can solve the problems of short service life, affecting the continuous operation of the ball mill, low screening efficiency, etc., and achieve the effect of stable output

Inactive Publication Date: 2013-12-04

TAIZHOU BOYANG AUTOMATIC EQUIP

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The worn steel balls in the ball mill need to be output and screened, and the steel balls that are not suitable for continuous use should be replaced. Since the ball mill itself does not have the output and screening functions, all steel balls must be cleaned out after the grinding is stopped, and then manually screened. This screening method Steel ball output, cumbersome screening operation, high labor intensity, and low screening efficiency affect the continuous operation of the ball mill

The existing patent No. 200320102659.5 discloses an automatic screening device for steel balls in a ball mill. A liner with sieve holes is provided inside the end cover of the ball mill. There is a ball discharge cavity between the liner and the end cover. When the ball mill is working, the worn steel balls Pass through the sieve holes and fall out from the ball outlet cavity and collect them. The ball mill can screen while working, but the steel balls pass through the sieve holes and the material is easy to pass through the sieve holes, which seriously affects the productivity of the ball mill, and the steel balls continue to impact the sieve holes. , the screen hole is easy to wear and has a short service life. Often the end cover of the ball mill is removed to replace the screen hole, which affects the working efficiency of the ball mill and increases the cost of use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0008] The specific embodiments of the present invention are described based on the above drawings.

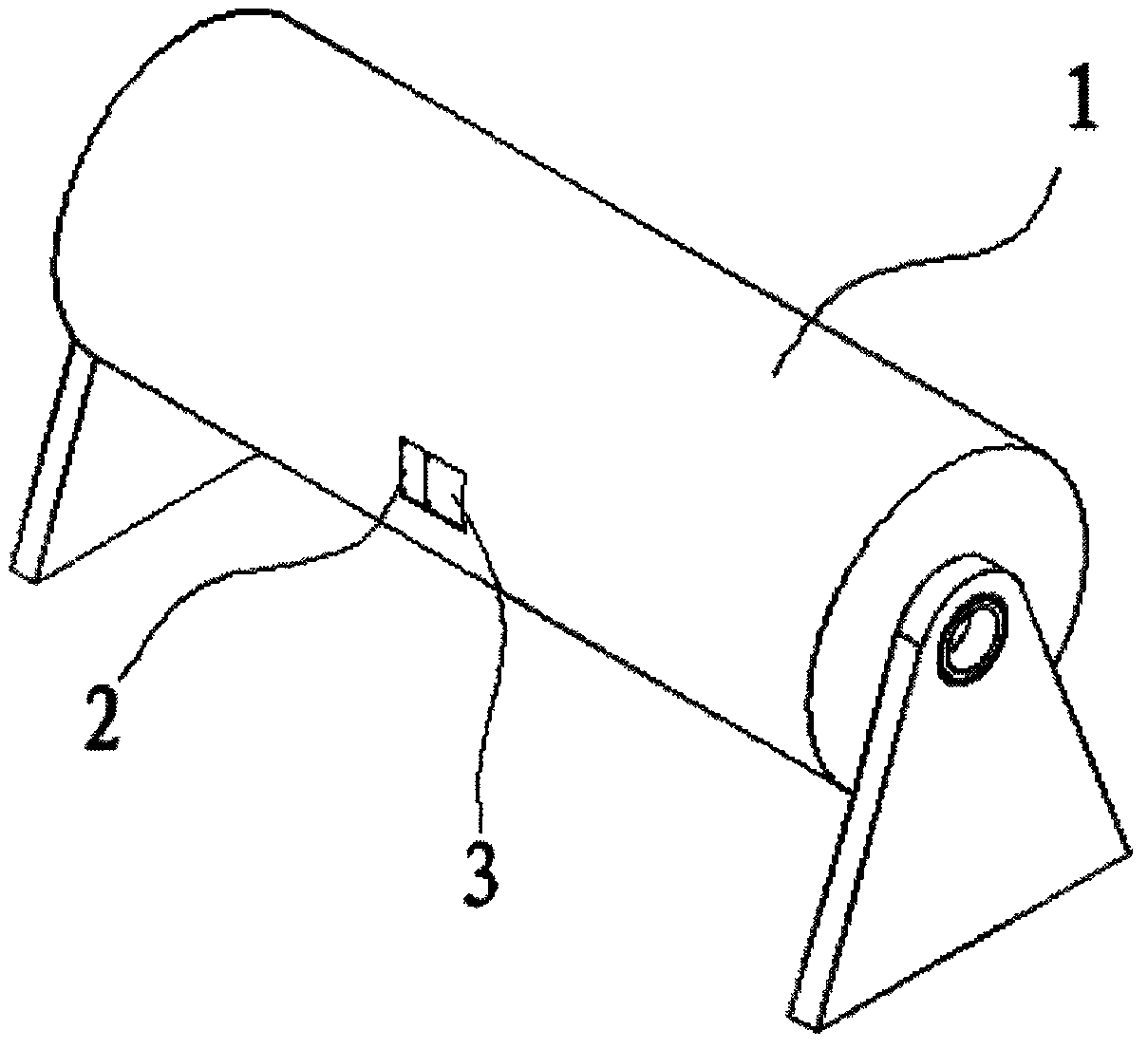

[0009] figure 1 As shown, a discharge width limiting gate for a ball mill is provided with an output port 2 on the outer cylinder wall of the ball mill 1, and a width limiting gate 3 capable of slidably adjusting the opening width of the output port is provided on the output port 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a discharging width limiting door for a ball grinding mill. The outer barrel wall of the ball grinding mill is provided with an output opening. The width limiting door which can be used for adjusting the width of the output opening in a sliding way is arranged in the output opening. After the ball grinding mill is stopped, materials and steel balls in the ball grinding mill are output together through the output opening. The width limiting door is capable of adjusting the size of the output opening, and controlling the output speed and the output quantity of the materials and the steel balls, so that stable output of the steel balls of various specifications is ensured.

Description

Technical field [0001] The invention relates to a discharge width limiting gate for a ball mill. Background technique [0002] Ball mills are one of the high-fine grinding machines widely used in industrial production. There are many types, such as horizontal ball mills, ball mill bearings, energy-saving ball mills, overflow ball mills, ceramic ball mills, lattice ball mills, etc. The ball mill is suitable for grinding various ores and other materials. It is widely used in mineral processing, building materials and chemical industries. It uses steel balls to grind ore. The friction and friction between the steel balls of the ball mill and between the steel balls and the materials produce grinding and stripping effects. During the operation of the ball mill, due to wear and tear, the weight and diameter of the steel balls are continuously reduced. In order to ensure the efficiency of the ball mill, new balls must be added regularly to maintain a certain amount of steel balls. The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C17/18

Inventor 严国栋戴戚军

Owner TAIZHOU BOYANG AUTOMATIC EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com