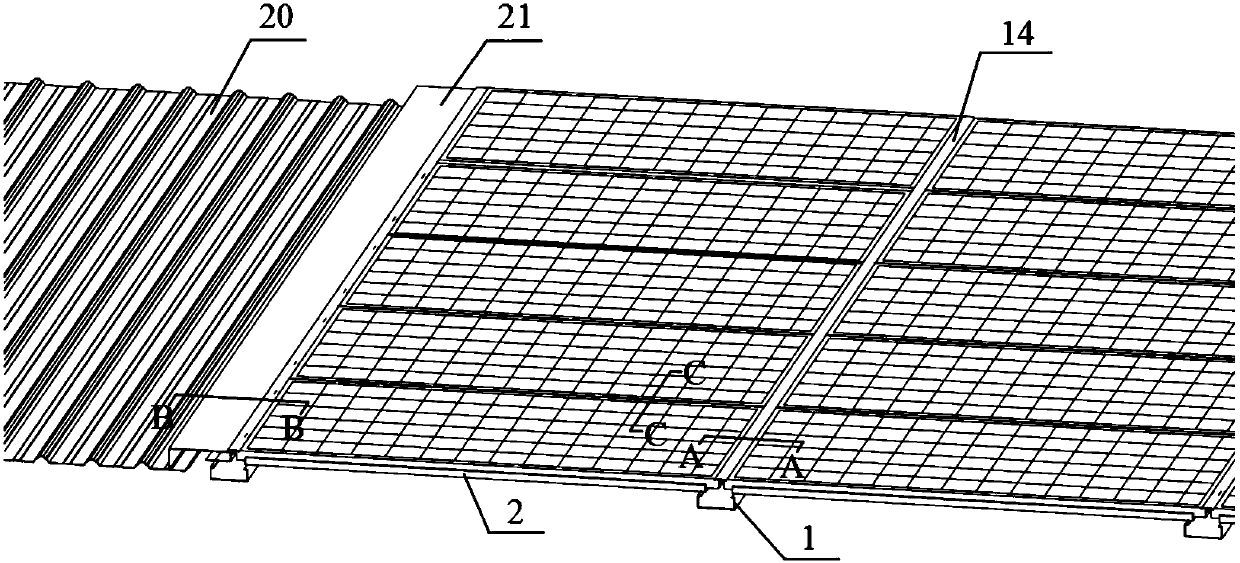

Integrated-type steel structure roof photovoltaic system

A photovoltaic system and steel structure technology, applied in the field of solar photovoltaics, can solve problems such as loose joints of photovoltaic panels and sliding of photovoltaic panels, and achieve the effects of improving roof drainage, saving materials, and optimizing structural forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

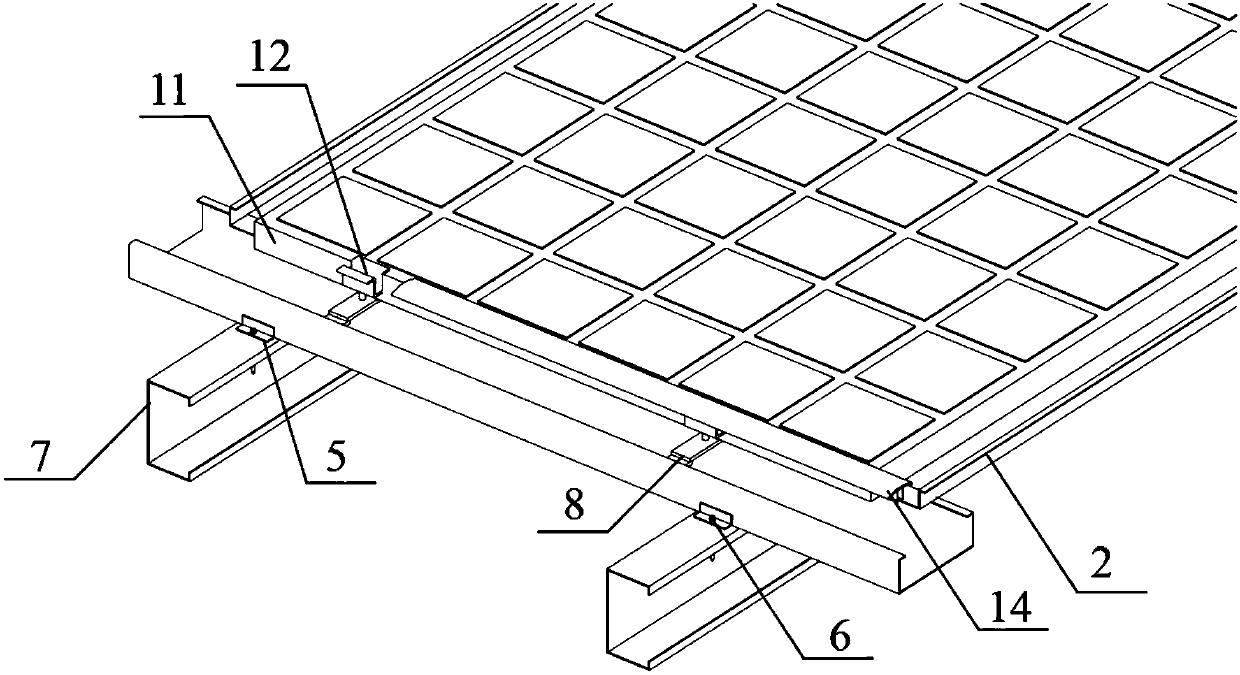

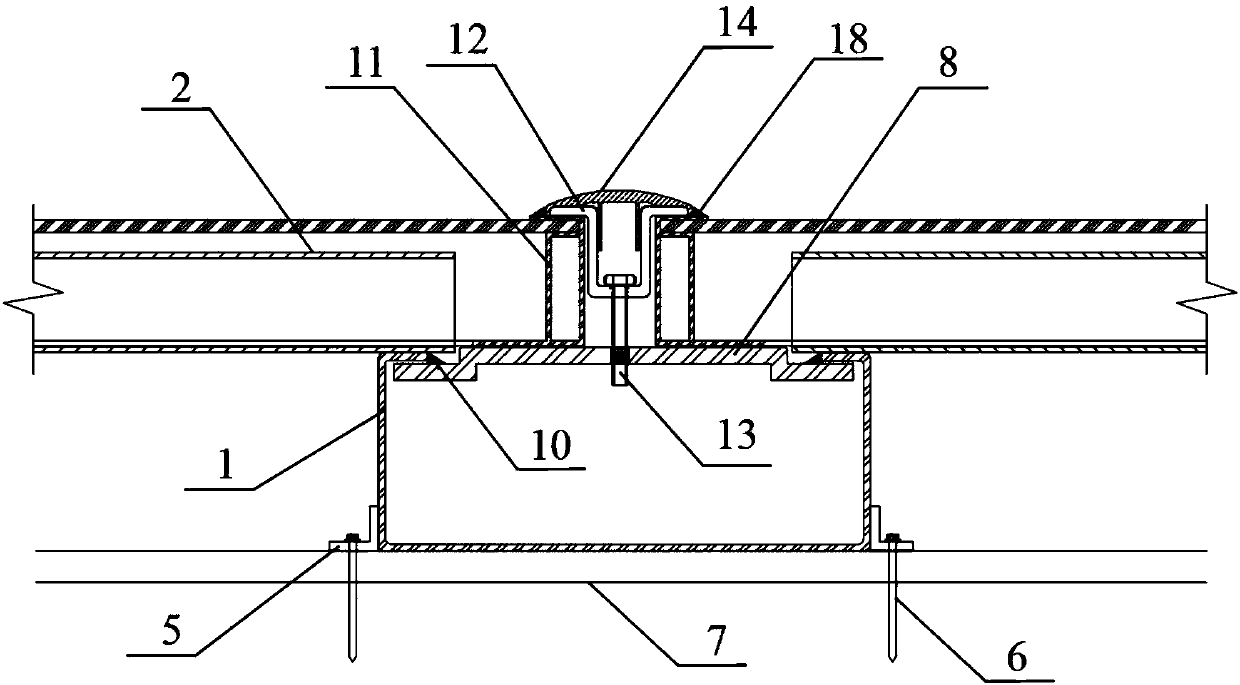

[0023] The integrated steel structure roof photovoltaic system includes main beam 1, secondary beam 2, main beam shoulder 3, semicircular notch 4, angle steel 5, first screw 6, purlin 7, support block 8, bolt hole 9, Electric welding 10, component frame 11, pressure block 12, bolt 13, bead 14, card cover 15, card foot 16, hook 17, sealant 18, waterproof tape 19, color steel tile 20, side cover plate 21, edge 22 , the second screw 23 and the photovoltaic panel. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com