Thermal storage energy-saving ceramic material and its preparation method

A technology of ceramic materials and heat storage materials, applied in building materials, building components, heat preservation, etc., can solve the problems of difficult energy-saving technology and complicated process, and achieve considerable economic benefits, simple preparation process, and shorten the completion period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

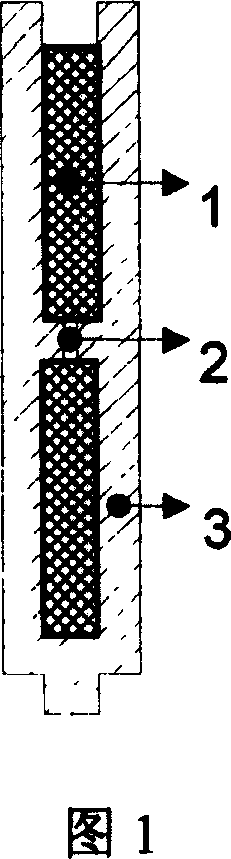

[0020] Embodiment 1: Preparation of regenerative ceramics by emulsification filling

[0021] Prepare hollow ceramic wall tiles with a size of 100×100×12mm. The size of the cavity part is 92×92×4mm. The cavity part is divided into small inner cavities. There are protrusions to facilitate the closure of the inner core when overlapping; the CaCl 2 ·6H 2 O, No. 25 emulsifying wax, CaSO 4 It is emulsified and mixed with APP according to the ratio of 30:60:8:2, and injected into the hollow ceramic wall brick to prepare a new type of heat storage ceramic wall brick (Figure 1).

[0022] This new heat storage ceramic wall tile has excellent air-conditioning performance, and can adjust the temperature of the surrounding environment at about 25°C to a certain extent. It is mainly suitable for the interior wall of the living room, keeping the room temperature at a suitable temperature, improving living comfort, and saving air-conditioning energy. expenditure. At the same time, this ne...

Embodiment approach 2

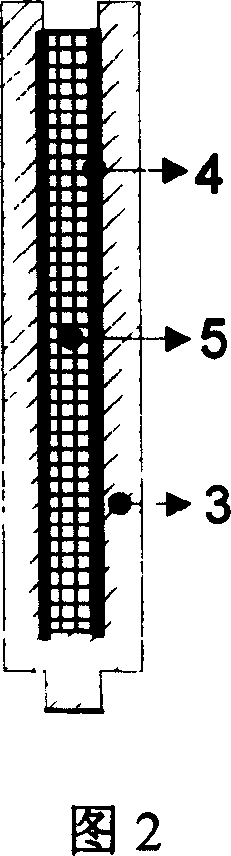

[0023] Embodiment 2: Preparation of regenerative ceramics by impregnating the plate and building it in

[0024] Prepare ceramic hollow wall bricks with a size of 100×100×12mm. The cavity size is 92×92×4mm. There may be protrusions under the ceramic hollow wall bricks to facilitate the sealing of the inner core when overlapping; soak the porous vermiculite board in No. 45 emulsified wax solution, and kept for 1 hour, to obtain a heat storage material plate with a wax content of 60%; then spray melamine and calcium carbonate on the surface of the heat storage material plate, and carry out flame retardant treatment; finally, the heat storage material plate Cut it into a plate with a size of 92×92×4mm, and put it in the ceramic hollow wall brick, that is, a new type of heat storage ceramic wall brick is prepared (Fig. 2).

[0025] This new heat storage and heat preservation ceramic wall tile has an excellent heat absorption and heat storage function, can make full use of solar ene...

Embodiment approach 3

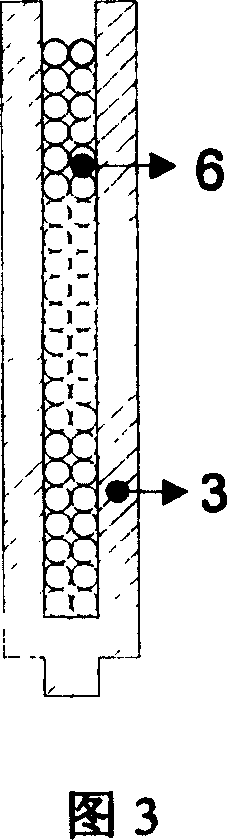

[0026] Embodiment 3: Capsule encapsulation and built-in method to prepare heat storage ceramics

[0027] Prepare ceramic hollow wall bricks with a size of 100×100×12mm, the cavity size is 92×92×4mm, and there may be protrusions under the ceramic hollow wall bricks, so as to close the inner core when overlapping; put Na 2 HPO 4 12H 2 O and No. 45 emulsified wax are evenly mixed into particles with a diameter of about 3 to 3.5 mm according to a ratio of 50:50, and then sprayed on the surface of the particles with a capsule material of melamine-calcium sulfate-formaldehyde resin with a thickness of 0.5 to 1 mm. The heat storage material capsules are prepared while the particles are flame retardant and stabilized. The diameter of the heat storage material capsules is less than 4mm; finally, the heat storage material capsules are placed in the ceramic hollow wall bricks, and a new type of heat storage ceramic wall bricks is prepared. (image 3)

[0028] This new heat storage and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com