Energy storage and thermal insulation building structure

A technology for building structure and energy storage, applied in building components, building structures, buildings, etc., can solve the problems of inability to meet the requirements of environmental comfort, poor heat storage capacity, small heat capacity, etc., and achieve significant energy storage and thermal insulation effects. , prolong the time, reduce the effect of air conditioning energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

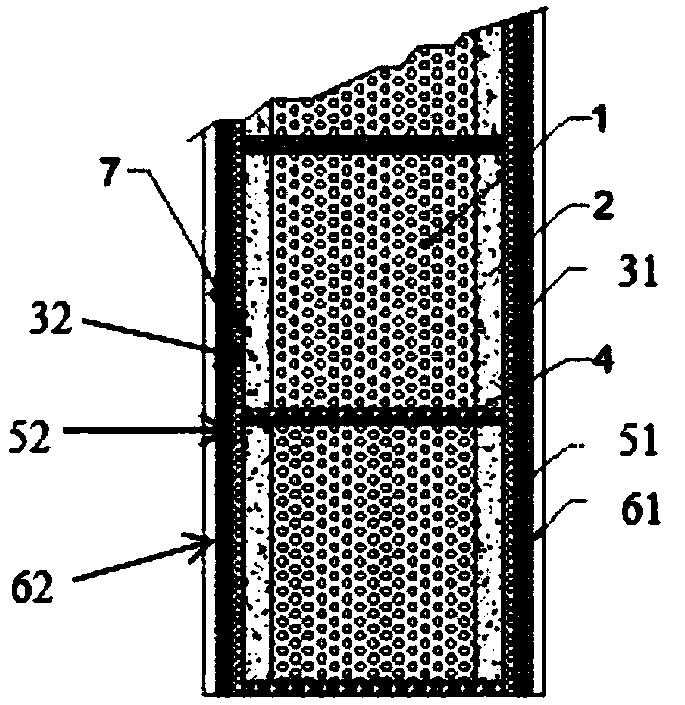

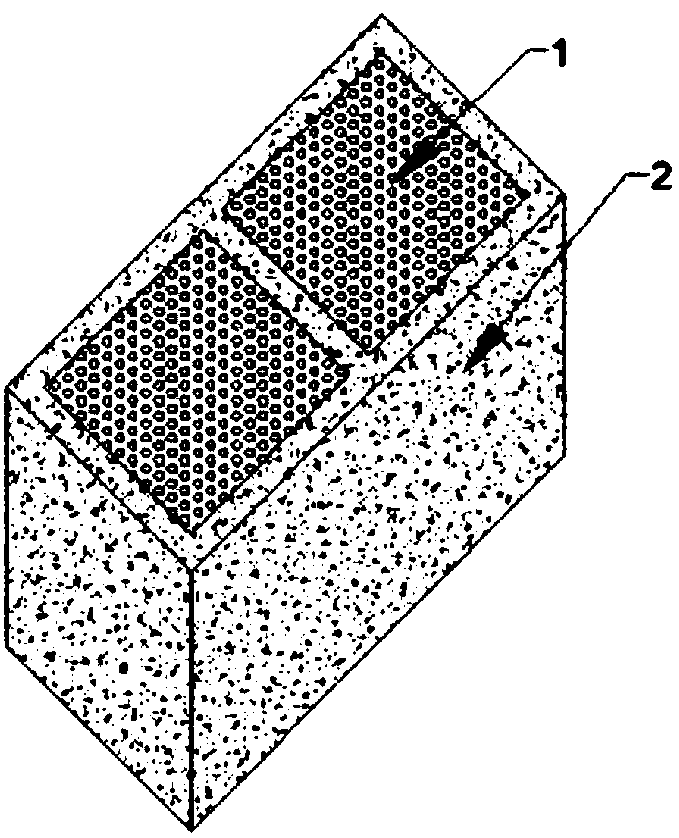

[0034] The present invention has no special limitation on the preparation method of the energy storage and thermal insulation building structure described in the above technical solution, and the preparation method well known to those skilled in the art can be used. The present invention preferably prepares block first, comprises the following steps:

[0035] Mix methyl palmitate and methyl stearate, and prepare a phase change material with a particle size of ≤3mm by hot melting and cooling granulation;

[0036] Mix cement, hydroxypropyl methylcellulose, redispersible latex powder, fly ash, mineral powder, polypropylene fiber, water and water reducing agent to obtain cement slurry;

[0037] mixing the phase change material with cement slurry to obtain phase change mortar;

[0038] The phase change mortar is injected into the hollow block until it is flush with the surface of the hollow block, and the block is obtained after curing.

[0039] The present invention has no speci...

Embodiment 1

[0048] The distribution ratio of each component in the phase change mortar is: according to the mass ratio, P·O32.5 cement: phase change material: hydroxypropyl methylcellulose: redispersible latex powder: class II fly ash: mineral powder: polypropylene Fiber (6 ~ 9mm): water: polycarboxylate high-performance water reducer = 1: 1: 0.0035: 0.05: 0.15: 0.10: 0.006: 0.18 ~ 0.25: 0.01, the phase change material is 4: 0.8 by mass ratio, Mix methyl palmitate and methyl stearate, and prepare granules with a particle size of ≤3mm by hot melting and cooling granulation;

[0049] The hollow rate of the hollow block is 58%, the length, width and height are 390mm, 190mm and 190mm respectively, and the density grade is 600;

[0050] Inject the phase-change mortar into the hollow block until it is flush with the surface of the hollow block, maintain it at a temperature of 12°C and a humidity greater than 95% for 7 days, and then naturally maintain it for 28 days to obtain a block;

[0051]...

Embodiment 2

[0056] The distribution ratio of each component in the phase change mortar is: according to the mass ratio, P·O32.5 cement: phase change material: hydroxypropyl methylcellulose: redispersible latex powder: class II fly ash: mineral powder: polypropylene Fiber (6 ~ 9mm): water: polycarboxylate high-performance water reducer = 1: 1.1: 0.004: 0.06: 0.15: 0.10: 0.008: 0.18 ~ 0.25: 0.015, the phase change material is 4: 1 by mass ratio, Mix methyl palmitate and methyl stearate, and prepare granules with a particle size of ≤3mm by hot melting and cooling granulation;

[0057] The hollow rate of the hollow block is 62%, the length, width and height are 390mm, 230mm and 230mm respectively, and the density grade is 500;

[0058] Inject the phase-change mortar into the hollow block until it is flush with the surface of the hollow block, maintain it for 7 days at a temperature of 12°C and a humidity greater than 95%, and then naturally maintain it for 28 days to obtain a block; The bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com