Full liquid type medium and high temperature heat accumulator and application thereof in flue gas waste heat recovery

A medium-high temperature heat accumulator technology, applied in the energy field, can solve the problem of low overall heat storage performance, achieve repeatable service life, high heat storage and heat release efficiency, and simple placement and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

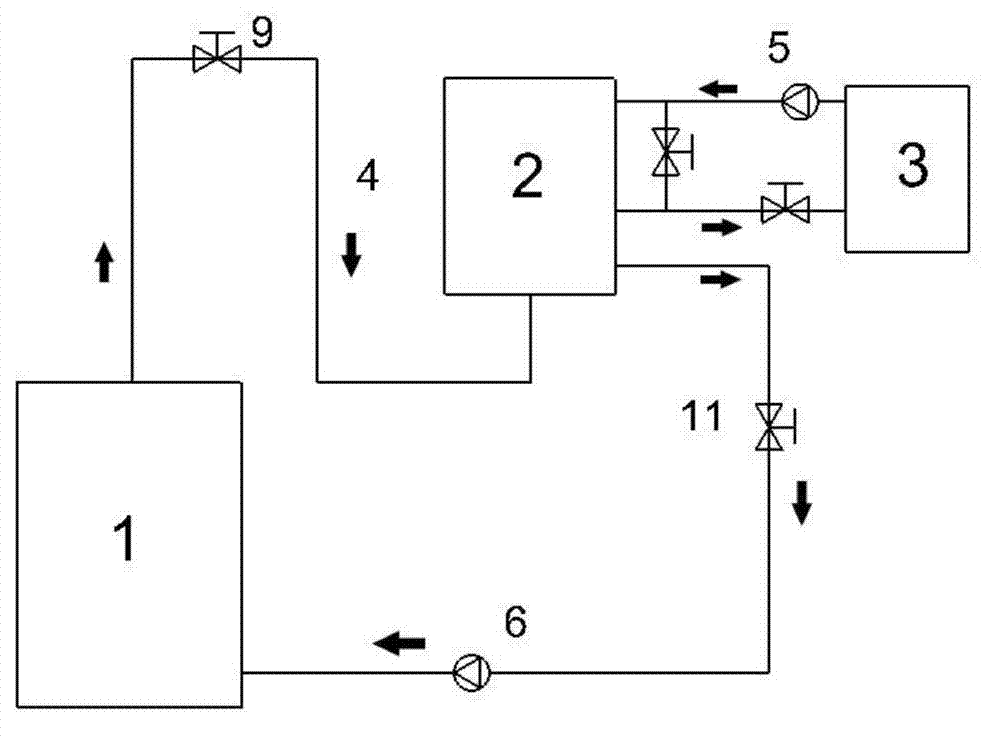

[0029] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solutions of the present invention, but the protection scope of the present invention is not limited to the following implementations example.

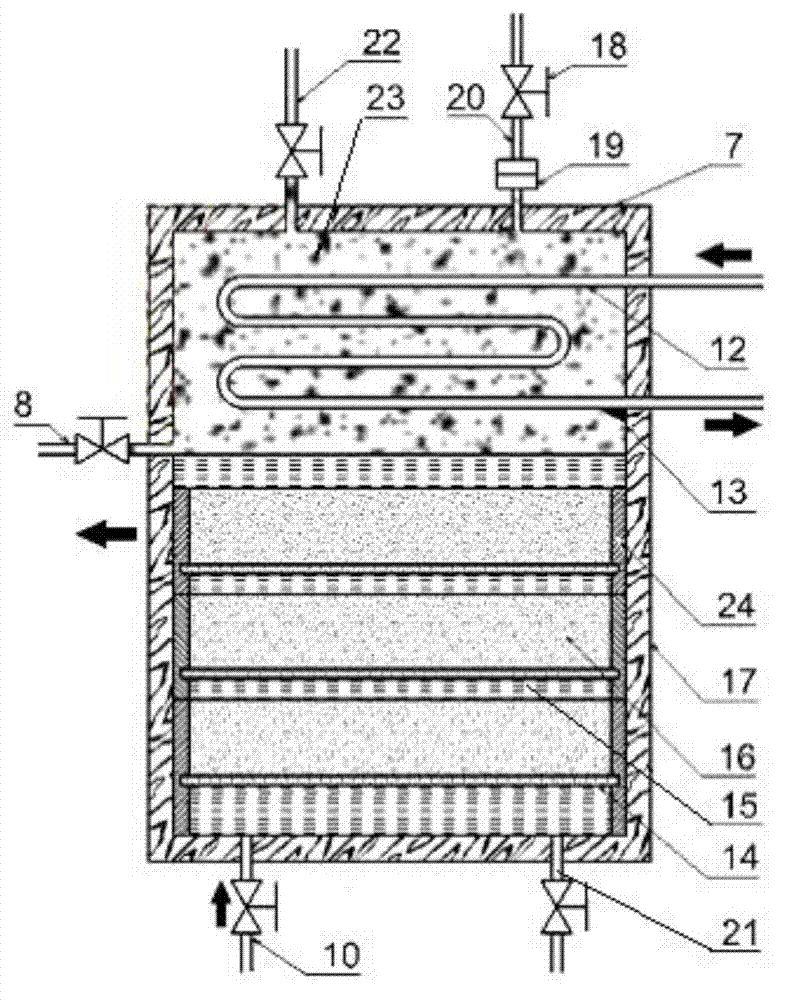

[0030] see figure 2 , as shown in the figure, the flooded medium-high temperature heat accumulator 2 is a stainless steel pressure-resistant container, generally in the shape of a cylinder, which includes a box body 7, multiple trays 14, multiple screens 15, porous composite phase change heat storage layer 16 and heat exchange tube 12. The bottom of the box body 7 is provided with a steam inlet 10, and the upper part is provided with a liquid outlet 8, and its outer periphery is wrapped with an insulating material 17; the upper part of the box body 7 is respectively provided with an air re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com