Microvesicle glass fireproofing insulation board and production method thereof

A technology of fireproof insulation board and production method, which is applied in the direction of glass/slag layered products, insulation, fire prevention, etc. It can solve the problems of poor water resistance affecting insulation effect, poor safety of bonding to the wall, and loss of insulation layer effect, etc., to achieve strengthening Surface strength and water resistance, simple and convenient construction, and the effect of improving bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

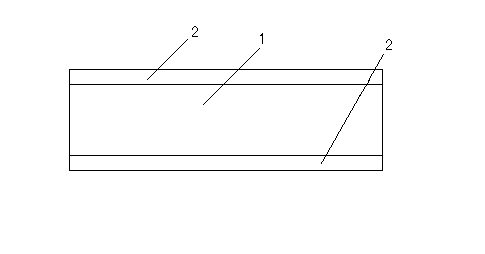

[0016] Embodiment 1: A kind of microbubble glass fire insulation board (see figure 1 ), which includes a mixed layer 1 of glass foam material and bonding material. There is a surface protection layer 2, and the surface protection layer 2 is a glass fiber grid cloth layer.

[0017] It is made according to the following process: the glass fiber mesh cloth is continuously laid flat, and a uniform mixture of vitrified microspheres and silicon-based binder is evenly spread on the surface. The mixture is vitrified microspheres and silicon The binder is fully mixed in a powder mixer. The selected vitrified microspheres have a bulk density of 120kg / m3 and the amount of silicon-based binder is 2kg / m3. The glass fiber mesh cloth enters the automatic continuous lamination machine through the chain plate for lamination, and then is dried and cured at 80-200 ° C, and then cut and packaged after curing.

Embodiment 2

[0018] Embodiment 2: A kind of microbubble glass fireproof insulation board (referring to figure 1 ), which includes a mixed layer 1 of glass foam material, short fiber and bonding material, the mixed layer is a mixed layer of microfoam foam glass, glass short fiber and acrylic emulsion, microfoam foam glass, glass short fiber and acrylic The upper and lower surfaces of the ester emulsion mixing layer 1 are provided with a surface protection layer 2, and the surface protection layer 2 is a cement coil layer.

[0019] It is made according to the following process: the cement coil is laid continuously, and the uniform mixture of microfoam foam glass, glass short fiber and acrylate emulsion is evenly spread on the surface. The mixture is microfoam foam glass , Short glass fiber and acrylate emulsion are fully mixed in a powder mixer. The bulk density of the selected microfoam foam glass is 200kg / m3, the amount of acrylate emulsion is 100kg / m3, and the short glass fiber accounts f...

Embodiment 3

[0020] Embodiment 3: A kind of microbubble glass fireproof insulation board (referring to figure 1 ), which includes a mixed layer 1 of glass foam material, short fibers and bonding material, the mixed layer is a mixed layer of vitrified microbeads, rock wool short fibers and aluminum binder, vitrified microbeads, rock wool short fibers and The upper and lower surfaces of the aluminum-based adhesive mixed layer 1 are provided with a surface protection layer 2, and the surface protection layer 2 is a glass fiber felt layer.

[0021] It is made according to the following process: the glass fiber mat is continuously laid flat, and the uniform mixture of vitrified microspheres, rock wool short fibers and aluminum binder is evenly spread on the surface. The mixture is vitrified microspheres. 1. Rock wool short fiber and aluminum-based binder are fully mixed in a powder mixer. The selected vitrified microspheres have a bulk density of 80kg / m3, the amount of aluminum binder is 150kg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com