Simply supported hollow plate girder bending resistance reinforcement method

A technology of hollow slabs and main girders, applied in bridge reinforcement, bridges, bridge maintenance, etc., can solve the problems of lagging stress and strain, limited improvement of the bending bearing capacity of main girders, and failure to reach the design value of tensile strength, so as to improve the utilization rate , Improve the effect of bending bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with drawings and embodiments.

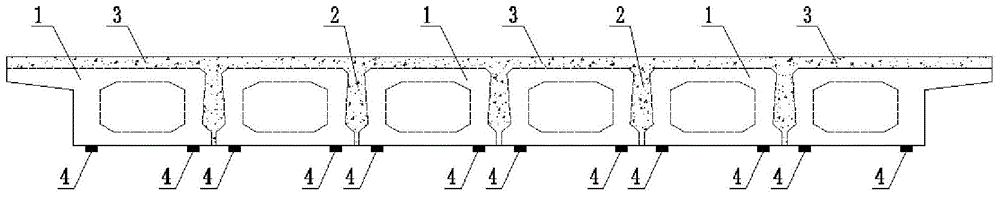

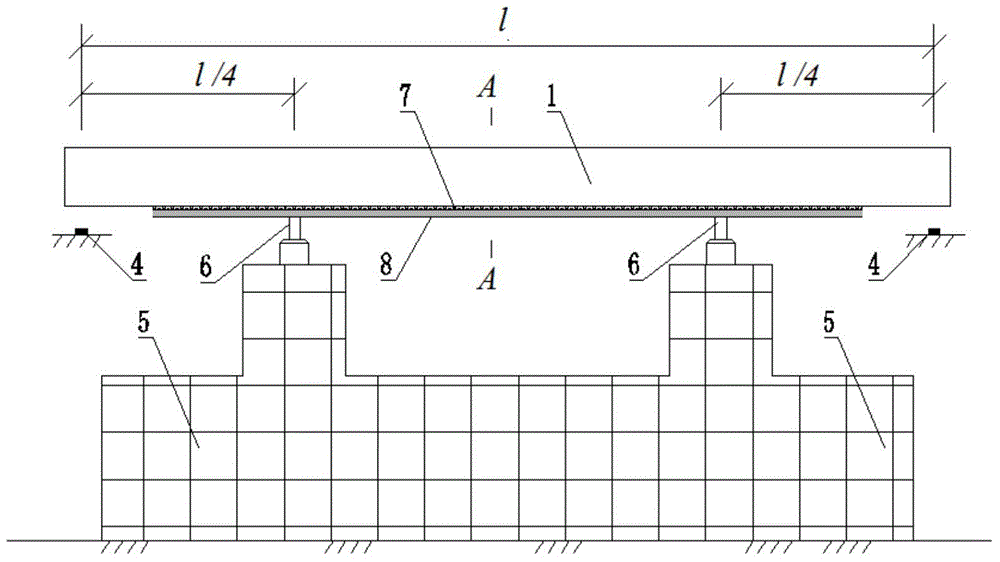

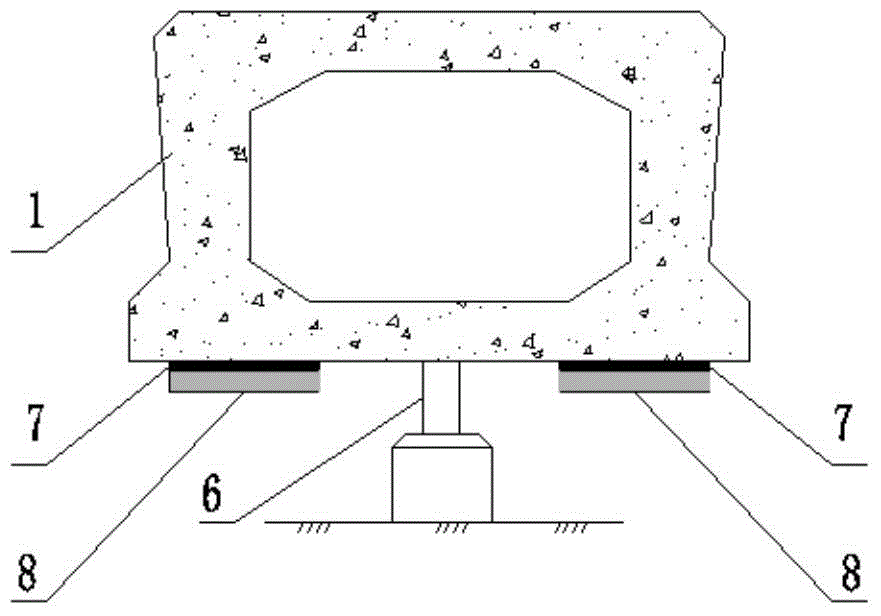

[0048] This embodiment is for figure 1 The hollow slab girder bridge consisting of six girders 1 is shown to be reinforced. The length, width and height of the main girder 1 of the bridge are (12960╳990╳700)mm, there are joints 2 for pouring concrete between the main girders, and the concrete bridge deck cast-in-place layer 3 is above the main girders. Before reinforcement, there is water seepage and whitening in the hinge joints of the hollow slab, and some hinge joints have cracking and falling off phenomena. There are many transverse cracks near the mid-span of multiple main girders. It is necessary to strengthen the main girder against bending and recast the hinge joints. .

[0049] Before the construction, determine whether the bridge possesses two conditions for adopting the reinforcement method of the present invention by following calculations:

[0050] A. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com