Low super-cooling degree phase-change material microcapsule and preparation method thereof

A technology of phase change material and supercooling degree, applied in microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problem of reducing the content of phase change material in microcapsules, imperfect preparation process, and changing color of microcapsules. Black and other problems, to avoid the low yield of microencapsulation, wide application range, and improve the effect of heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

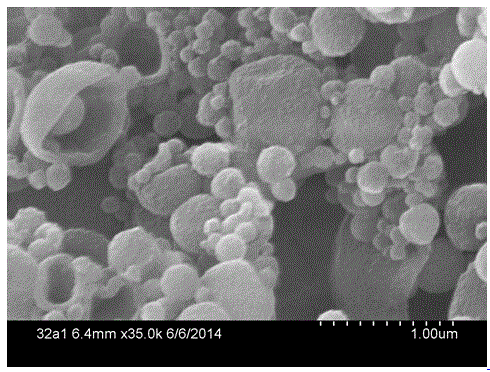

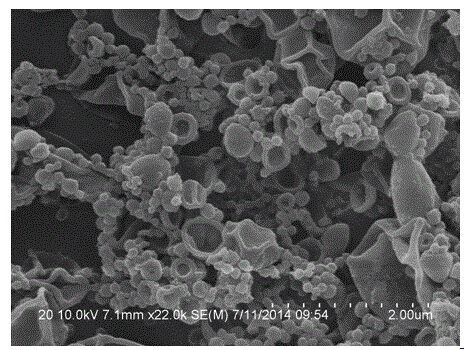

Image

Examples

Embodiment 1

[0036] In the embodiment of the present invention, a microcapsule of a phase change material with low supercooling degree is composed of a capsule core and a capsule wall. Acrylamide 7.5g, initiator azobisisobutyronitrile (AIBN) 3g, capsule wall 110g, wherein methyl methacrylate and crosslinking agent allyl methacrylate are 100g and 10g respectively.

[0037] The preparation method of the phase change material microcapsule with low supercooling degree comprises the following steps:

[0038] (1) Preparation of the aqueous phase mixture: Weigh 2000g of water, 100gTA (19% styrene-maleic anhydride copolymer sodium salt solution, purchased from Shanghai Leather Chemical Factory) in a 5L glass reactor, stir evenly and heat in a water bath to 35°C, so as not to solidify the oil phase when mixed with the oil phase, and make a water phase mixture;

[0039] (2) Preparation of oil phase mixture:

[0040] Mix the above-mentioned organic phase change material, supercooling inhibitor, ini...

Embodiment 2

[0047] In the embodiment of the present invention, a microcapsule of a low supercooling phase change material is composed of a capsule core and a capsule wall. The capsule core is 132g, and the organic phase change material n-octadecane is 120g, and the supercooling inhibitor N-isopropyl Acrylamide 9g, initiator azobisisobutyronitrile (AIBN) 3g, capsule wall 110g, wherein methyl methacrylate and crosslinking agent allyl methacrylate are 100g and 10g respectively.

[0048] (1) Preparation of the aqueous phase mixture: Weigh 2000g of water, 100gTA (19% styrene-maleic acid copolymer sodium salt solution, purchased from Shanghai Leather Chemical Factory) in a 5L glass reactor, stir evenly and place in a water bath Heating to 45°C so as not to solidify the oil phase when mixed with the oil phase to make a water phase mixture;

[0049] (2) Preparation of oil phase mixture:

[0050] Mix the above-mentioned organic phase change material, supercooling inhibitor, initiator, alkyl metha...

Embodiment 3

[0057] In the embodiment of the present invention, a microcapsule of a phase change material with low supercooling degree is composed of a capsule core and a capsule wall. The capsule core is 123g, and the organic phase change material n-octadecane is 120g, and the supercooling inhibitor N-isopropyl Acrylamide (NIPA) 0g, initiator azobisisobutyronitrile (AIBN) 3g, capsule wall 110g, of which methyl methacrylate and crosslinking agent allyl methacrylate are 100g and 10g respectively. The preparation method was the same as in Example 2, wherein the oil phase mixture accounted for 10% of the total weight fraction of the emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com