Material of noise-reducing and radiating shell of transformer

A heat dissipation shell and shell material technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor heat conduction effect of sound insulation shell materials, and achieve good sound absorption and heat dissipation effects, low density, and good electrical conductivity The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

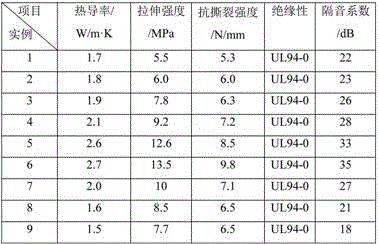

Examples

Embodiment 1

[0020] A transformer noise-reducing and heat-dissipating housing material, the housing material comprising the following raw materials in parts by weight: 30 parts of polyurethane resin, 15 parts of methyl vinyl silicone rubber, 20 parts of carbon fiber, 10 parts of aluminum oxide, 7 parts of diatomaceous earth 2 parts, 2 parts of silicone oil, 0.5 parts of antioxidant and 2 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane.

[0021] The alumina is α-Al 2 o 3 , the particle size is 0.5-3μm, and the thermal conductivity is 30W / m·K.

[0022] The preparation method of the above-mentioned transformer noise reduction and heat dissipation housing material comprises the following steps: adding polyurethane resin, methyl vinyl silicone rubber, carbon fiber, aluminum oxide, diatomaceous earth, silicone oil and antioxidant into a mixer, and stirring for 20 min , then add 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, knead at 80°C for 25min, and finally put it into a metal grinding...

Embodiment 2

[0024] A transformer noise-reducing and heat-dissipating housing material, the housing material comprising the following raw materials in parts by weight: 35 parts of polyurethane resin, 20 parts of methyl vinyl silicone rubber, 25 parts of carbon fiber, 15 parts of aluminum oxide, 10 parts of diatomaceous earth 1 part, 6 parts of silicone oil, 1 part of antioxidant and 5 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane.

[0025] The alumina is α-Al 2 o 3 , the particle size is 0.5-3μm, and the thermal conductivity is 30W / m·K.

[0026] The preparation method of the above-mentioned transformer noise reduction and heat dissipation housing material comprises the following steps: adding polyurethane resin, methyl vinyl silicone rubber, carbon fiber, aluminum oxide, diatomaceous earth, silicone oil and antioxidant into a mixer, and stirring for 25 min , then add 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, knead at 70°C for 30min, and finally put it into a metal mold, and u...

Embodiment 3

[0028] A transformer noise-reducing and heat-dissipating housing material, the housing material comprising the following raw materials in parts by weight: 30 parts of polyurethane resin, 15 parts of methyl vinyl silicone rubber, 10 parts of phenolic resin, 20 parts of carbon fiber, and 10 parts of aluminum oxide , 7 parts of diatomaceous earth, 2 parts of silicone oil, 0.5 parts of antioxidant and 2 parts of 2,5-dimethyl-2,5-di(t-butylperoxy)hexane.

[0029] The alumina is α-Al 2 o 3 , the particle size is 0.5-3μm, and the thermal conductivity is 30W / m·K.

[0030] The preparation method of the above-mentioned transformer noise reduction and heat dissipation housing material includes the following steps: adding polyurethane resin, methyl vinyl silicone rubber, phenolic resin, carbon fiber, aluminum oxide, diatomaceous earth, silicone oil and antioxidant into the mixer, Stir for 20 minutes, then add 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, knead for 20 minutes at 100°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com