Wastewater filtering and purifying device

A technology for filtering and purifying waste water, which is applied in the fields of filtration and separation, chemical instruments and methods, and separation methods, and can solve problems such as the inability to automatically change the filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

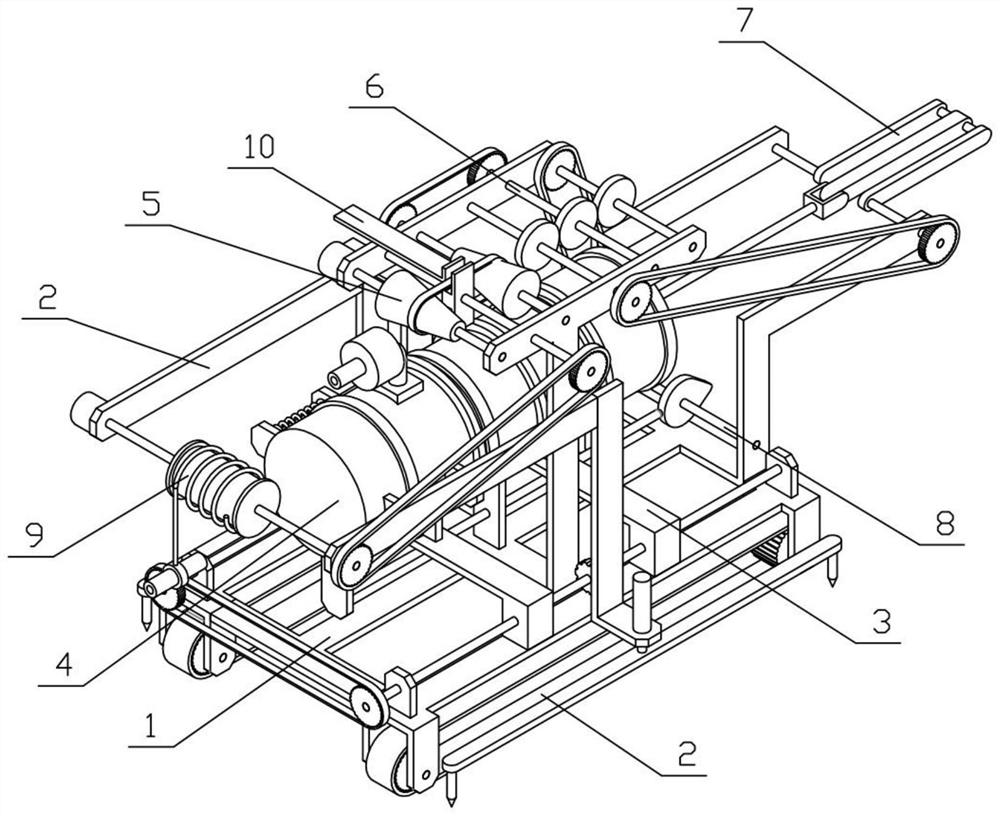

specific Embodiment approach 1

[0037] Combine below Figures 1 to 13 Describe this embodiment, a wastewater filtration and purification device, including a device bracket 1, a moving mechanism 2, a disassembly mechanism 3, a purification mechanism 4, a power mechanism 5, a transmission mechanism 6, an extrusion mechanism 7, a push mechanism 8, and a retractable mechanism 9 and the speed change mechanism 10, the left and right sides of the device support 1 are fixedly connected with the moving mechanism 2, the device support 1 is connected with the dismounting mechanism 3, the purification mechanism 4 is fixedly connected on the device support 1, and the purification mechanism 4 is fixedly connected on the disassembly On the mechanism 3, on the device bracket 1, a power mechanism 5 is connected, on the device bracket 1, a transmission mechanism 6 is rotatably connected, and the transmission mechanism 6 and the power mechanism 5 are connected in transmission, and the rear end of the device bracket 1 is rotatab...

specific Embodiment approach 2

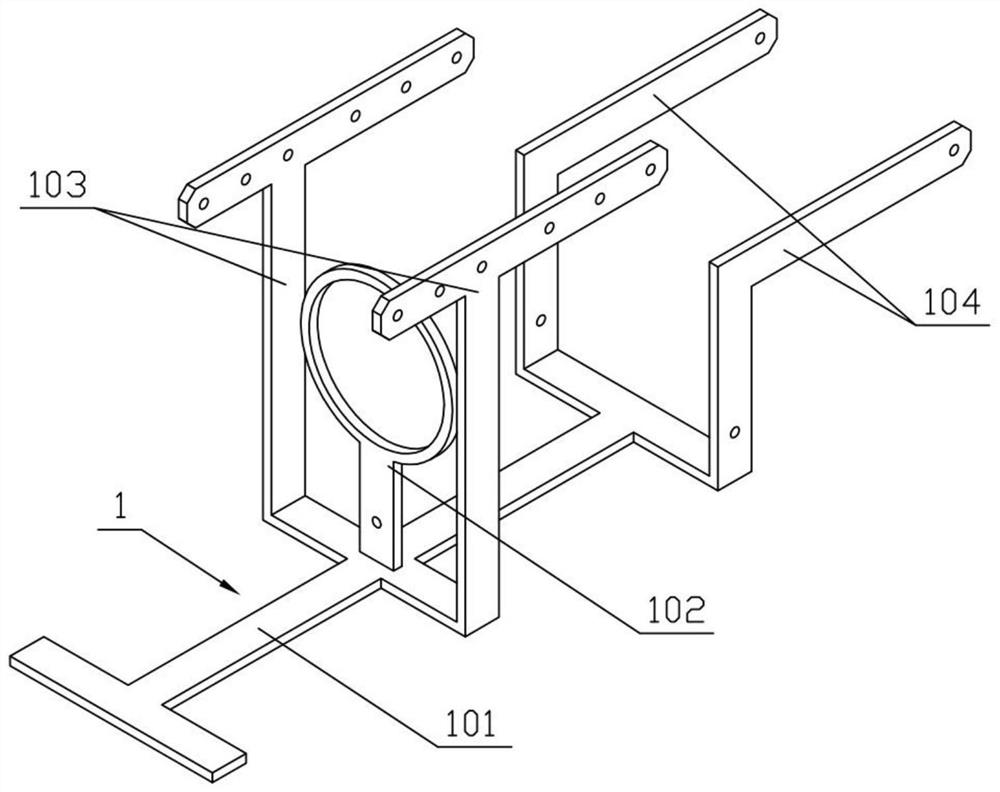

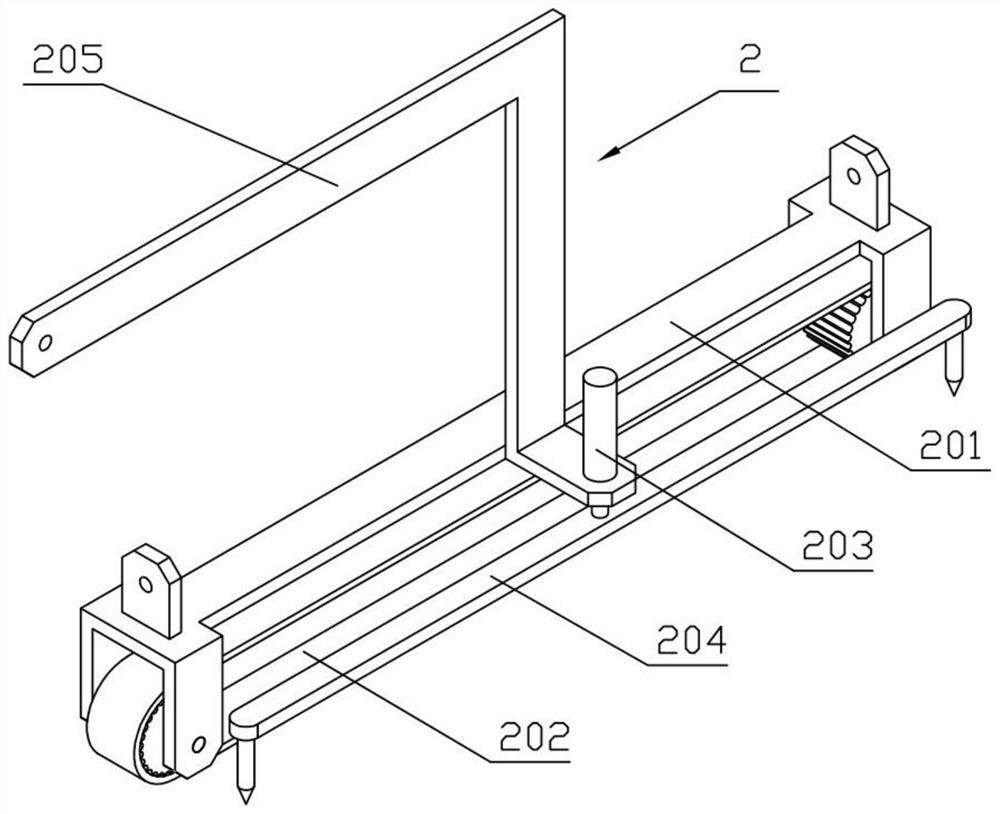

[0039] Combine below Figures 1 to 13 Describe this embodiment, this embodiment will further explain the first embodiment, the device bracket 1 includes a bottom bracket 101, a support ring I102, an installation side plate I103 and an installation side plate II104, and the middle part of the bottom bracket 101 is fixedly connected with a support ring I102 , the left and right sides of the bottom bracket 101 are fixedly connected with installation side panels I 103, the left and right sides of the rear end of the bottom bracket 101 are fixedly connected with installation side panels II 104, the moving mechanism 2 includes a moving bracket 201, a crawler mechanism 202, a telescopic mechanism 203, The positioning bottom plate 204 and the installation side plate III 205, the crawler mechanism 202 is connected to the mobile support 201, the telescopic mechanism 203 is fixedly connected to the mobile support 201, the telescopic end of the telescopic mechanism 203 is fixedly connected...

specific Embodiment approach 3

[0041] Combine below Figures 1 to 13 Describe this embodiment, this embodiment will further explain Embodiment 2. The disassembly mechanism 3 includes a disassembly screw 301, a disassembly bracket 302 and a support ring II 303. There are two disassembly screw 301, and two disassembly screw 301 The two dismantling screw rods 301 are respectively connected to the two movable brackets 201 in rotation, and the two dismantling screw rods 301 are connected with two dismantling brackets 302 by threads, and the two dismantling brackets 302 are fixedly connected with For the support ring II 303, the threads at both ends of the two dismantling screw rods 301 have opposite directions of rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com