Safe and energy-saving control device and control method of hot rolling high-pressure descaling system

An energy-saving control and descaling system technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as intermittent operation state and short-term shutdown without consideration, achieve stable speed, reduce motor rotor damage, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

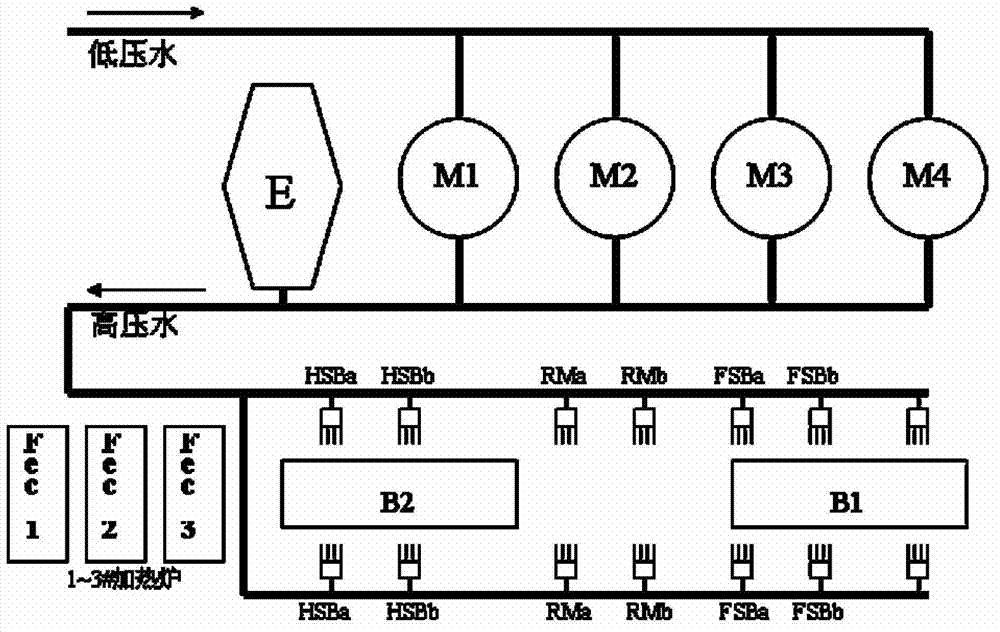

[0090] The process flow diagram of an embodiment of the hot-rolled high-pressure descaling system is as follows figure 1 Shown: During the production process of the hot-rolled high-pressure descaling system, the low-pressure water is pressurized into high-pressure water by the descaling pumps M1, M2, M3, and M4, and energy is stored in the gas-water energy storage tank E. When the heating furnace Fec1 , Fec2, and Fec3, the billets B1 and B2 arrive at the entrance and exit descaling points HSBa and HSBb of the rough rolling descaling box, the rough rolling mill entrance descaling point RMa, the exit descaling point RMb, the finishing rolling mill For scale points FSBa and FSBb, different descaling processes are carried out according to different steel billets. Different steel types have different descaling times at each descaling point. Some billets need descaling at a certain descaling point, and some do not. Descaling is required. When descaling is required, high-pressure wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com