Multilayer material based on microfiber and polyurethane and process for obtaining it

A multi-layer material and support layer technology, which is applied in the field of auto parts, can solve the problems that are not suitable for some applications, and achieve the effect of high thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

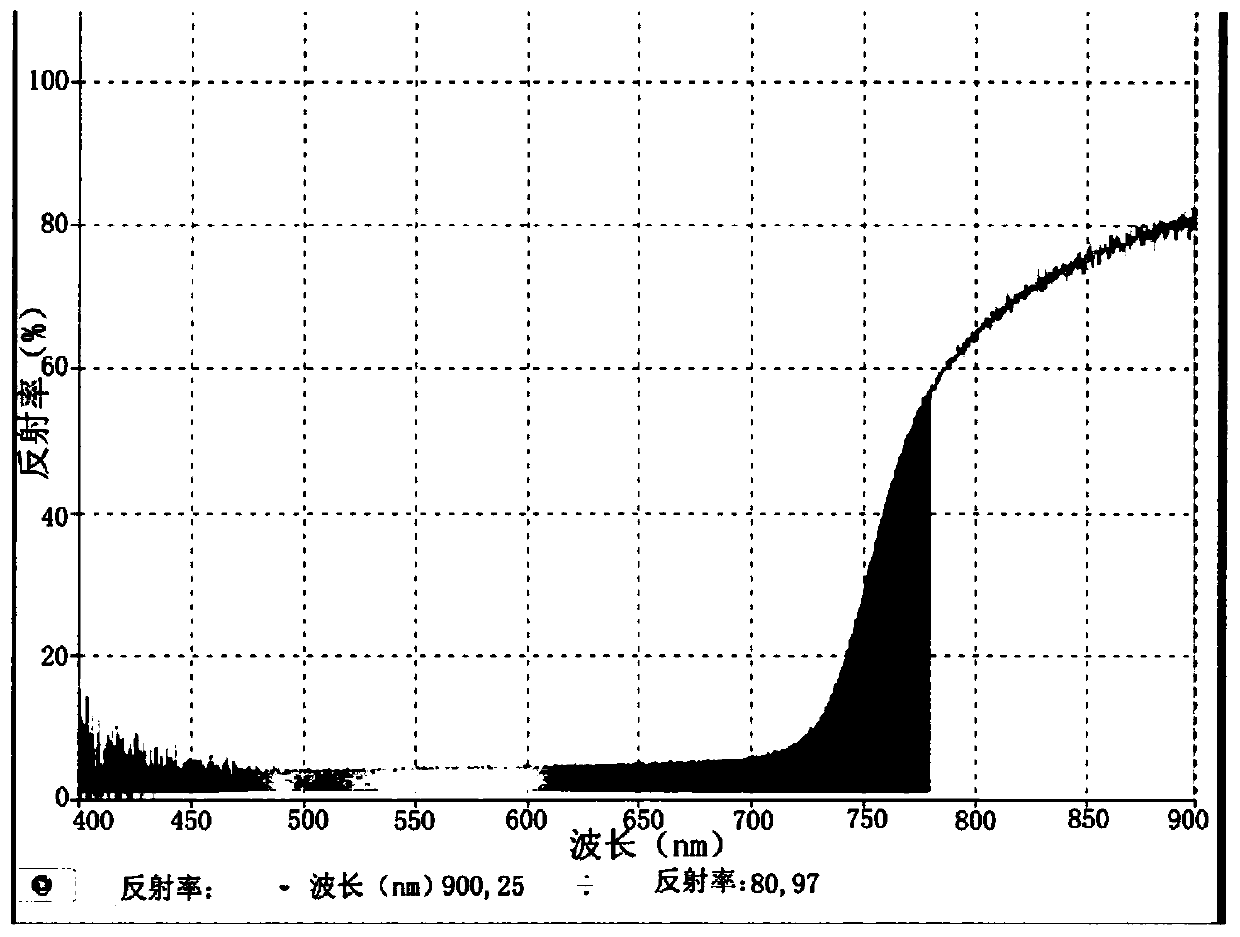

[0189] in figure 2 Reports on the reflectance spectra of multilayer materials obtained according to the present invention.

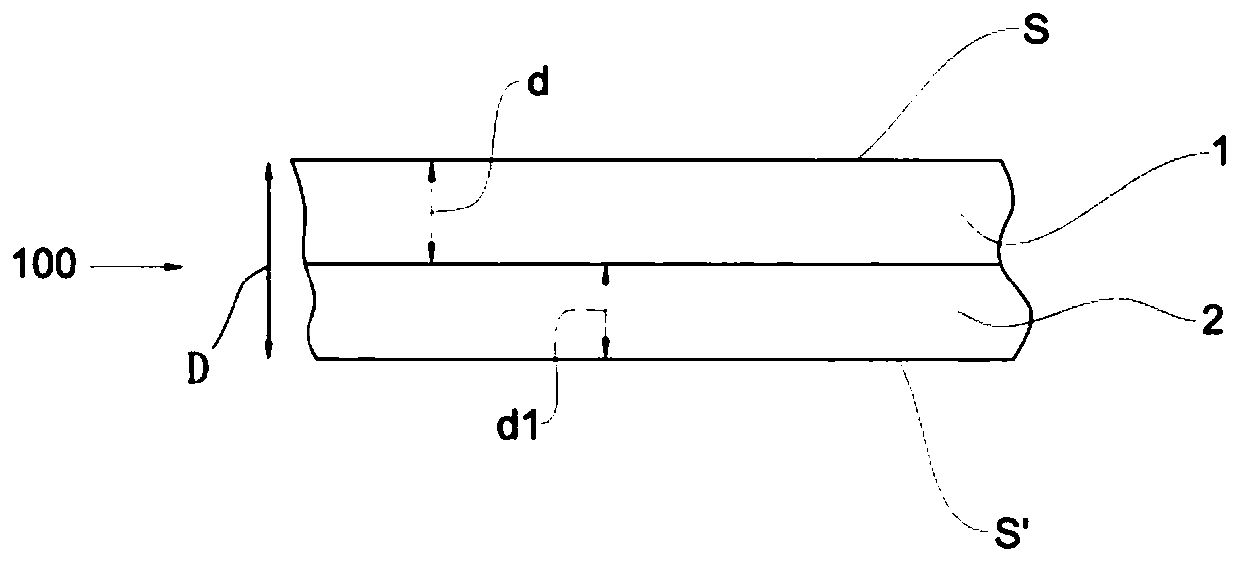

[0190] The multilayer material includes a support layer 1 of microfibers formed of 50% PU and 50% Pa, and has a thickness "d" of 0.9 mm + / - 0.05 mm.

[0191] The support layer 1 of microfibers has been dyed with a dyeing solution including about 6% by weight of the first coloring compound in a dry state relative to the weight of the microfibers to be dyed.

[0192] The multilayer material includes a polyurethane cover layer 2 having a thickness "d1" of 0.06 mm + / - 0.03 mm.

[0193] The cover layer 2 has been colored with 10% by weight of the second coloring compound relative to the weight of the polyurethane composition to be colored.

[0194] From figure 2 From the analysis of the figure, it can be seen that the multilayer material of this example has low reflection and high absorption in the visible light wavelength (400-700nm), and therefore is perceived as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com