Liquid crystal display panel and display device

A liquid crystal display panel and panel technology, applied in the direction of nonlinear optics, instruments, optics, etc., can solve the problems that the PI film cannot completely cover the display area, the liquid crystal display panel cannot display normally, and the sealant falls off, so as to improve the accuracy and coating Covering efficiency, suppression of unevenness, and effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Certain words are used to refer to specific components in the description and claims, and those skilled in the art should understand that manufacturers may use different terms to refer to the same component. The specification and claims do not use the difference in name as a way to distinguish components, but use the difference in function of components as a basis for distinction. The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

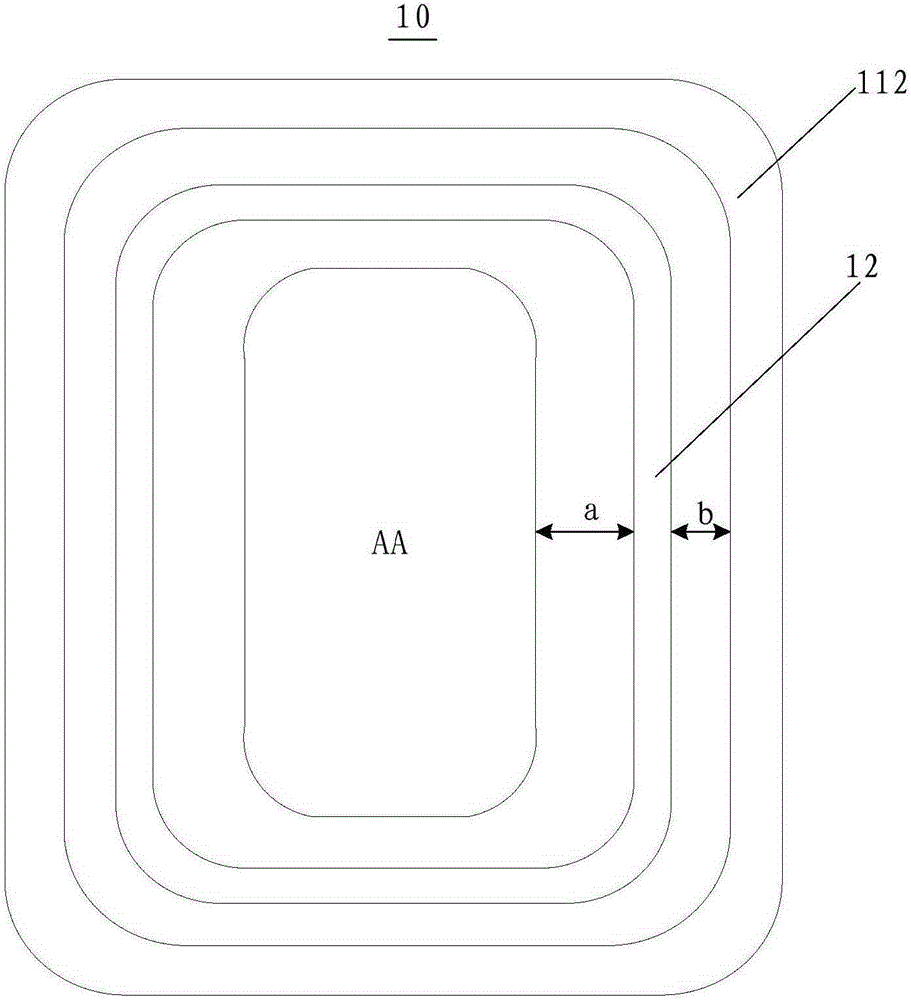

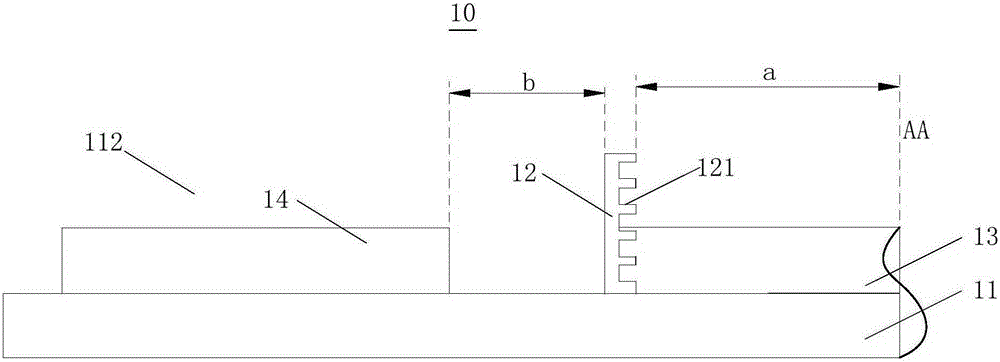

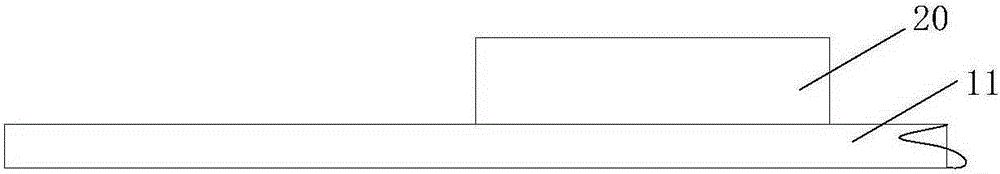

[0021] Please also refer to figure 1 with figure 2 , figure 1 is a schematic top view structure diagram of the liquid crystal display panel according to the first embodiment of the present invention, figure 2 is a schematic cross-sectional structure diagram of the liquid crystal display panel according to the first embodiment of the present invention. Such as figure 1 with figure 2 As shown, the liquid crystal display panel 10 includes a substrate 11 , a barrier wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com