Adjustable phase change heat storage floor based on heat storage heating pipes

A technology of phase change heat storage and heating pipes, which is applied in the direction of heat storage equipment, heat exchanger type, space heating and ventilation details, etc., can solve the problems of inability to feedback and adjust the heat supply of the floor system, low utilization rate of phase change materials, Problems such as poor heat exchange effect can be achieved to alleviate the peak power shortage, increase latent heat storage, and increase thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

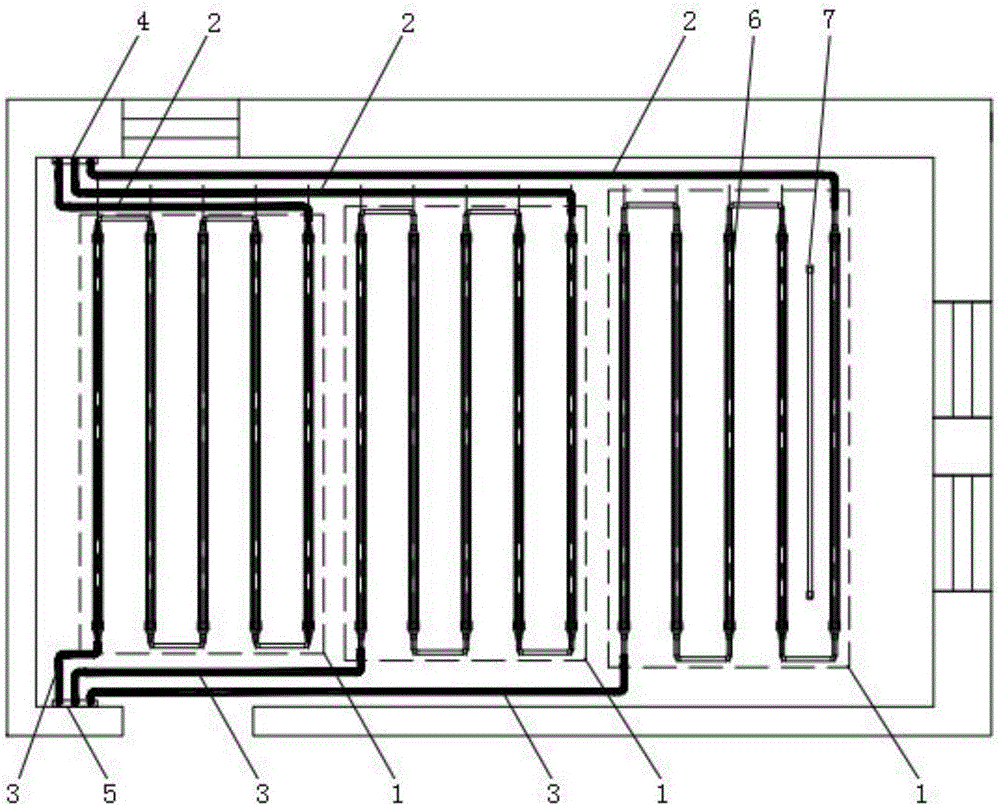

[0036] In this embodiment, the heat storage floor of the present invention adopts three sets of heating pipe modules 1, and its working process is as follows:

[0037] A temperature sensor is set outdoors to sense the outdoor temperature. During the heating period, when the outdoor temperature is higher than 0°C, only open the valves of one set of heating pipe module 1, and close the valves of the other two sets of heating pipe module 1; when the outdoor temperature is -10~0°C, open the two sets of heating For the valves of pipe module 1, close the valves of the third group of heating pipe module 1; when the outdoor temperature is below -10°C, open the valves of three groups of heating pipe module 1. Turn on the heat source and circulation pump to heat the room and store energy. After the energy storage is completed, the rest of the time depends on the energy stored in the floor to maintain the indoor temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com