Steel structure reinforcing joint part with multiple anti-seismic progressive-collapse-resisting defensive lines

A steel structure and defense line technology, which is applied in building components, earthquake resistance, building structure, etc., can solve the problems of insufficient earthquake resistance and continuous collapse resistance, structural brittle damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

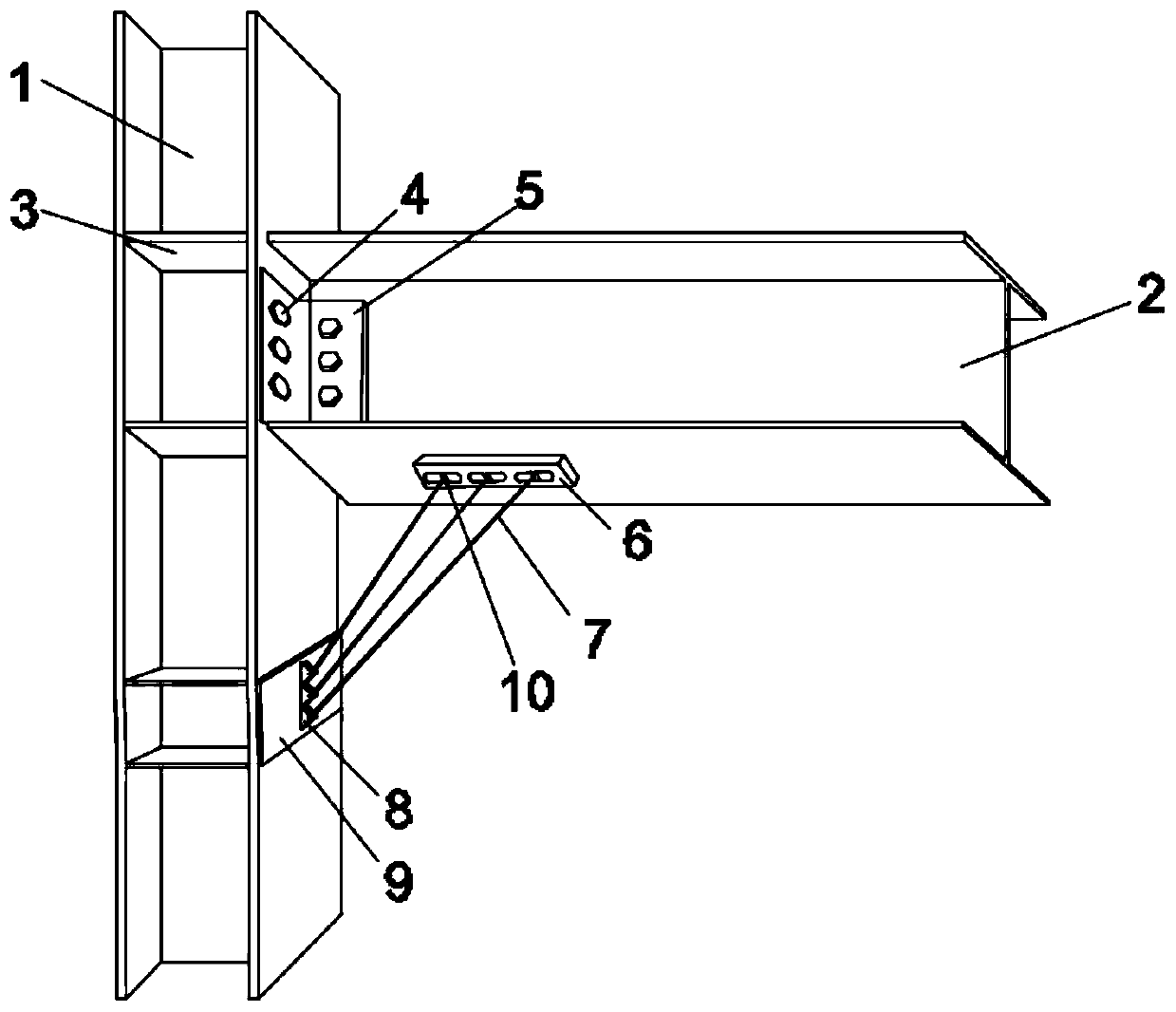

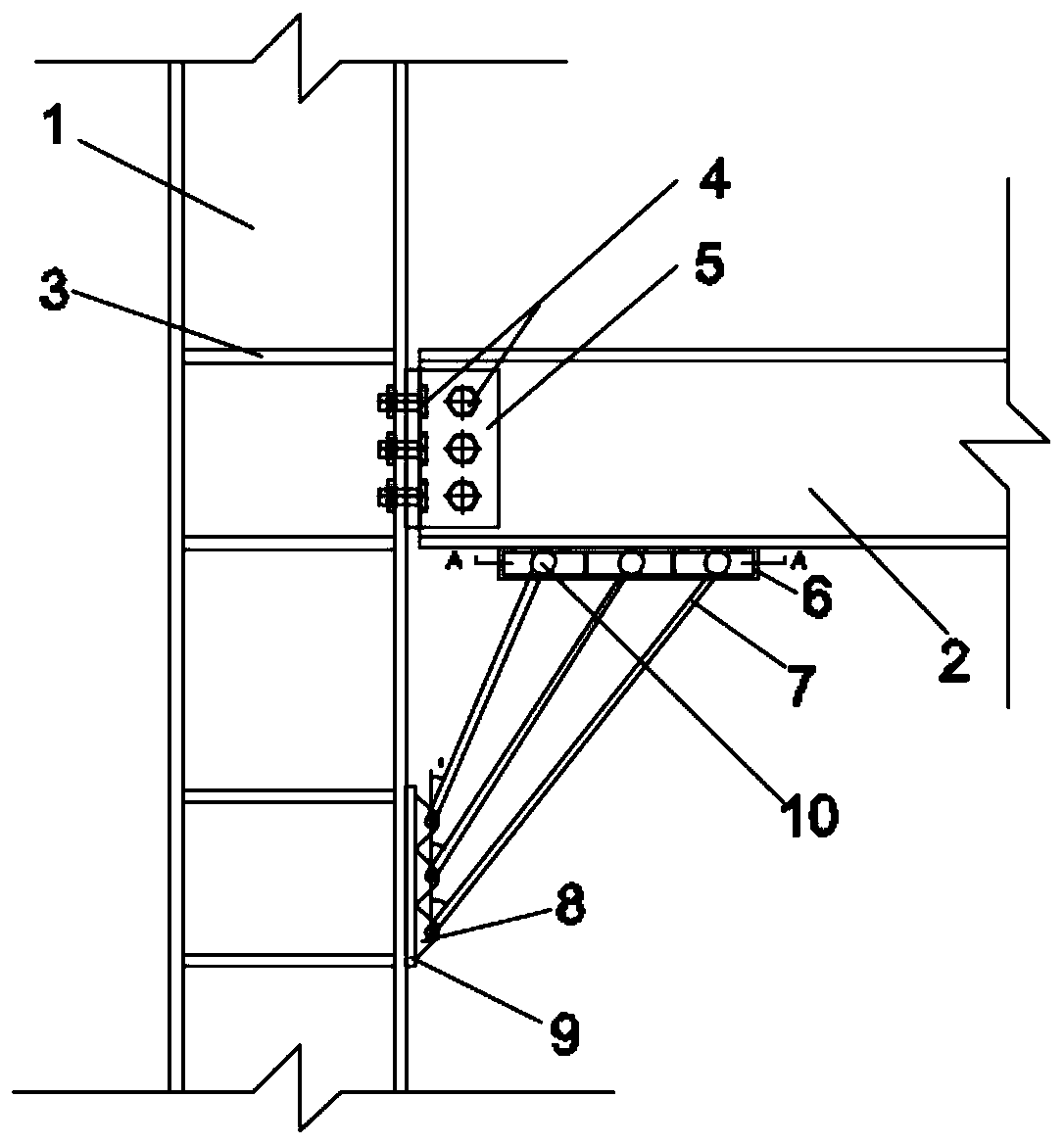

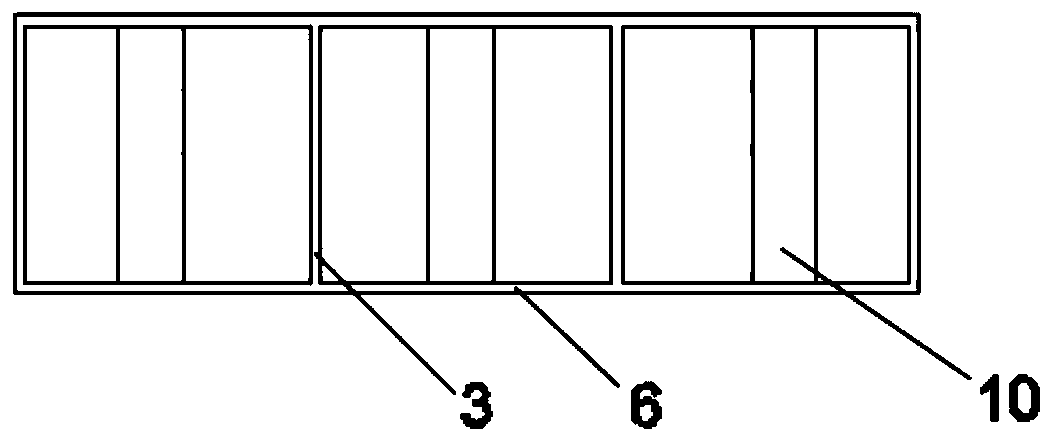

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , the steel structure reinforcement node member with multiple anti-seismic and anti-continuous collapse defense lines according to the present invention includes steel beam 2, steel column 1, steel channel 6 and truss chord 7; the end of steel beam 2 is fixed on steel column 1 , the steel channel 6 is fixed on the lower surface of the lower flange of the steel beam 2, the side of the steel column 1 is provided with a hinge support 8, the inner friction slider 10 of the steel channel 6 is provided with a through hole on the bottom surface of the steel channel 6, and the truss One end of the chord 7 is connected to the friction slider 10 through the through hole, and the other end of the truss chord 7 is connected to the hinge support 8 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com