Electronic product shell and manufacture method thereof

A technology for electronic products and manufacturing methods, which is applied in the field of electronic product shells and their manufacturing with thermosetting resins as raw materials. It can solve the problems of long curing time of epoxy resin, uneven internal stress of materials, high cost of raw materials, etc., and achieve the apparent quality of products. Good, good molding process, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

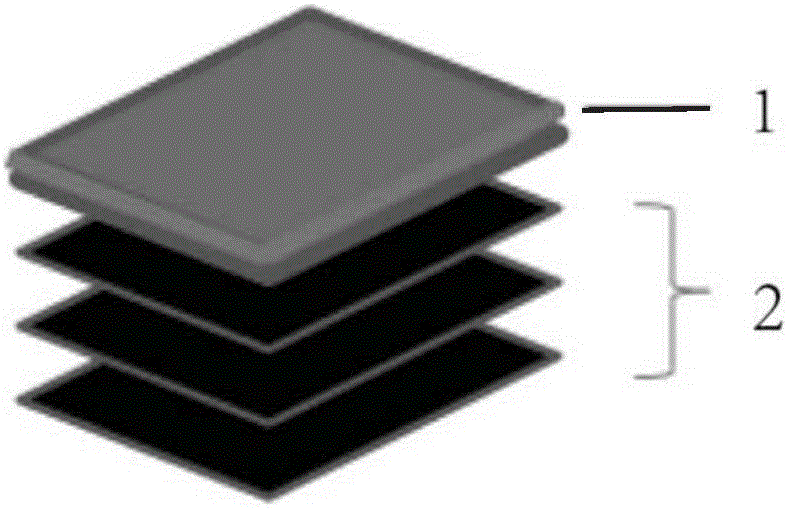

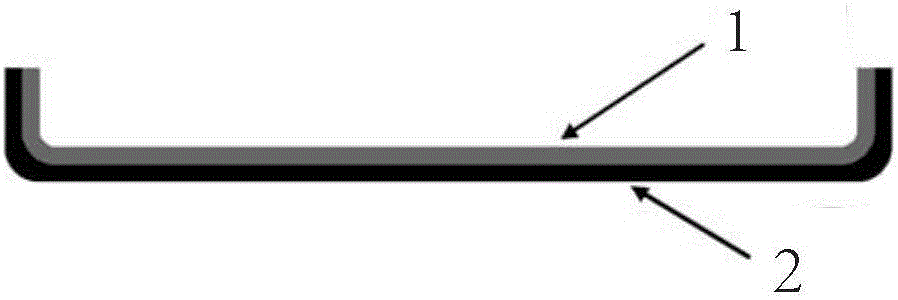

[0044] figure 1 An exploded view showing a layup design of an electronic product according to the present disclosure. According to the first embodiment of the present disclosure, an electronic product housing is proposed, which includes a chopped prepreg sheet 1 and a continuous prepreg sheet 2 and the continuous prepreg sheet 2 and the continuous prepreg sheet are formed by using a compression molding method. The chopped prepreg sheets 1 are bonded together and made after curing, as figure 2 shown.

[0045] The chopped prepreg sheet 1 includes chopped fibers including carbon fibers or glass fibers and a thermosetting resin. The thermosetting resin is, for example, a thermosetting epoxy resin.

[0046] The content of the chopped fibers is between 20% and 50%; the length of the chopped fibers ranges from 3 to 30 mm; the thickness of the chopped prepreg sheet is between 1 and 5 mm.

[0047] The continuous prepreg sheet 2 comprises continuous fibers comprising carbon fibers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com