An oil control and profile control device

A technology of profile control and base pipe, which is applied in the direction of wellbore/well components, production fluid, sealing/isolation, etc., can solve the problems of chemical agent damage to the reservoir, high cost, etc., and achieve the improvement of single well production and recovery, Suppresses water coning at the edge and bottom and increases flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

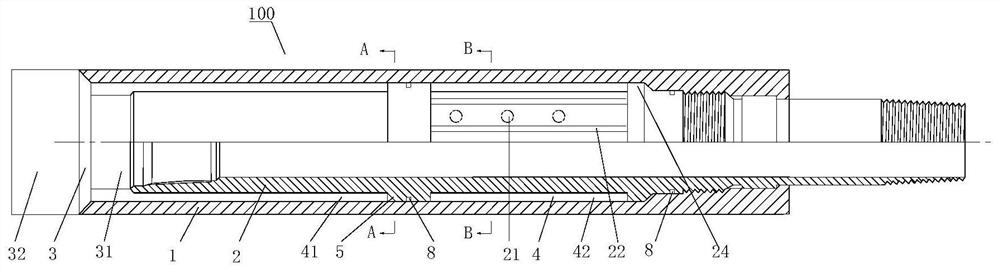

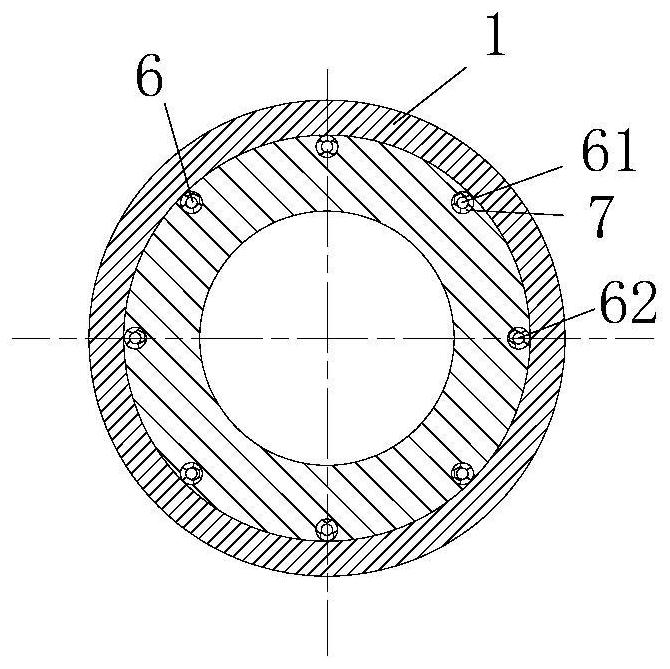

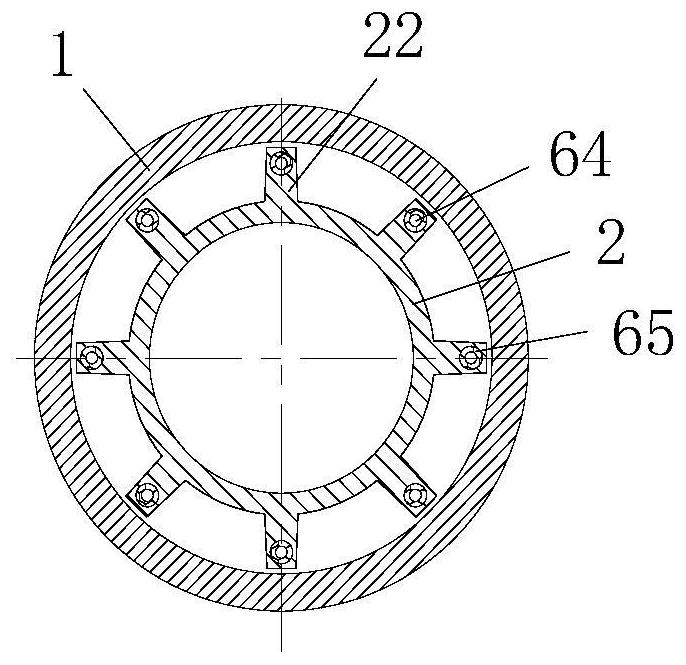

[0029] figure 1 Shown is an oil control profile control device 100 according to the present invention. Such as figure 1 As shown, the oil control profile control device 100 includes an outer cylinder 1 , a base pipe 2 and a filter assembly 3 . Wherein, the base pipe 2 is sleeved in the inner cavity of the outer cylinder 1, and forms an annular space 4 with the outer cylinder 1 with an open upstream end and a closed downstream end. Flow holes 21 are provided on the wall of the base pipe 2 to connect the annular space 4 with the inner cavity of the base pipe 2 . The filter assembly 3 is arranged at the upstream end of the annular space 4 , and is used to supply the annular space 4 after filtering the fluid in the wellbore.

[0030] During the oil and gas development process of a horizontal well, the device 100 is installed on the production string, so that the fluid in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com