Novel phase change-heat preservation composite wall structure

A technology for thermal insulation composite and wall structure, which is applied in the directions of thermal insulation, wall, building components, etc. It can solve the problem of not considering the best method and position of the composite layer of the phase change material and the best thickness of the thermal insulation layer, and cannot guarantee the uniformity of the phase change material. , affecting the phase change energy storage efficiency and other issues, to achieve the effect of improving the thermal inertia of the wall, facilitating mechanized production, and improving the effect of peak shaving and delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

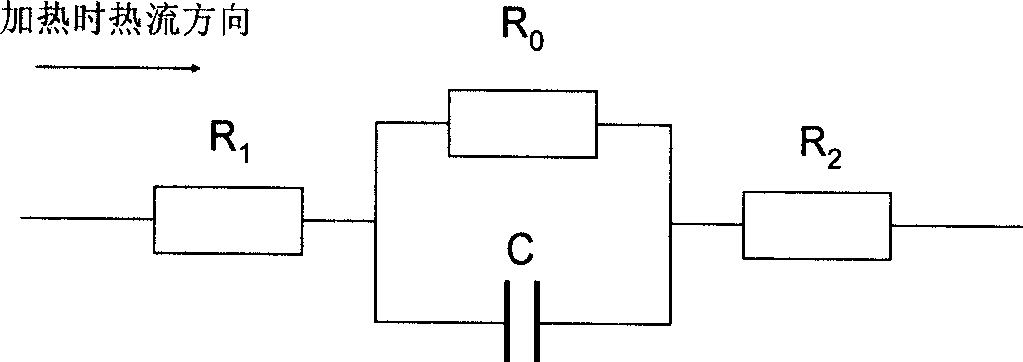

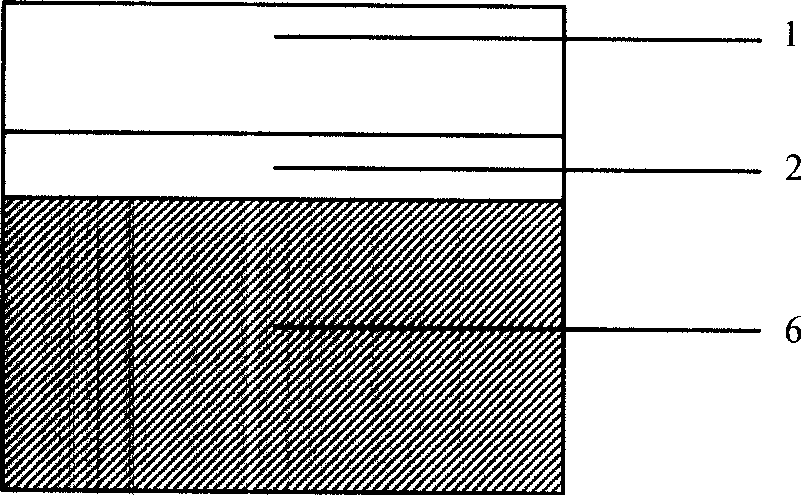

[0017] A phase change-insulation composite wall structure is an integrated plate structure composed of an insulation layer, a shape-setting phase change layer, and a wall base layer. A crack-resistant mortar protective layer and a decorative layer can be added on the surface of the insulation layer.

[0018] 1. Insulation layer 1 and insulation layer 2 are selected with a thickness of 1 to 3 cm and a density of 20 to 40 kg / m 3 Polystyrene foam board or polyurethane foam board; and calculate the thickness of the required insulation layer material according to the thermal resistance of different wall substrates. For example: the thermal conductivity of clay hollow brick wall λ=0.58W / m K, if its thickness is 24cm, its thermal resistance is R=0.41m 2 / K·W. From this, it can be calculated that when the thermal insulation material is polyurethane with a thermal conductivity of 0.02-0.03W / m K, its thickness is 0.8-1.2cm; when the thermal insulation material is polyurethane with a th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com