Anti-seismic tubular pile production method

A production method and the technology of anti-seismic tubes, which are applied in the field of pile foundation materials, can solve the problems of application limitations, low seismic performance, and poor bending resistance, and achieve strong penetration capacity, high concrete strength of the pile body, and improved ductility and bending resistance The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

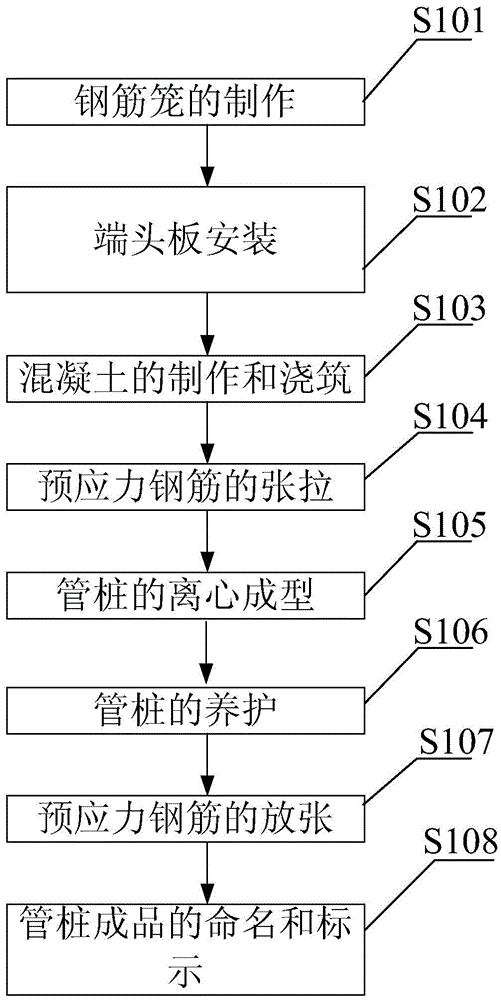

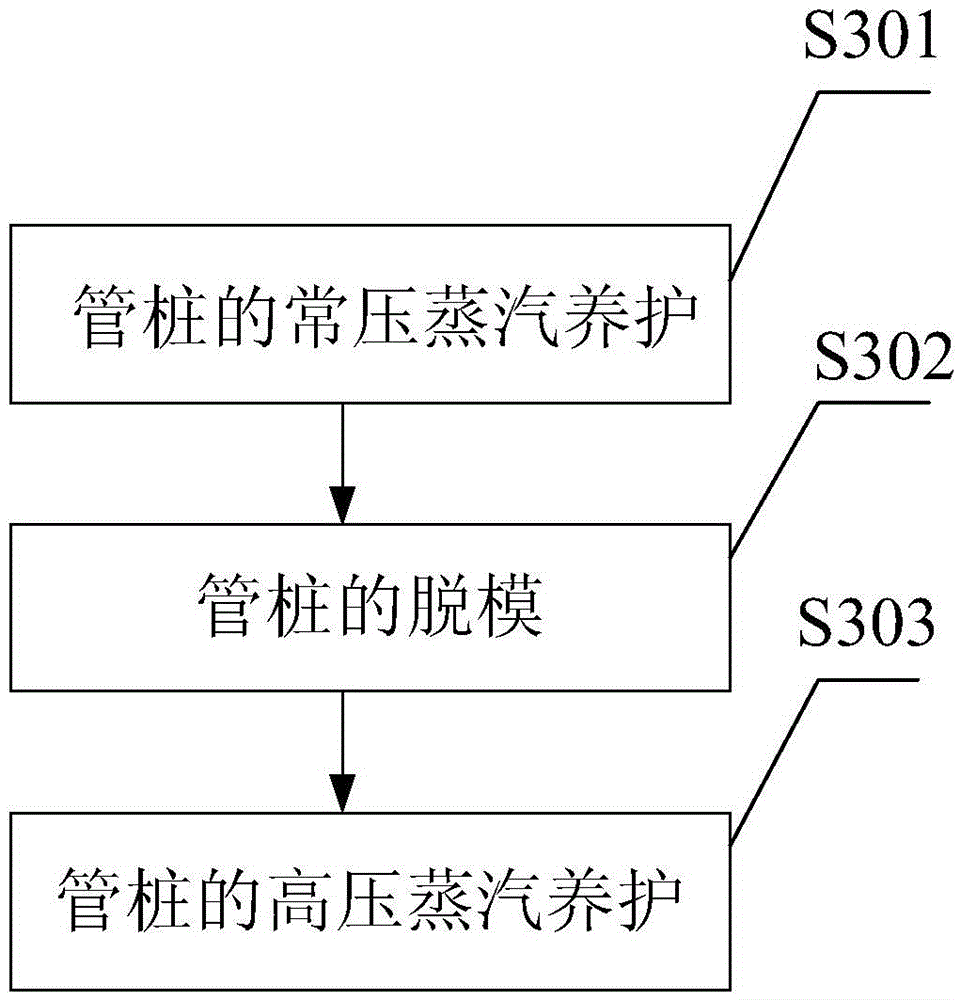

[0032] as attached figure 1 to attach image 3 shown

[0033] The invention provides a method for producing an anti-seismic pipe pile, comprising:

[0034] S101: Fabrication of reinforcement cages;

[0035] S102: install the end plate;

[0036] S103: Concrete production and pouring;

[0037] S104: tensioning of prestressed steel bars;

[0038] S105: Centrifugal forming of pipe piles;

[0039] S106: Maintenance of pipe piles;

[0040] S107: Release of prestressed steel bars;

[0041] S108: Naming and labeling of pipe pile products.

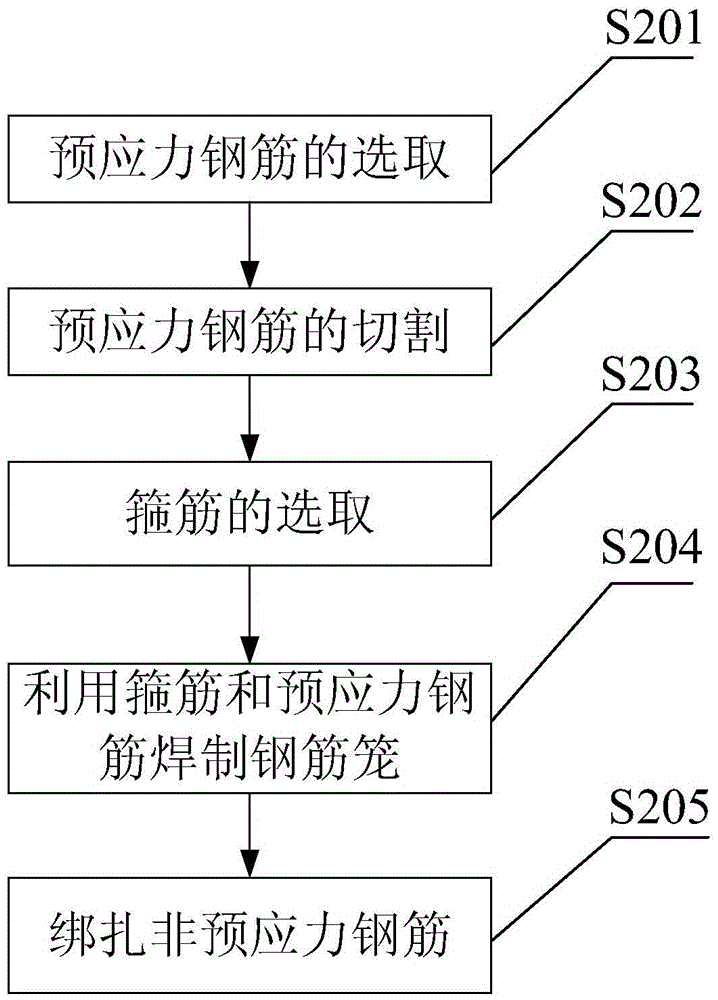

[0042] Further, in S101, the making of the reinforcement cage includes selection of prestressed reinforcement; cutting of prestressed reinforcement; selection of stirrup; welding of reinforcement cage with stirrup and prestressed reinforcement and binding of non-prestressed reinforcement.

[0043] Further, in S204, specifically, seam welding is adopted to form a reinforcement cage, and the spacing between the stirrups is 40 mm to 50 mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com