Two-component polyurethane composition for concrete modification and preparation method thereof

A two-component polyurethane and concrete technology, applied in the field of polyurethane elastomers, can solve the problems of easy foaming, affecting the mechanical properties of polyurethane composite concrete materials, troublesome operation, etc., achieve strong permeability, facilitate large-scale application and on-site construction, The effect of sufficient operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare and use the two-component polyurethane composition for concrete modification as follows:

[0036] (1) Component A: Dehydrate 10kg of polyether polyol PPG1000 at a temperature of 100°C and a vacuum of -0.095MPa until the water content is less than 0.05wt%, then add 150kg of PM200, and carry out a polymerization reaction at 80°C for 3 hours to obtain iso The prepolymer with a mass content of cyanate group of 28wt% is sealed and stored after vacuumizing and defoaming, which is the A component;

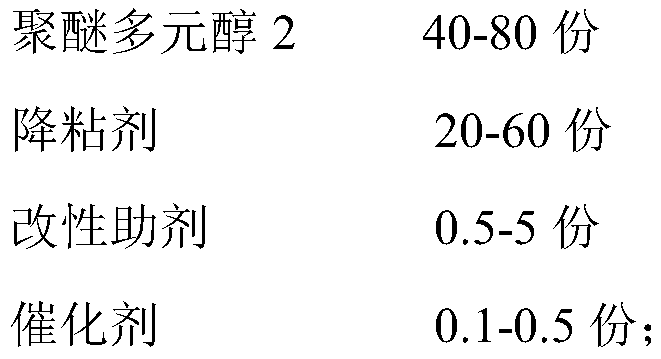

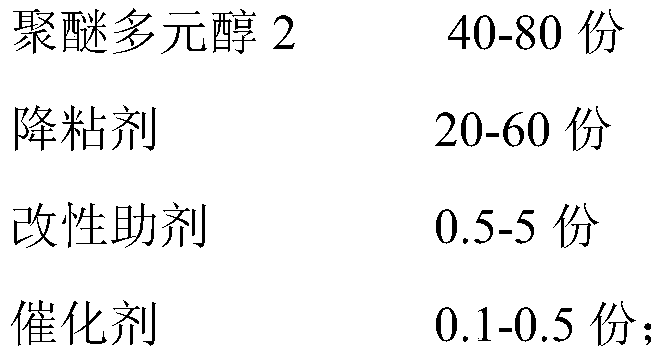

[0037] (2) Component B: obtained by mixing 40kg of modified soybean oil polyol, 60kg988SG, 2.5kg of KH560 and 0.3kg of tetramethylbutylene diamine catalyst at room temperature;

[0038] (3) Use: Mix component B and component A at a temperature of 30°C in a mass ratio of 100:50 to obtain a polyurethane composition, and then add concrete materials 5 times the total mass of the polyurethane composition (among which the amount of sand and cement The ratio is 1:1) to obtain the...

Embodiment 2

[0040] Prepare and use the two-component polyurethane composition for concrete modification as follows:

[0041] (1) Component A: Dehydrate 10kg of polyether polyol PPG305 at a temperature of 105°C and a vacuum of -0.095MPa until the water content is less than 0.05wt%, then add 100kg of MDI-50, and carry out a polymerization reaction at 75°C for 4 hours. Obtain a prepolymer with an isocyanate mass content of 28wt%, and store it in a sealed manner after vacuuming and defoaming, which is the B component;

[0042] (2) Component B: obtained by mixing 60kg of modified soybean oil polyol, 40kg of butyl benzyl phthalate, 1.5kg of KH560 and 0.3kg of zinc diethylhexanoate catalyst at room temperature;

[0043] (3) Use: Mix component B and component A at a temperature of 30°C in a mass ratio of 100:50 to obtain a polyurethane composition, and then add concrete materials 10 times the total mass of the polyurethane composition (wherein the amount of sand and cement The ratio is 1:1) to o...

Embodiment 3

[0045] Prepare and use the two-component polyurethane composition for concrete modification as follows:

[0046] (1) Component A: Dehydrate 10kg of polyether polyol PPG1000 at a temperature of 105°C and a vacuum of -0.095MPa until the water content is less than 0.05wt%, then add 40kg of MDI-50, and carry out polymerization at 75°C for 4 hours , to obtain a prepolymer with an isocyanate mass content of 25wt%, which is sealed and preserved after vacuumizing and degassing, which is the B component;

[0047] (2) Component B: 50kg modified castor oil polyol, 50kg dioctyl terephthalate, 3.0kg KH550 and 0.3kg zinc diethylhexanoate catalyst were mixed at normal temperature;

[0048](3) Use: Mix component B and component A at a temperature of 30°C in a mass ratio of 100:70 to obtain a polyurethane composition, and then mix in concrete materials 13 times the total mass of the polyurethane composition (the amount of sand and cement The ratio is 1:1) to obtain the polyurethane modified c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com