Aquatic floating and transportation method of ultra-large type component

A super-large, component technology, used in transportation and packaging, special-purpose ships, ships, etc., can solve problems such as damage to the structure of the component itself, inability to adjust the left and right heels, and increase the difficulty of floating, to reduce resistance and increase fore and aft defense. Crash-safe float function, easy to control and adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

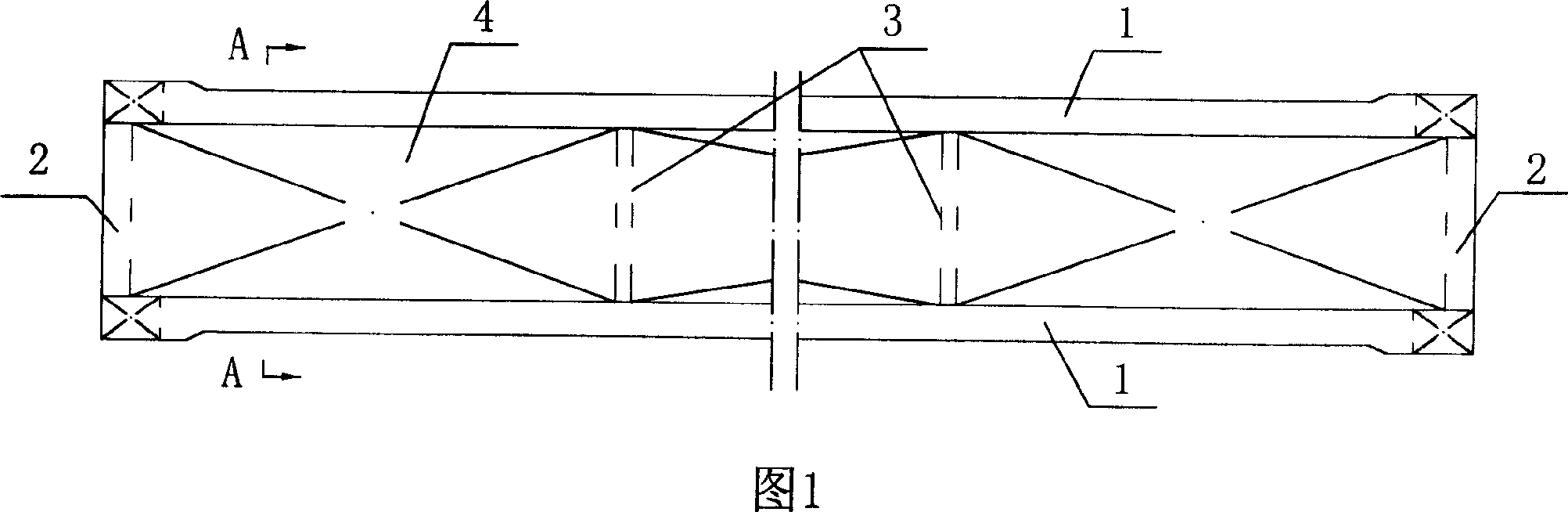

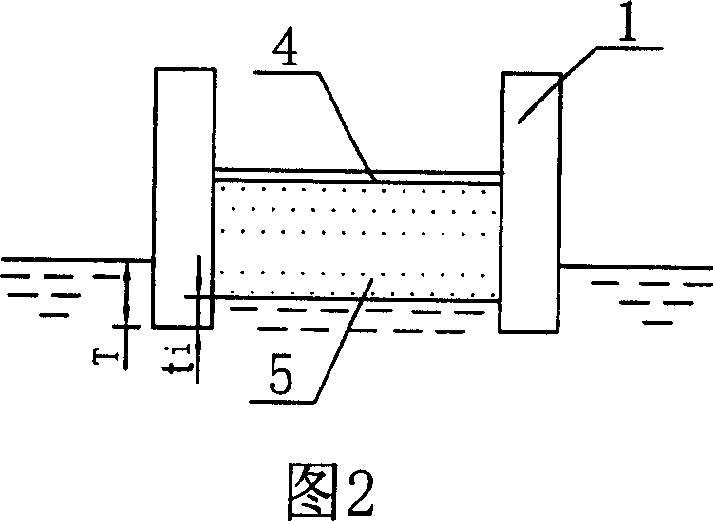

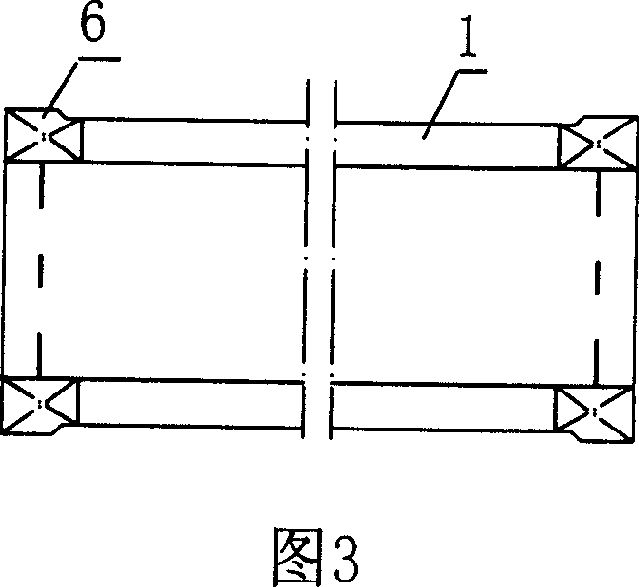

[0025] The embodiment of the present invention will be further described below in conjunction with the accompanying drawings. For the overall floating of the main longitudinal beam member of the ship-bearing compartment of the Three Gorges ship lift in the Yangtze River, a long steel welded structure includes a main body with box-shaped cross-sections arranged on both sides. Longitudinal beam 1, both ends of the main longitudinal beam are closed to form a sealed cabin, and airtight ballast water tanks are arranged at the two ends of the two main longitudinal beams, thereby forming four independent ballast water tanks 6 at the front, rear, left, and right , the ballast water tank is connected with the ballast pump water system, which is used to adjust the heel and pitch of the floating body. The ballast pumping system is arranged in the box-shaped main longitudinal girder and beam, and the ballast water tank is communicated with the floating water surface through connecting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com