Welding manipulator driving device

A technology for welding manipulators and driving devices, applied in fluid pressure actuating devices, auxiliary devices, mechanical equipment, etc., can solve the problems of unstable output, large compressed air compression ratio, unstable cylinder output, etc., to prevent leakage, accurate Control and solve the effect of unstable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

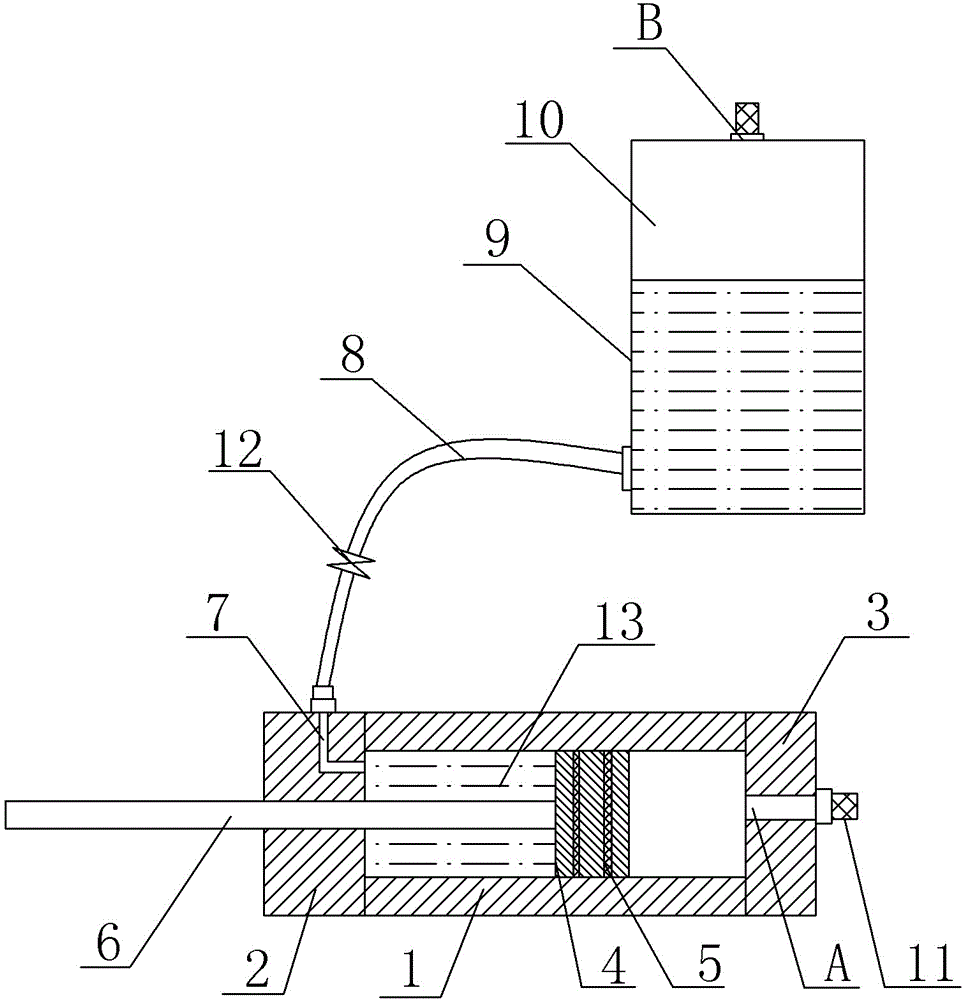

[0011] The reference signs in the accompanying drawings of the specification include: 1- cylinder body; 2- front cover; 3- rear cover; 4- piston; 5- piston sealing ring; 6- piston rod; 7- hydraulic oil inlet and outlet; 8- inlet Oil pipeline; 9-oil tank; 10-air chamber; 11-cylinder muffler; 12-needle valve; 13-oil chamber.

[0012] The embodiment is basically as attached figure 1 Shown: The driving device of the welding manipulator, including a single-acting cylinder, including cylinder block 1, front cover 2 and rear cover 3 from left to right. A piston cavity is opened in the cylinder body 1, a piston 4 is installed in the piston cavity, and at least two piston sealing rings 5 are fixed on the side wall of the piston 4. The piston 4 is connected with a piston rod 6 extending through the front cover 2 . The front cover 2 has a hydraulic oil inlet and outlet 7 commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com