Biomass gasifying hydrogen making reactor based on induction heating

A hydrogen production reactor and induction heating technology, applied in hydrogen production, chemical industry, climate sustainability, etc., can solve the problems of long heating time, affecting the overall operation of the system, and serious wear of high temperature wall surface, etc., and achieve magnetic permeability Good thermal conductivity, good heat storage and heat transfer, wide range of raw material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

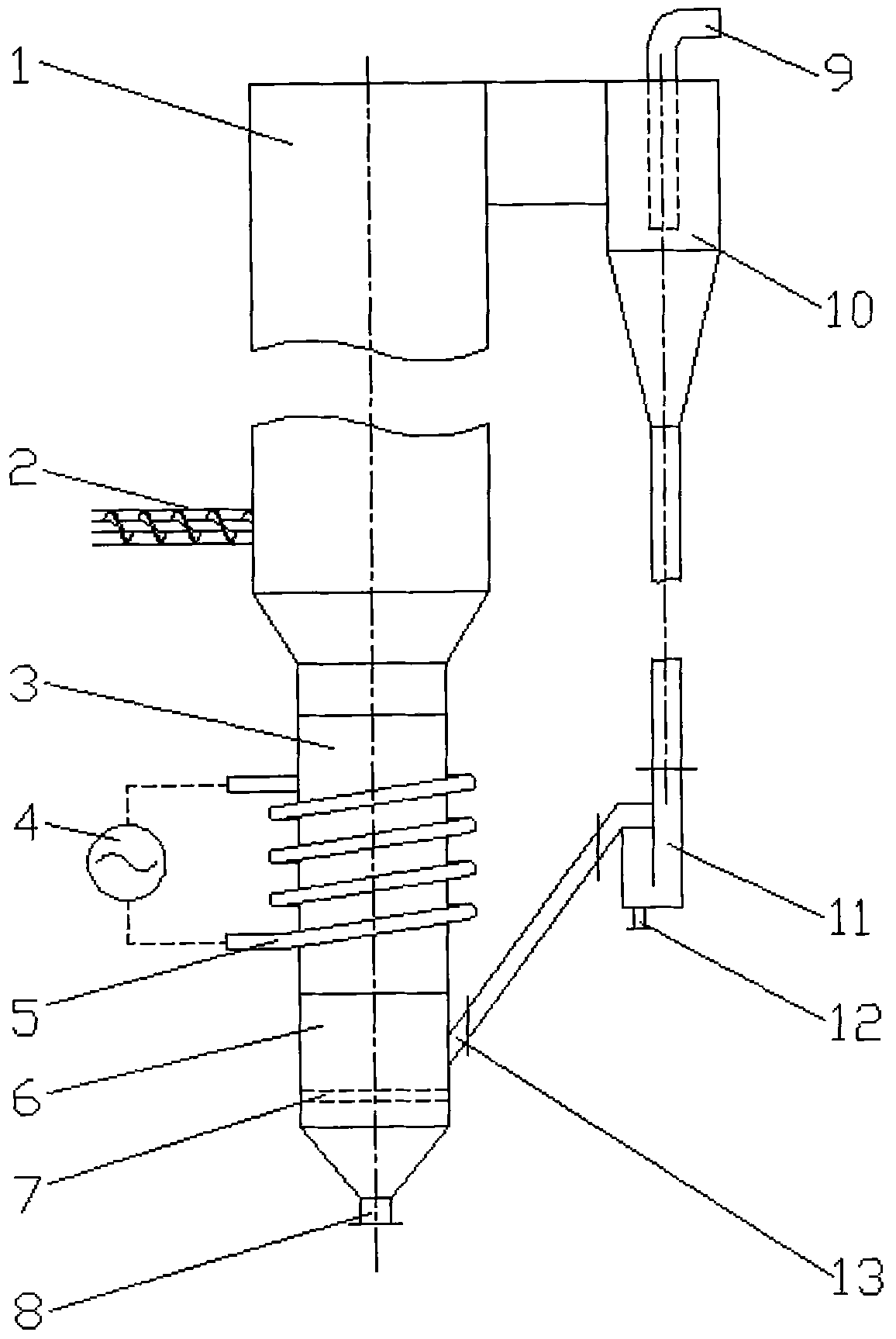

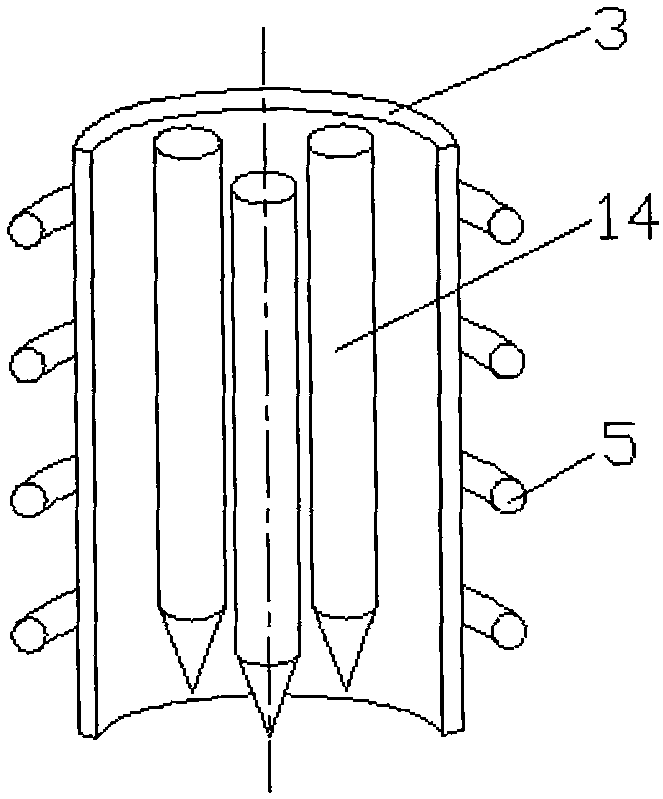

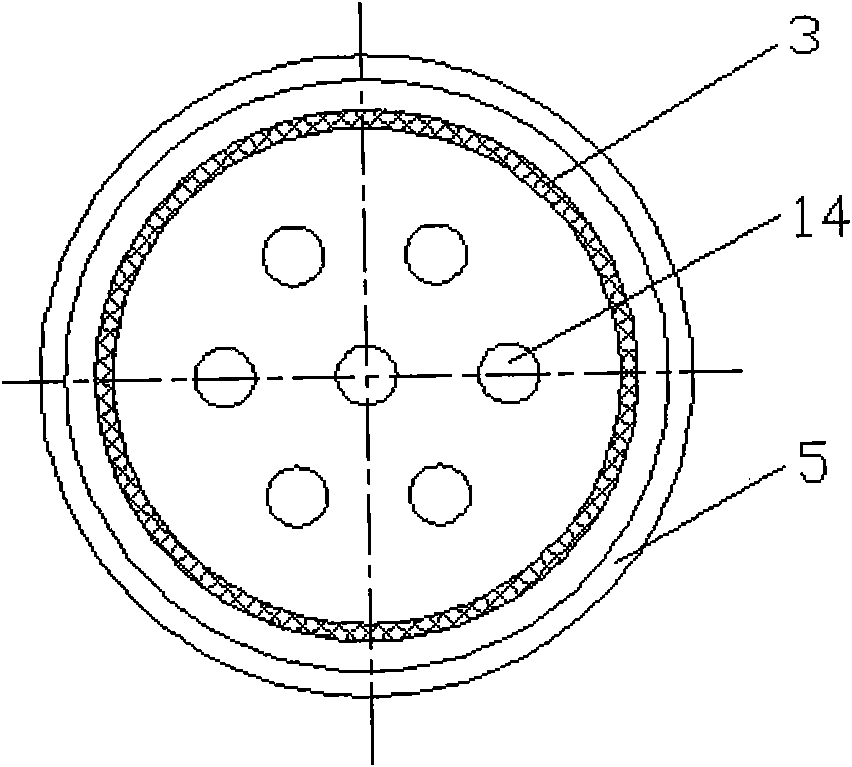

[0022] Such as figure 1 As shown, one side of the upper shell 1 of the reactor is connected with the cyclone dust collector 10, the other side is connected with the biomass feed port 2, and the bottom is socketed with the cylindrical furnace lining 3, and the induction heating element is suspended inside the cylindrical furnace lining 3 14. The induction coil 5 is wound outside the cylindrical furnace lining 3, the two ends of the induction coil 5 are connected to the induction heating power supply 4, the bottom of the cylindrical furnace lining 3 is socketed with the lower shell 6 of the reactor, and the feeding port 13 is located at Above the air distribution plate 7, the high temperature steam inlet 8 is located at the bottom of the lower shell 6 of the reactor. The material return device 11 is located directly below the cyclone dust collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com