Visual sorting line for directionally feeding bottle garbage

A waste sorting technology, applied in sorting and other directions, can solve the problems of uneven feeding speed of vibrating feeder, inaccurate camera positioning, and misjudgment of jet valve group, so as to achieve good sorting effect and production efficiency. Fast, smooth and active feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

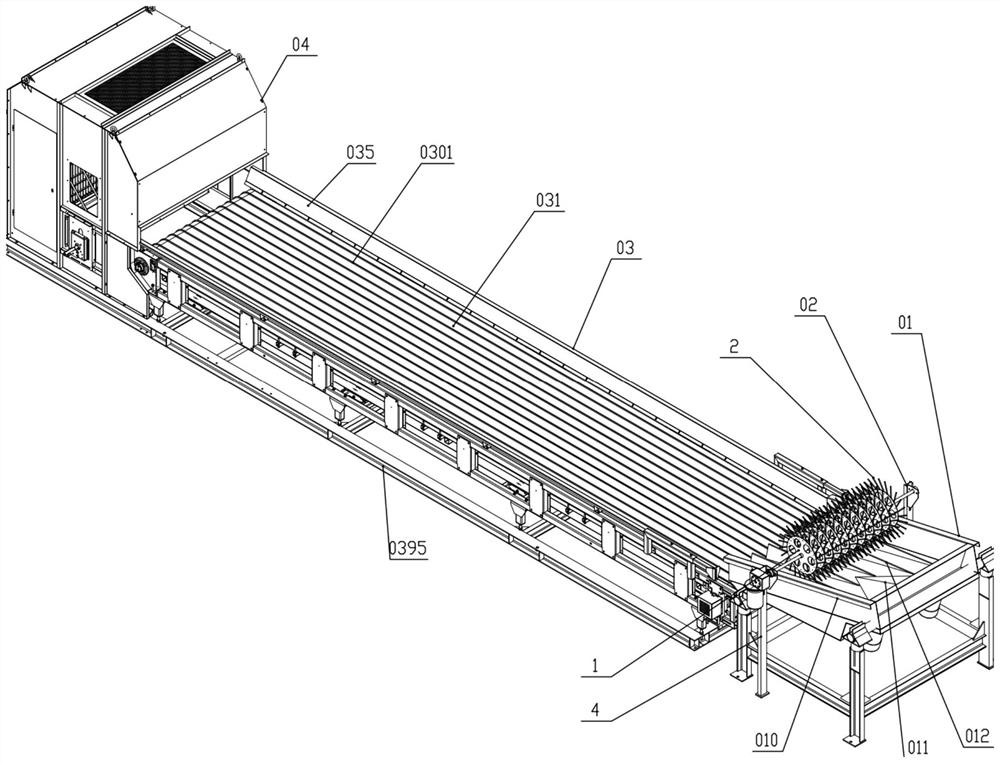

[0049] Figure 1 to Figure 12 It schematically shows a visual sorting line for directional feeding bottle waste according to an embodiment of the present invention. As shown in the figure, the device includes a directional vibrating feeder 01, a bottle pulling machine 02, a guide belt conveyor 03 and a high-speed jet optical separator 04;

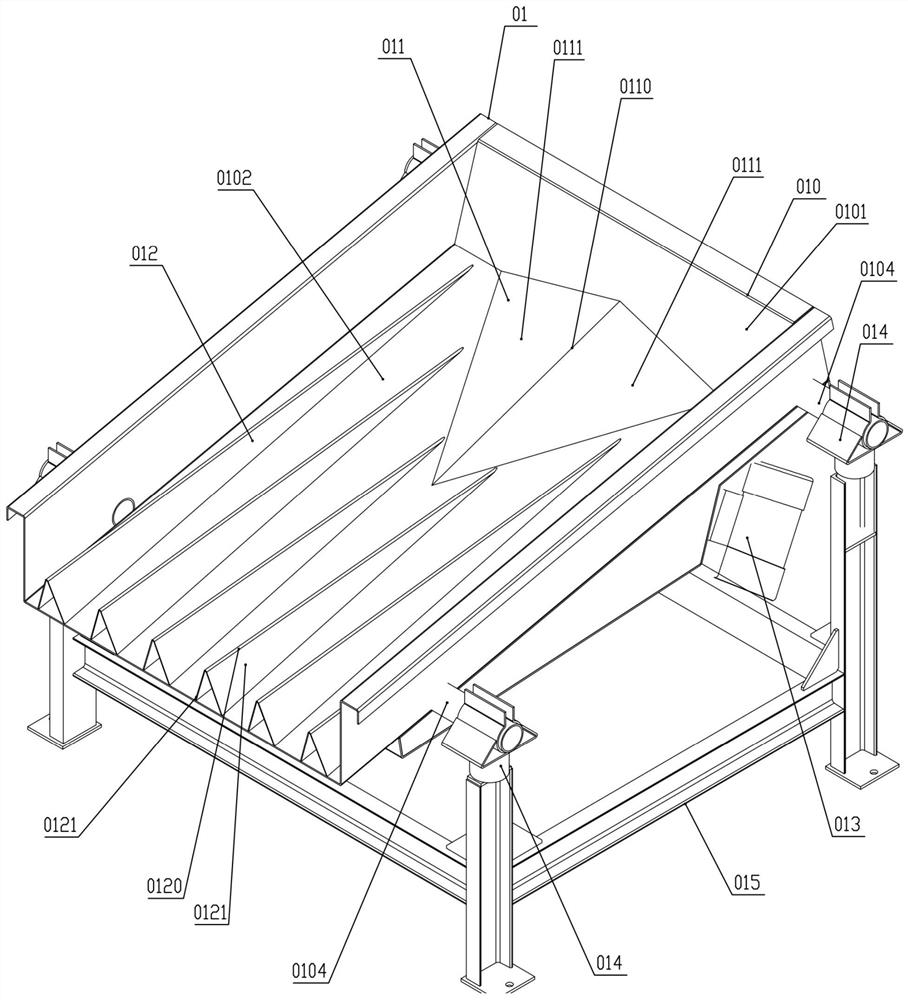

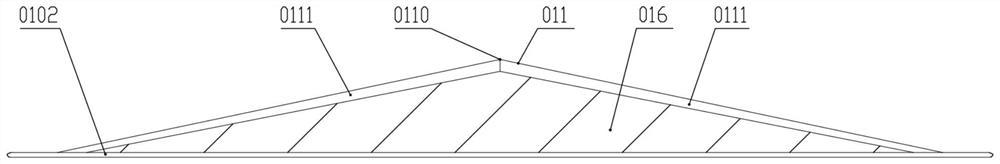

[0050] The directional vibrating feeder 01 includes a hopper 010 that slopes from upper right to lower left. A uniform material plate 011 is installed in the middle of the feed end of the lower chamber wall of the hopper 010, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com