Servo Control Method of Gasoline Engine Speed in Legged Robot Hydraulic System

A gasoline engine and hydraulic system technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as increased assembly difficulty, complicated speed measurement, and inability to meet high-power engine speed control, reducing the difficulty of mechanical assembly and ensuring The effect of rotational speed stability, good dynamic and static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

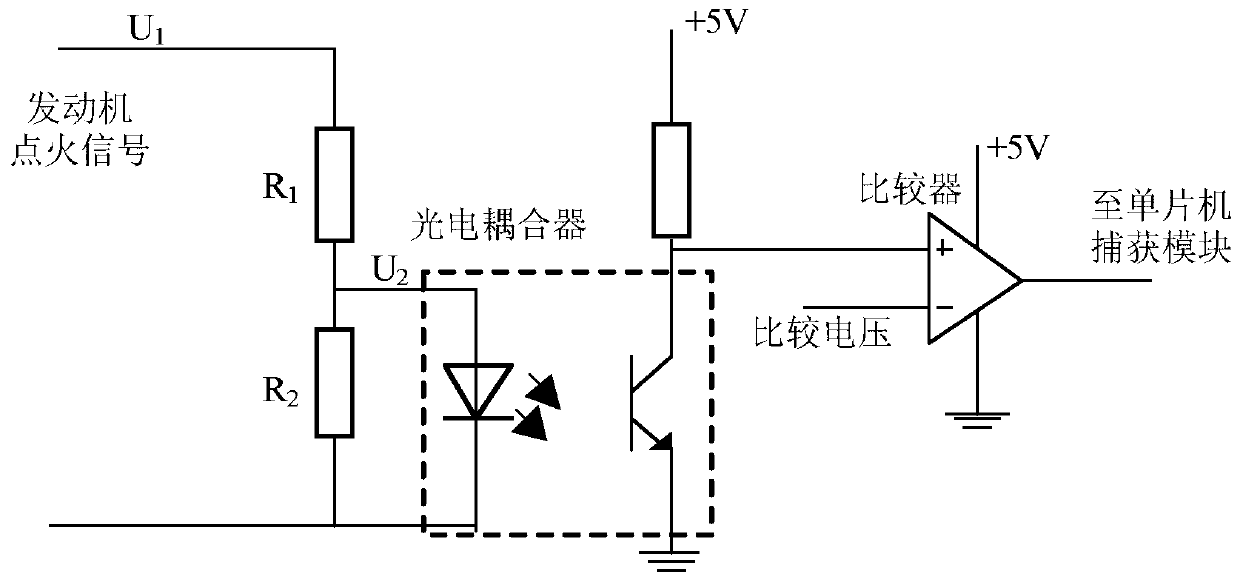

[0040] The speed servo control method of the gasoline engine of the leg-foot type robot hydraulic system of the present invention adopts a speed measuring circuit such as figure 1 As shown, the method of directly using the engine ignition signal to measure the engine speed is adopted. Since the initial signal peak-to-peak value is about 100V, it needs to be controlled by R 1 and R 2 The resistor divider network formed in series is used for step-down processing, and the processed voltage U 2 =U 1 *R 2 / (R 1 +R 2); after passing through the photocoupler, the signal is converted into a DC signal by using its one-way pass characteristic; finally, after the comparator LM393 is compared with the comparison voltage, the output square wave waveform with an amplitude of 5V is captured and calculated by the microcontroller capture module Speed, the calculation formula is v fed =60*f, where f is the frequency of the square wave captured by the single chip microcomputer.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com