Flow regulation and water control device, pup joint, pipe string and secondary water control completion method

A water control device and flow regulation technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of chemical damage to the reservoir and high cost, and achieve the improvement of single well production and recovery rate, The effect of inhibiting the water coning at the edge and bottom and delaying the water-seeing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

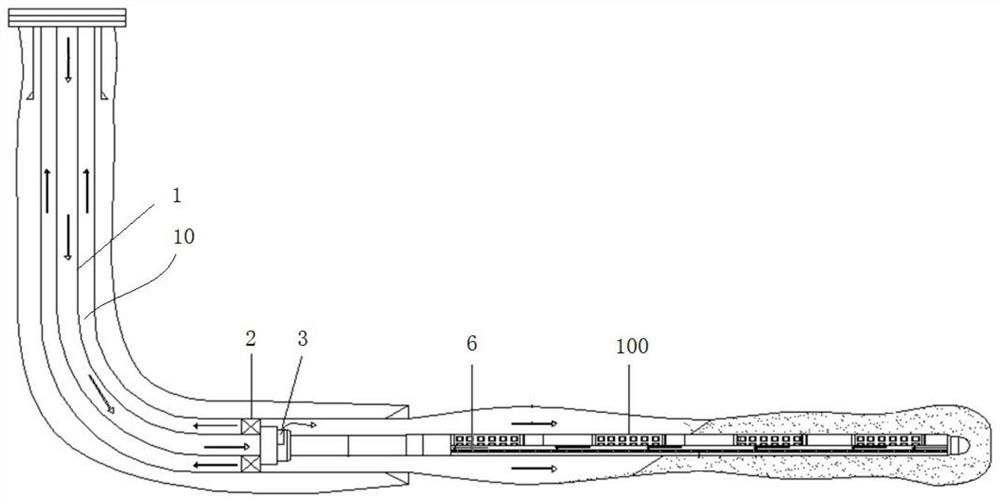

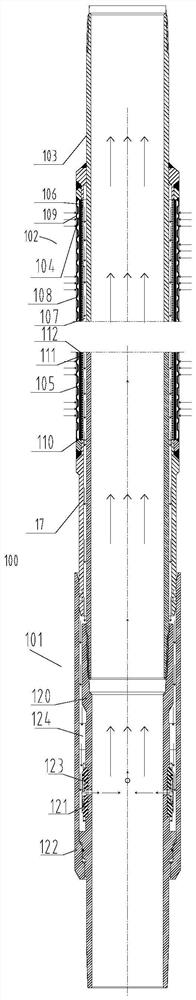

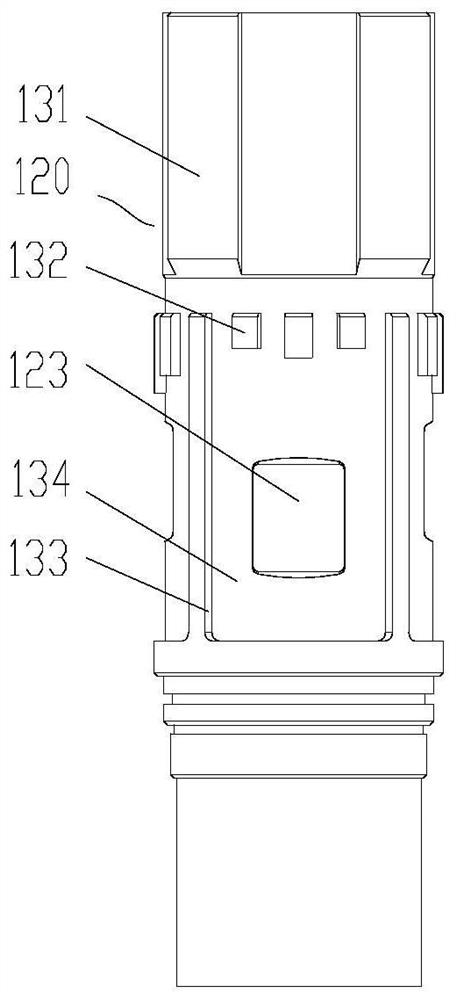

[0057] figure 1 A column 10 according to the invention is shown. Such as figure 1 As shown, the tubing string 10 includes a coiled tubing 1 , a packer 2 , a packing converter 3 and a short joint 100 arranged in sequence from upstream to downstream. Wherein, the packer 2 is arranged at the lower end of the coiled tubing 1, and is used to isolate the annular space between the tubing string 10 and the original well wall, so as to ensure that the horizontal section will not go up after filling with gravel. The packing converter 3 is located downstream of the packer 2, and is used to switch the passage of the fluid, and is used to ensure that the gravel and sand-carrying fluid injected into the inner cavity of the pipe string 10 from the wellhead enter the horizontal well section sub-joint 100 after passing through the packing converter 3 The ring between the original wellbor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com