Preparation method and application of silicon-carbon composite material

A silicon-carbon composite material and silicon-based technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of unsatisfactory packaging and high energy consumption, and achieve improved electrochemical performance, less usage, and a reasonable proportion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

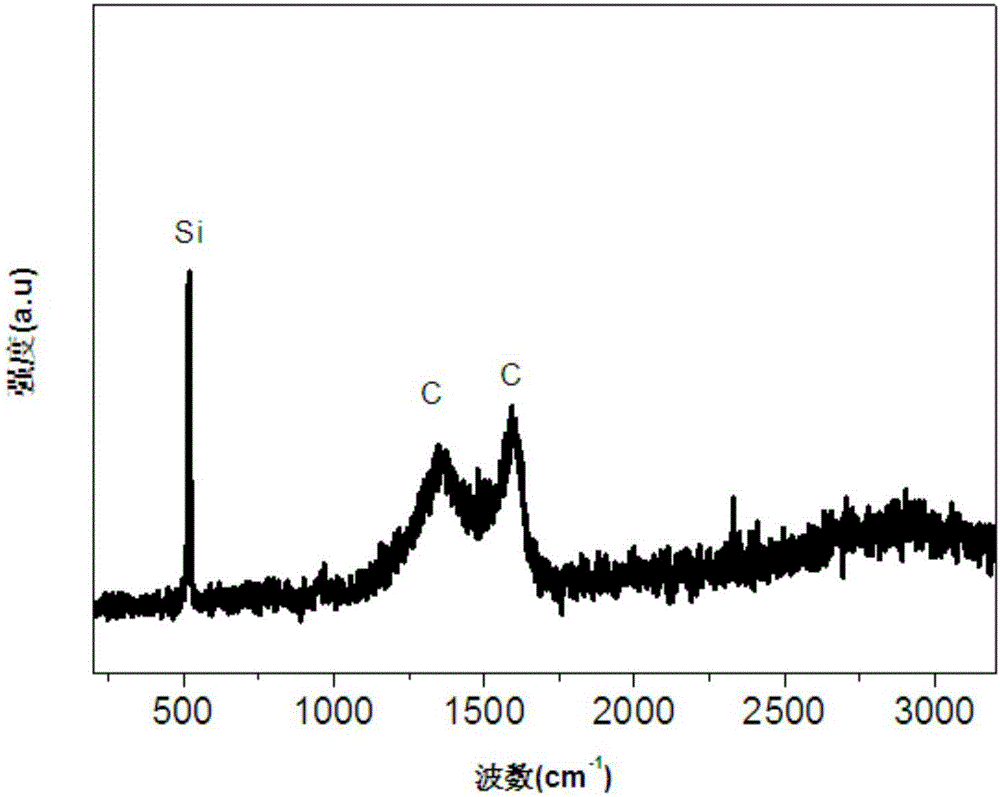

Method used

Image

Examples

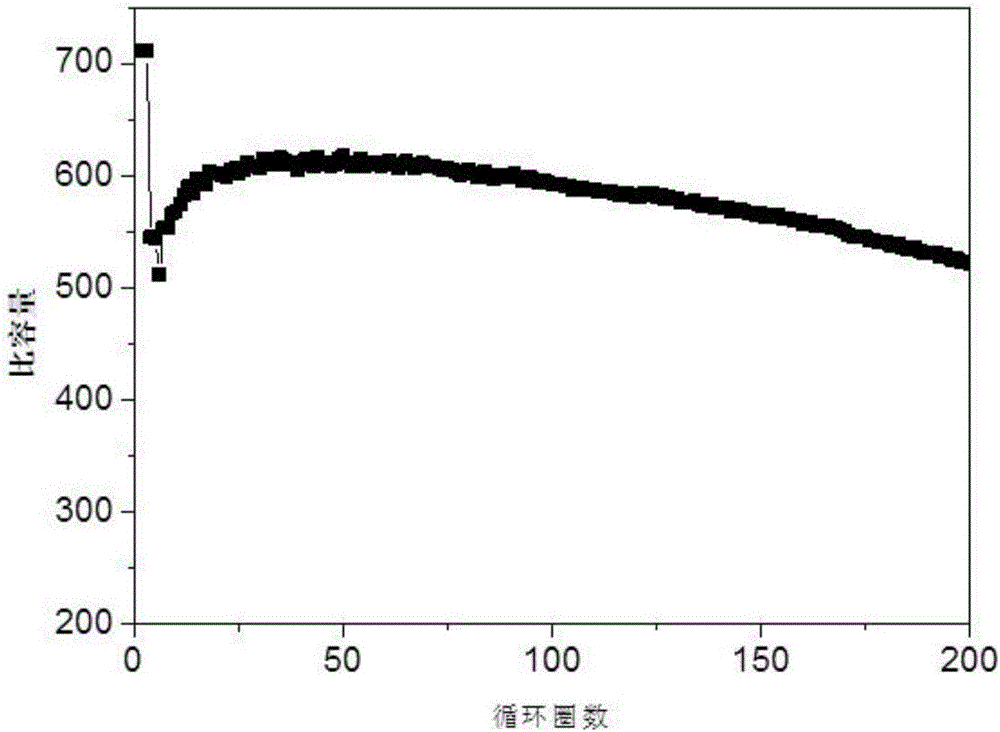

Embodiment 1

[0037] 1. Preparation of silicon-carbon composite materials

[0038] Using a planetary ball mill, 1 g of ferrosilicon alloy with a silicon content of 65% was pulverized into small particles, wherein the mass ratio of the ball to material was about 4:1, the rotation speed was 500 rpm, and the ferrosilicon alloy powder was obtained after 6 hours of ball milling time.

[0039] Place the ferrosilicon alloy material obtained in a beaker, add an excess of sulfuric acid with a molar concentration of 1 mol / L, and stir with a magnetic stirrer at room temperature for 24 hours to remove iron metal elements, and the reaction product is washed 3 times with deionized water; then The product was added to excess hydrofluoric acid solution with a mass fraction of 5% to remove silicon oxide, magnetically stirred at room temperature for 12 hours, and the reaction product was washed three times with deionized water and hydrofluoric acid respectively to obtain a porous silicon material.

[0040]Ad...

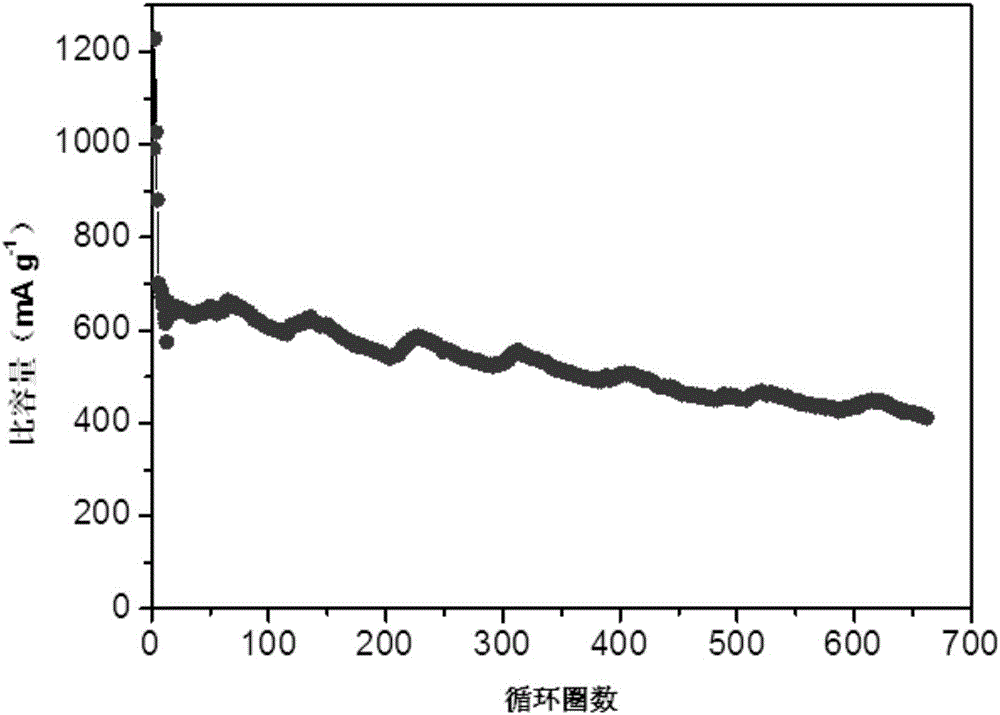

Embodiment 2

[0047] 1. Preparation of silicon-carbon composite materials

[0048] Using a planetary ball mill, 5 g of ferrosilicon alloy with a silicon content of 75% was pulverized into small particles, wherein the mass ratio of the ball to material was about 4:1, the rotating speed was 550 rpm, and the ferrosilicon alloy powder was obtained after ball milling for 8 hours.

[0049] Place the ferrosilicon alloy material obtained in a beaker, add an excess of sulfuric acid with a molar concentration of 1 mol / L, and stir with a magnetic stirrer at room temperature for 24 hours to remove iron metal elements, and the reaction product is washed 3 times with deionized water; then The product was added to excess hydrofluoric acid solution with a mass fraction of 5% to remove silicon oxide, magnetically stirred at room temperature for 12 hours, and the reaction product was washed three times with deionized water and hydrofluoric acid respectively to obtain a porous silicon material.

[0050] Add 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com