Construction method of corrugated steel pipe culvert

A construction method and technology of corrugated steel pipes, applied in the construction field of corrugated steel pipe culverts, can solve problems such as lack of splicing methods, poor mechanical performance, and heavy maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

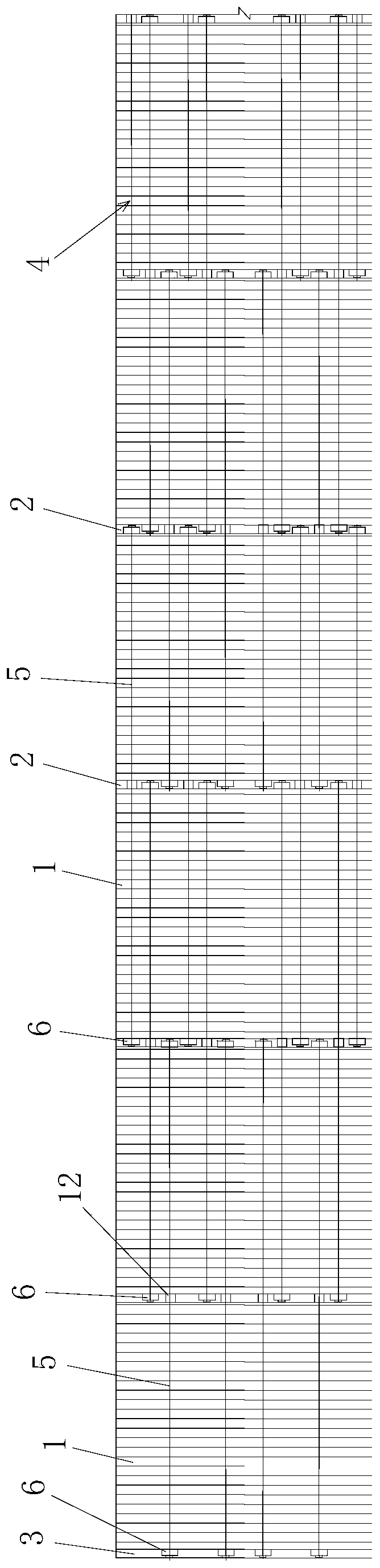

[0103] like Figure 12 A construction method of a corrugated steel culvert shown, the constructed pipe culvert includes a base 16 and a corrugated steel culvert supported on the base 16, the base 16 is a cast-in-place reinforced concrete base; the base 16 and the corrugated steel pipe culverts are arranged along the longitudinal extension direction of the constructed pipe culverts; a filling layer 15 is arranged outside the constructed pipe culverts, and the base 16 and the corrugated steel pipe culverts are all located in the filling soil layer 15. See Figure 10 ; The bottom of the base 16 and the bottom of the filling layer 15 are arranged on the same horizontal plane;

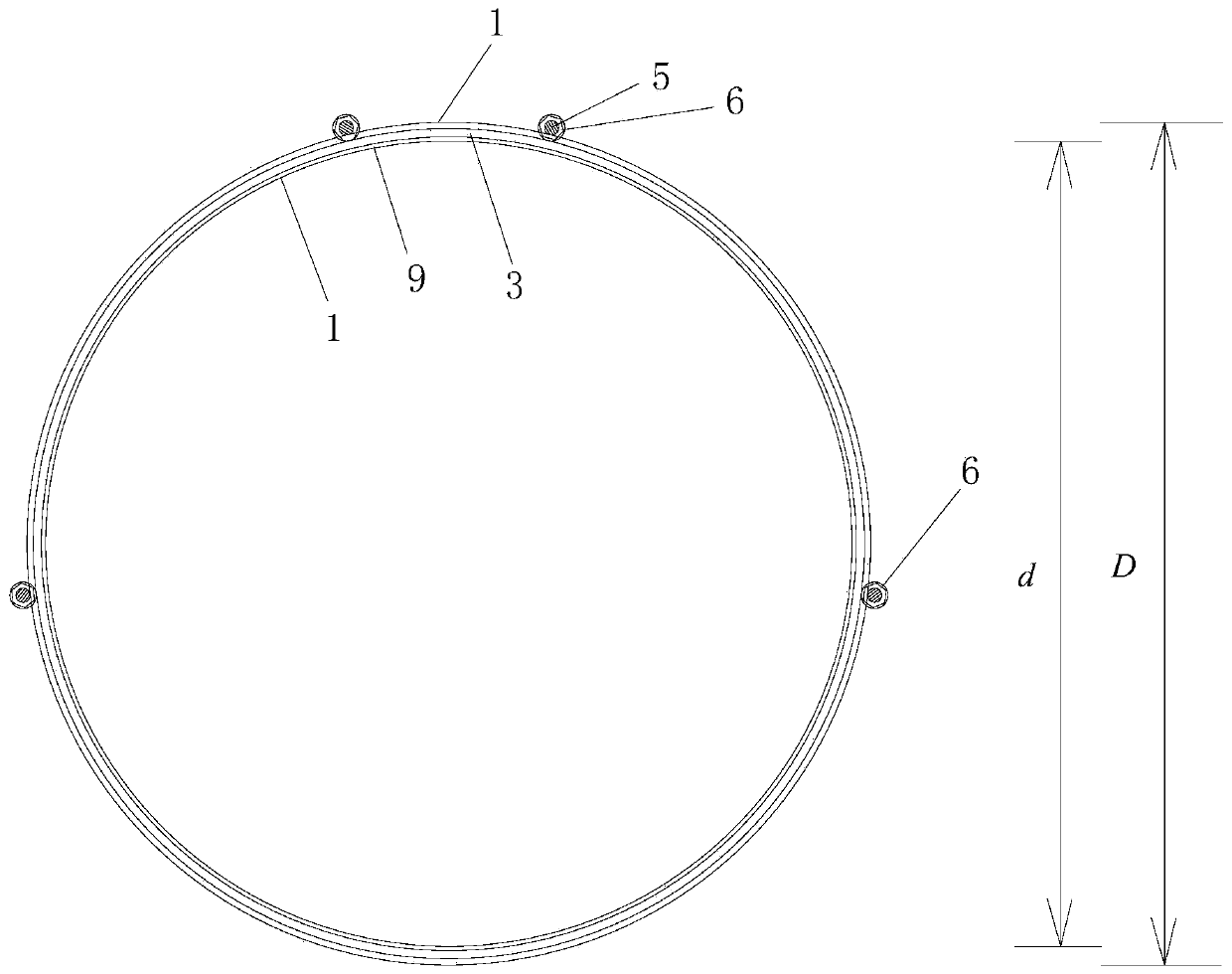

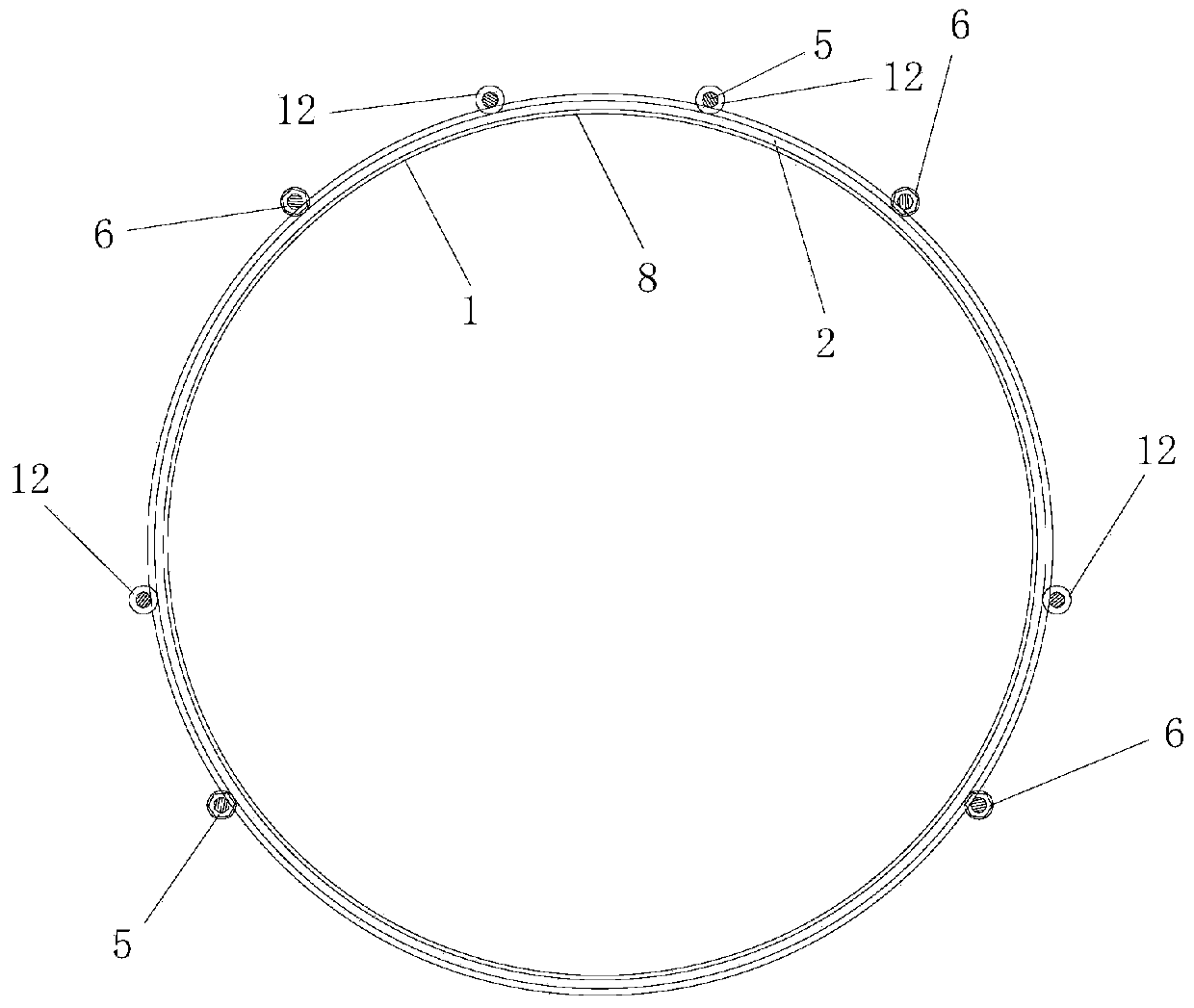

[0104] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 , Figure 8 and Figure 9 , the corrugated steel culvert includes a pipe culvert body spliced by a plurality of pipe culvert splicing sections 1 and a prestressed reinforcement structure arranged outside the pipe c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com