Patents

Literature

39results about How to "Improve thermal inertia" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

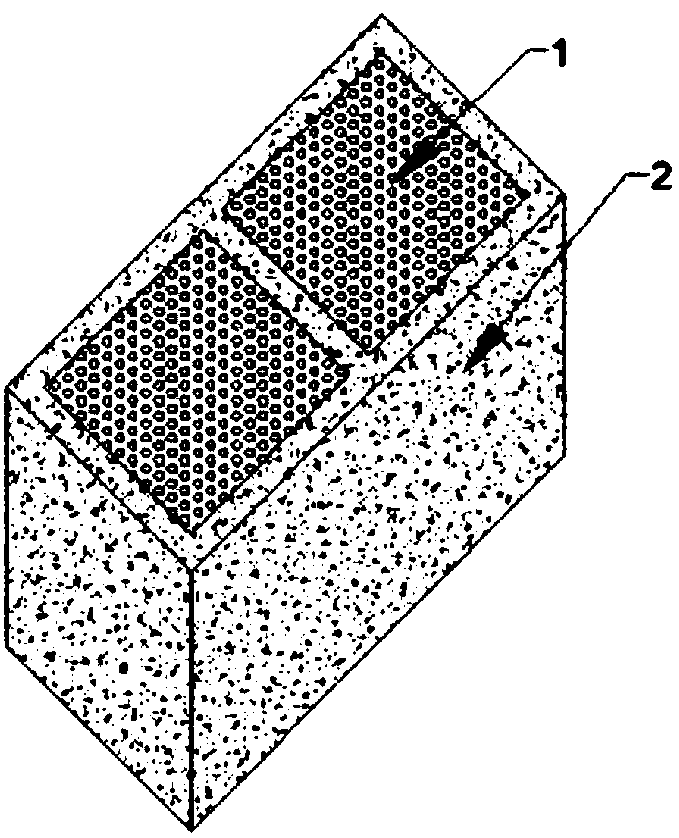

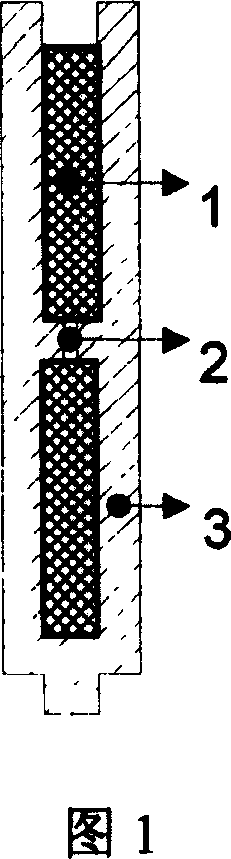

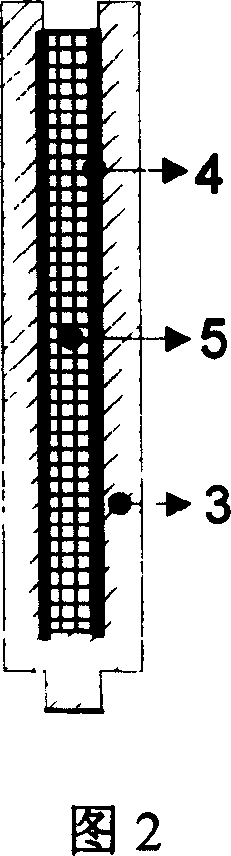

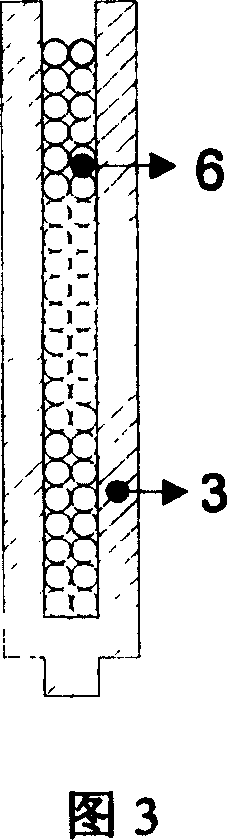

Novel phase change-heat preservation composite wall structure

InactiveCN101413299AImprove peak clipping delay effectImprove thermal inertiaWallsHeat proofingInsulation layerThermal insulation

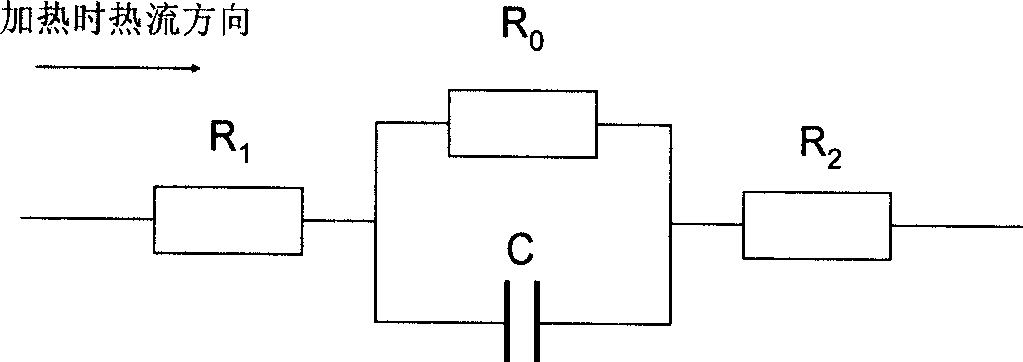

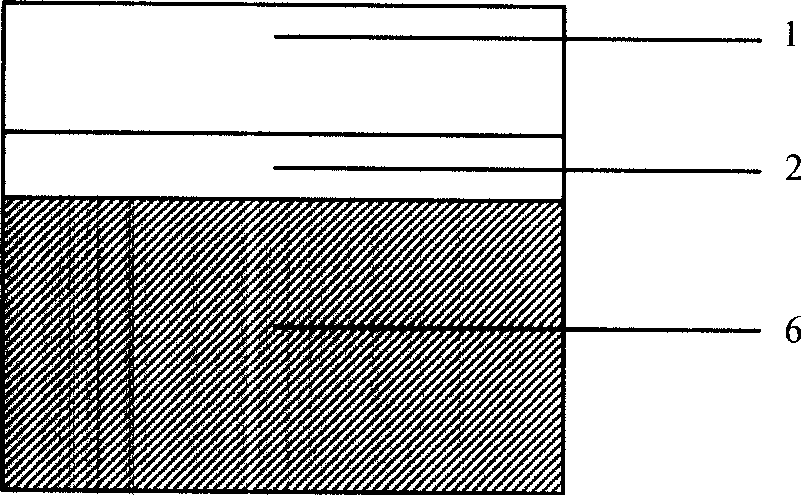

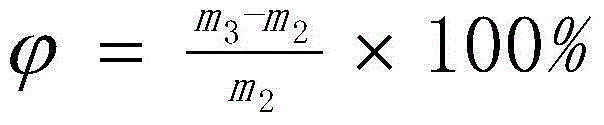

The invention relates to a novel phase change and heat insulation composite wall structure, which is applied to the heat insulation of a wall and mainly comprises a heat insulation layer, a figurate phase change layer and a wall base body to form an integrative composite structure. The heat transmission resistance of the composite wall structure can be evaluated according to the material and the thickness of the wall base body so as to figure out the material thickness of the heat insulation layer and ensure that the heat transmission resistance of the wall base body is equal to that of the heat insulation layer, so that the despicking delay effect of the phase change layer to the temperature variation is improved to the utmost extent. The composite wall structure gives full play to the heat insulation effect of the heat insulation layer and the heat storage and temperature regulation effect of the phase change layer to improve the thermal inertia of the wall body greatly. The composite wall structure has stable performance and is convenient in construction and energy-saving reconstruction of old buildings to achieve the effects of high efficiency and environmental protection.

Owner:武汉科华高新材料发展有限公司

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

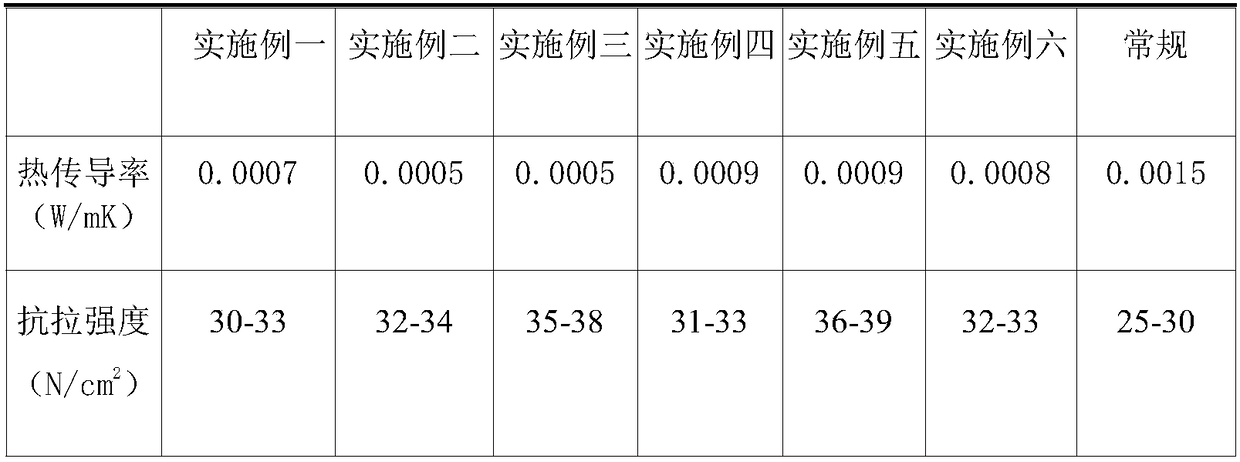

Vacuum thermal-insulation plate core material for building

InactiveCN106946535AImprove stabilityReduce manufacturing costClimate change adaptationInsulation improvementSodium BentonitePolyvinyl alcohol

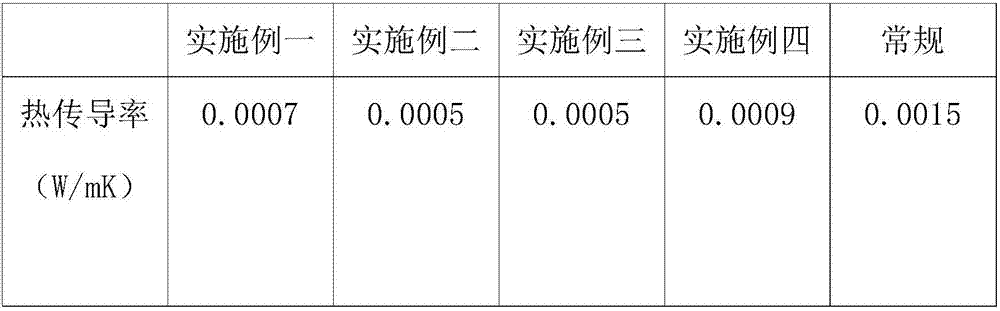

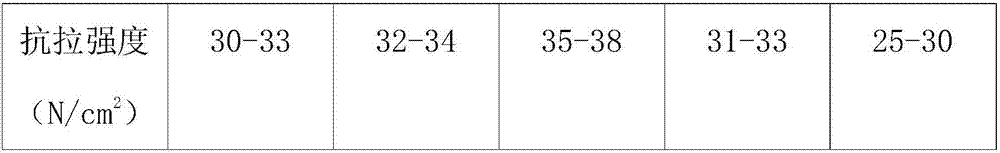

The invention belongs to the field of vacuum thermal-insulation plates, and particularly relates to a vacuum thermal-insulation plate core material for building. In the prior art, the existing core material does not have excellent pressure-resistant stability and excellent thermal-insulation stability, and has disadvantages of high heat thermal conductivity, high cost and difficult processing, and the heat inertness and the thermal insulation do not meet the stringent requirements. A purpose of the present invention is to solve the problems in the prior art. The technical scheme of the present invention is that the raw materials comprise, by weight, 20-25 parts of stone wool fibers, 18-22 parts of glass fibers, 23-26 parts of mineral wool, 22-26 parts of silicon dioxide, 14-18 parts of calcium chloride hexahydrate, 8-12 parts of quicklime, 6-9 parts of acrylic acid, 7-11 parts of polyvinyl alcohol, 4-8 parts of potassium bisulfite, 13-16 parts of bentonite, 11-14 parts of quartz sand, 9-13 parts of magnesium oxide, 5-8 parts of zinc oxide, and 30-35 parts of deionized water. The preparation method comprises: S1, adding acrylic acid and deionized water to a reaction kettle. According to the present invention, the vacuum thermal-insulation plate core material has advantages of excellent pressure-resistant stability, excellent thermal-insulation stability, low thermal conductivity, high hardness, excellent heat inertness, excellent heat insulation effect, low production cost, and convenient processing.

Owner:HUANGHE S & T COLLEGE

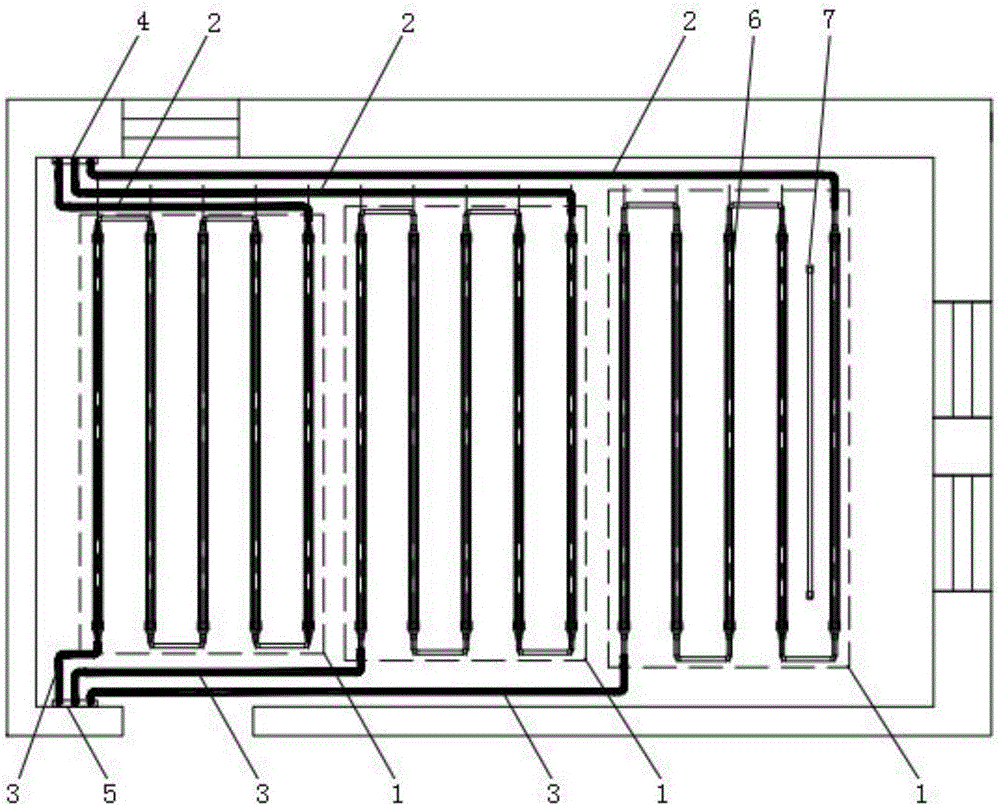

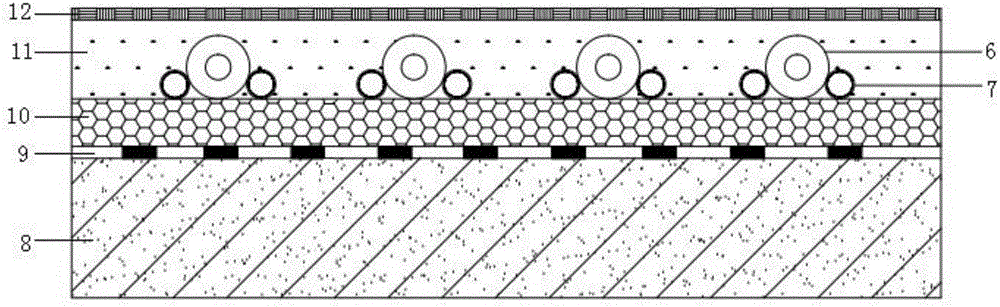

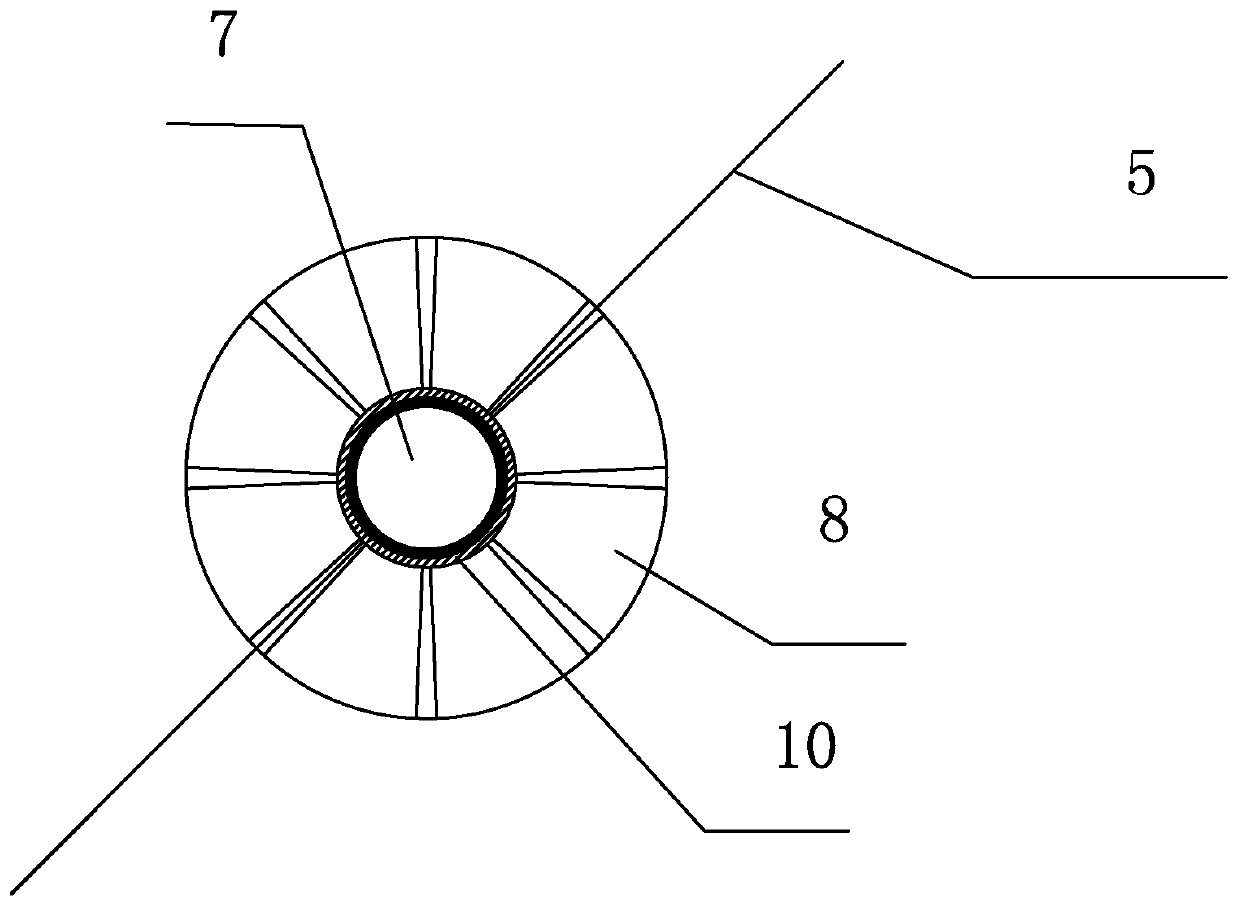

Adjustable phase change heat storage floor based on heat storage heating pipes

InactiveCN106594853AHeating evenlyIncrease profitElectric heating systemHeat storage plantsEngineeringPeak load

The invention discloses an adjustable phase change heat storage floor based on heat storage heating pipes. The adjustable phase change heat storage floor comprises a structural layer, a damp-roof layer, a thermal insulating layer, a packing layer and a decoration surface layer. A plurality of heating pipe modules are laid in the packing layer, connected in parallel in an equal pipe road mode, and arranged between a water distributing device and a water collecting device located on the two sides of a room. A water inlet of each heating pipe module is connected to the water distributing device through a water supply pipe of the module. A water outlet of each heating pipe module is connected to the water collecting device through a water return pipe of the module. Each heating pipe module is a loop composed of the multiple heat storage heating pipes connected in series. The packing layer is further internally provided with heat storage bars. By adoption of the adjustable phase change heat storage floor, efficient and diversified utilization of solar energy in building heating in winter can be achieved, and the problem that coal-fired heating is adopted in rural areas in northern China and the environment is polluted is relieved; and meanwhile, the problem of peak power shortage can be solved, peak-load shifting is achieved, and development of coal-to-electricity projects is facilitated.

Owner:TIANJIN UNIV

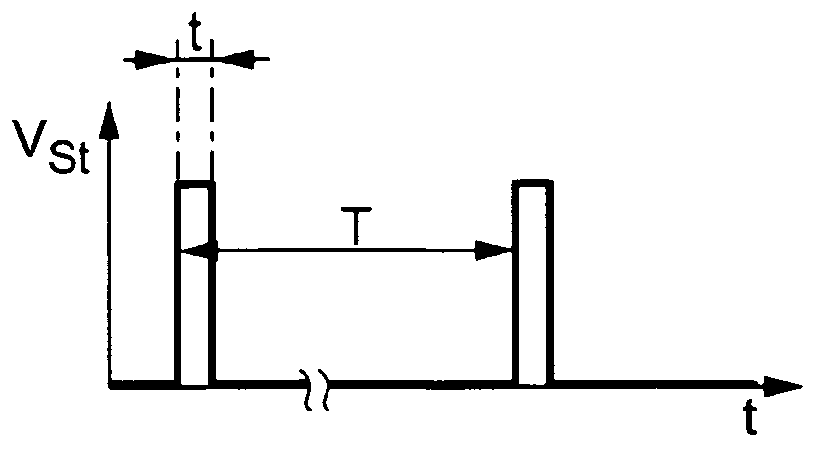

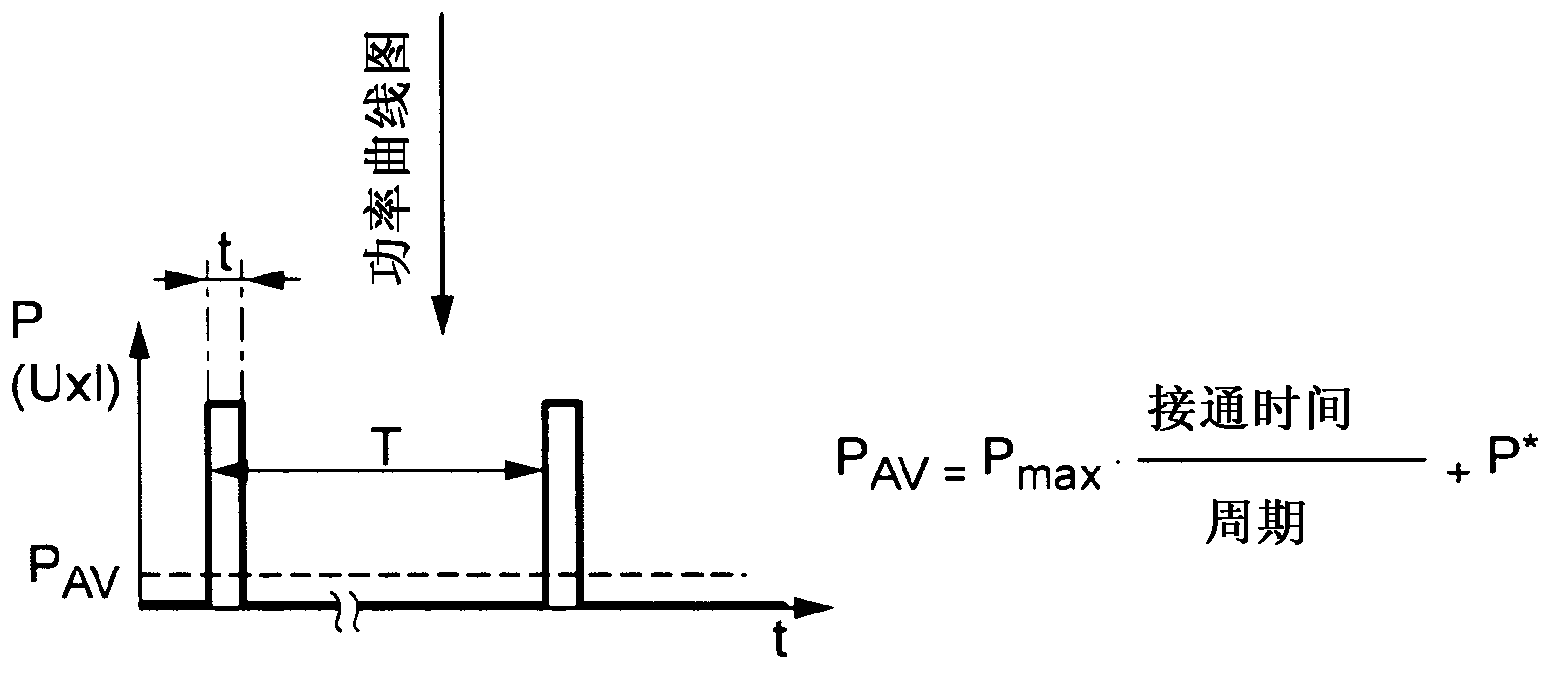

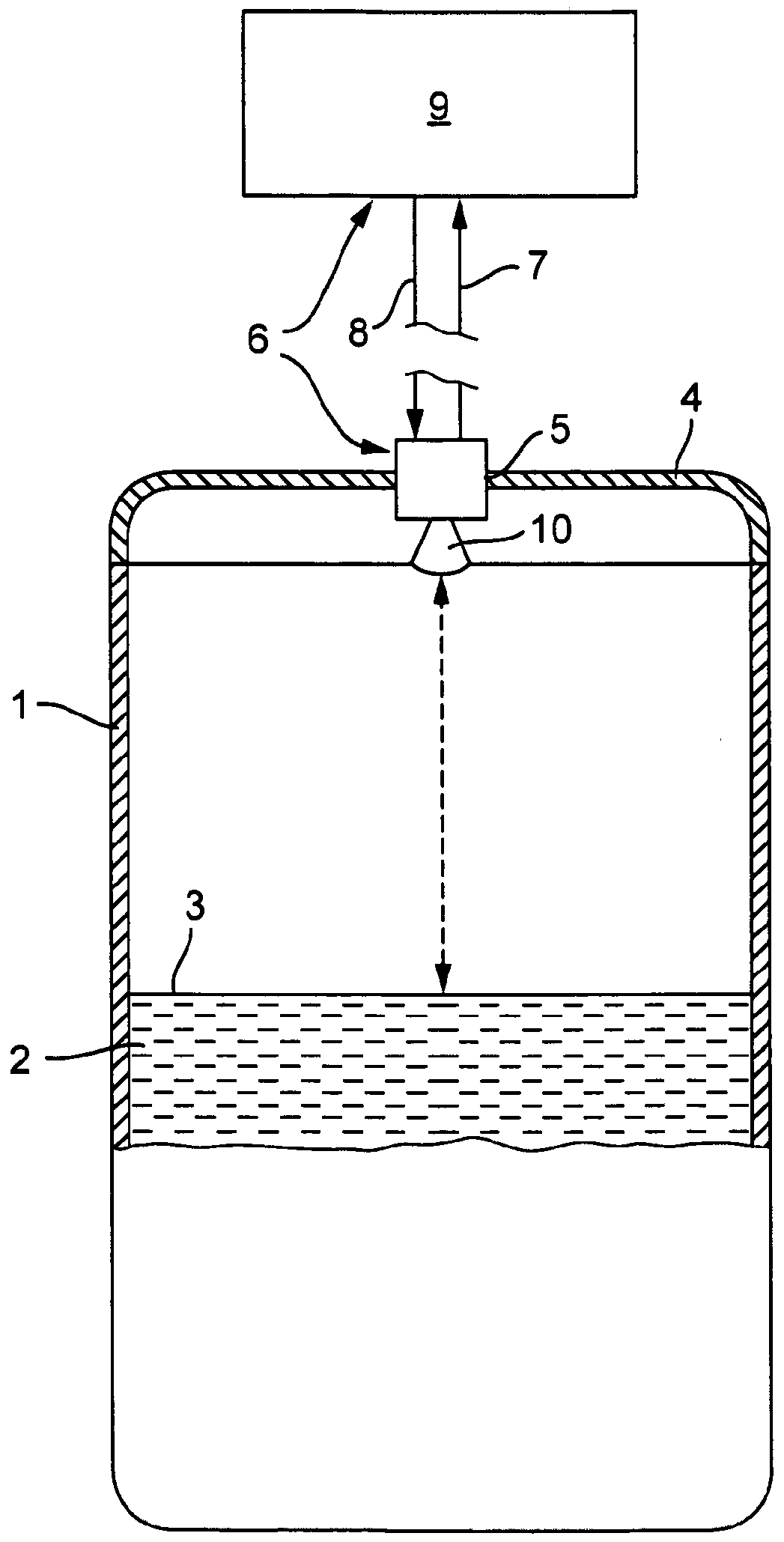

Electrical or electronic safety module

InactiveCN103250034AImprove thermal inertiaFast measurement speedVolume indication and recording devicesMachines/enginesElectronic componentElectronic security

A time triggered crowbar, which is so embodied that it monitors the on-time of at least one downstream electronic component and the period of clocking and therewith the power supply in such a manner that a predetermined maximum allowable surface temperature of the at least one downstream component is not exceeded in the explosion endangered area.

Owner:EHNDRESS KHAUZER GMBKH KO KG

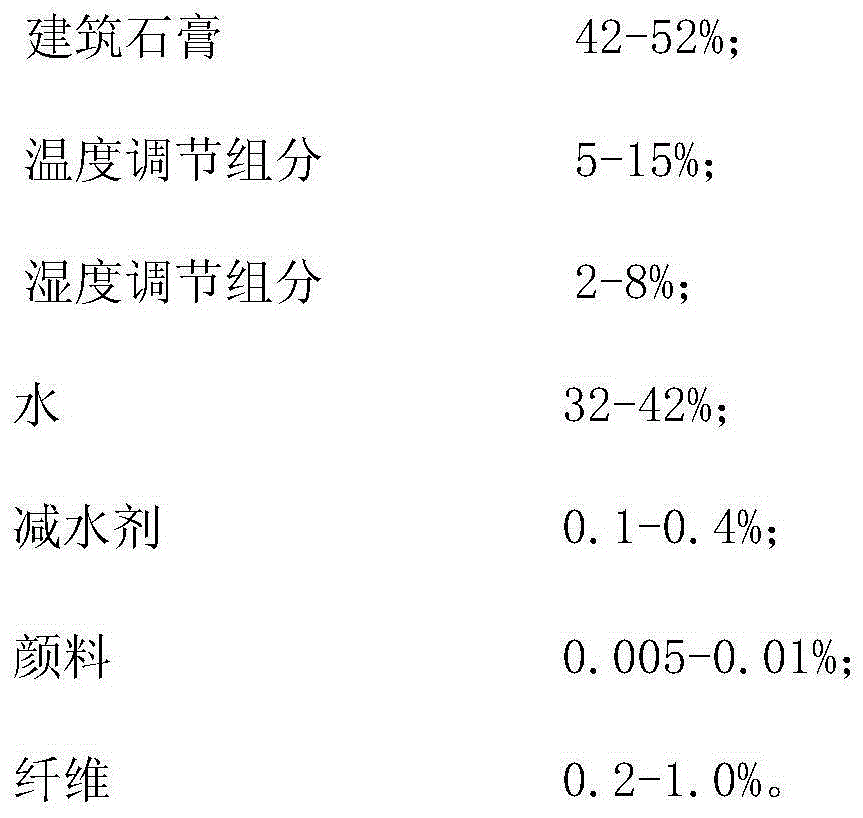

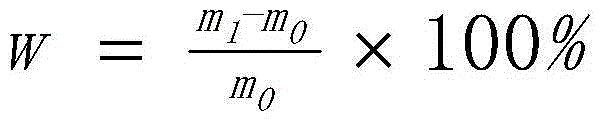

Wall material capable of adjusting indoor environmental temperature and humidity and preparation method of wall material

InactiveCN105218056ASimple preparation processImprove thermophysical propertiesFiberThermal insulation

The invention discloses a wall material capable of adjusting indoor environmental temperature and humidity and a preparation method of the wall material. The wall material is prepared from components in percentage by weight as follows: 42%-52% of building plaster, 5%-15% of temperature adjustment components, 2%-8% of humidity control components, 32%-42% of water, 0.1%-0.4% of water reducing agents, 0.005%-0.01% of pigments and 0.2%-1.0% of fiber. According to the wall material, the preparation process of a functional wall material is optimized, fluctuation of indoor environmental temperature and humidity is reduced, the durability, the anti-permeability, the anti-cracking performance and the fireproof performance of a wall body are improved, and energy consumption is reduced during construction; with the adoption of the temperature adjustment components and the humidity control components, the wall material has the function of indoor environmental temperature and humidity adjustment, the homogeneity of the wall material is guaranteed, and a product has high strength and seldom contracts; the thermal physical performance of the wall material is excellent, the wall body does not require a thermal-insulation layer, and construction procedures are reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

Energy storage building material and preparation method thereof

The invention discloses an energy storage building material and a preparation method thereof. The energy storage building material is prepared by mixing a mixture of polyethylene glycol and cement and expanded graphite, wherein the mass ratio of the polyethylene glycol to the cement is 1:1-10, and the expanded graphite is 1 to 10 percent of the mass concentration of the mixture of the polyethylene glycol and cement. The preparation method comprises the following steps of: mixing the polyethylene glycol with the molecular weight of 1,000 and the cement in the mass ratio of 1:1-10 to form the mixture of the polyethylene glycol and the cement, heating the polyethylene glycol in the mixture into a completely molten state, and uniformly stirring with the cement to form an uniform mixture; and adding the expanded graphite with the mass concentration of 1 to 10 percent into the uniform mixture, and continuously stirring uniformly to obtain the energy storage building material. By compounding wall materials and the energy storage building material, the temperature regulation capacity of the buildings can be enhanced, and the energy-saving and comfortable effects can be achieved.

Owner:NANJING UNIV

Wall body intelligent heat-insulation building envelope

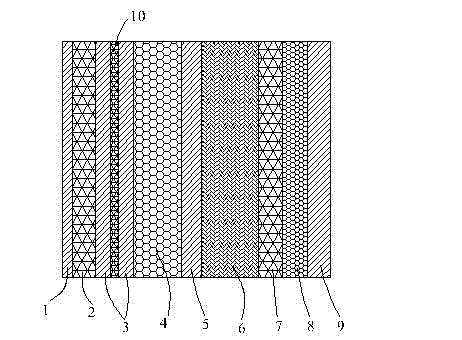

InactiveCN103306396AImprove thermal insulationImprove thermal insulation performanceWallsClimate change adaptationEnvironmental resistanceFiberglass mesh

The invention discloses a wall body intelligent heat-insulation building envelope, which is characterized in that the building envelope comprises an outer wall thermal reflecting coating layer, a plaster layer, a foamed cement infrared-shielding heat-insulation layer, an adhesive layer, a wall body base material layer, an inner wall leveling mortar layer, a putty layer and a phase-change inner wall coating energy storage layer sequentially from outer side to inner side, wherein a glass fiber net layer is covered in the plaster layer. The outer surface of the outer wall thermal reflecting coating layer is coated with a photocatalyst purification layer. The arranged outer wall thermal reflecting coating layer has a heat-insulation effect, and meanwhile the arranged foamed cement infrared-shielding heat-insulation layer realizes integration of safe, energy-saving, durable, green and environment-friendly performances and has a better heat-insulation effect; the phase-change energy-storage building material has greater phase-change latent heat, and can store and release heat energy so as to realize an intelligent heat-insulation effect; finally, the outer surface is coated with the photocatalyst purification layer which has an outer wall purification and cleaning effect.

Owner:JIYUZHE XIAMEN MATERIAL TECH CO LTD

Method of preparing building bricks by adopting gangue

InactiveCN109095889AReduce usageOvercome the current situation of scarcityCeramic materials productionClaywaresFiberBrick

The invention discloses a method of preparing building bricks by adopting gangue and relates to the technical field of building materials. The method specifically comprises the following steps: (1) weighing raw materials: gangue, coal ash, weathered shale, sludge, clay, cement, cotton fibers, wood fibers, a defoamer, a water reducer, an early strength agent and water; (2) crushing and screening the gangue, coal ash and weathered shale; (3) preparing a mixed material A; (4) preparing a mixed material B; (5) mixing the mixed materials A and B; (6) preparing brick blocks; (7) drying the brick blocks; and (8) sintering the brick blocks. The building bricks not only are light in weight, great in thermal inertia and good in insulating and heat isolating property, and the use level of a ceramic waste material can be reduced greatly.

Owner:宜宾恒旭窑炉科技开发有限公司

Composite energy storage building material with inflaming retarding function

InactiveCN101880148AReduce energy consumptionEqualization or partial elimination of heatingHeat transmissionPhase change

The invention discloses a composite energy storage building material with an inflaming retarding function, comprising the mixture of nonadecane and gypsum powder. The tripolycyanamide inflaming retarding material with quality concentration of 1-8% is added in the mixture, wherein, the weight ratio of nonadecane to gypsum powder in the mixture is 1: (1-5). The composite energy storage building material of the invention compounds the organic phase change energy storage materials and proper building materials, adds proper amount of the inflaming retarding material, increases the temperature regulation capacity of buildings, strengthens heat transmission in heat storage and releasing, solves the problems of liquid phase leakage and corrosion of the energy storage materials, simultaneously has inflaming retarding function, and is especially suitable for energy saving field of buildings.

Owner:NANJING UNIV +1

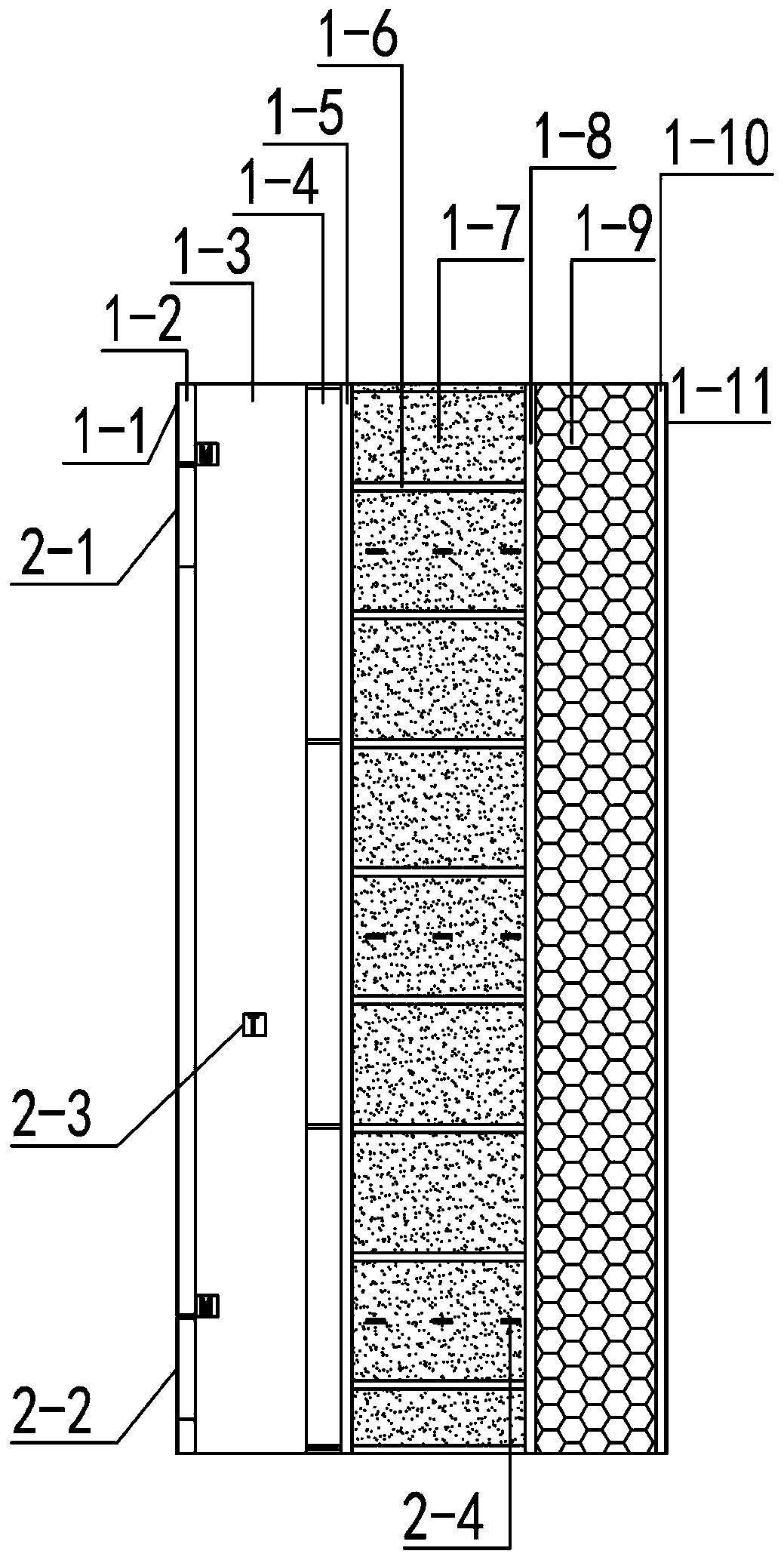

Alpine region prefabricated active and passive combined energy-saving wall body

PendingCN110158804AThermally inert liftImprove insulation effectPhotovoltaic supportsSolar heating energyThermal comfortEngineering

The invention discloses an alpine region prefabricated active and passive combined energy-saving wall body which comprises a low energy consumed outer wall, wherein the low energy consumed outer wallis connected with a heat storage inner wall through a wall body assembling connecting piece; transparent tempered glass, a thickened color steel plate, a first color steel plate and a second color steel plate are sequentially arranged on the low energy consumed outer wall from outside to inside; a solar energy cavity is formed between the transparent tempered glass and the thickened color steel plate; sandy soil is filled between the thickened color steel plate and the first color steel plate; and a slidable photovoltaic panel is arranged in the solar energy cavity. Compared with the common color steel plate temporary shed, the alpine region prefabricated active and passive combined energy-saving wall body adds a wall body sandwiched with sandy soil with high thermal inertia, so that the thermal inertia, the heat-retaining capacity and the heat storage capacity of the entire composite wall body are remarkably improved; and the large temperature difference characteristic at day and night is further utilized to store the sun radiation energy and air source energy at high temperature of noon so as to be used at low temperature, so that the thermal comfort of a room is improved, and the energy consumption of an air conditioner is reduced.

Owner:CHINA RAILWAY CONSTR GROUP

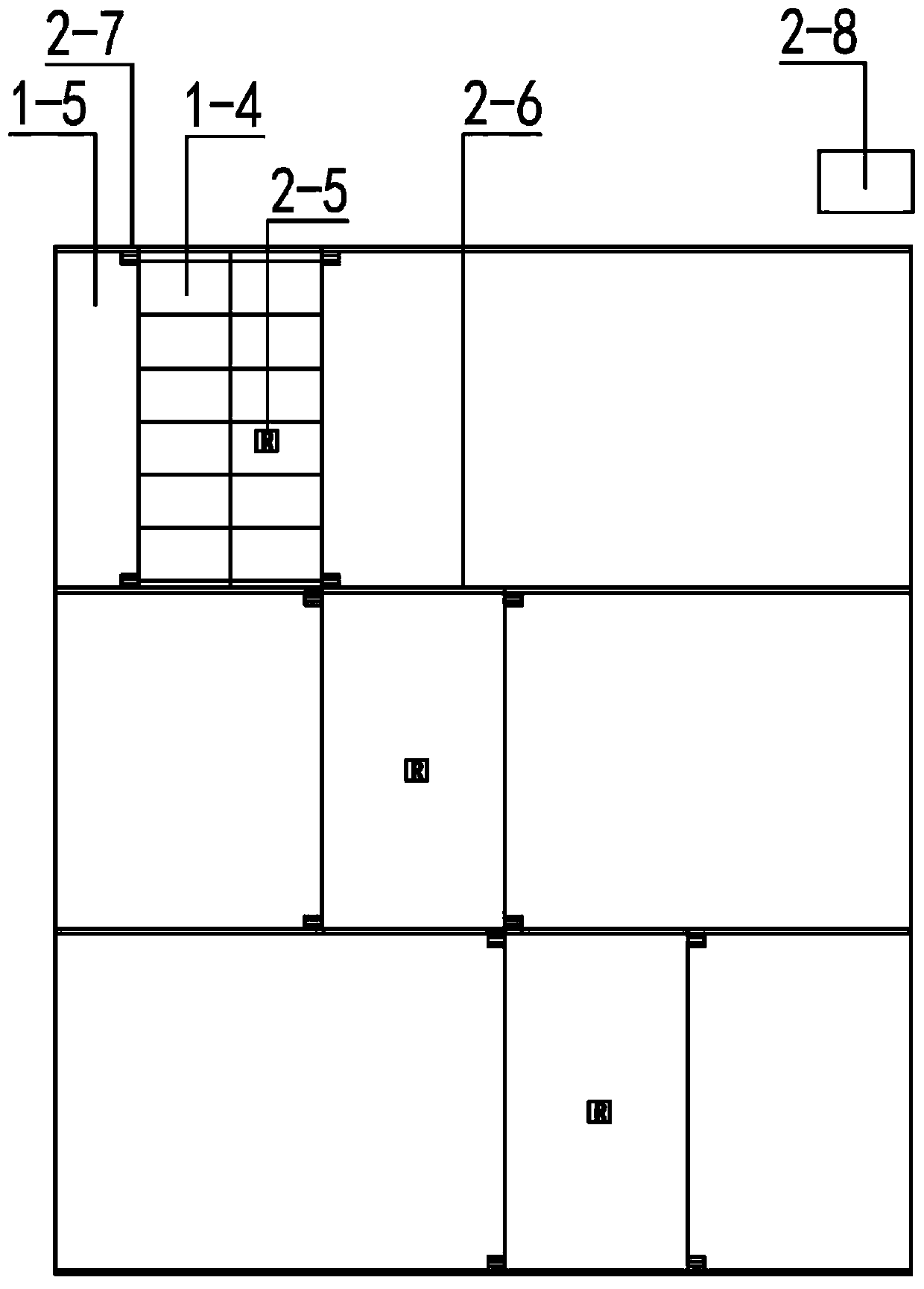

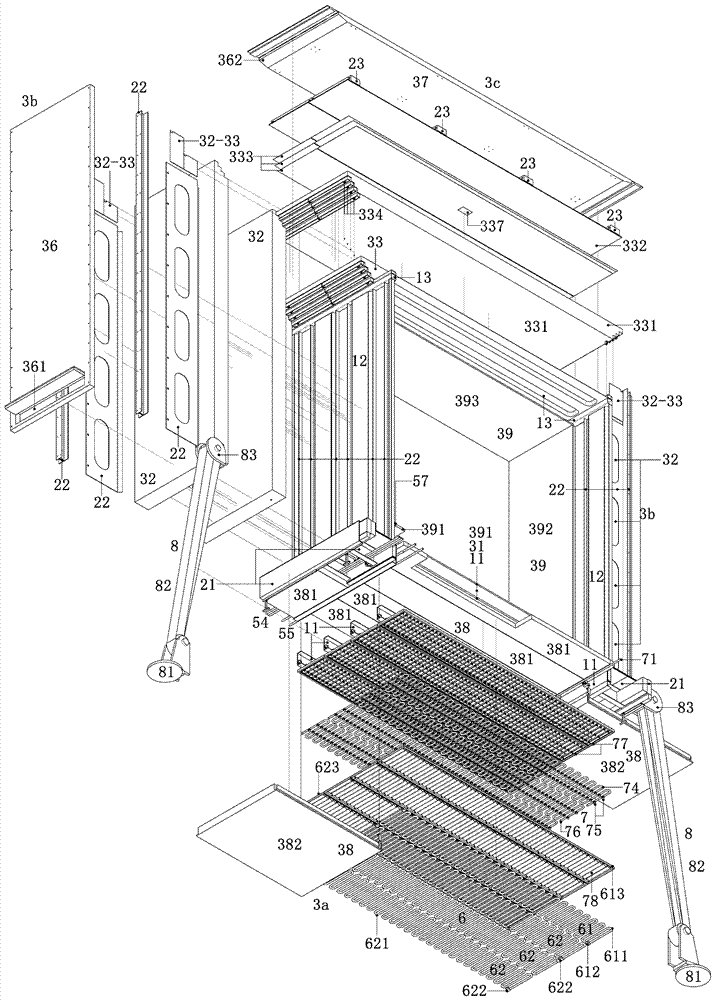

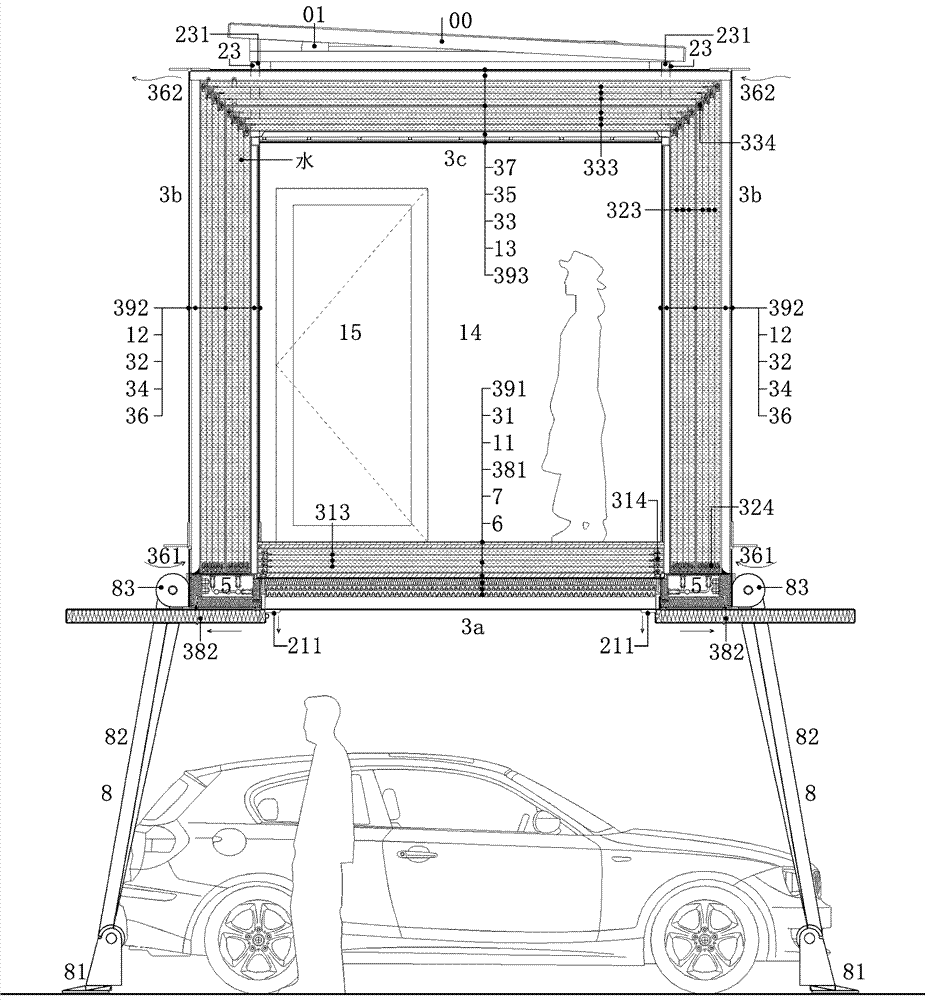

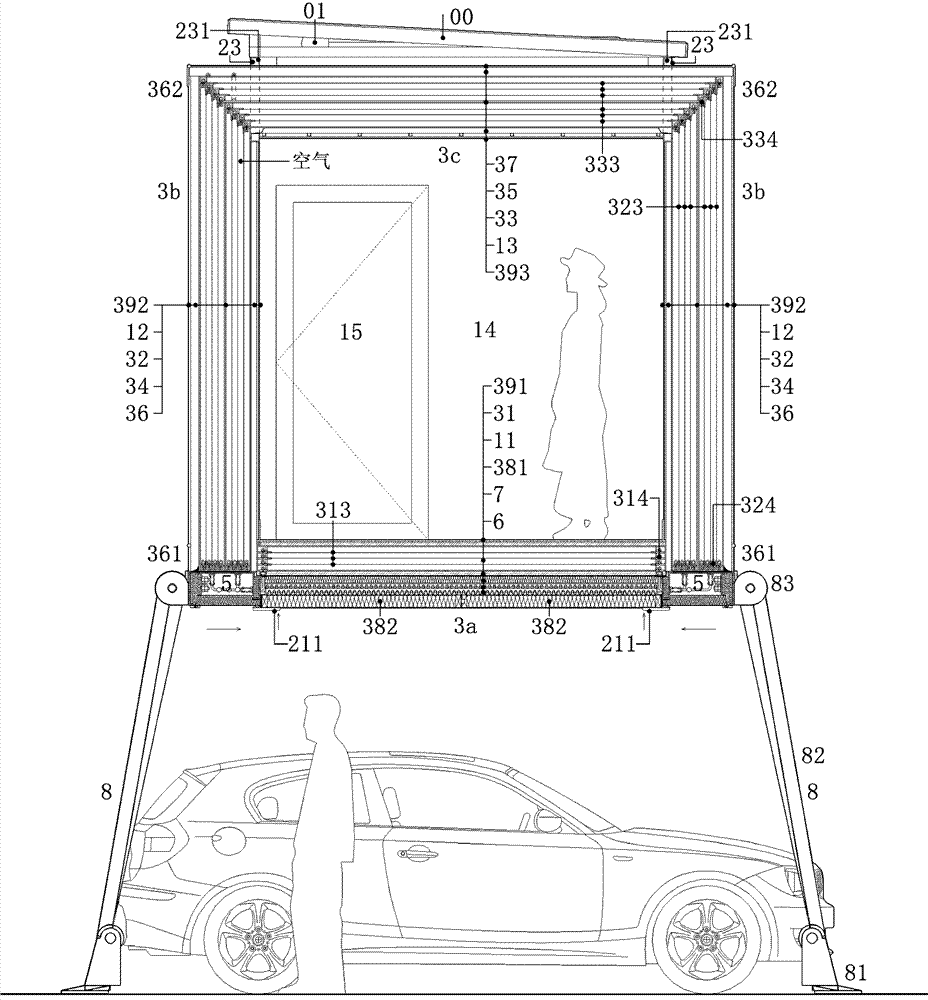

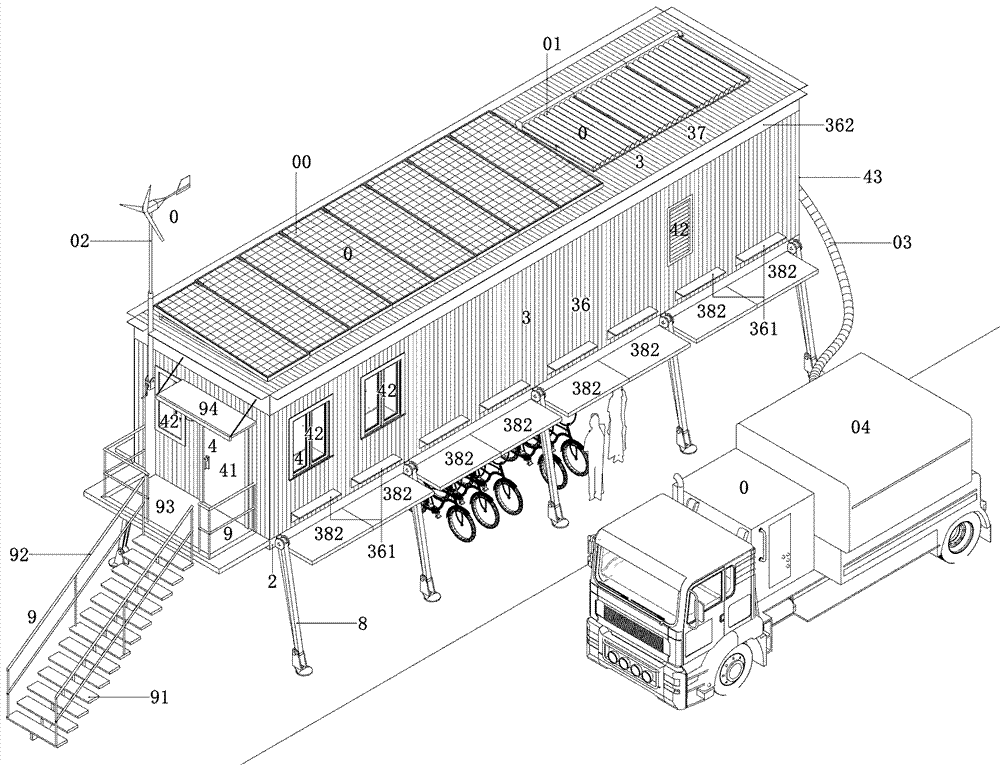

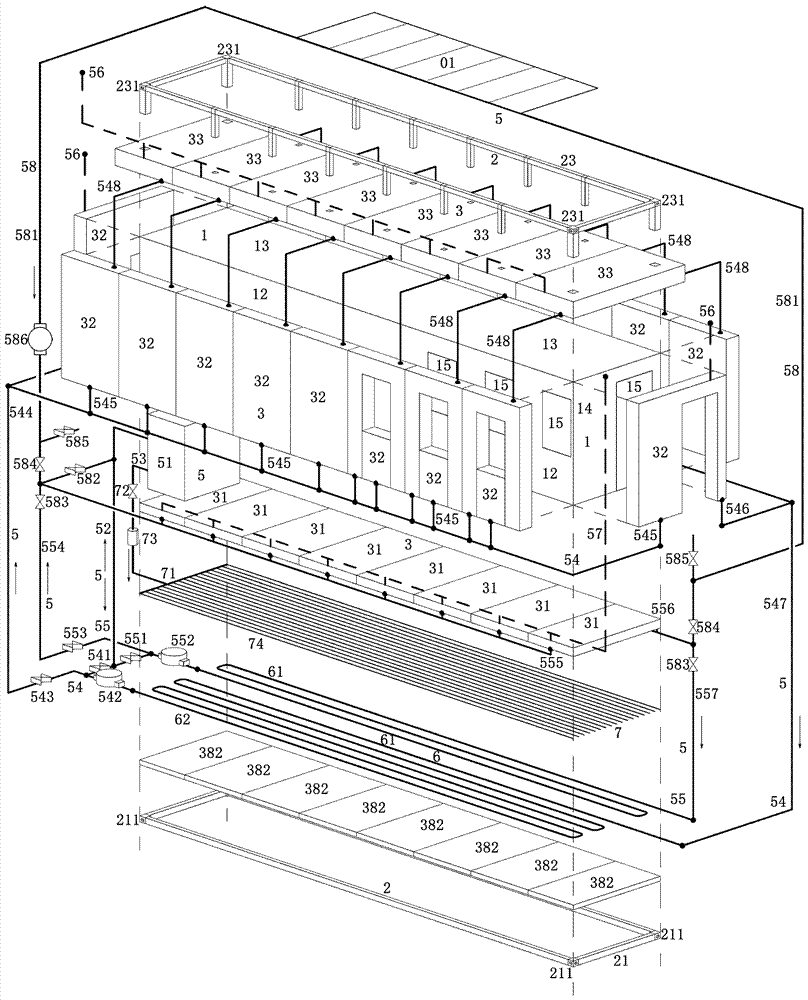

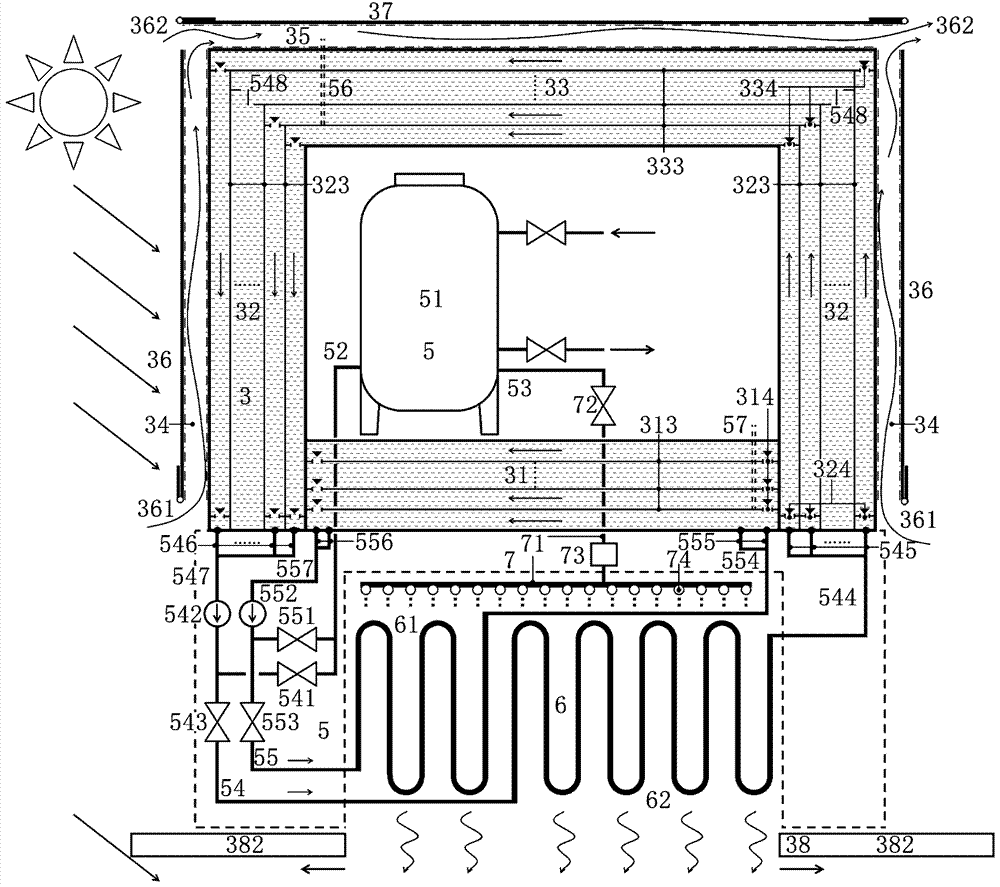

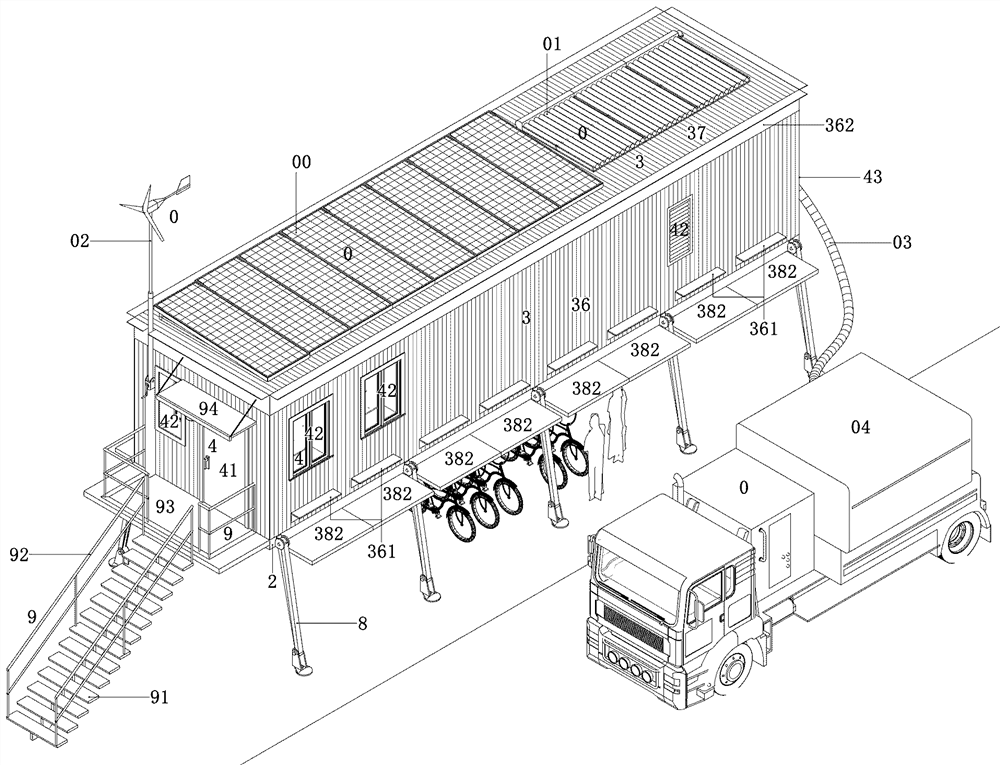

Compound retaining structure used for low-energy consumption container house

ActiveCN107965166AImprove insulation effectResistance to temperature fluctuationsSpecial buildingSmall buildingsThermal insulationThermal comfort

The invention provides a compound retaining structure used for a low-energy consumption container house, and relates to the technical field of building energy conservation and building retaining structures. In order to solve the problems that currently, a container house provided with a metal board light retaining structure is low in comfort level in summer and winter and high in energy consumption per unit area, the compound retaining structure used for the low-energy consumption container house can be divided into a baseboard compound retaining structure, a wall compound retaining structureand a top board compound retaining structure, and the compound retaining structure comprises a baseboard water storage module, a wall water storage module, a top board water storage module, a wall low-radiation air space, a top board low-radiation air space, a wall thermal-insulation sunshading board, a top board thermal-insulation sunshading board, a baseboard thermal-insulating board and an indoor decoration surface layer. The compound retaining structure used for the low-energy container house has the advantages that in the summer, the thermal inertia can be improved through sunshading, ventilation and water filling of the compound retaining structure in combination with recycling water heat dissipation and evaporative cooling; in the winter, after water drainage, the air spaces can beformed to improve the thermal insulation effect, and meanwhile, by means of baseboard low-temperature hot water radiant heating, indoor thermal comfort and yearly low-energy consumption running are achieved.

Owner:刘向峰

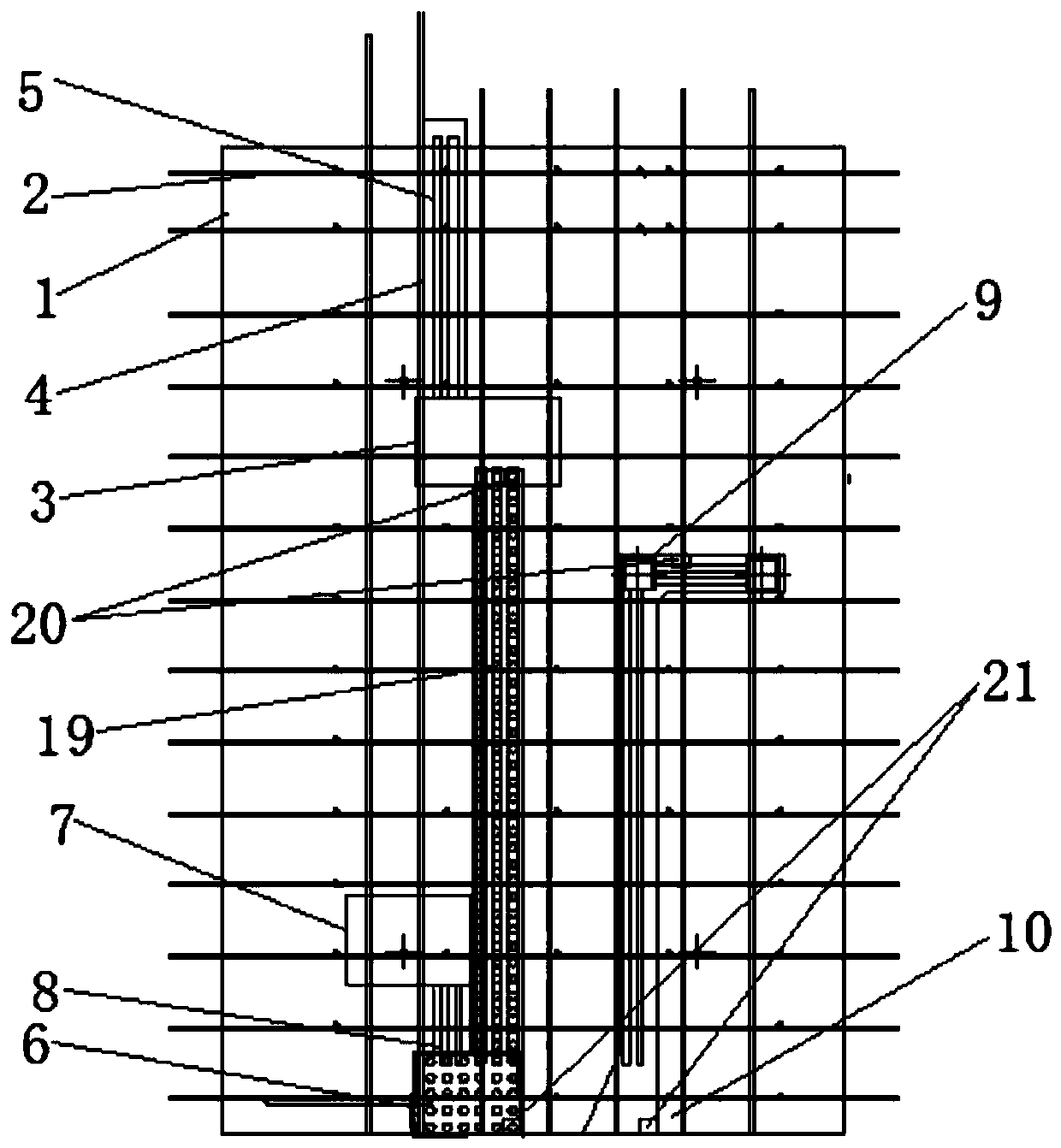

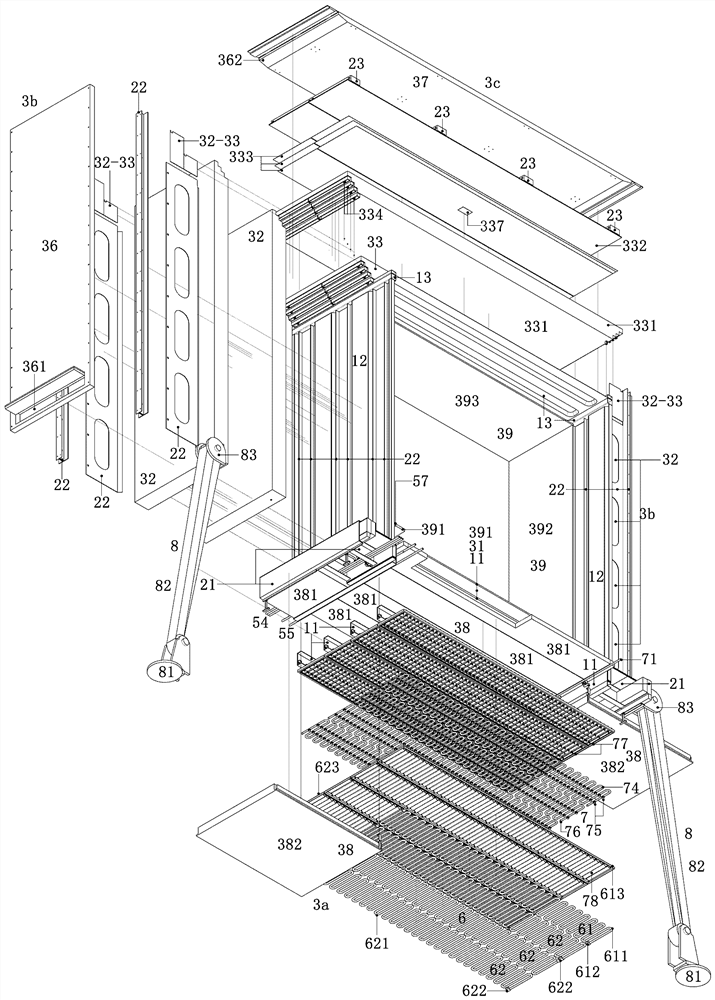

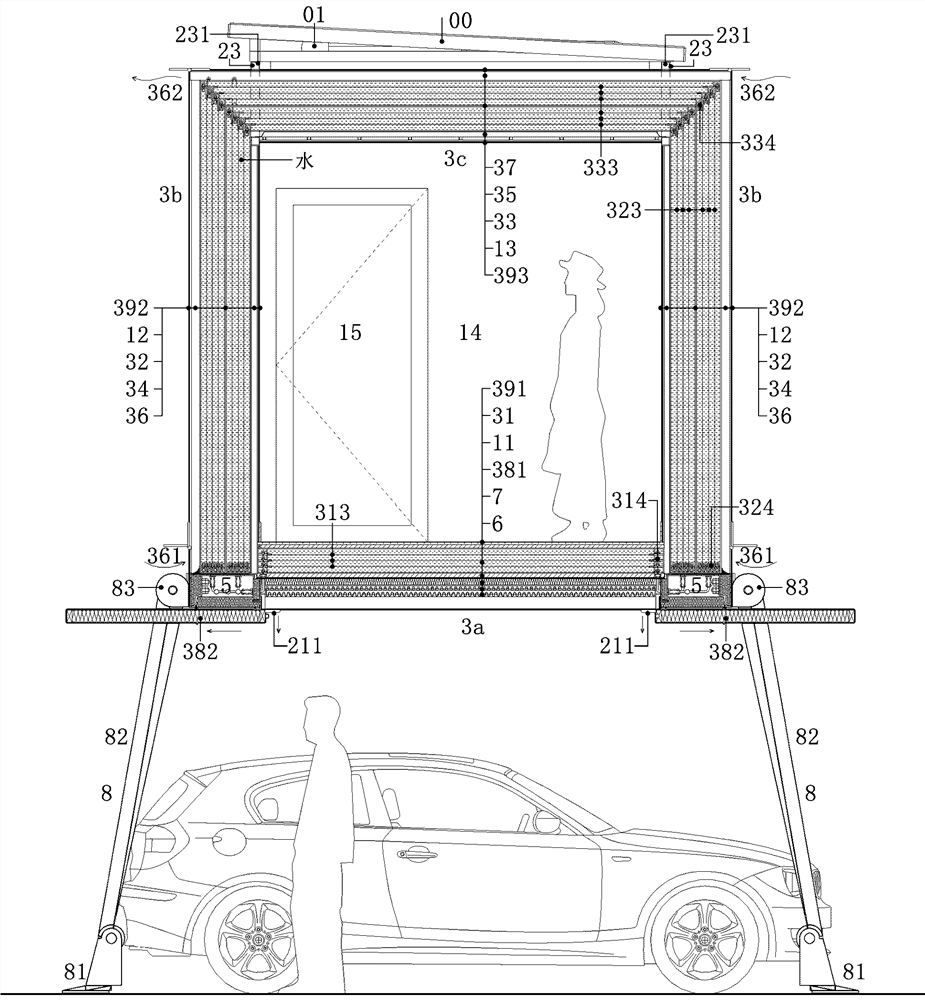

Low-energy-consumption container house and operation method thereof

ActiveCN108005417AEnhanced summer heat insulationImprove thermal inertiaRoof covering using slabs/sheetsRoof covering using tiles/slatesEngineeringEnergy consumption

The invention provides a low-energy-consumption container house and an operation method thereof and belongs to the field of buildings. The low-energy-consumption container house and the operation method are used for solving the problems that an existing container house is poor in thermal performance, poor in comfort degree under the hot condition in summer and the cold condition in winter, and high in energy consumption per unit area. The low-energy-consumption container house comprises accessories such as a universal container plate and frame, an additional supporting structure, a bottom plate, a wall and top plate composite enclosure structure, a door-window and hole enclosure structure, an enclosure structure additional pipeline and water tank, a circulation water radiator, a capillaryhumidifying and evaporative cooling device, foldable supporting feet and foldable stair railing platform awning. The low-energy-consumption container house has the main characteristics that the low-energy-consumption container house can be arranged overhead; in summer, through the composite enclosure structure, sun-shading and ventilation can be achieved, the thermal inertia can be improved by filling water, and radiating and evaporative cooling are achieved through bottom plate circulation water; and in winter, heat preservation capacity can be improved through an air interlayer formed by draining water, meanwhile, low-temperature hot water radiation heating is conducted through the bottom plate; and thus indoor comfort and low-energy-consumption operation all year round are achieved.

Owner:刘向峰

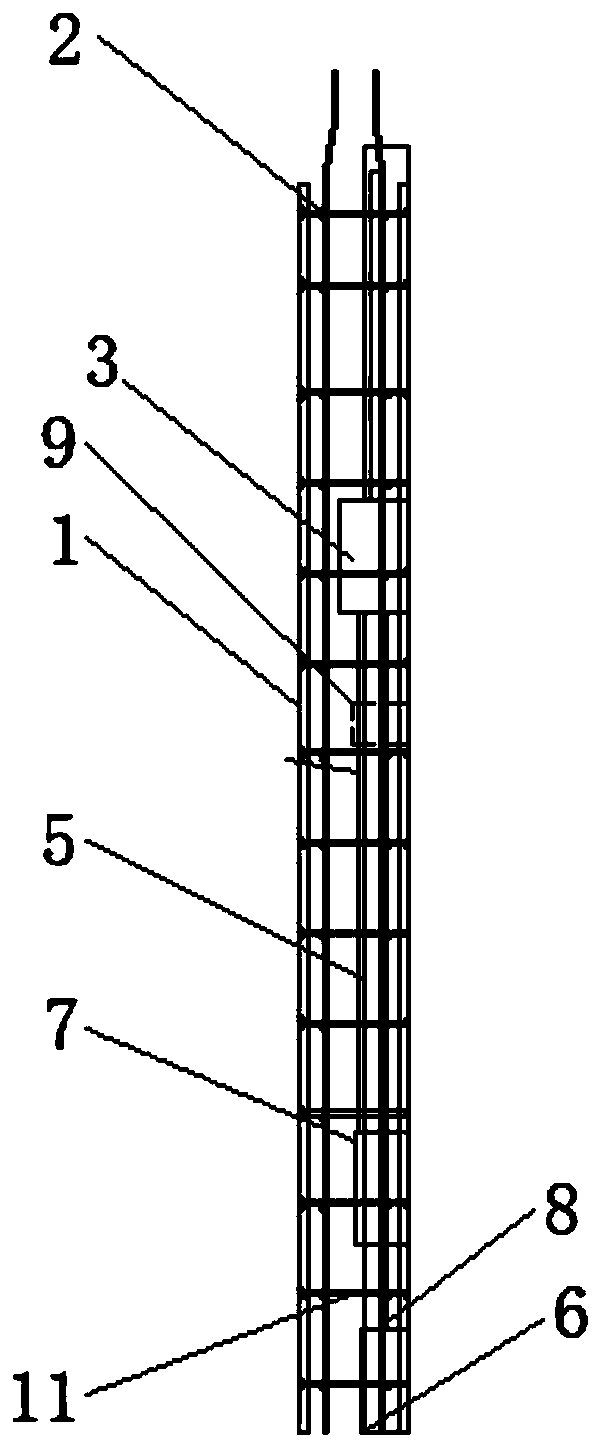

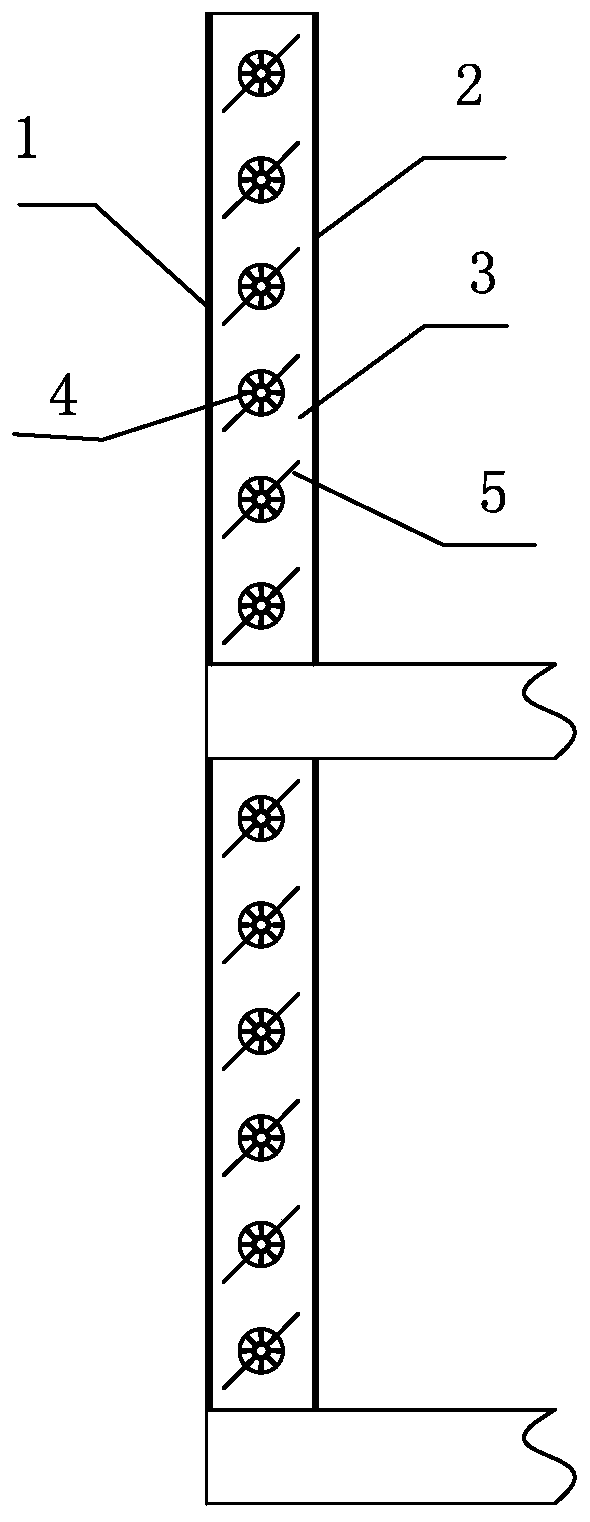

Steel bar and form integrated wall assembly type electrical system

The invention discloses a steel bar and form integrated wall assembly type electrical system. The steel bar and form integrated wall assembly type electrical system comprises a disassembly-free prefabricated concrete form, wall steel bars and a shielding wire pipe groove, the disassembly-free prefabricated form is arranged on the outer sides of the wall steel bars, the disassembly-free prefabricated form and the wall steel bars are fixed through opposite-pull connecting pieces, and the shielding wire pipe groove is arranged at a gap between the disassembly-free prefabricated form and the wallsteel bars. The steel bar and form integrated wall assembly type electrical system has the beneficial effects that the shielding wire pipe groove is formed so that a mounting space can be reserved foran electric wire pipe, installation of an electric pipe is performed after a wall is completed to be installed and concrete is completed to be poured, so that the phenomenon that the wire pipe is damaged during wall installation or concrete pouring is avoided, by arranging the transverse shielding wire pipe groove, adjacent strong current boxes or weak current boxes can communicate, the number ofbottom mounting hand holes can be reduced, and the workload and transportation of wallboard production and the risk points of damage or grout leakage during concrete pouring can be further reduced.

Owner:CHINA RAILWAY CONSTR GROUP +1

A composite building material capable of energy storage

InactiveCN104592948AReduce energy consumptionImprove thermal inertiaHeat-exchange elementsBuilding materialManufacturing engineering

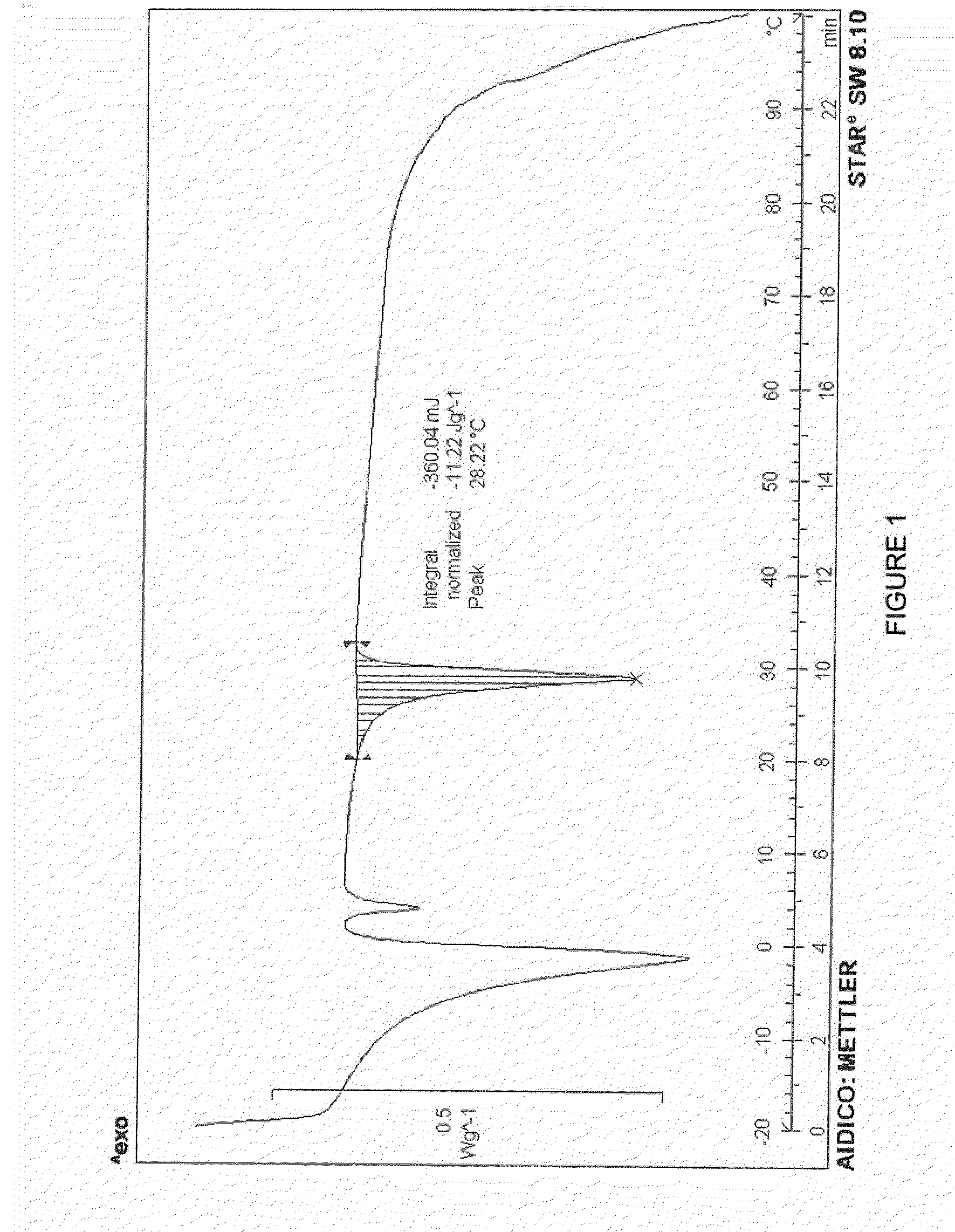

A composite building material capable of energy storage is disclosed. The composite material is obtained by compositing a mixture comprising capric acid and lauric acid, and a building base material, wherein the weight ratio of the capric acid and the lauric acid is 5:2. A preparing method of the composite material includes: heating the capric acid and the lauric acid separately, mixing the capric acid and the lauric acid according to the ratio above mentioned after the capric acid and the lauric acid are fully melt to form an eutectic mixture, heating the eutectic mixture to a complete melting state, and compositing the eutectic mixture to a building base material to form the building material capable of energy storage. In the field of building energy conservation, through compositing a wall material and an energy storing material, the temperature adjusting capability of a building can be improved, and the objectives of energy conservation and comfort can be achieved. The phase-transition temperature (19-24 DEG C) of the energy storing material agrees well with the adjusting temperature (18-25 DEG C) in a room, and the energy storing material is high in latent heat of phase change (120-150 kJ / kg), free of supercooling and phase separation phenomena, nontoxic, non-corrosive, stable in performance and good in repeatability.

Owner:阚健美

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN100499940CImprove electrical performanceImprove wettabilityOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid componentMass ratio

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

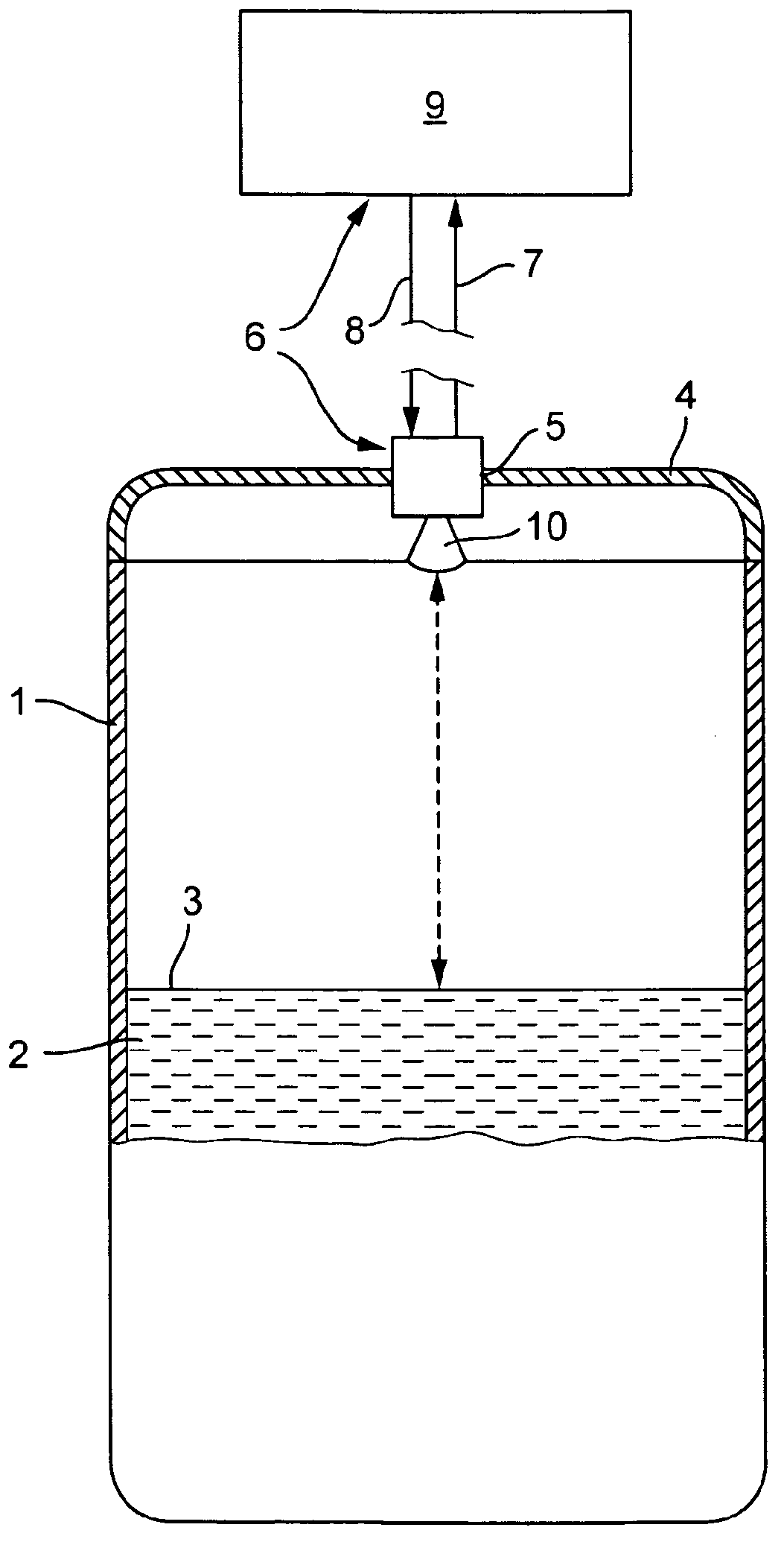

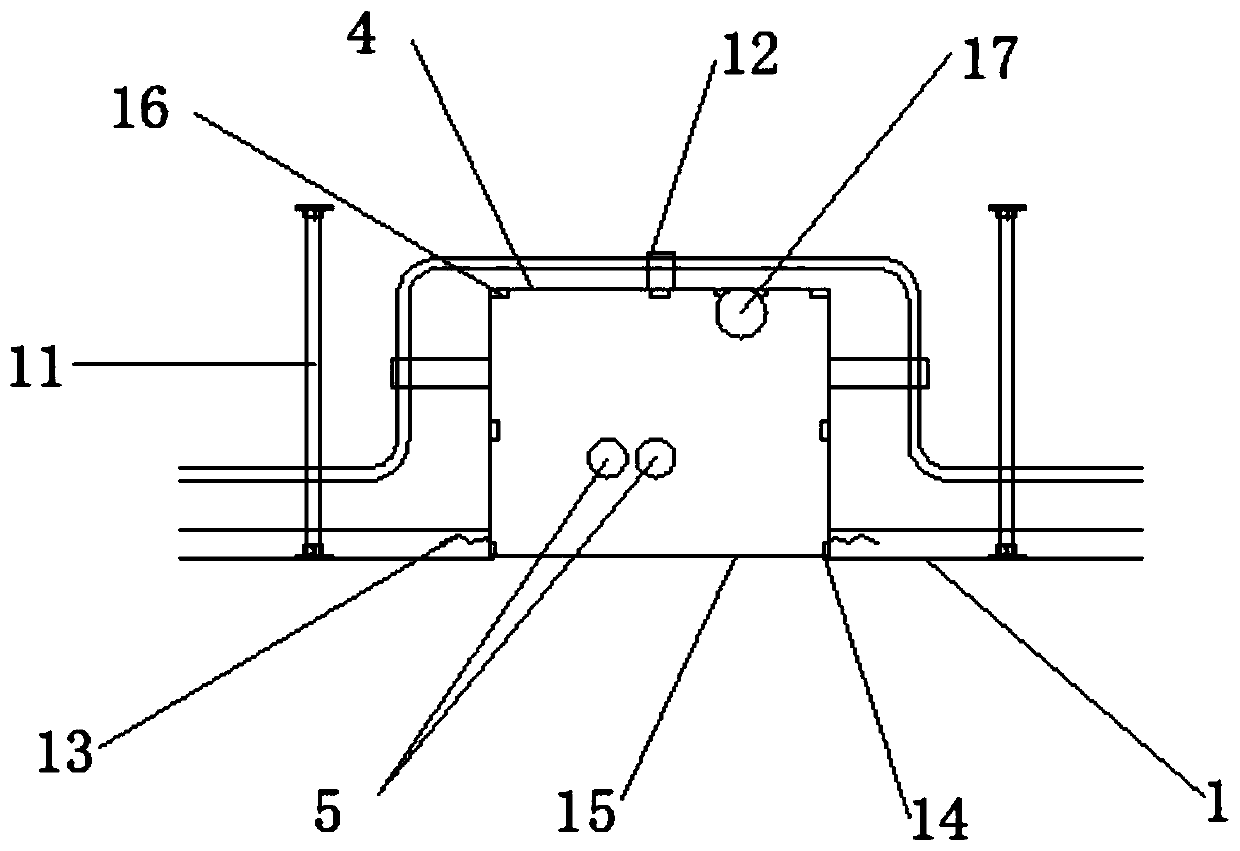

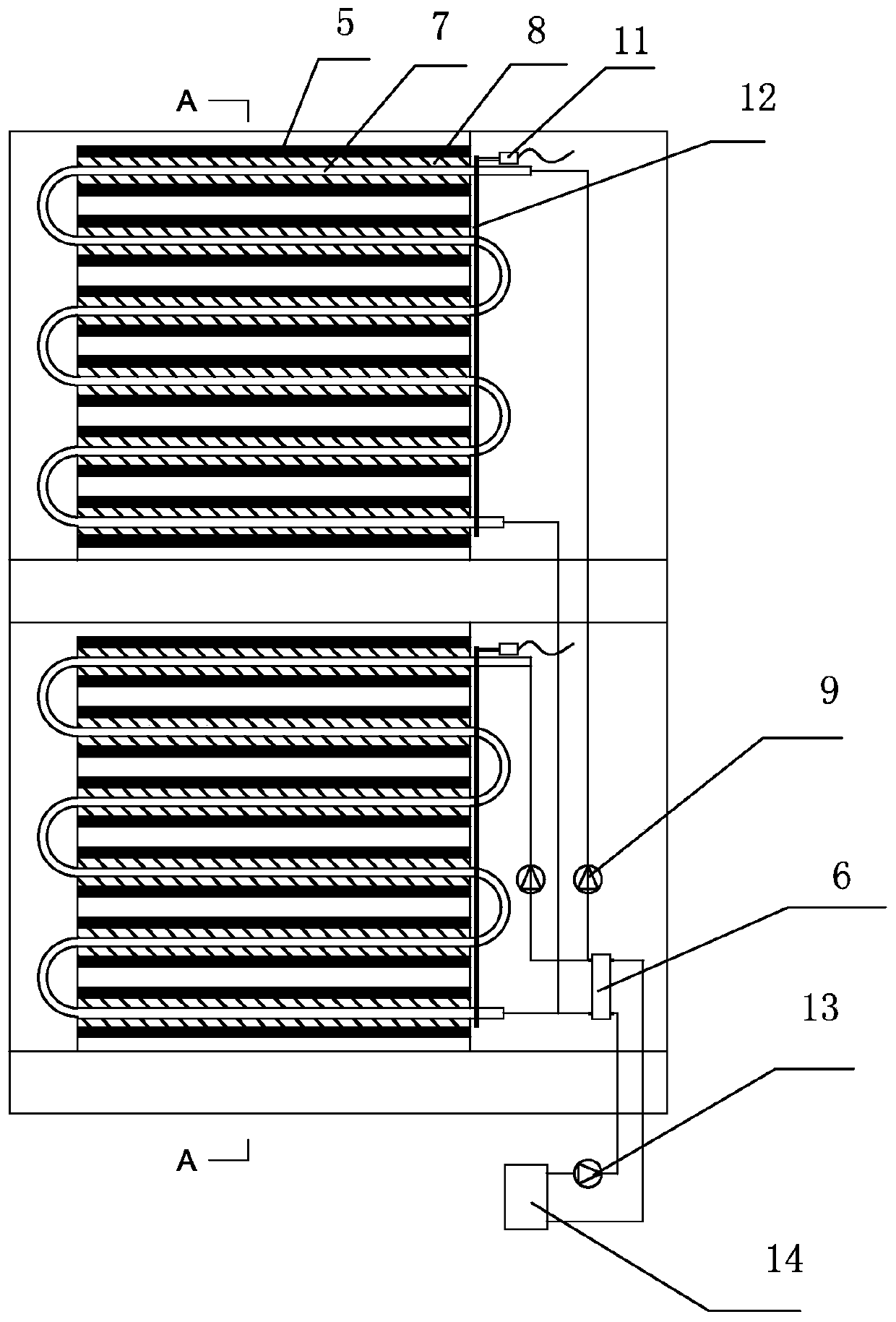

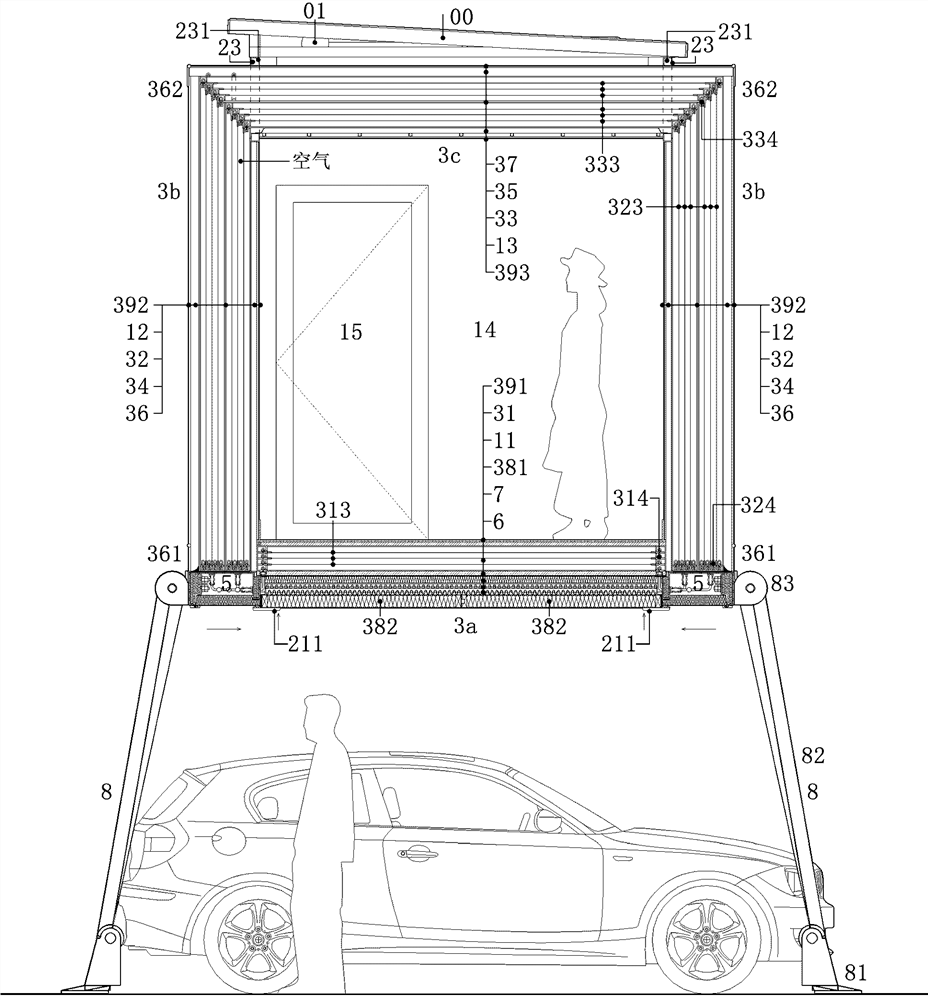

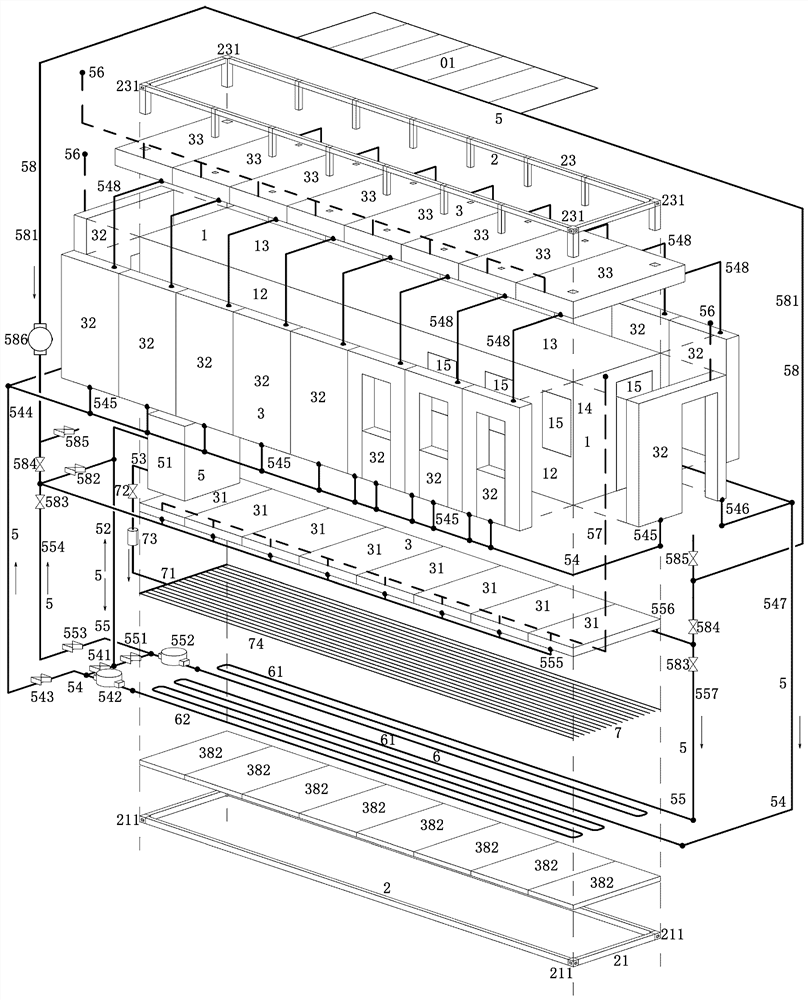

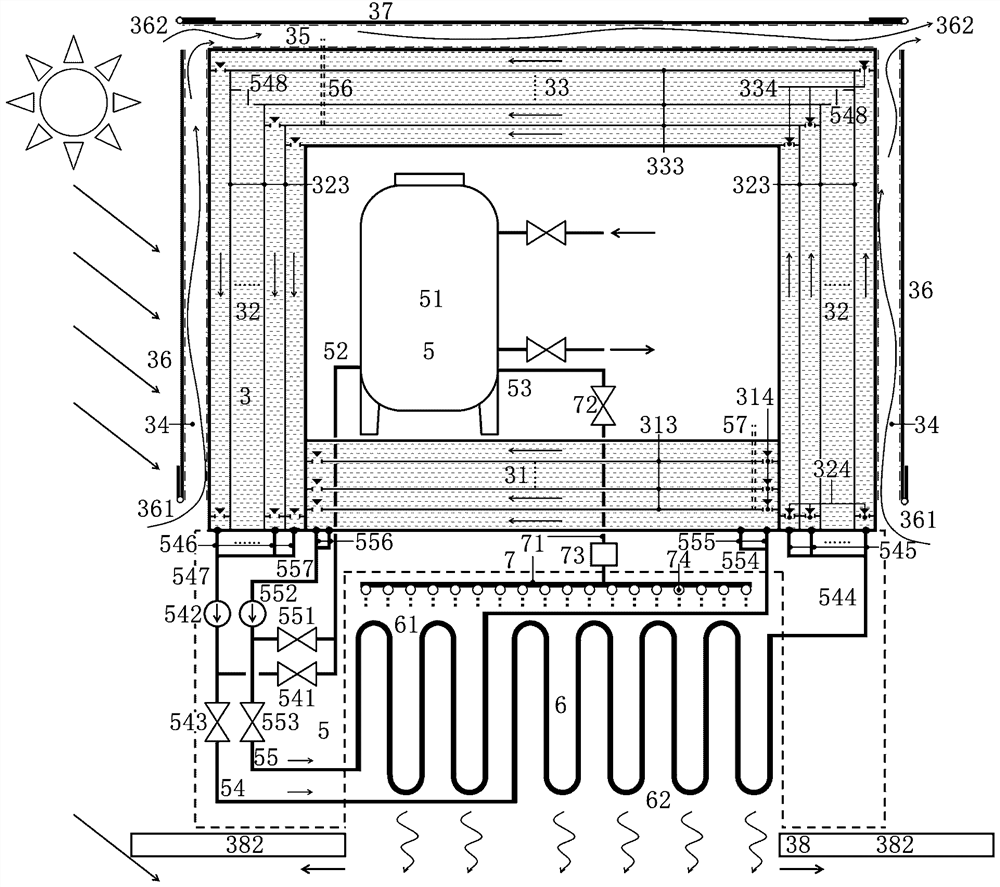

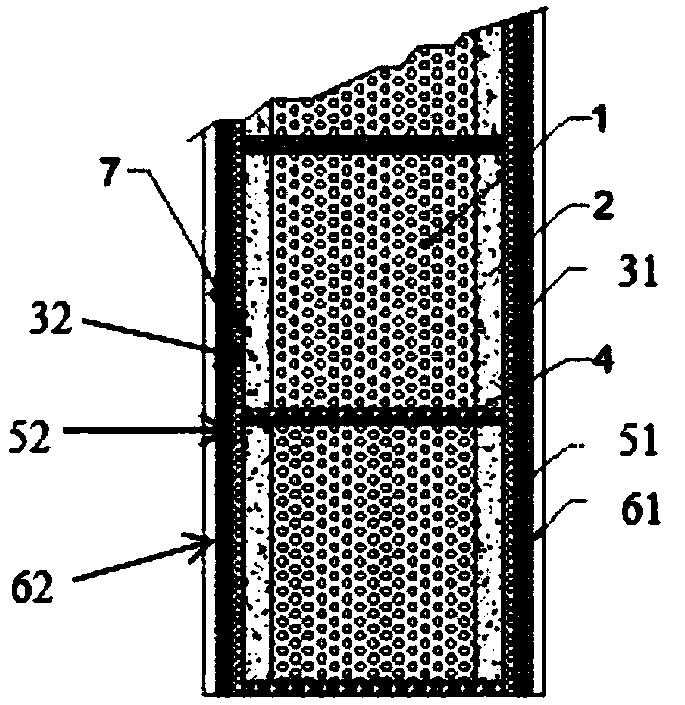

Light-transmitting enclosure structure with energy supply and energy storage functions

PendingCN109870051AImprove insulation effectImprove thermal inertiaIndirect heat exchangersHeat exchanger casingsElectricityEngineering

The invention discloses a light-transmitting enclosure structure with energy supply and energy storage functions. The nighttime valley electricity moment is fully utilized for energy storage, and theoperating cost is reduced. The light-transmitting enclosure structure comprises a non-light-transmitting wall, a source end active energy supply system, an intermediate heat exchange device and a tailend active energy supply and storage system; the source end active energy supply system comprises a source end cold and heat source device and a source end water pump, the source end cold and heat source device, the source end water pump and the intermediate heat exchange device communicate with each other to form a source end energy supply cycle, and the tail end active energy supply and storagesystem includes at least one set of active heat exchange energy storage unit and a tail end circulating power device; the active heat exchange energy storage unit comprises a heat exchange unit formed by communicating heat exchange pipes and an energy storage chamber arranged outside the heat exchange pipes, and the active heat exchange energy storage unit is placed in an air chamber; and the active heat exchange energy storage unit, the tail end active energy supply and storage system and the intermediate heat exchange device communicate with each other to form a tail end heat exchange energy storage cycle. By means of the system, the heat transfer temperature difference between the inner surface of the enclosure structure and the indoor place can be reduced, and the running cost is reduced.

Owner:TIANJIN UNIV OF COMMERCE

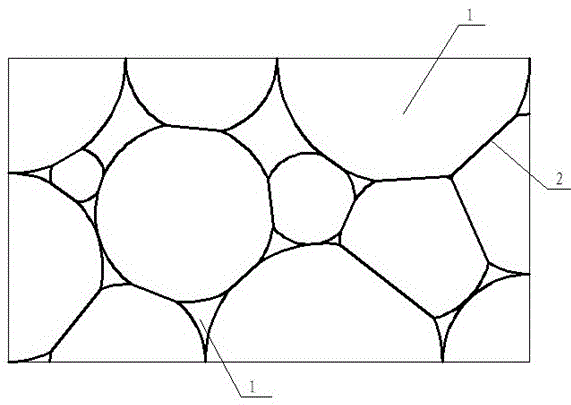

Compressed glulam and production method of compressed glulam

Compressed laminated wood is formed of several compressed wood materials (1) glued together by means of an adhesive (2). Prior to compression, mutual contact faces of the wood materials are flat and / or curved. A method of manufacturing the compressed laminated timber comprises the processes of assembly, compression and shaping. The six sides of the wood materials are subjected to pressure, the pressure is uniform, and the curved faces between the materials are also easily deformed and adhered, reducing the demands on the original material. The compressed laminated timber is strong, has good stability, and is suitable for houses and furniture of wooden structure, and materials for use outdoors, etc.

Owner:唐君畏 +3

A Composite Envelope for Low Energy Consumption Container Houses

ActiveCN107965166BImprove insulation effectResistance to temperature fluctuationsSpecial buildingSmall buildingsWater storageThermal insulation

The invention provides a compound retaining structure used for a low-energy consumption container house, and relates to the technical field of building energy conservation and building retaining structures. In order to solve the problems that currently, a container house provided with a metal board light retaining structure is low in comfort level in summer and winter and high in energy consumption per unit area, the compound retaining structure used for the low-energy consumption container house can be divided into a baseboard compound retaining structure, a wall compound retaining structureand a top board compound retaining structure, and the compound retaining structure comprises a baseboard water storage module, a wall water storage module, a top board water storage module, a wall low-radiation air space, a top board low-radiation air space, a wall thermal-insulation sunshading board, a top board thermal-insulation sunshading board, a baseboard thermal-insulating board and an indoor decoration surface layer. The compound retaining structure used for the low-energy container house has the advantages that in the summer, the thermal inertia can be improved through sunshading, ventilation and water filling of the compound retaining structure in combination with recycling water heat dissipation and evaporative cooling; in the winter, after water drainage, the air spaces can beformed to improve the thermal insulation effect, and meanwhile, by means of baseboard low-temperature hot water radiant heating, indoor thermal comfort and yearly low-energy consumption running are achieved.

Owner:刘向峰

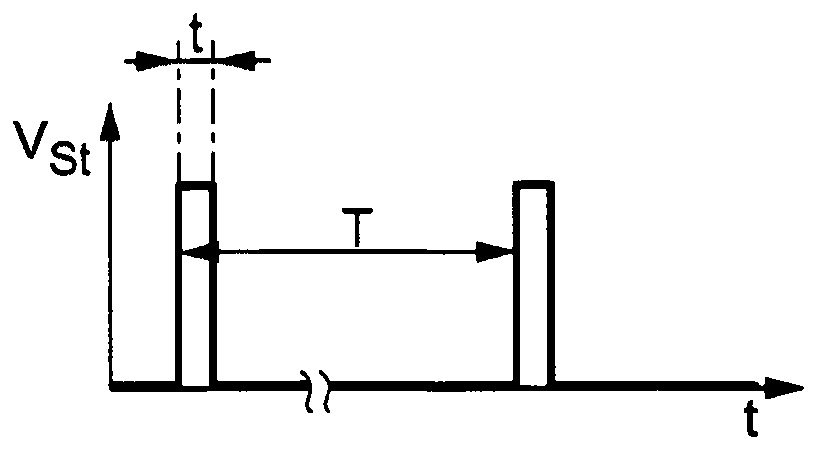

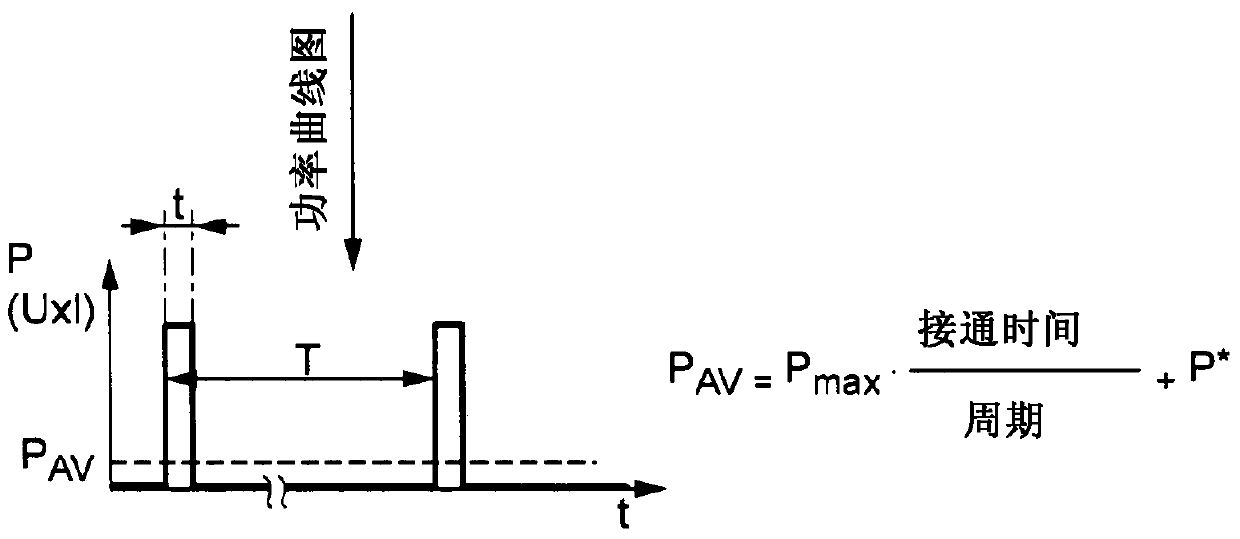

Electrical or electronic safety circuits

InactiveCN103250034BImprove thermal inertiaFast measurement speedVolume indication and recording devicesMachines/enginesElectronic componentElectronic security

The invention relates to a time-triggered crowbar (11) designed in such a way that it monitors the switch-on time (t) and the timing period (T) of at least one downstream electronic component (12) and thus monitors the power supply , such that a predetermined maximum permissible surface temperature of the at least one downstream component (12) in the explosion-endangered area is not exceeded.

Owner:ENDRESS HAUSER GMBH CO KG

Building environment-friendly flame-retarding wall composite material

InactiveCN102303966AReduce energy consumptionEqualization or partial elimination of heatingEnvironmental resistanceMixing ratio

The invention discloses a building environment-friendly flame-retarding wall composite material, which is characterized by comprising the following components in percentage by weight: 20 to 80 percent of gypsum powder, 5 to 20 percent of low-calcium fly ash, 5 to 10 percent of water and 10 to 40 percent of nonadecane. The mixture formed by mixing the components in the range of a mixing ratio is added with a tripolycyanamide environment-friendly flame-retarding material at a mass concentration of 1 to 7 percent. In the invention, organic phase-change energy-storage material and a proper building material are combined, and a proper amount of environment-friendly flame-retarding material is added into the composite material; therefore, the heat transfer in the heat storage and release process is reinforced, the liquid leakage and corrosion problems of the energy-storage material are solved, and the composite material has environment-protection and flame-retarding functions.

Owner:江苏中原建设集团有限公司

Core board material of vacuum insulation board for buildings

InactiveCN108424095AImprove stabilityReduce manufacturing costClimate change adaptationInsulation improvementFiberSodium Bentonite

The invention belongs to the field of vacuum heat insulation boards, particularly relates to a core board material of a vacuum heat insulation board for buildings and aims at the problems that existing core materials do not have excellent pressure resistance stability and heat insulation stability, and are higher in heat conductivity, high in cost and difficult to process, and thermal inertia andheat insulation fail to meet strict requirements. The core board material is prepared from the following raw materials in parts by weight: 23-26 parts of mineral wool, 18-22 parts of glass fiber, 22-26 parts of silica, 14-18 parts of calcium chloride hexahydrate, 8-12 parts of quicklime, 6-9 parts of acrylic acid, 7-11 parts of polyvinyl alcohol, 4-8 parts of potassium hydrogen sulfite, 13-16 parts of bentonite, 11-14 parts of quartz sand, 9-13 parts of magnesium oxide, 5-8 parts of zinc oxide and 30-35 parts of deionized water, wherein rock cotton fiber accounts for 20-25 parts of the mineralwool. A preparation method of the core board material comprises the following step: S1, adding acrylic acid and deionized water to a reaction kettle. The core board material has excellent pressure resistance stability and heat insulation stability, low heat conductivity, high hardness, excellent thermal inertia and heat insulation effect and low manufacturing cost, and is convenient to process.

Owner:HUANGHE S & T COLLEGE

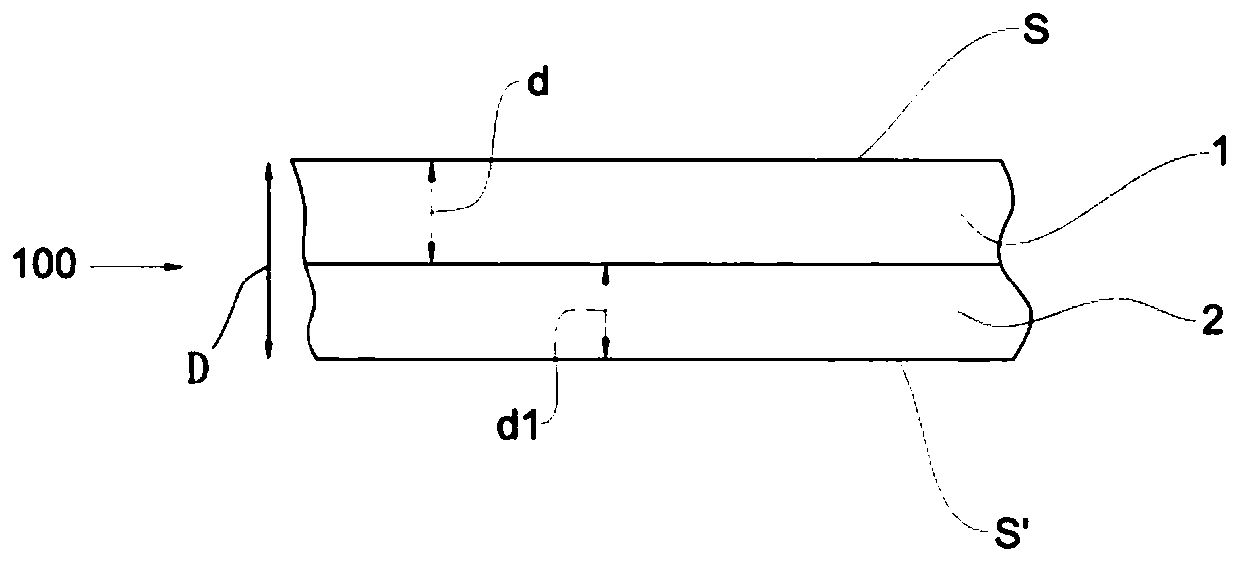

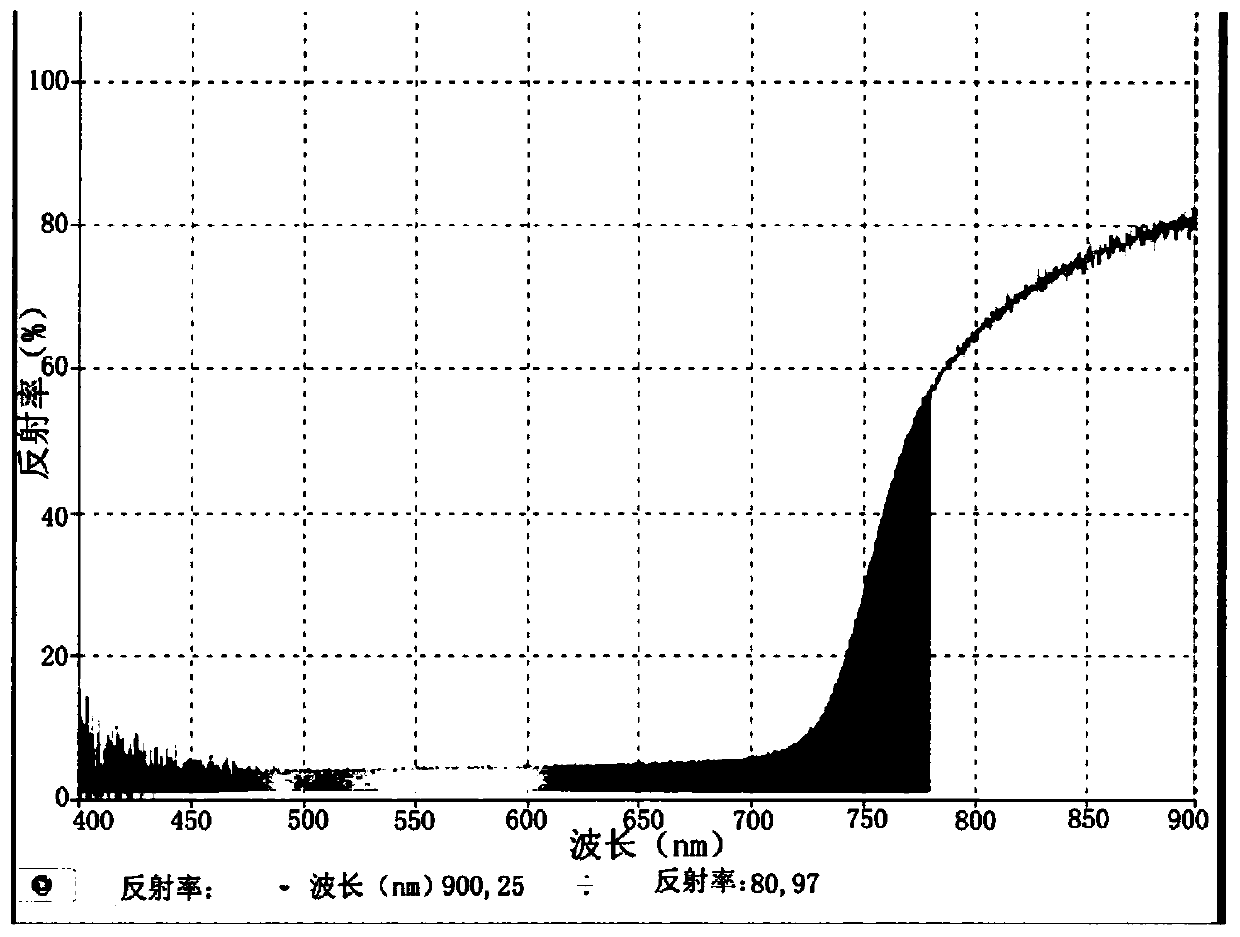

Multilayer material based on microfiber and polyurethane and process for obtaining it

PendingCN110466229AImprove thermal inertiaSeat coveringsSynthetic resin layered productsMicrofiberReflectivity

A multilayer material (100) comprises at least a support layer of coagulated microfiber (1) and at least a cover layer (2) made of polyurethane applied by spreading on said support layer of coagulatedmicrofiber (1), characterised in that said support layer of coagulated microfiber (1) and said cover layer (2) comprise one or more colouring compounds suitable for giving to said support layer (1) and to said cover layer (2) a dark coloration, said one or more colouring compound being so adjusted to obtain a multilayer material (100) having a reflectance greater than 60%, preferably greater than75%, in a greatly preferred manner greater than 80%, and in a maximally preferred manner greater than 85% in the infrared wavelength.

Owner:洛伦齐斯公司

A low energy consumption container house

ActiveCN108005417BEnhanced summer heat insulationImprove thermal inertiaRoof covering using slabs/sheetsRoof covering using tiles/slatesCapillary TubingEngineering

Owner:刘向峰

Energy storage and thermal insulation building structure

PendingCN108166647AImprove comfortProductive timeConstruction materialWallsThermal insulationPhase change

The invention provides an energy storage and thermal insulation building structure. The building structure successively comprises an interior facing layer, a first anti-fracture layer, a first thermalinsulation mortar layer, a masonry layer, a second thermal insulation mortar layer, a second anti-fracture layer and an outer facing layer from inside to outside. The masonry layer is formed by blocks and masonry mortars which fill between the blocks; the blocks comprise hollow blocks and phase change mortars which fill the interiors of the hollow blocks. The energy storage and thermal insulationbuilding structure contains phase change materials which can improve thermal inertia, increase heat storage capacity, delay indoor peak temperature occurrence time and reduce indoor temperature fluctuation. The experimental results of examples show that, compared with an ordinary building structure, the temperature fluctuation in experimental rooms formed by the energy storage and thermal insulation building structure is reduced by 6 DEG C or above, and the maximum temperature is delayed by 28 min or above, and the energy storage and thermal insulation effect is very remarkable.

Owner:深圳市越众绿色建筑科技发展有限公司

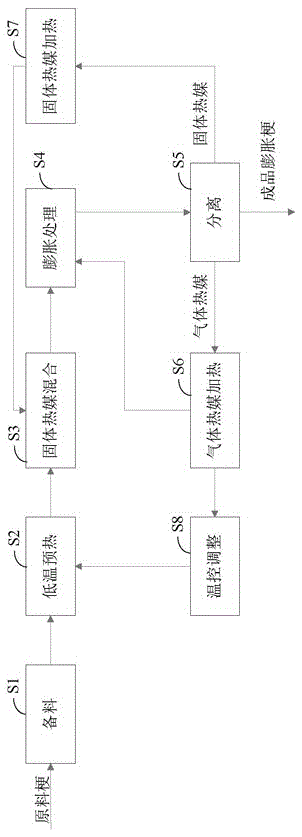

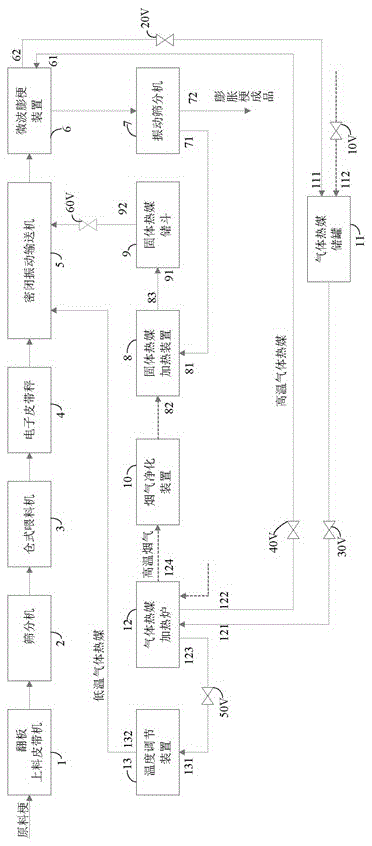

Method and device for processing tobacco stems

ActiveCN104146335BImprove qualityImprove thermal inertiaTobacco treatmentMicrowaveProcess engineering

The invention discloses a treatment method and a treatment device for tobacco stems. The processing method of the tobacco stems mainly includes the steps of material preparation, solid heat medium mixing, expansion treatment, and separation. By mixing the tobacco stems with solid heat medium and high-temperature gas heat medium, they are irradiated with microwaves, and the gas, solid heat medium and microwave radiation are irradiated. High-quality expanded tobacco stems can be obtained by simultaneously heating the inside and outside of the tobacco stems according to the common practice; the processing device is provided with sequentially connected feeding equipment, a closed vibrating conveyor, a microwave stem expanding device, and a vibrating screening machine. Tobacco stems mixed with solid heat medium, high-temperature gas heat medium are fed into the stem expansion device, and microwaves are emitted, so that the gas, solid heat medium and microwave irradiation can heat the inside and outside of the tobacco stem simultaneously, thereby obtaining high-quality expansion. Tobacco stems.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

Composite energy storage building material with inflaming retarding function

The invention discloses a composite energy storage building material with an inflaming retarding function, comprising the mixture of nonadecane and gypsum powder. The tripolycyanamide inflaming retarding material with quality concentration of 1-8% is added in the mixture, wherein, the weight ratio of nonadecane to gypsum powder in the mixture is 1: (1-5). The composite energy storage building material of the invention compounds the organic phase change energy storage materials and proper building materials, adds proper amount of the inflaming retarding material, increases the temperature regulation capacity of buildings, strengthens heat transmission in heat storage and releasing, solves the problems of liquid phase leakage and corrosion of the energy storage materials, simultaneously hasinflaming retarding function, and is especially suitable for energy saving field of buildings.

Owner:NANJING UNIV +1

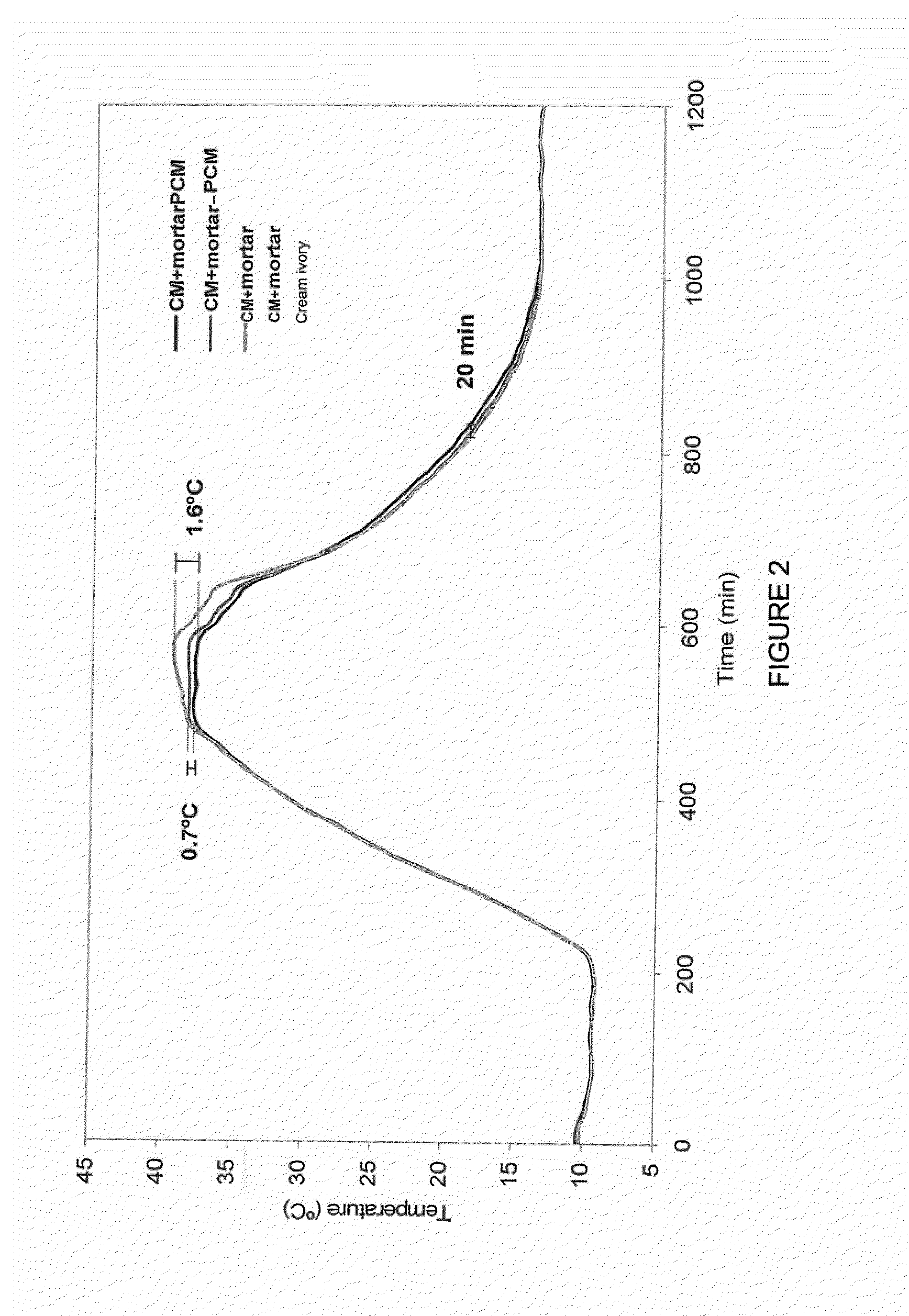

Composition and procedure for applying phase change materials (PCMS) to natural stone

InactiveUS20110293837A1Shorten the timeIncreases stone lifetimeHeat storage plantsPretreated surfacesPorositySurface layer

The present invention relates to a composition of phase change materials (PCMs) and to the application thereof to natural stone in order to improve the thermal properties of same. Different PCMs are used depending on the type of stone and the manner in which they are introduced into or applied to the stone. The use of PCMs in powder form, emulsions, etc., depends on the porosity of the stone and the manner in which the PCMs are applied. PCMs are added to natural stone: as a surface layer on the stone, as a mastic applied to the posterior surface of the natural stone, as a reinforcing layer (for example in the form of mortar) applied to the posterior surface of the natural stone, or by impregnation through immersion of the stone in a PCMcontaining solution.

Owner:ROMERO SANCHEZ MARIA DOLORES +3

Thermal storage energy-saving ceramic material and its preparation method

InactiveCN1302187CIncrease heat storageImprove thermal inertiaConstruction materialHeat proofingCompound structureConductive materials

The invention discloses a heat accumulating and energy saving ceramic material and its manufacturing method, which relates to a new constructing material and energy saving technology field, its character lies in: it is a energy saving unit compound structure material and by combining the inner core made up of heat accumulating material, conductive material, fire resisting material and corrosion stabilizing material and the ceramic material external shell, and its manufacturing method. The advantages are simple process, and low cost.

Owner:原效坤 +1

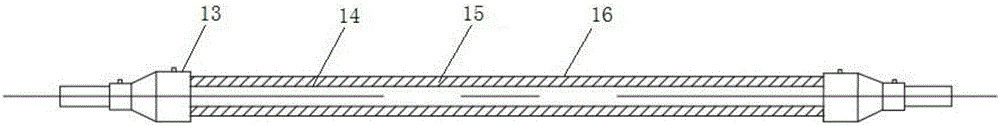

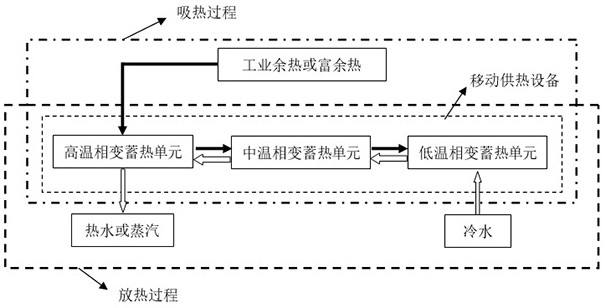

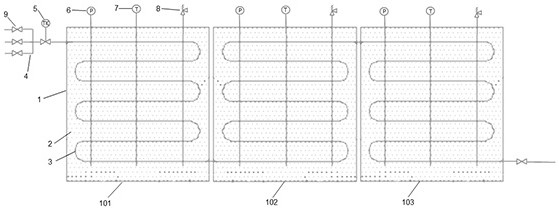

Wide-temperature-range movable heat supply system based on latent heat type heat transfer fluid

PendingCN114791238AImprove thermal inertiaExtend heating timeHeat storage plantsHeat exchange apparatusHeat transfer fluidEngineering

The invention discloses a wide-temperature-range movable heat supply system based on latent heat type heat transfer fluid, which comprises a phase change micro heat pipe suspension, a phase change heat storage distributor, a heat exchange pipe, a temperature controller and a vehicle tank, and a low-temperature phase change heat storage unit, a medium-temperature phase change heat storage unit and a high-temperature phase change heat storage unit which are connected are arranged in the vehicle tank; the phase-change heat storage units are filled with the phase-change micro heat pipe suspension, the heat exchange pipes are distributed in the phase-change heat storage units, the two ends of each heat exchange pipe serve as connectors, the heat exchange pipes of the low-temperature phase-change heat storage unit, the medium-temperature phase-change heat storage unit and the high-temperature phase-change heat storage unit are sequentially connected, the external connection ends of the heat exchange pipes of the high-temperature phase-change heat storage unit are connected with the phase-change heat storage distributor, and the external connection ends of the heat exchange pipes of the medium-temperature phase-change heat storage unit are connected with the phase-change heat storage distributor. And the vehicle tank is provided with a temperature controller. Heat at different temperatures can be stored, and the heat storage capacity is improved by adding the phase change material, so that the movable heat supply capacity is improved, and the economical efficiency of the system is improved.

Owner:GUANGDONG IND TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com