Heat insulation decoration board and its connecting component on site construction method

A technology for thermal insulation decorative panels and on-site construction, applied in covering/lining, architecture, building structure, etc., can solve the problems of high production cost, complex on-site installation process, numerous steps, etc., and achieve good decorative effect, simple and reasonable structure, Manipulate flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

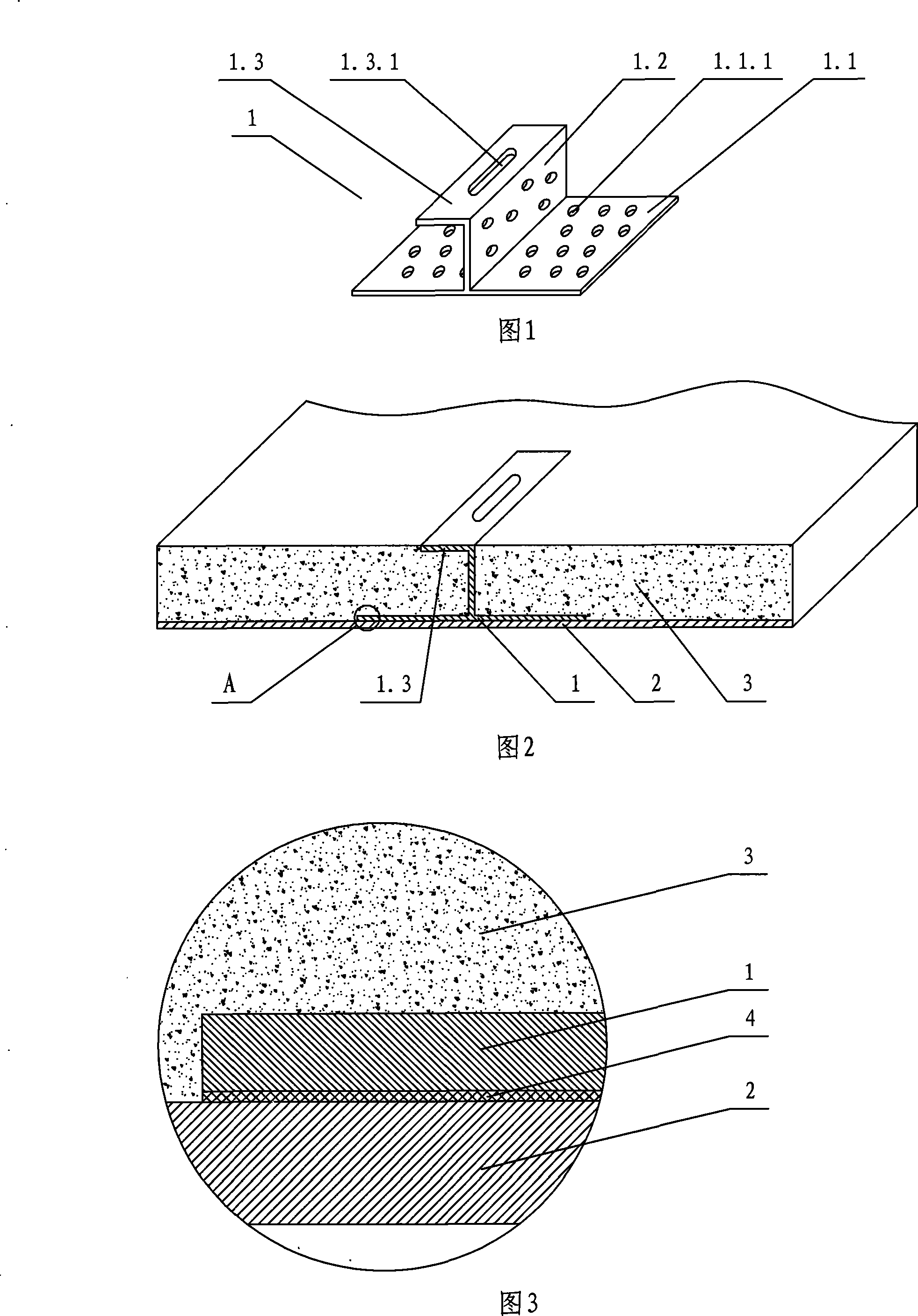

[0042] Referring to Fig. 1-Fig. 5, the thermal insulation decorative board and its connecting parts are embedded with one or more thin-walled first connecting parts 1, and the first connecting parts include the first horizontal bottom board 1.1. A vertical vertical board 1.2, the top of the first vertical vertical board is provided with a first horizontal fold 1.3, the first horizontal fold is arranged at right angles to the first vertical vertical board, the top surface of the first horizontal fold and the polyurethane layer 3 The upper surface is even, and the first positioning hole is provided on the first transverse flange, the first positioning hole is a strip hole 1.3.1 or a round hole 1.3.2, and the first transverse bottom plate and the first vertical vertical plate are provided with The first small hole for reinforcement 1.1.1. After the first horizontal fold 1.3 is bent outward, it is set at an obtuse angle with the first vertical vertical plate 1.2, the polyurethane ...

no. 2 example

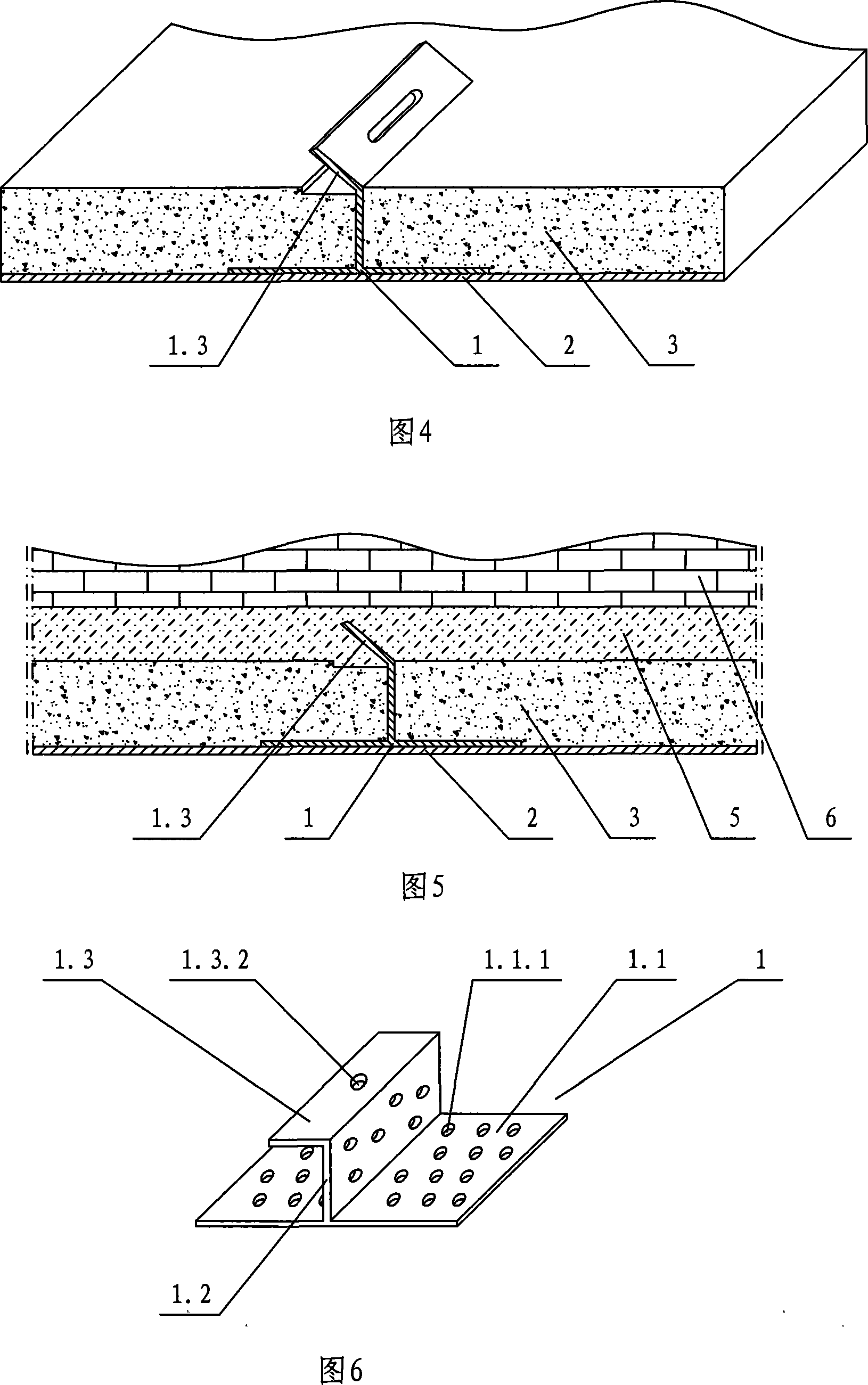

[0046]Referring to Fig. 6-Fig. 7, after the first transverse flange is bent outward, it is set at an obtuse angle with the first vertical vertical plate, and a short positioning rod 1.4 or a screw is arranged in the first positioning hole, and the short positioning rod or screw is connected with the second positioning hole. The transverse folds are arranged at an angle, the polyurethane layer of the thermal insulation decorative board is attached to the putty layer, and the second transverse fold and short positioning rods or screws are embedded in the putty layer together.

[0047] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

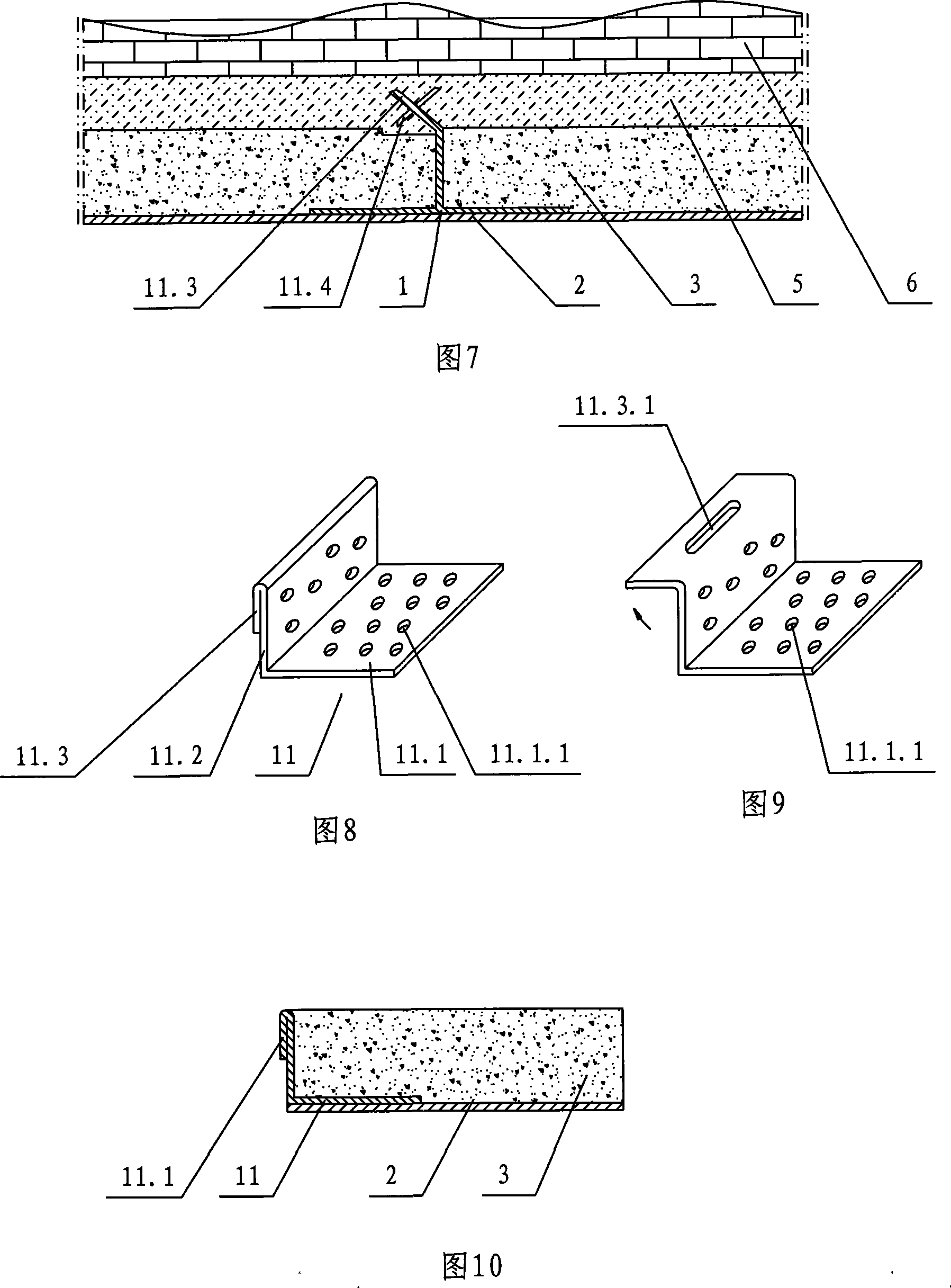

[0049] 8-10, the second connecting piece 11 includes a second vertical vertical plate 11.2 arranged on the second horizontal bottom plate 11.1, the end of the second vertical vertical plate is provided with a second transverse flange 11.3, the second The horizontal fold is close to the second vertical vertical plate, the highest point of the second vertical vertical plate and the second horizontal fold is flush with the upper surface of the polyurethane layer 3, and the second horizontal fold is provided with a second positioning hole 11.3.1 , the second connecting piece is arranged on the edge of the decorative substrate, the second vertical vertical plate is arranged outwardly, and the second transverse fold is arranged outwardly. The second transverse fold 11.3 is set at right angles to the second vertical vertical plate 11.2 after being folded, and the second transverse fold is laid on the putty layer 5, and the second transverse fold of two adjacent thermal insulation deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com