Carbon fiber decorative ballpoint pen and manufacturing method thereof

A manufacturing method and technology of carbon fiber, which is applied in the direction of ballpoint pens, printing, writing utensils, etc., can solve the problems of poor decoration, low strength of ballpoint pens, and low grades, and achieve good transparency, good decorative effects, and high-grade products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

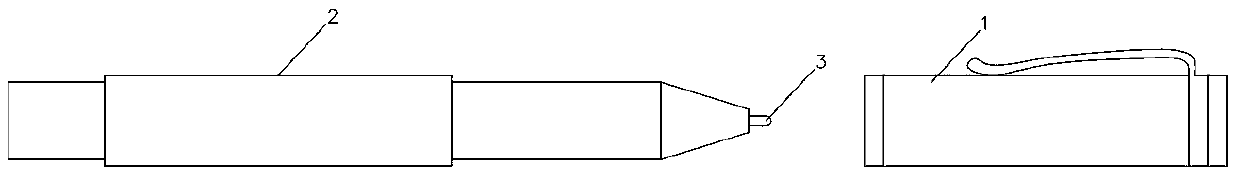

[0024] A kind of carbon fiber decorative ballpoint pen described in Embodiment 1 of the present invention, such as Figure 1-2 As shown, it includes a pen cover 1, a pen core 3, and a pen body 2, wherein the pen body and / or the pen cover are provided with a cylindrical sleeve formed by a carbon fiber reinforced epoxy resin roll tube, and the carbon fiber reinforced epoxy resin roll The cylindrical sleeve for tube forming uses carbon fiber reinforced epoxy resin prepreg as raw material, and the carbon fiber composite material tube is made by thermosetting composite material hot-pressed tube forming process, and then processed according to the specifications and sizes, such as cutting, threading, polishing, etc. Get the carbon fiber composite sleeve. Utilizing the performance advantages of carbon fiber reinforced epoxy resin composite materials such as "light weight, high performance, and good decoration", the carbon fiber composite material sleeve is made, which solves the prob...

Embodiment 2

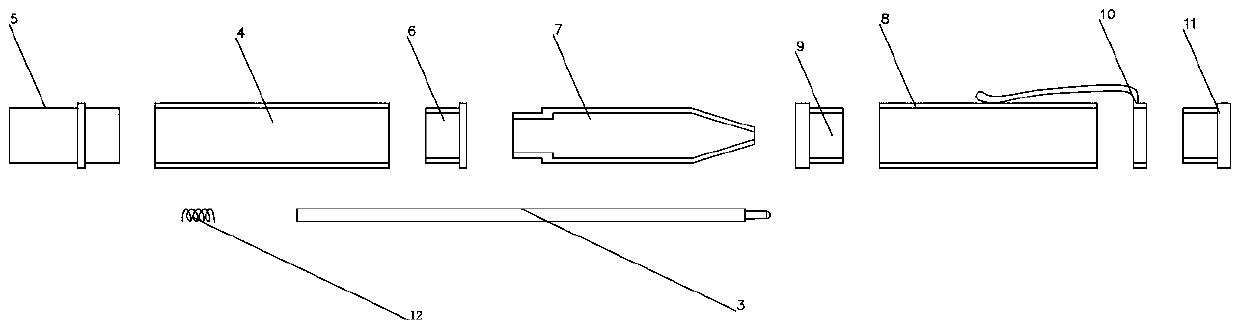

[0029] A method for manufacturing a carbon fiber decorative ballpoint pen described in Embodiment 2 of the present invention comprises the following steps:

[0030] Step 1. The metal accessories of the ballpoint pen include: metal pen body cover 5, pen body connection cover 6, metal pen case connection cover 9, metal pen case cover 11, ready;

[0031] Step 2. Position the metal pen body cover 5 and the pen body connection cover 6 with a fixture, wrap the glass fiber in parallel and unidirectionally wrap the cylinder formed by the metal pen body cover 5 and the pen body connection cover 6; The connection cover 9 and the metal pen case cover 11 are positioned with a fixture, and the glass fiber is wound in parallel and unidirectionally to wrap the cylinder formed by the metal pen case connection cover 9 and the metal pen case cover 11;

[0032] Step 3, will account for the unsaturated polyester resin that the mass percentage of raw material is 30%, account for the nanometer magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com