Horizontal Well Acidizing Process Based on Composite Acid Liquid System

A composite acid, horizontal well technology, applied in the directions of production fluids, wellbore/well components, drilling composition, etc., can solve the problems of difficult acidification and weak heterogeneity of horizontal wells, avoid premature reaction or Layered, reduced usage, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

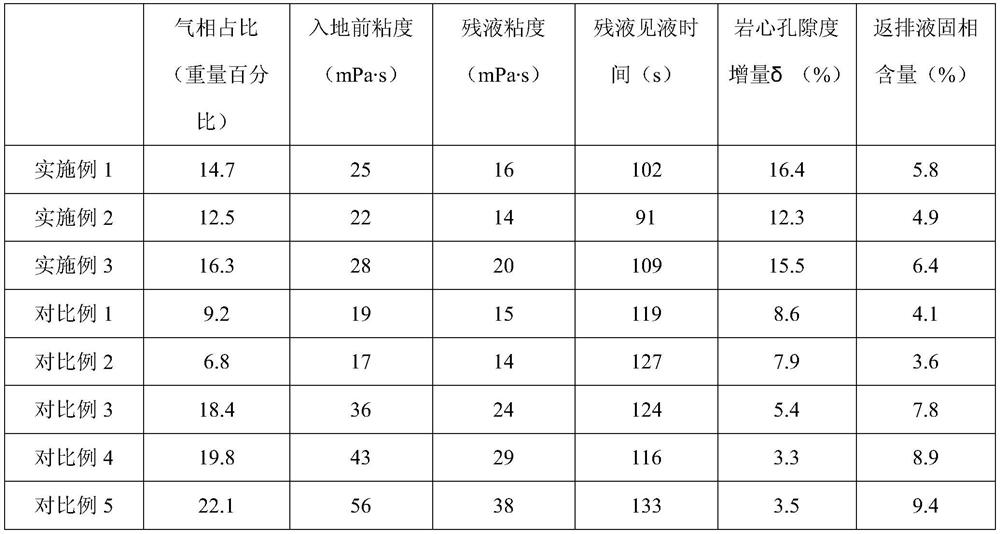

Examples

Embodiment 1

[0029] The horizontal well acidizing process based on the composite acid liquid system includes the following steps: S1, completion of the well, running into the production string; S2, running the coiled tubing into the production string to the position of the reservoir to be stimulated; S3, running the coiled tubing into the production string The acid liquid is injected, and the treatment liquid is injected into the annular space between the coiled tubing and the production string, so that the acid liquid and the treatment liquid are mixed at the position of the reservoir to be stimulated to form an acidizing liquid.

[0030] Wherein, the acid solution includes a gelling agent, a thickener, a corrosion inhibitor, a drainage aid, an iron ion stabilizer, and hydrochloric acid; the treatment solution includes a foaming agent, a foam stabilizer, and calcium carbonate; the acid solution Mixed with treatment liquid to form acidizing liquid, said acidizing liquid includes the followi...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that the proportioning of the mixed acidizing solution is different: 0.8% gelling agent, 0.4% thickening agent, 5% corrosion inhibitor, 1.5% drainage aid, 1 iron ion stabilizer %, foaming agent 3%, foam stabilizer 0.2%, calcium carbonate 1%, hydrochloric acid 15%, and the balance is water.

Embodiment 3

[0036] The difference between this example and example 1 is that the proportioning of the acidified solution after mixing is different: 1.2% gelling agent, 0.3-0.5% thickening agent, 5% corrosion inhibitor, 1.5% drainage aid, stable iron ion 1% agent, 5% blowing agent, 0.2% foam stabilizer, 1% calcium carbonate, 15% hydrochloric acid, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com