Wall body intelligent heat-insulation building envelope

A technology for enclosure structures and walls, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of unguaranteed thermal insulation performance, decline in the overall quality of foamed cement, poor durability, etc., and achieve environmental protection and thermal insulation Heat insulation effect, good heat insulation effect, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

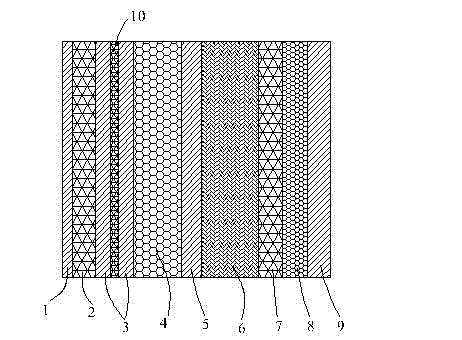

[0016] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment: figure 1 Shown is a wall intelligent thermal insulation enclosure structure of the present invention, which is characterized in that: from the outside to the inside, it includes a photocatalyst purification layer 1, an outer wall heat reflective coating layer 2, a plastering layer 3, and a foam cement infrared shielding insulation layer 4. Adhesive layer 5, wall substrate layer 6, interior wall leveling mortar layer 7, putty layer 8 and phase change interior wall paint energy storage layer 9, the plastering layer 3 is covered with a glass fiber mesh layer 10.

[0017] The key point of the present invention is that, firstly, the outer wall heat-reflecting coating layer 2 is arranged on the outer wall to play a heat insulation effect, and at the same time, the foam cement infrared shielding heat preservation layer 4 is set to realize the integration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com