Preparation device and method for stirring casting of particle reinforced aluminum matrix composite material

A particle-reinforced aluminum and composite material technology, which is applied in the field of metal matrix composite material stirring casting preparation devices, can solve the problems of reducing the performance of the composite material, increasing the content of the oxide film of the composite material, lack of linkage, etc., so as to reduce the manufacturing difficulty and cost, reduce the Effect of gettering and surface oxidation, improving stability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

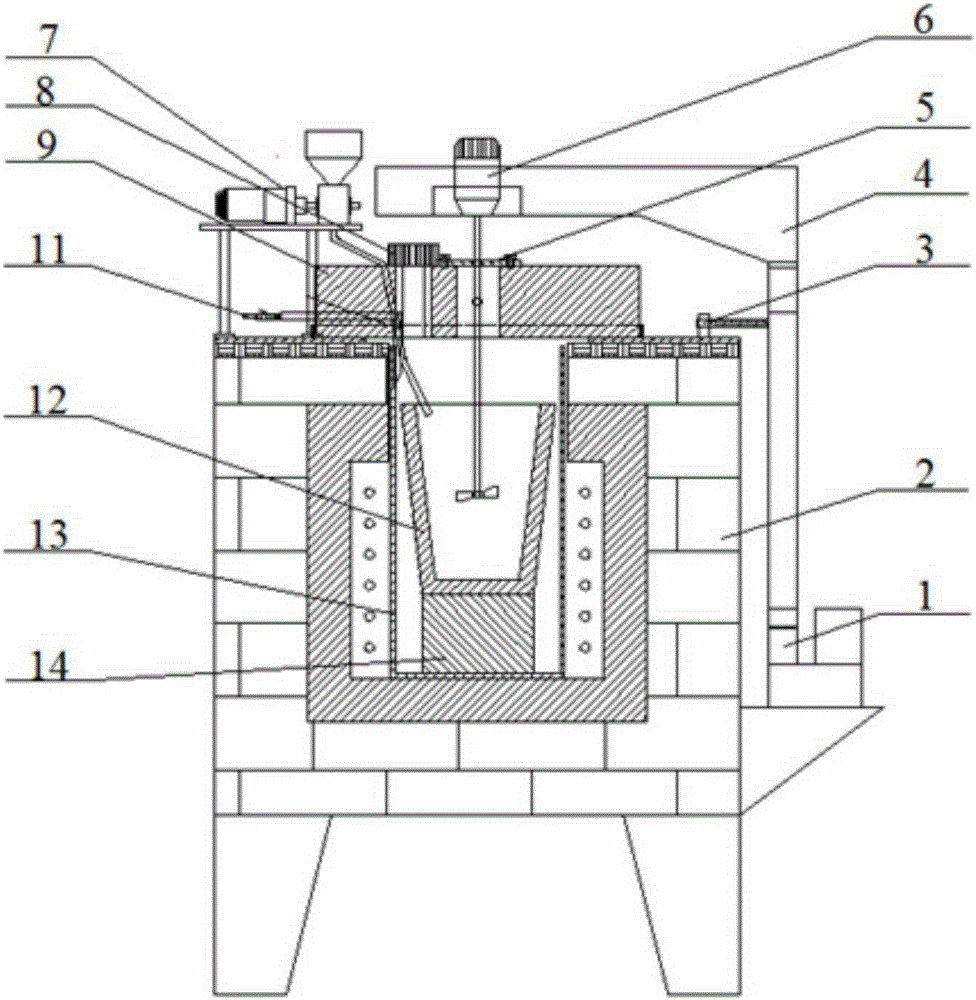

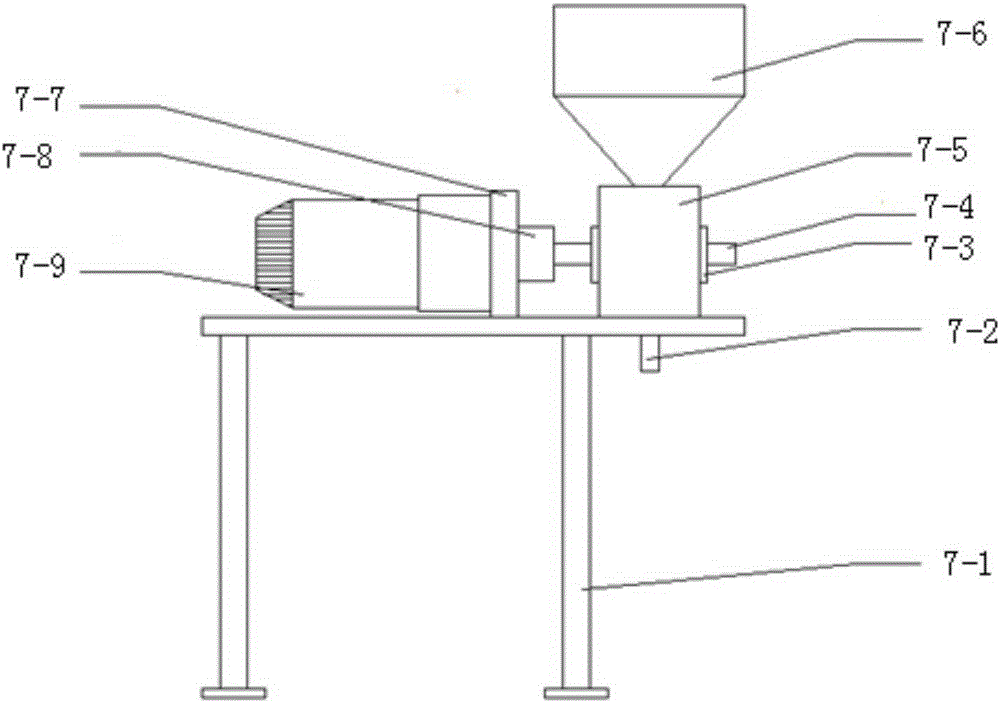

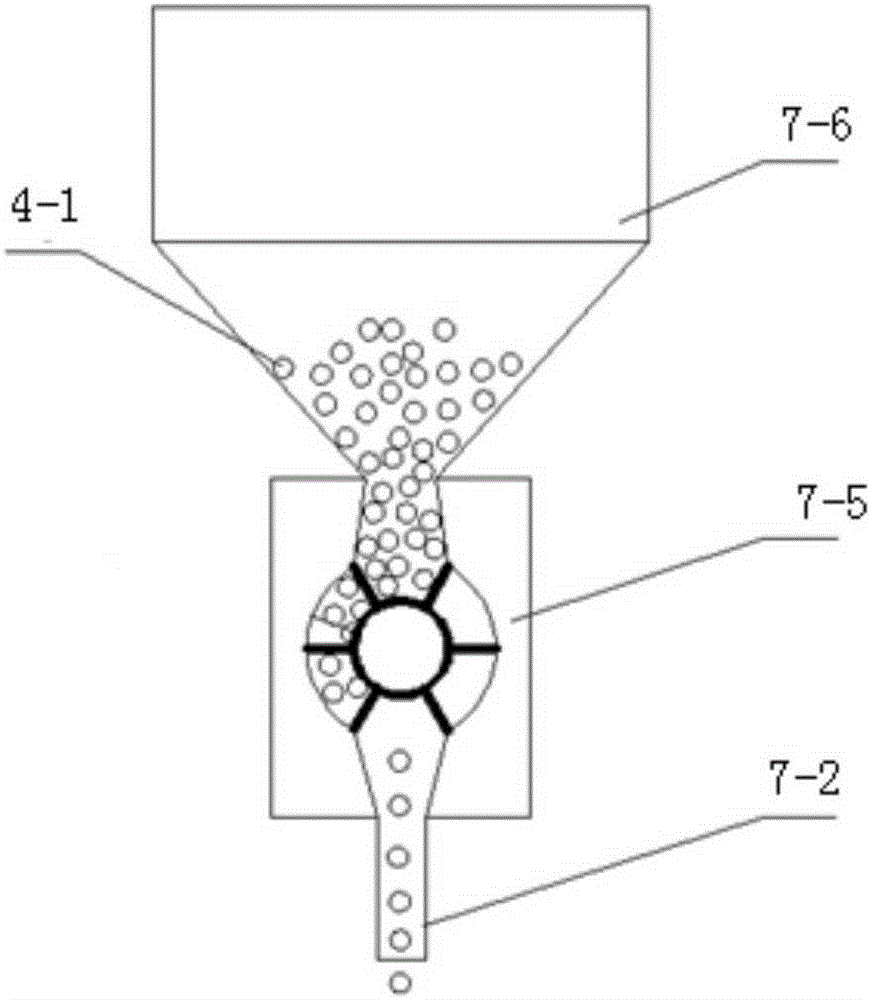

[0039] Such as Figure 1 to Figure 3 shown. The invention discloses a particle reinforced aluminum-based composite material stirring casting preparation device, which comprises a lifting mechanism 1, a resistance furnace 2, a fixed column 3, a load-bearing mechanism 4, a stirring device 6, a particle conveying device 7, a furnace cover 9, a feeding Port 10, intake pipe 11, graphite crucible 12, stainless steel crucible 13;

[0040] The stainless steel crucible 13 is placed in the resistance furnace 2; the graphite crucible 12 is placed in the closed space formed by the stainless steel crucible 13 and the furnace cover 9 of the resistance furnace 2, the inert gas enters through the intake pipe 11, and the stirring rod and the cover plate of the stirring device 6 The gap between 5 flows out; the load-bearing mechanism 4 is fixed on the outer wall of the resistance furnace 2; the stirring device 6 is installed on the load-bearing mechanism 4, and the load-bearing mechanism 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com